Single-body concentration-type small welding machine

A centralized and single technology, applied in welding accessories, welding rod characteristics, welding equipment and other directions, can solve the problems of miniaturization, lightweight limitation, heavy voltage drop transformers and reactors, complex structure, etc., to improve the heat dissipation effect, realize The effect of miniaturization and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Referring to the accompanying drawings, the present invention will be described in detail as follows.

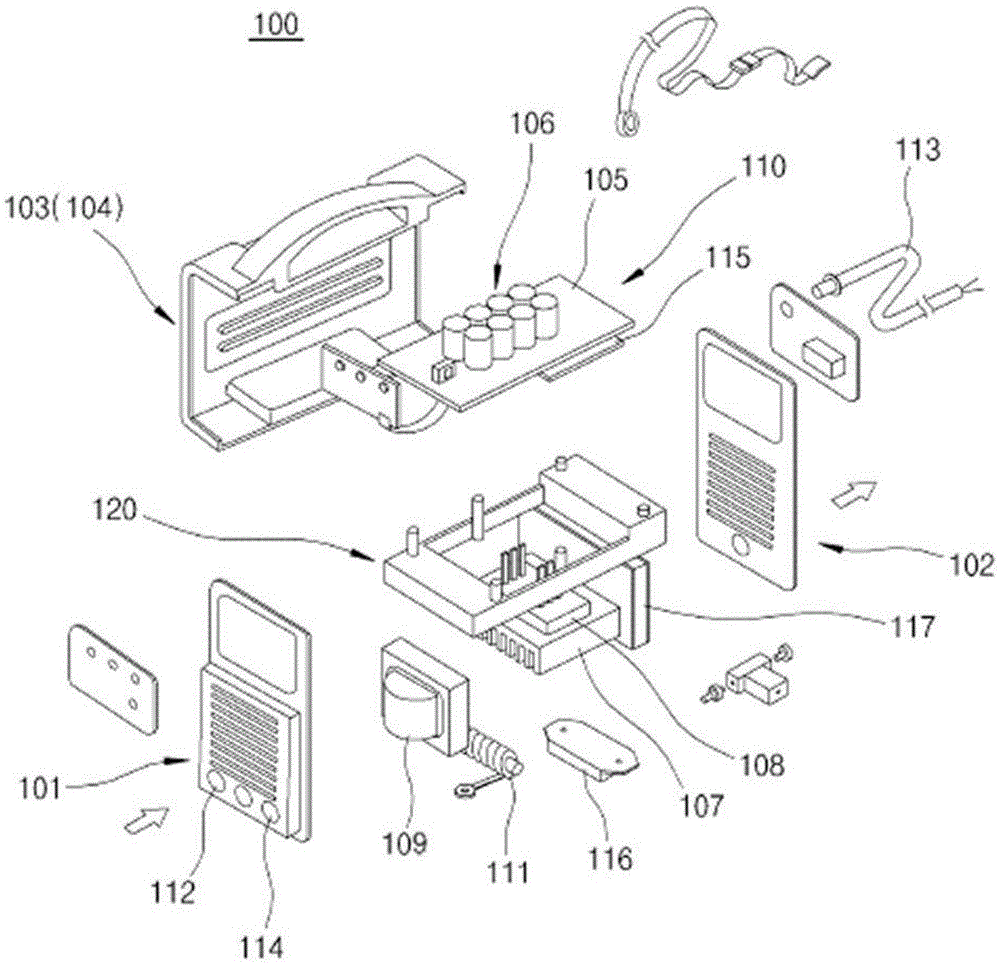

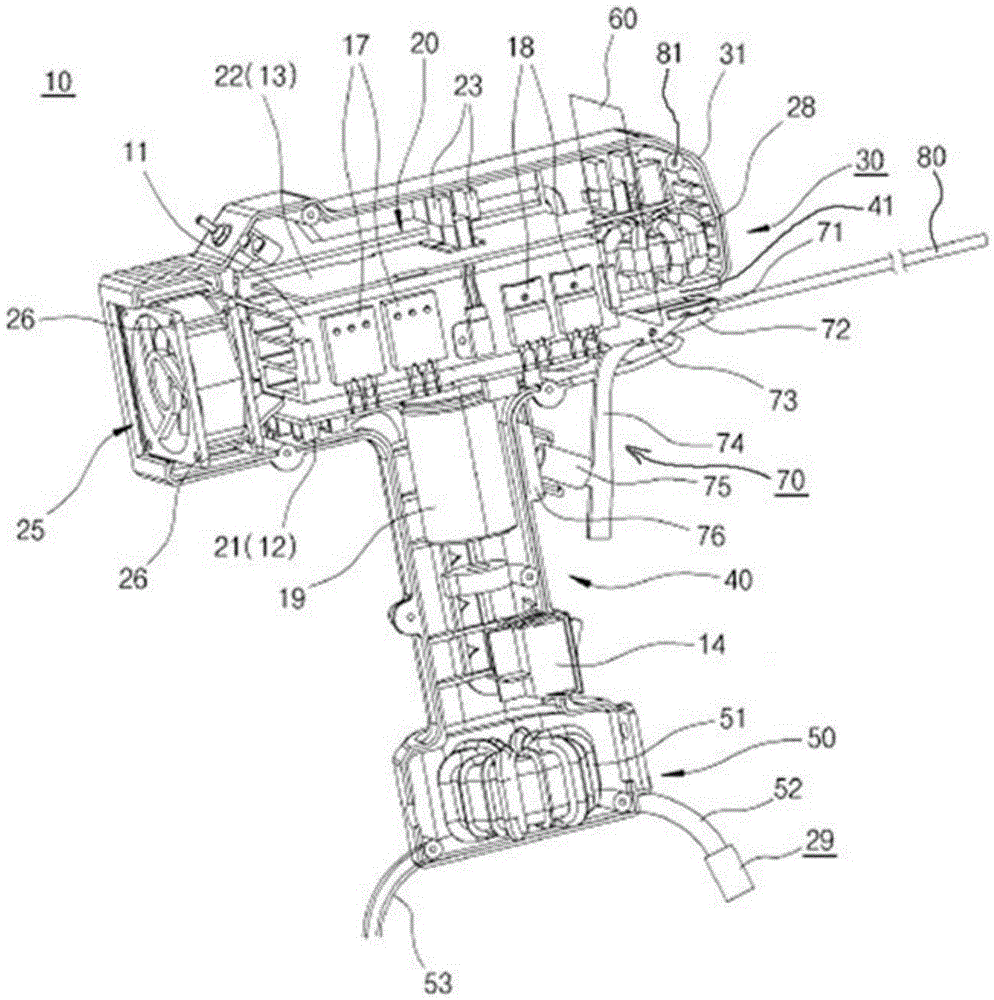

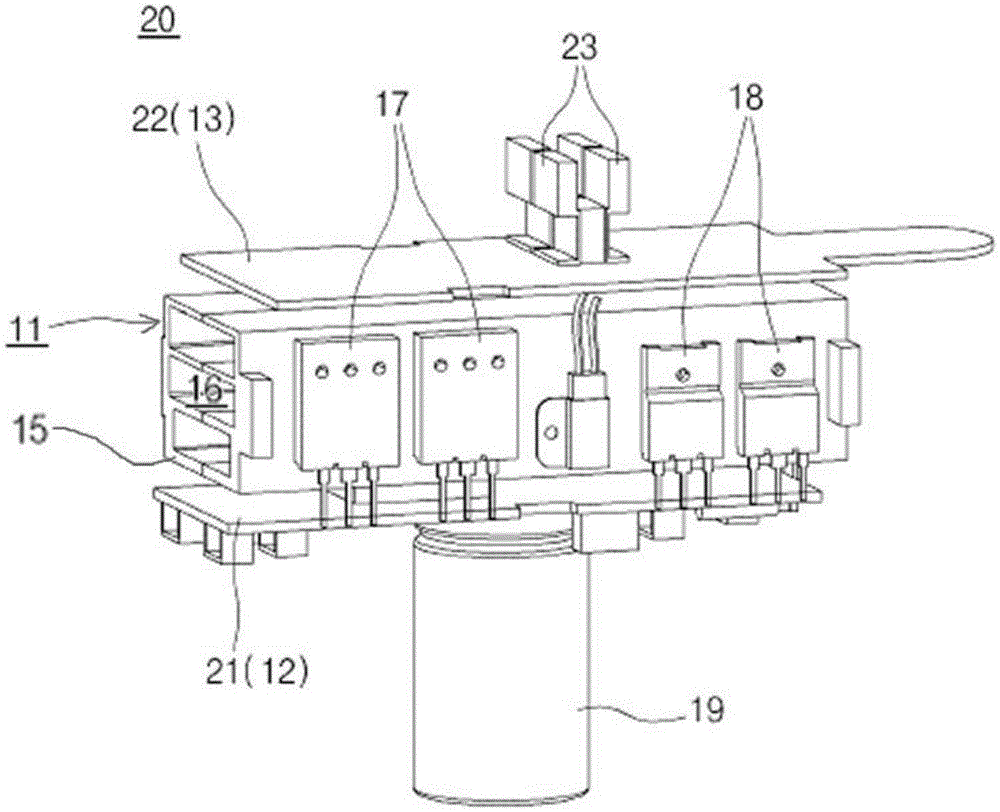

[0027] figure 2 It is a side sectional view of a single centralized small welding machine formed according to the first embodiment of the present invention, image 3 It is a perspective view briefly showing the structure of a single unit.

[0028]As shown in the figure, the small-sized welding machine 10 of the first embodiment of the present invention is composed of an intensive single unit 20, and is constituted as a single intensive structure. The single unit 20 includes: a body part 30 provided with the radiator 11 ; a handle part 40 integrated with the body part 30 ;

[0029] A heat sink 11 is provided on the main body portion 30, and a centralized single unit 20 is provided on the heat sink 11 in which almost all main components of the electric system are collectively provided.

[0030] The single unit 20 includes: a radiator 11; a power input and output cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com