Calcitriol solid lipidic dispersion and preparation method thereof

A technology of calcitriol and solid lipid, applied in the field of medicine, can solve the problems of poor thermal stability of calcitriol, drug content of toxic and side effects, and failure to reach the therapeutic level, etc., and achieve high drug stability and high affinity Sexuality, the effect of being beneficial to storage and taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

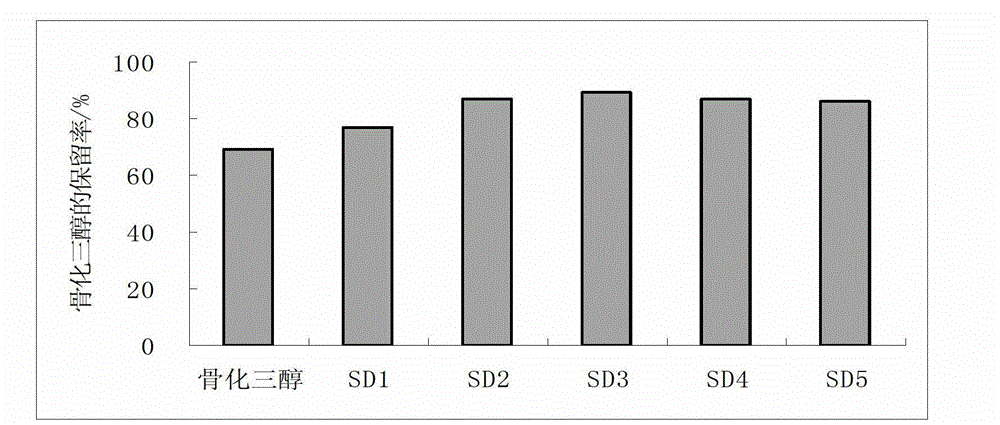

[0052] In this example, 4 samples of calcitriol solid lipid dispersion were prepared, and the raw material ratios are shown in Table 2.

[0053] Preparation of calcitriol solid lipid dispersion: according to the raw material ratio listed in Table 2, add calcitriol and BHT into the molten lipid carrier, and dissolve calcitriol by vortexing and ultrasound for 5-20 minutes Disperse in a lipid carrier to obtain a calcitriol lipid mixture; quickly add the calcitriol lipid mixture in a molten state to a solid carrier to adsorb and solidify.

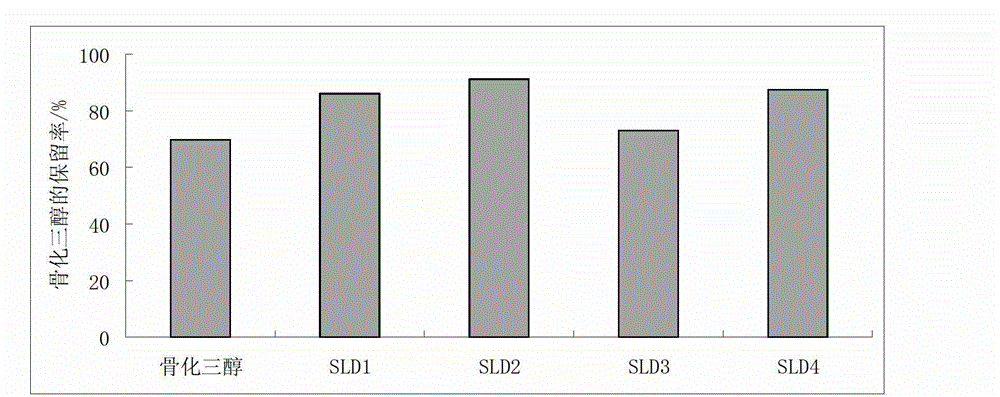

[0054] Stability test: The samples SLD1, SLD2, SLD3, and SLD4 were placed in an oven at 40°C and sealed from light, and samples were taken on the 10th day. The retention rate of calcitriol in the samples was determined by high performance liquid chromatography.

[0055] Table 2 The ratio of raw materials for calcitriol solid lipid dispersion (mass ratio)

[0056]

[0057]

[0058] The stability test results of calcitriol in the 4 calcitriol solid lipid...

Embodiment 2

[0060] In this example, five calcitriol solid lipid dispersions were prepared. The raw material formulations are shown in Table 3, and the preparation method is the same as that of Example 1. The difference lies in that the 5 calcitriol solid lipid dispersions in this example use 2 types of lipid carriers. The stability test method is the same as in Example 1.

[0061] Table 3 The ratio of raw materials of calcitriol solid lipid dispersion (mass ratio)

[0062]

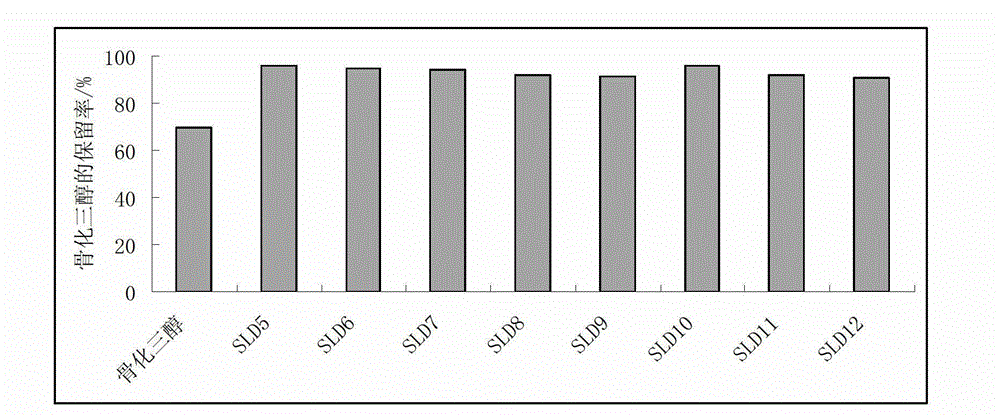

[0063] The stability test results of calcitriol in the 5 calcitriol solid lipid dispersions prepared in this example are as follows: figure 2 , As shown in Table 5. From figure 2 Table 5 It can be seen that the stability of SLD5-SLD9 is nearly 20% higher than that of the bulk drug; among them, SLD8-SLD9 is equivalent to SLD2 in Example 1. After the lipid carrier TPGS is added to SLD5-SLD7, the stability is better. SLD2 in Example 1 is better.

Embodiment 3

[0065] In this example, three calcitriol solid lipid dispersions were prepared. The raw material formulations are shown in Table 4, and the preparation method is the same as in Example 1. The difference is that the 3 calcitriol solid lipid dispersions in this example use 3 lipid carriers. The stability test method is the same as in Example 1.

[0066] Table 4 The ratio of raw materials of calcitriol solid lipid dispersion (mass ratio)

[0067]

[0068] The stability test results of calcitriol in the three calcitriol solid lipid dispersions prepared in this example are as follows: image 3 , As shown in Table 5. It can be seen from Table 5 that the stability of SLD10-SLD12 is nearly 20% higher than that of the bulk drug; among them, SLD12 is equivalent to SLD2 in Example 1. After the lipid carrier TPGS is added to SLD10 and SLD11, the stability is better than that in Example 1. SLD2 is better.

[0069] Table 5: Stability of Calcitriol Solid Dispersion at 40℃ for 10 Days

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com