Multifunctional post-extraction production line for enzyme preparation fermentation liquid

A multi-functional, fermentation broth technology, applied in enzyme production/bioreactors, biochemical instruments, biomass post-processing, etc., can solve the problems of high labor intensity, bacterial contamination, poor product clarity, etc., to reduce labor Strength, preventing secondary pollution and improving the purity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

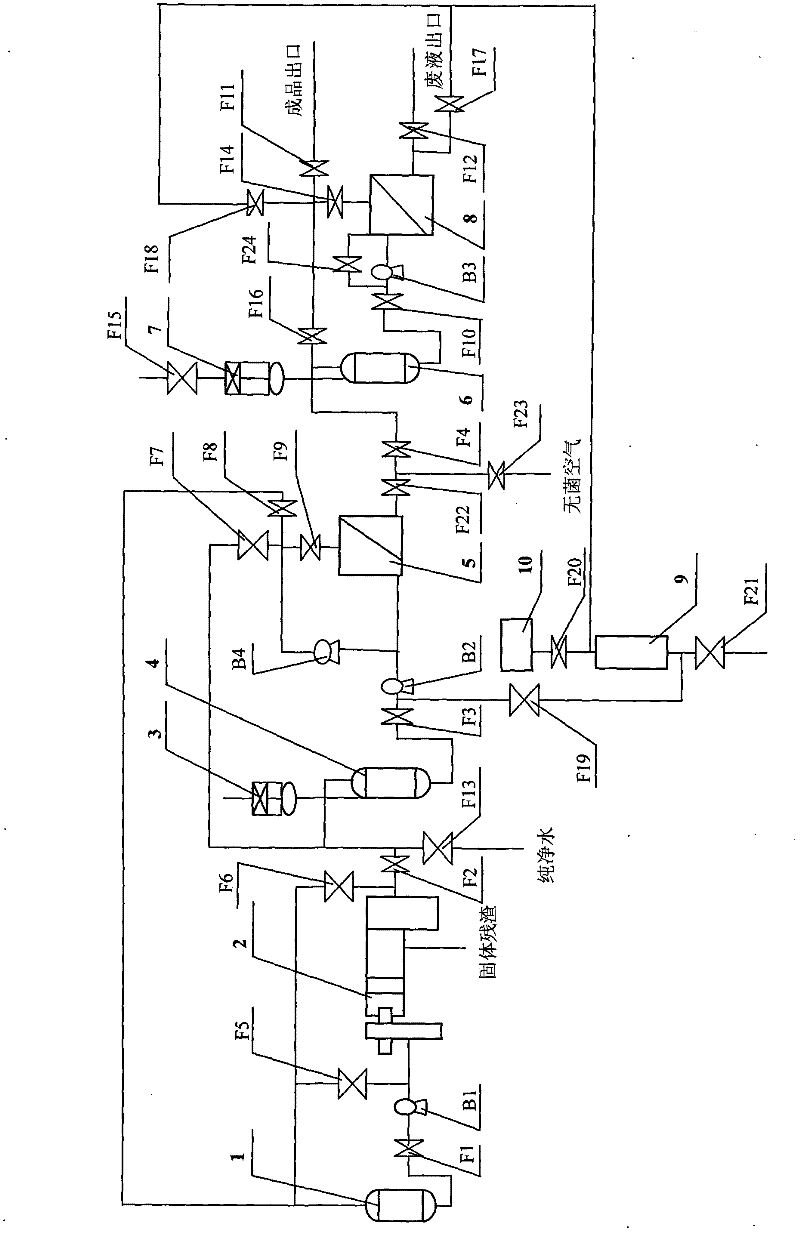

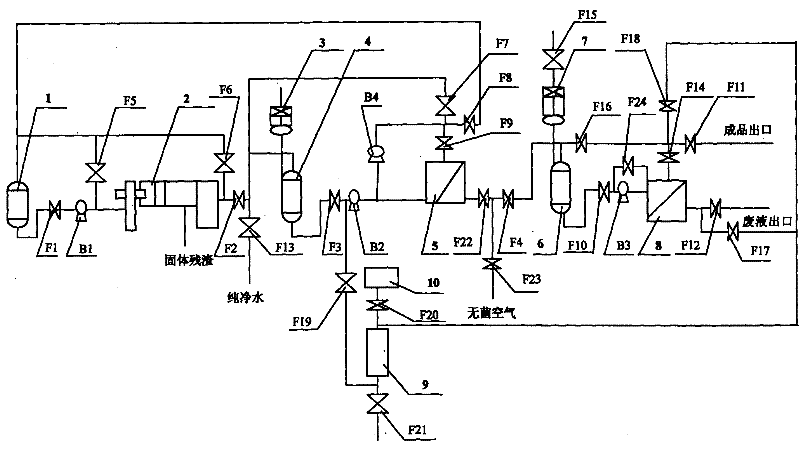

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] As shown in the accompanying drawings, the present invention includes a system main body structure and a system branch structure.

[0025] About the main structure of the system:

[0026] The outlet of the fermentation liquid storage tank 1 is connected to the inlet of the plate and frame filter press 2 through the valve F1 and the pump B1, and the outlet of the plate and frame filter press 2 is connected to the press filter liquid storage tank 4 through the valve F2 to form a plate and frame filter press. Filtration system; the outlet of the pressure filtrate storage tank 4 is connected with the inlet of the microfiltration membrane filter 5 through the valve F3 and the pump B2, and at the outlet of the pump B2, the entrapped liquid of the microfiltration membrane filter 5 is connected through the pump B4 and the valve F9 The outlet is connected into a small l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com