Negative pressure drilling liquid vibration sieve

A drilling fluid and vibrating screen technology, which is applied in the fields of screen screening, earth-moving drilling, flushing wellbore, etc., can solve the problems of high liquid content and small processing capacity of discharged cuttings, and achieve low liquid content and high recovery rate. , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

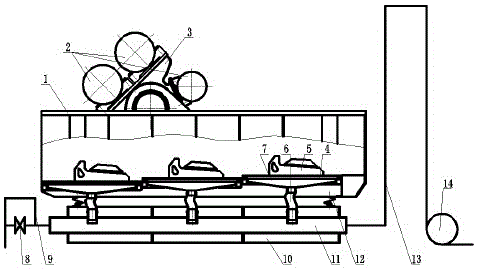

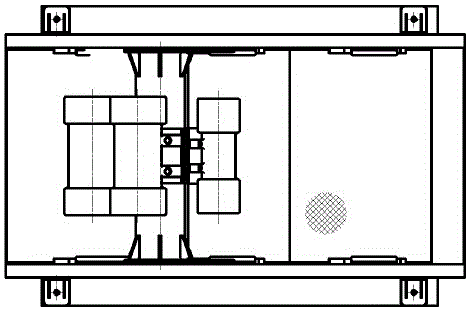

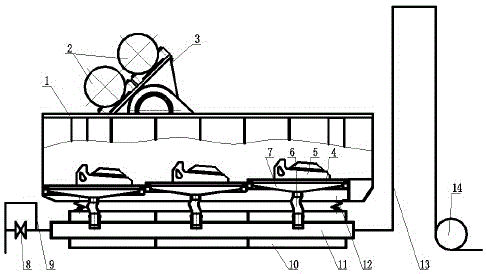

[0015] Further illustrate the present invention below in conjunction with accompanying drawing:

[0016] exist figure 1 , figure 2 , image 3 , Figure 4 Among them, a negative pressure drilling fluid vibrating screen of the present invention is mainly composed of a screen frame 1, an excitation motor 2, a motor base 3, a frame screen 4, a screen tensioning wedge 5, a flexible negative pressure pipe 6, and a screen surface The lower mud pan 7, the effluent venting valve 8, the drilling fluid discharge pipeline 9, the vibrating screen base 10, the negative pressure manifold 11, the damping spring 12, the negative pressure standpipe 13, and the vacuum pump 14 are composed. The motor base 3 is connected to the screen frame 1 as a whole by welding or bolt connection, and the excitation motor 2 is fixed on the motor base 3 by bolts; the mud pan 7 under the screen surface is supported on the beam and side beam of the screen frame 1, Then install the frame screen 4 on the mud tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com