Continuous automatic belt type hydraulic squeezing press

A press, hydraulic technology, applied in the field of continuous automatic belt hydraulic press, can solve the problems of poor equipment versatility, low degree of automation, filter cloth pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

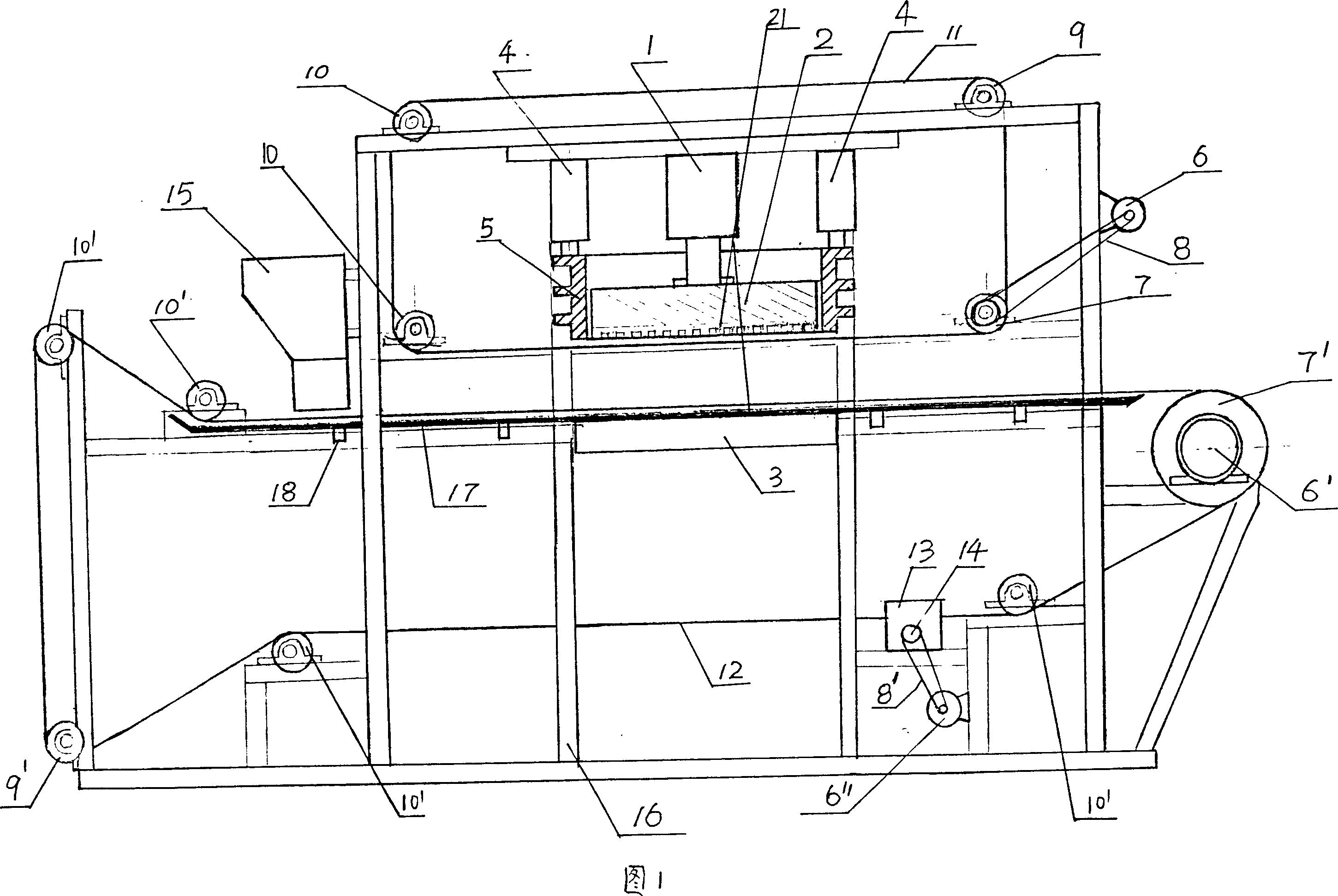

[0031] Embodiment 1: A kind of continuous automatic belt type hydraulic press machine (referring to Fig. 1), is especially applicable to the squeezing of solid and semi-solid materials that are not easy to flow. It has a frame 16, which is respectively connected with an annular filter cloth running device And the lower ring-shaped filter cloth running device, the upper ring-shaped filter cloth running device is composed of 2 guide rollers 10, 1 tension roller 9, 1 driving roller 7 and the upper ring-shaped filter cloth 11 connected to them. The driving roller 7 passes through the triangular The belt 8 is connected to the power machine 6, the power machine 6 can be an electric motor or a hydraulic motor, the guide roller 10, the tension roller 9, the driving roller 7 and the power machine 6 are all connected to the frame 16, and the lower annular filter cloth running device consists of 4 guide rollers 10', a tension roller 9', a driving roller 7' and the lower annular filter clo...

Embodiment 2

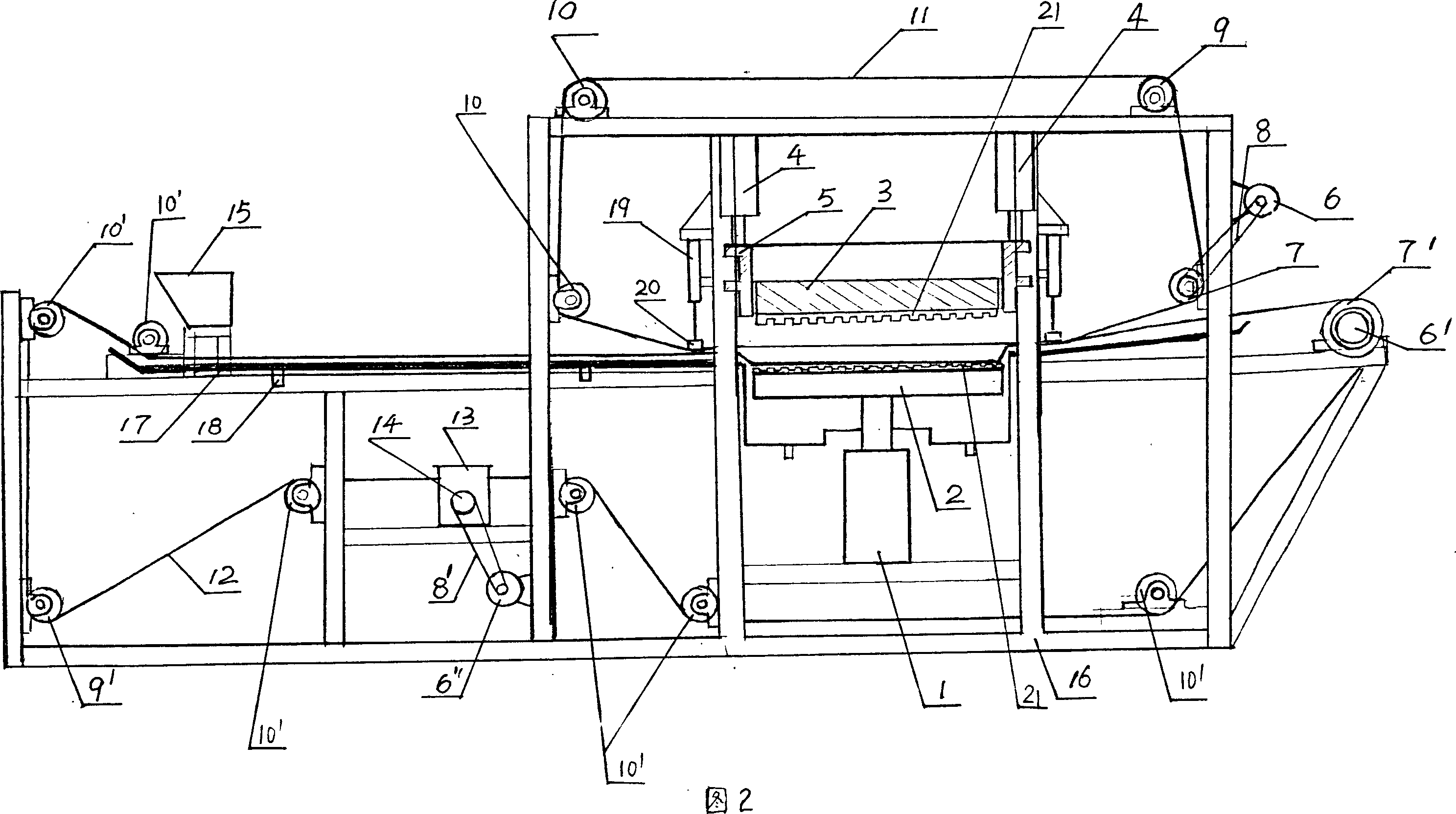

[0033]Embodiment 2: A kind of continuous automatic belt type hydraulic press machine (referring to Fig. 2), is especially suitable for the squeezing of fluid material, and it has frame 16, is respectively connected on the frame 16 the upper annular filter cloth running device and the lower annular filter cloth The running device, the upper annular filter cloth running device is composed of 2 guide rollers 10, 1 tension roller 9, 1 driving roller 7 and the upper annular filter cloth 11 connected to them. The driving roller 7 is connected to the power machine 6 through the V-belt 8 , the power machine 6 can be an electric motor or a hydraulic motor, the guide roller 10, the tension roller 9, the driving roller 7 and the power machine 6 are all connected to the frame 16, and the lower annular filter cloth running device consists of 6 guide rollers 10', 1 Tensioning roller 9', a driving roller 7' and the lower annular filter cloth 12 connected to them, the driving roller 7' is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com