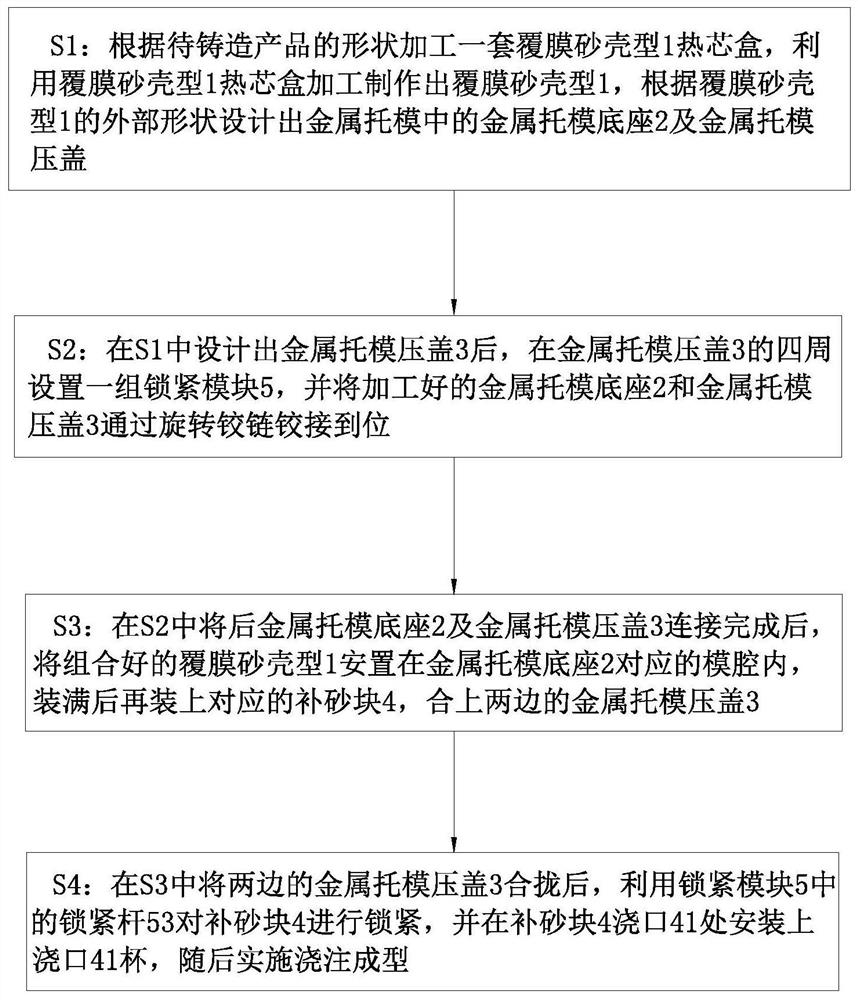

A film-coated sand shell mold casting process

A technology of shell mold casting and coated sand, which is applied in the direction of manufacturing tools, casting molding equipment, mold cores, etc., can solve the problems of increased casting cost, waste of time, affecting the quality and processing accuracy of coated sand shell mold casting, and achieves Enhanced convenience and improved casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

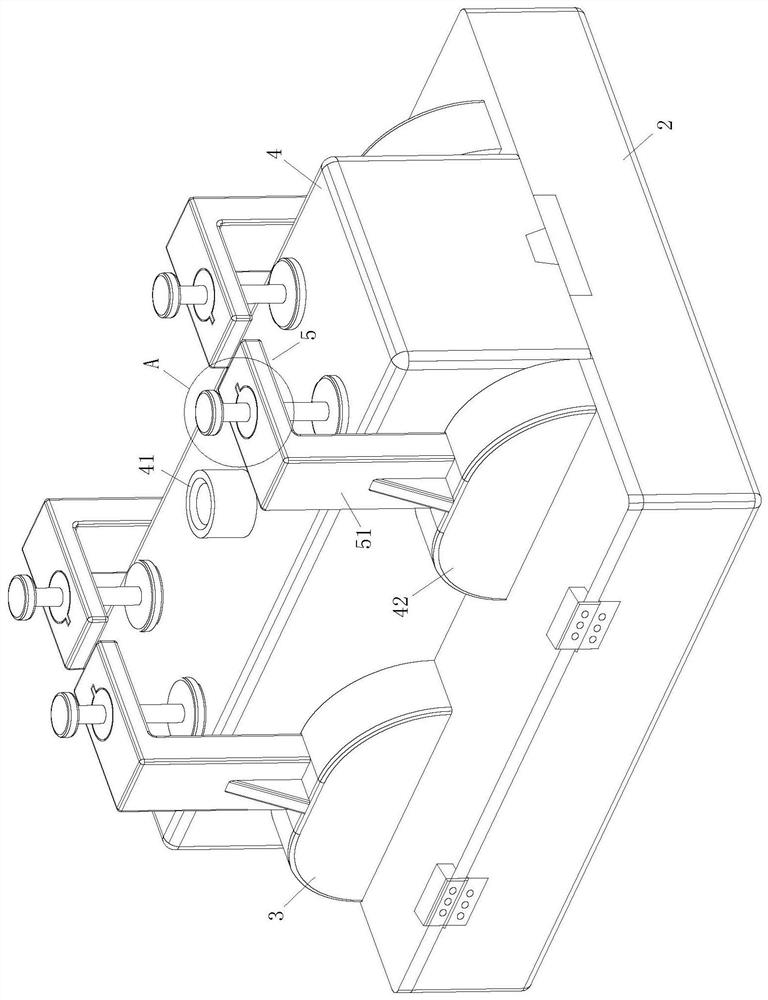

Examples

Embodiment approach

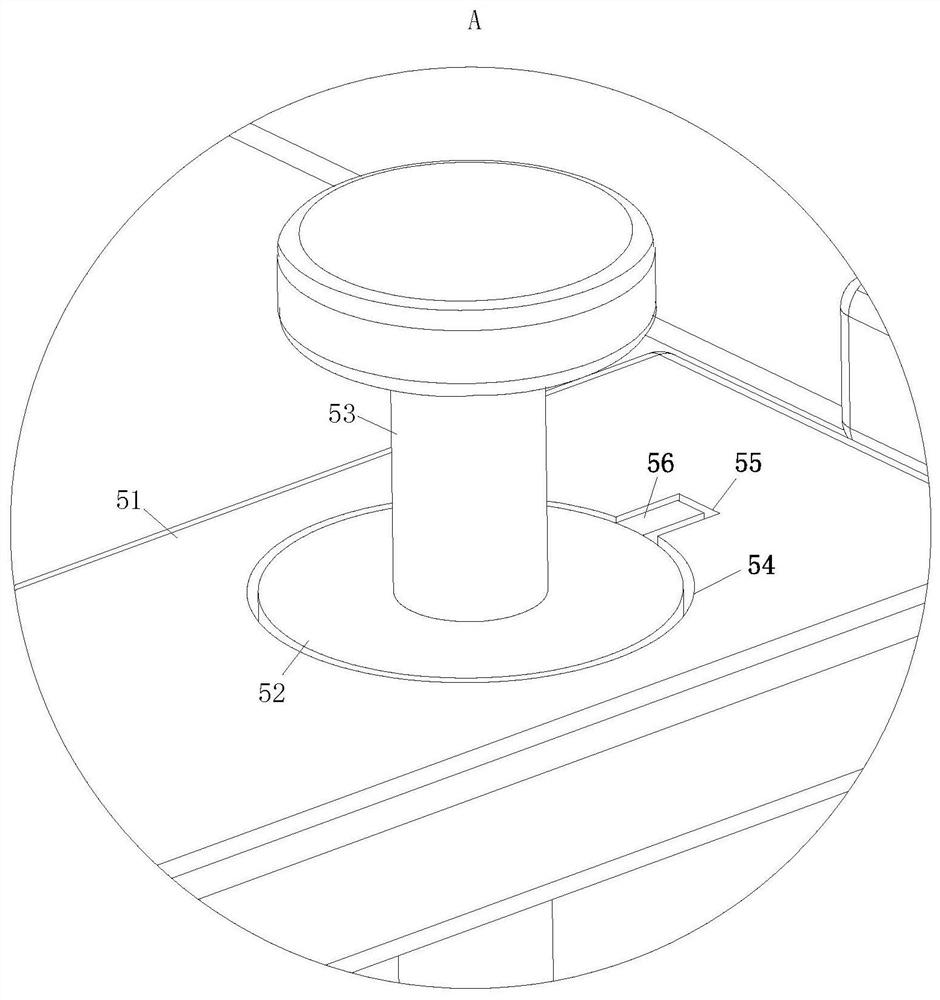

[0037] As an embodiment of the present invention, the bottom end of the rotating plate 61 is connected with a pressing block 62, the bottom surface of the pressing block 62 is connected with an arc-shaped pressing rod 63, and the other end of the pressing rod 63 is connected with a pressing plate 64; During work, by turning the rotating plate 61 to make it drive the pressing bar 63 connected on the pressing block 62 to rotate synchronously with the pressing plate 64, so that the pressing plate 64 can move to a position flush with the outer end surface of the positioning block 58 and squeeze it, The pressing plate 64 provided at this time can apply a horizontal force to the outer end surface of the positioning block 58 and make it easily slide into the positioning cavity, and when the positioning block 58 is completely squeezed into the positioning groove 57, the pressing plate 64 Rotate between the opening of the positioning groove 57 and the side wall of the locking ring 52 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com