A high-pressure differential pressure forming method for large thin-walled SIC-reinforced 2014 aluminum alloy matrix composite castings

A technology of aluminum alloy base and composite materials, which is applied in the field of high-pressure differential pressure forming, can solve the problems of micro-crack sources and uneven distribution of SiC reinforcement, and achieve the effect of improving uniformity, eliminating micro-crack sources, and achieving uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

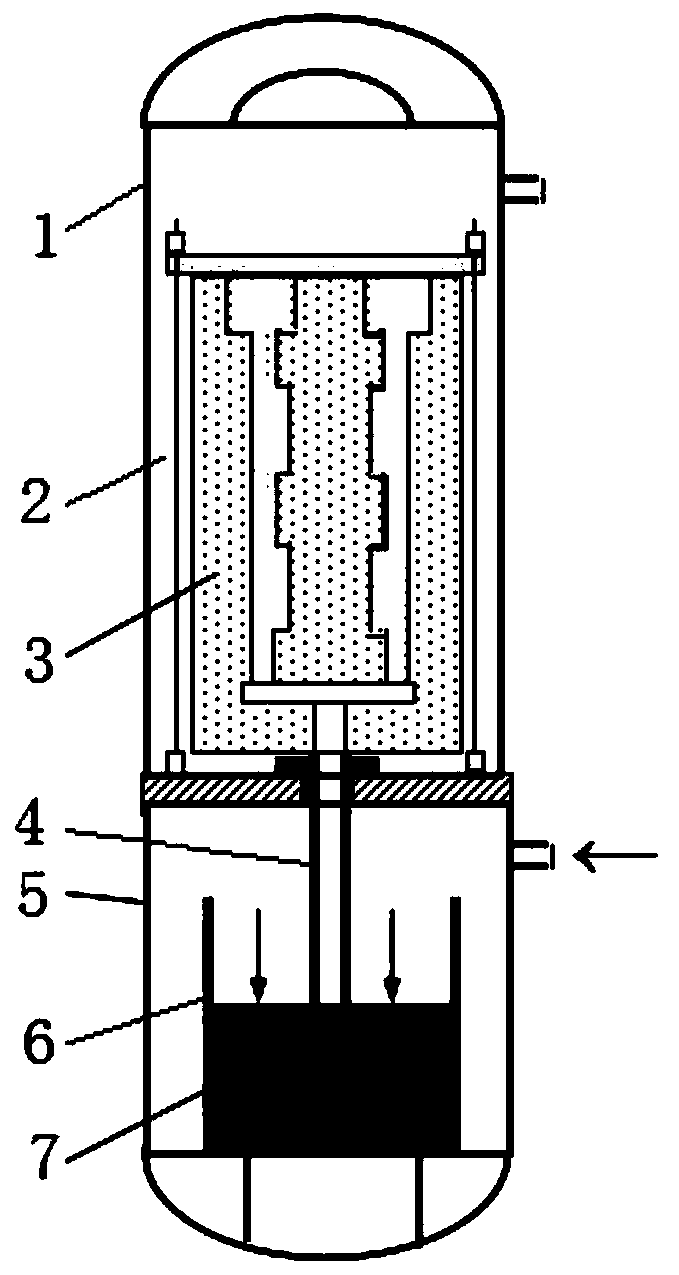

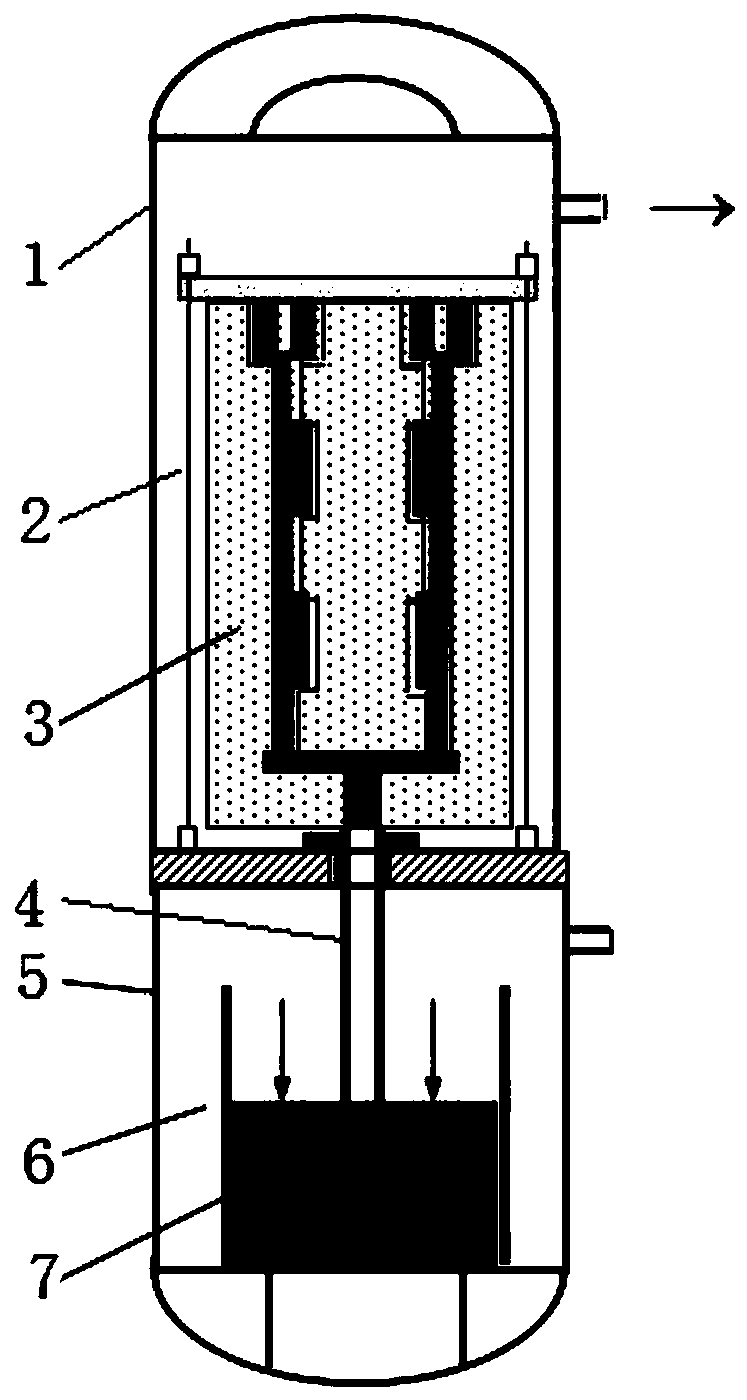

[0020] Specific Embodiment 1: In this embodiment, a high pressure differential pressure forming method for a large thin-walled SiC reinforced 2014 aluminum alloy matrix composite material casting is carried out according to the following steps:

[0021] Step 1. Take the SiC-reinforced 2014 aluminum alloy-based composite material and divide it into two parts, A and B, wherein part A accounts for 30% of the total weight of the SiC-reinforced 2014 aluminum-alloy-based composite material, and the rest is part B;

[0022] Step 2. Put part A in the crucible of the lower pressure tank of the anti-gravity forming device, and when it melts to 740°C, add part B, control the melt temperature at 700°C, and keep it warm for 20 minutes;

[0023] Step 3, then close the lower pressure tank, insert the riser pipe into the crucible, place and lock the mold, install the upper pressure tank and close it;

[0024] Step 4. Open the communication valve between the upper pressure tank and the lower p...

specific Embodiment approach 2

[0029] Specific implementation mode two: In this implementation mode, a high-pressure differential pressure forming method of a large thin-walled SiC reinforced 2014 aluminum alloy matrix composite material casting is carried out according to the following steps:

[0030] Step 1. Take the SiC-reinforced 2014 aluminum alloy-based composite material and divide it into two parts, A and B, wherein part A accounts for 40% of the total weight of the SiC-reinforced 2014 aluminum-alloy-based composite material, and the rest is part B;

[0031] Step 2. Put part A in the crucible of the lower pressure tank of the anti-gravity forming device, and when it melts to 720°C, add part B, control the melt temperature at 690°C, and keep it warm for 40 minutes;

[0032] Step 3, then close the lower pressure tank, insert the riser pipe into the crucible, place and lock the mold, install the upper pressure tank and close it;

[0033] Step 4. Open the communication valve between the upper pressure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com