Process method for reinforced alkali-united filtration

A process method and combined alkali technology are applied in the field of combined alkali enhanced filtration process, which can solve the problems of difficulty in producing high-quality products, low solid content of carbonized extraction liquid, and high free ammonia content, so as to improve production capacity and save raw material consumption. , the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

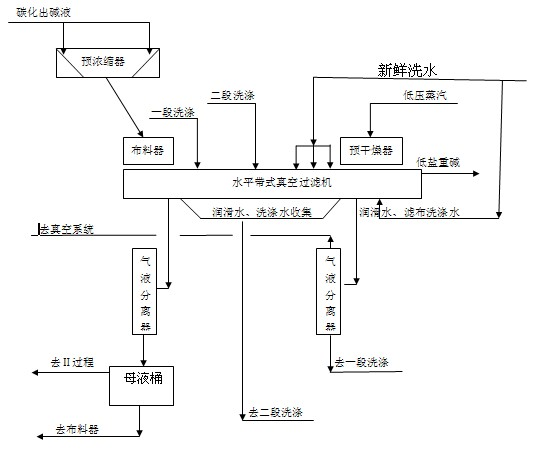

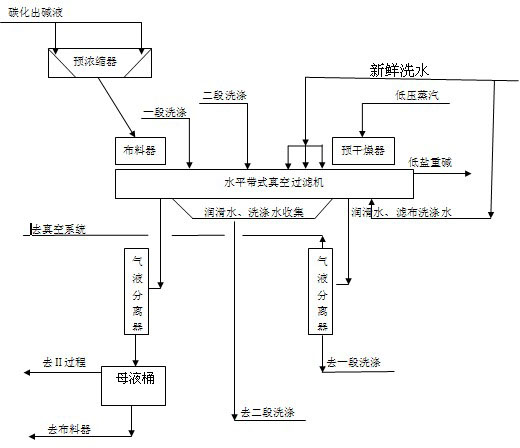

Image

Examples

Embodiment 1

[0032] Taking the 300,000 tons / year combined alkali plant as an example, the description is as follows:

[0033]The combined alkali carbonization extraction liquid (containing solid sodium bicarbonate 12-20%wt) is self-pressed into the alkali discharge tank with a curved screen, and the solid sodium bicarbonate crystal slurry is pre-concentrated through the alkali discharge tank, and the solid hydrogen carbonate on the solid-liquid side When the sodium content reaches 25-35%wt, it flows into the distribution box of the belt filter through the pipeline, and the liquid side flows into the mother liquid tank by itself. The pre-concentrated sodium bicarbonate crystal slurry is evenly distributed to the filter section of the belt filter through the distributor. The sodium bicarbonate slurry realizes solid-liquid separation by virtue of its own gravity and vacuum suction, and then enters the belt filter after forming a filter cake. washing section.

[0034] The washing of the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com