Finished product residual liquid recoverable post-extraction production line of enzyme preparation fermentation liquid

A technology of residual liquid and fermentation liquid, applied in the direction of enzyme production/bioreactor, biochemical instrument, biomass post-processing, etc., can solve the problems of poor sterilization and solidification removal, large water consumption, high labor intensity, and achieve good solidification. The effect of liquid separation, reducing waste water discharge and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

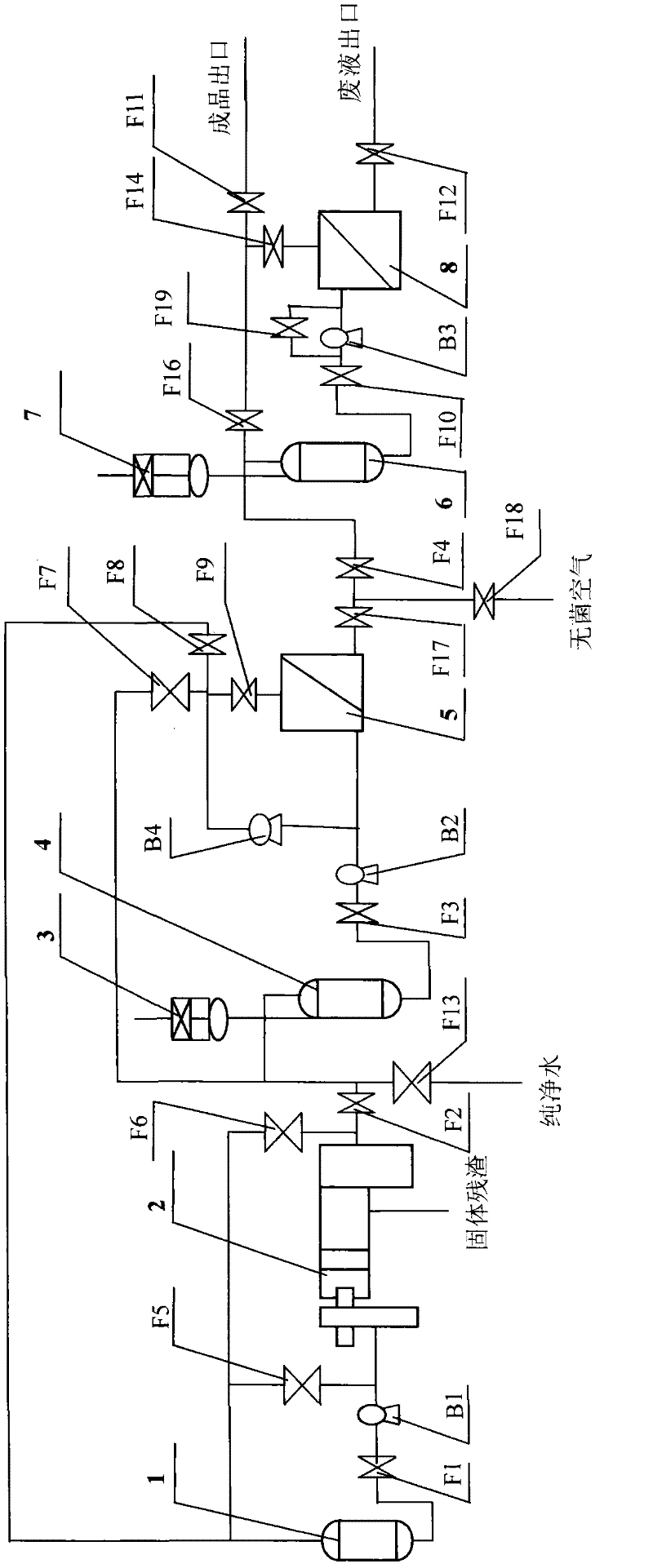

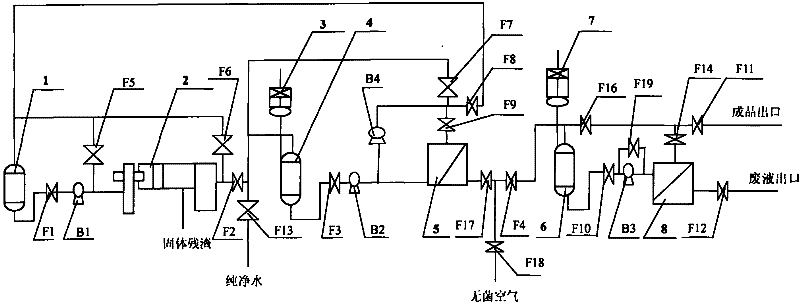

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] As shown in the accompanying drawings, the present invention includes a system main body structure and a system branch structure.

[0022] About the main structure of the system:

[0023] The outlet of the fermentation liquid storage tank 1 is connected to the inlet of the plate and frame filter press 2 through the valve F1 and the pump B1, and the outlet of the plate and frame filter press 2 is connected to the press filter liquid storage tank 4 through the valve F2 to form a plate and frame filter press. Filtration system; the outlet of the pressure filtrate storage tank 4 is connected with the inlet of the microfiltration membrane filter 5 through the valve F3 and the pump B2, and at the outlet of the pump B2, the entrapped liquid of the microfiltration membrane filter 5 is connected through the pump B4 and the valve F9 The outlet is connected into a small l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com