Kitchen waste treatment system and treatment method

A food waste and processing system technology, applied in the field of food waste, can solve the problems of ineffective automatic treatment, solid-liquid mixing in food waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

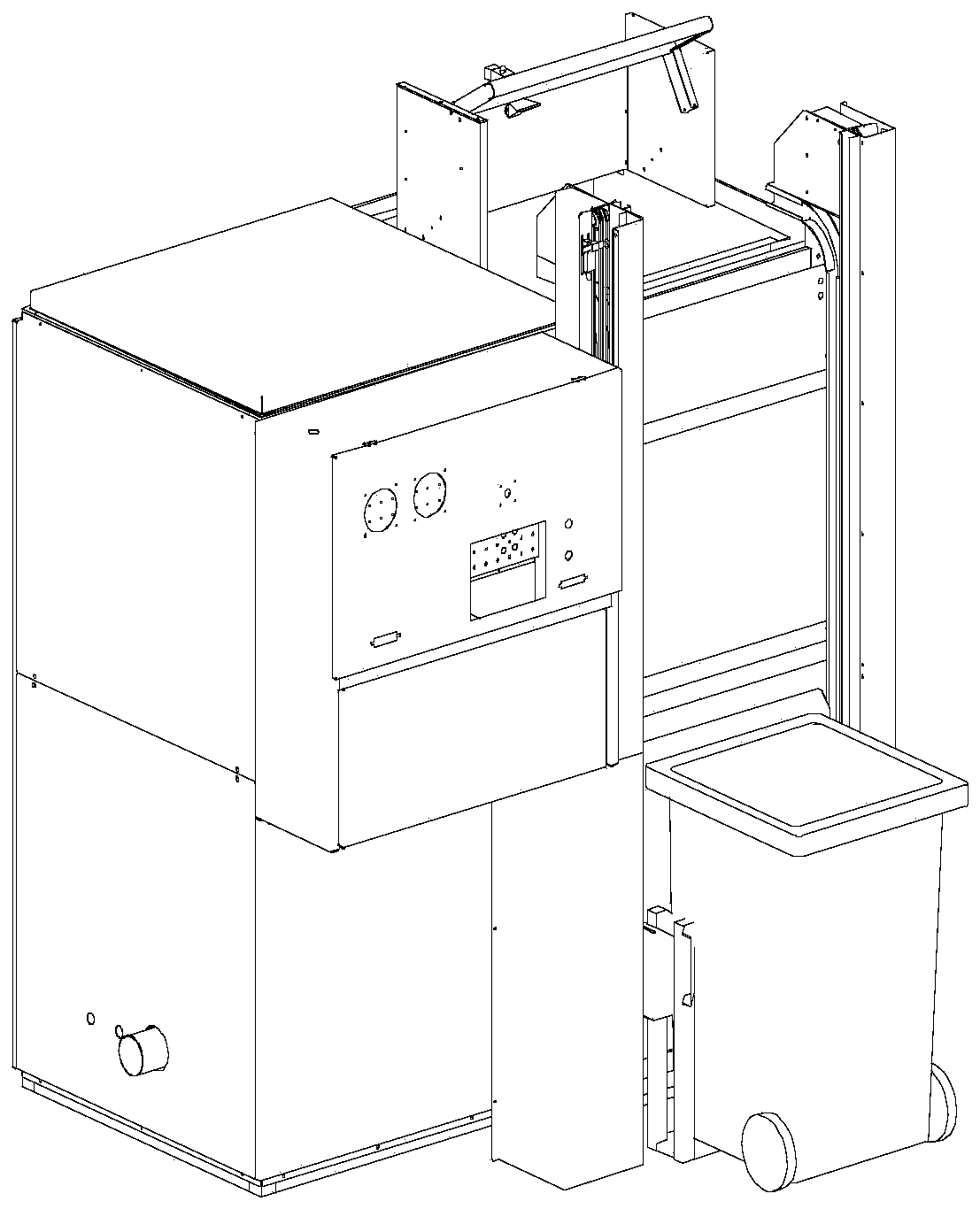

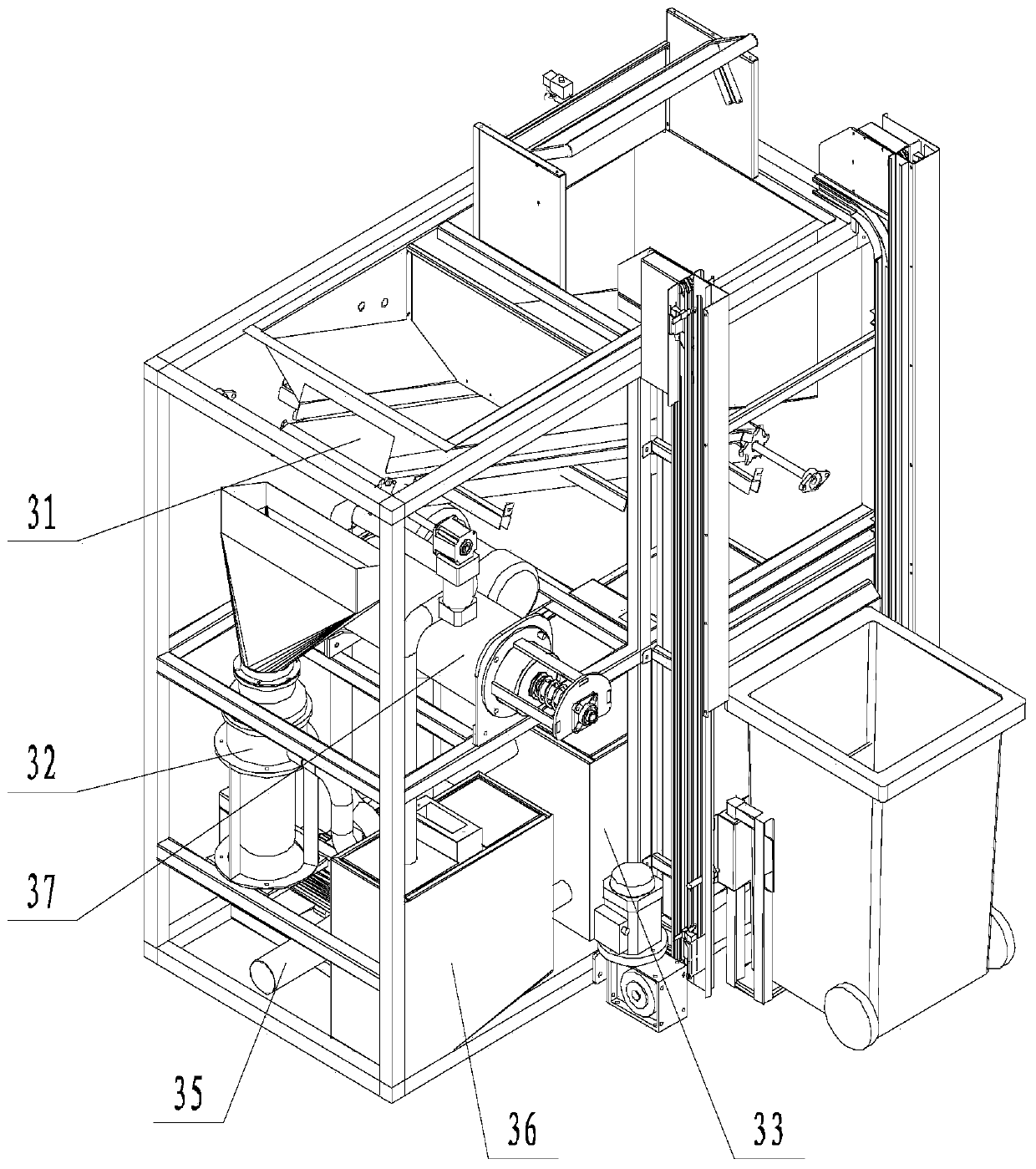

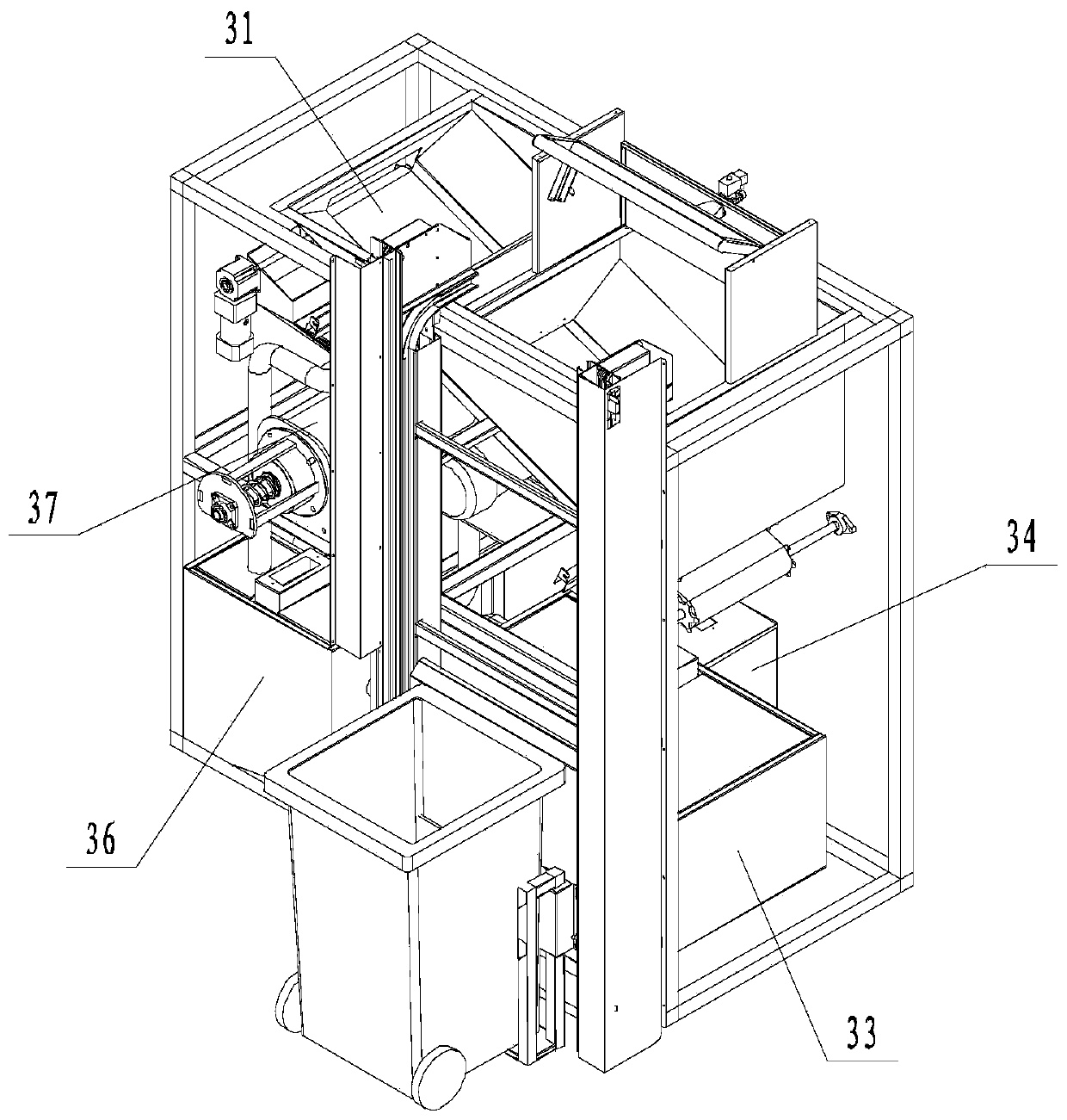

[0054]A food waste treatment system, comprising a conveyor belt 31 for conveying food waste from bottom to top, a grinder 32 is arranged under the top end of the conveyor belt 31, and a grinder 32 is arranged under the bottom end of the conveyor belt 31 for separating oil and water. Oil trap 33, the oil trap 33 communicates with the oil tank 34, the oil separated by the oil trap 33 enters the oil tank 34, and the oil tank 34 communicates with the drain pipe 35 through a pump; it also includes a press for extruding the liquid machine 37, the inlet end of the squeezer 37 is the discharge port 4, the outlet end of the squeezer 37 is the liquid discharge port 8 and the slag discharge port, the liquid squeezed out by the squeezer 37 is discharged from the liquid discharge port, and the remaining The residue is discharged from the slag outlet; the discharge end of the grinder 32 is connected to the slurry tank 36, and the slurry tank 36 and the grease trap 33 are all connected to the...

Embodiment 2

[0056] A food waste treatment system, on the basis of Embodiment 1, the conveyor belt 31 is a circle of mesh belt driven by a motor, and also includes a spray device for washing the mesh belt. Several dividing plates 38 are arranged in the described grease trap 33, and breaches 39 are all set on the described dividing plate 38; Oil enters the oil tank 34 through the opening 30; a sensor at the same height as the opening 30 is arranged in the grease trap 33, and the sensor is used to monitor whether the liquid at the height of the opening 30 in the grease trap 33 is oil or water; The sensor detects that the liquid in the grease trap 33 at the height of the opening 30 is water, and the liquid in the grease trap 33 is pumped to the inlet port of the press 37 by a corresponding pump.

Embodiment 3

[0058] A food waste treatment system, on the basis of any of the above-mentioned embodiments, the squeezer 37 includes a screw conveying shaft 1, the spiral conveying shaft 1 is surrounded by a circle of filter screen 2, and the outside of the filter screen 2 is The casing 3 is provided with a liquid discharge port 8, the discharge port 4 communicates with the inner space of the filter screen 2, and the tail of the screw conveying shaft 1 along the conveying direction is provided with a pressure plate 5, and the pressure plate 5 is covered by an elastic member 6 is pressed on the end of the shell 3, and the pressing plate 5 blocks one end of the shell 3, and also includes a pressure regulating mechanism for adjusting the elastic force of the elastic member 6. Both ends of the housing 3 along the axial direction are fixed with mounting plates 7, the screw conveying shaft 1 passes through two mounting plates 7, and the pressing plate 5 is held on one mounting plate 7; the two mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com