Method for making banana fruit vinegar through corncob immobilized acetobacter

A corncob and acetic acid bacteria technology, which is applied in the field of food processing, can solve the problems of wasting nutritional value and discarding banana peels, and achieves the effects of refreshing taste, sufficient fermentation, and shortening fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

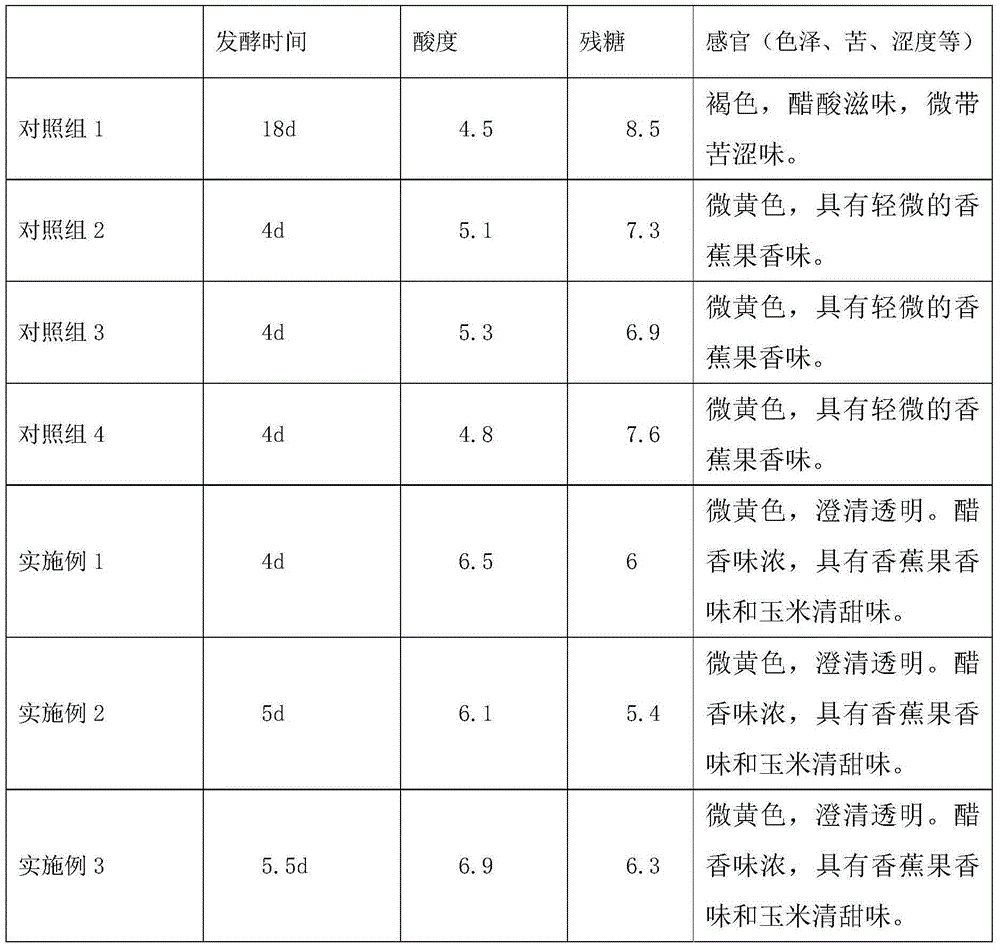

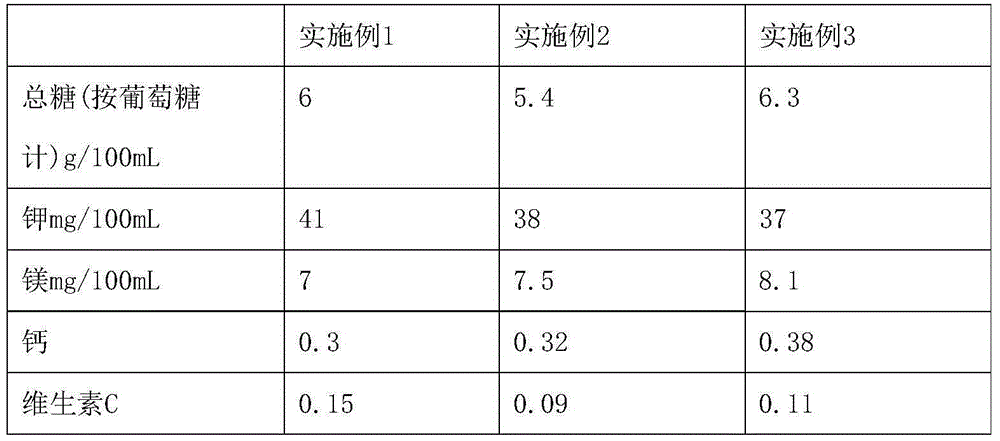

Embodiment 1

[0025] Get the whole ripe banana fruit, wash it with clear water, add water 5 times of the fruit weight to make a slurry, heat to 35°C, add pectinase, cellulase, amylase (mass ratio is 5:2: 1) Carrying out enzymatic hydrolysis for 3 hours to obtain the original pulp liquid.

[0026] Take white granulated sugar (15% of the weight of the banana fruit slurry) and mix water at a weight ratio of 1:3, add citric acid with a weight ratio of 0.05% and stir, heat to 90°C for 120 minutes to prepare the sugar solution, and mix the sugar solution and the weight of the slurry Add 0.02% fruit wine active dry yeast to the banana whole fruit pulp, lower the temperature to 20°C and ferment for 3 days, then filter to obtain banana whole fruit wine with an alcohol content of 9 degrees;

[0027] Wash the corncobs, sterilize them at 0.1MPa for 15 minutes, and after drying, sprinkle active dry acetic acid bacteria with a weight ratio of 0.05% on the periphery of the corncobs, place them in a solid-...

Embodiment 2

[0029] Get the ripe banana whole fruit, add water 5 times of fruit weight after washing with clear water to make a slurry, heat to 35 ℃, add pectinase, cellulase and amylase (mass ratio is 4:2: 2) Carrying out enzymatic hydrolysis for 3 hours to obtain pulp stock solution.

[0030] Take white granulated sugar (12% of the weight of the banana fruit slurry) and mix water at a weight ratio of 1:3, add citric acid with a weight ratio of 0.05% and stir, heat to 90°C and keep it for 120 minutes to prepare the sugar solution, and mix the sugar solution and the weight of the slurry Add 0.02% fruit wine active dry yeast to the banana whole fruit slurry, lower the temperature to 20°C and ferment for 4 days, then filter to obtain banana whole fruit wine with an alcohol content of 8 degrees;

[0031] Clean the corncob, sterilize it at 0.15MPa for 20 minutes, sprinkle active dry acetic acid bacteria with a weight ratio of 0.08% on the periphery of the corncob, place it in a solid core cage...

Embodiment 3

[0033] Get the ripe banana whole fruit, add water 5 times of fruit weight after washing with clear water to make a slurry, heat to 35 ℃, add pectinase, cellulase, amylase (mass ratio is 3:1: 1) Carrying out enzymatic hydrolysis for 3 hours to obtain the original pulp liquid.

[0034] Take white granulated sugar (16% of the weight of the banana fruit slurry) and mix water with a weight ratio of 1:3, add citric acid with a weight ratio of 0.05% and stir, heat to 90°C for 120 minutes to prepare the sugar solution, and mix the sugar solution and the weight of the slurry Add 0.05% fruit wine active dry yeast to the banana whole fruit slurry, lower the temperature to 20°C and ferment for 4 days, then filter to obtain banana whole fruit wine with an alcohol content of 9.5 degrees;

[0035] Wash the corncobs, sterilize them at 0.15MPa for 15 minutes, and after drying, sprinkle active dry acetic acid bacteria with a weight ratio of 0.1% on the periphery of the corncobs, place them in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com