Gas-oil-water three-phase separator

A three-phase separator, gas-oil-water technology, applied in the direction of liquid separation, separation method, liquid degassing, etc., can solve the problems of releaser clogging, affecting production efficiency, complicated maintenance operations, etc., and achieve labor-saving maintenance and ideal results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

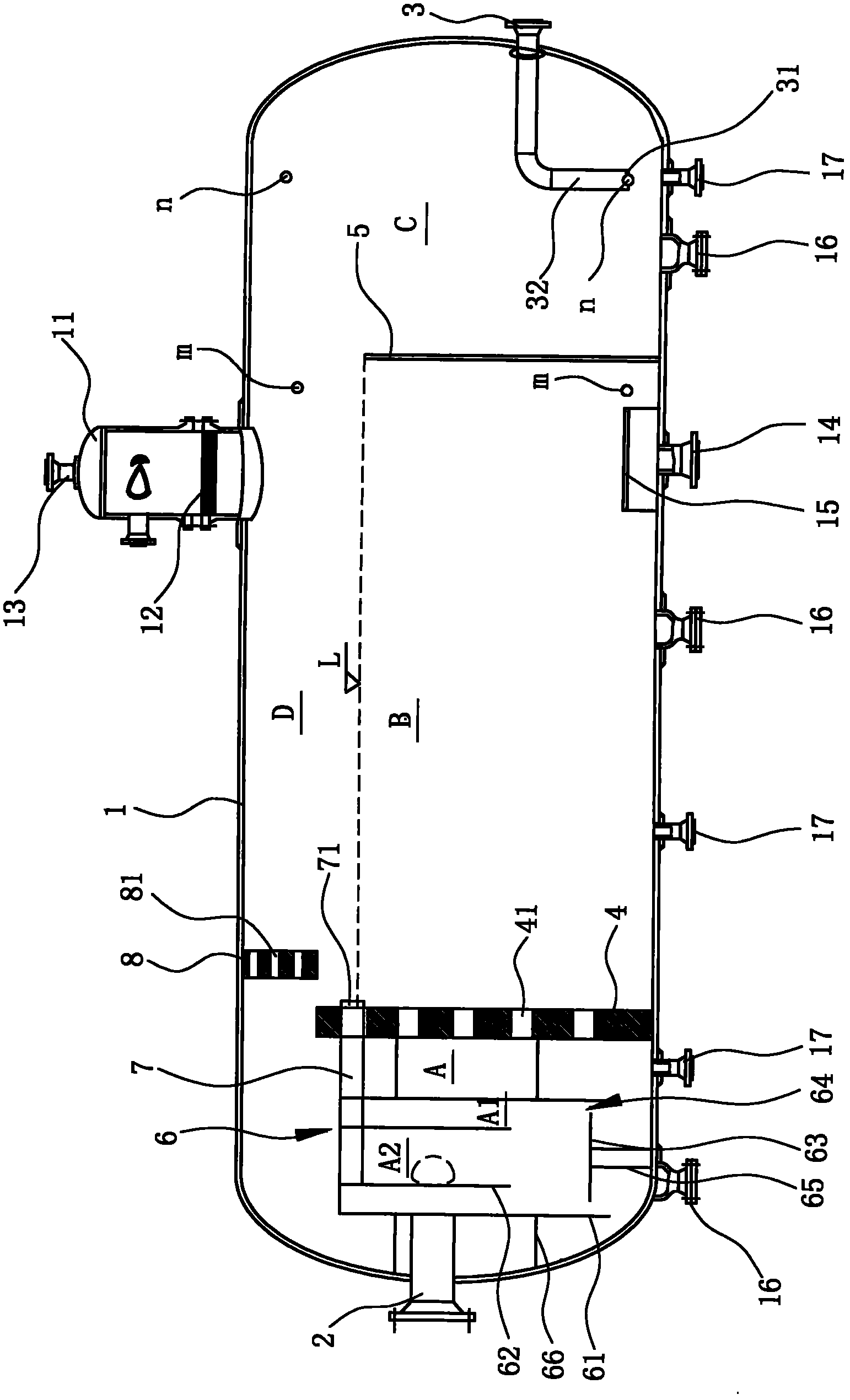

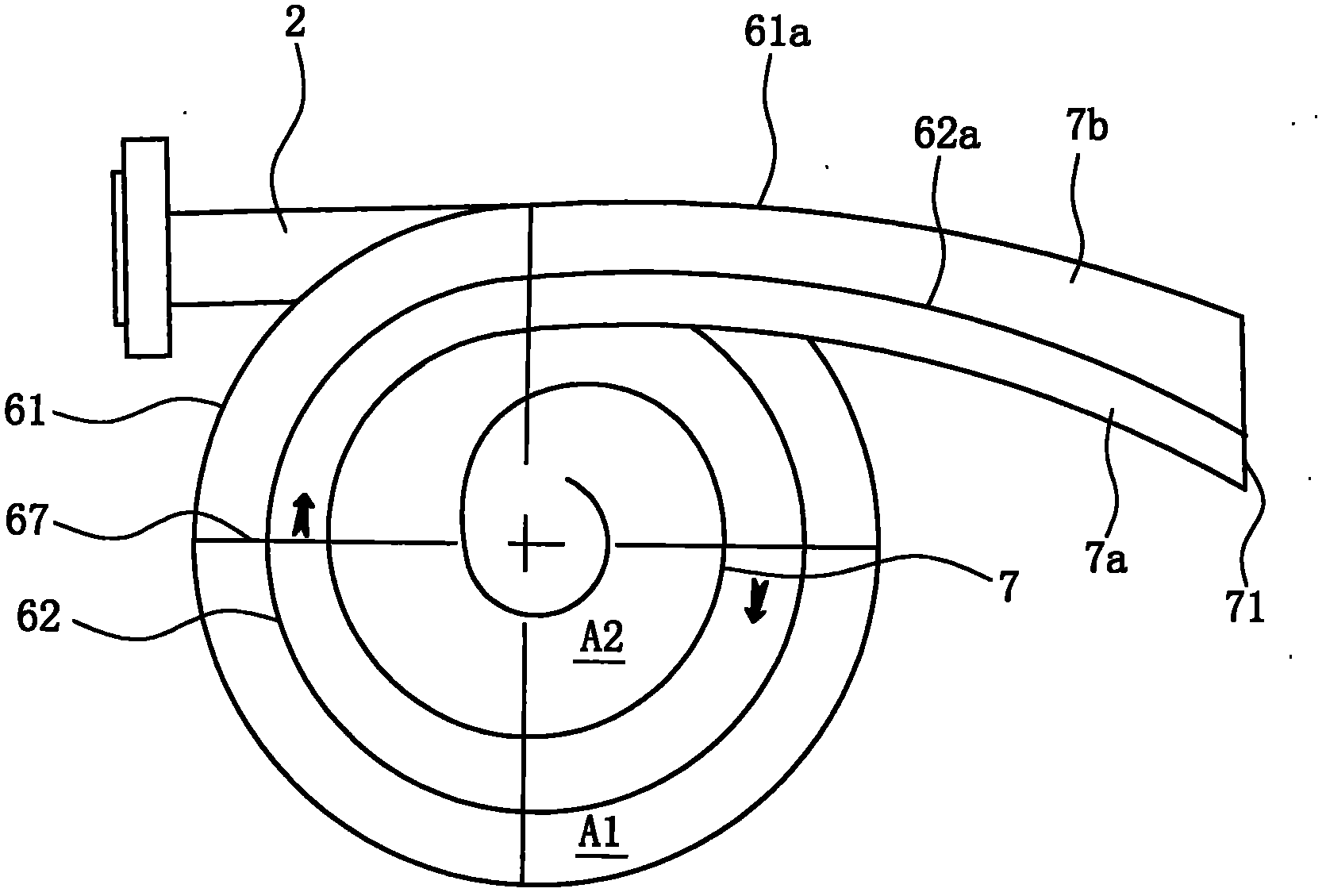

[0036] Such as figure 1 , figure 2 As shown, the gas-oil-water three-phase separator includes a horizontal tank body 1, a crude oil input pipe 2 and an oil discharge pipe 3;

[0037] Wherein, the interior of the tank body 1 is erected with a liquid stabilizing plate 4 and a baffle plate 5 in sequence from left to right, and the interior of the tank body 1 is divided into a separation area A, a liquid collection area B and an oil collection area in sequence from left to right. In zone C, the top of the liquid stabilizing plate 4 is higher than the baffle 5, and there is a gap between the tops of the liquid stabilizing plate 4 and the baffle 5 and the top of the tank 1, and the inside of the tank 1 is at the top of the baffle 5. A gas gathering area D is formed above;

[0038]The bottom of the tank body 1 is provided with a drainage pipe 14 at the position where the liquid collection area B is located and on the left side of the baffle plate 5;

[0039] The top of the tank b...

Embodiment 2

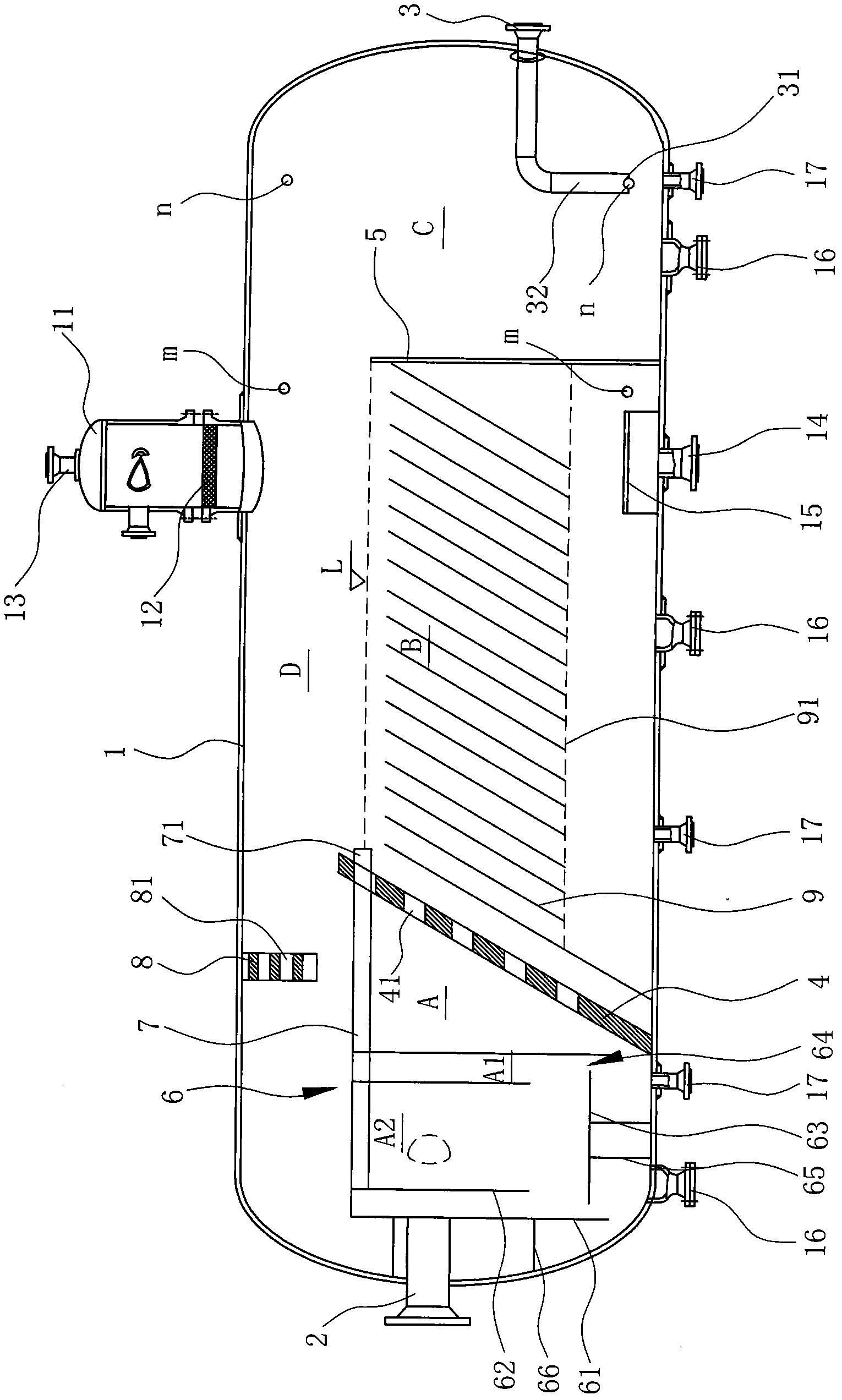

[0059] As shown in Figure 5, the difference between Embodiment 2 and Embodiment 1 of the present invention is that: the liquid stabilizing plate 4 is inclined in such a way that the top is inclined to the right, and there are multiple parallel plates in the liquid collection area B. And the corrugated plates 9 arranged at intervals form a corrugated plate group, the bottom of the corrugated plate closest to the liquid stabilizing plate 4 in the corrugated plate group is in contact with the bottom of the tank body 1, and the corrugated plate group is supported by a bracket 91 arranged at the bottom Fixed, in this embodiment, the corrugated plate 9 is also parallel to the liquid stabilizing plate 4 .

[0060] The liquid phase will pass through the corrugated plate 9 from top to bottom and enter the bottom area of the tank 1, the oil phase will naturally float on the top of the liquid collection area B, and the water phase will be discharged from the tank 1 through the drain pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com