Remote Control System for Locomotive Rolling Table Test

A technology of remote control system and main transmission system, which is applied in the field of rail transit, which can solve the problems of unfavorable operators, heavy workload during maintenance, and troublesome wiring, so as to avoid missed operation or misoperation, and the experimental process is simple and easy, Facilitate the effect of inspection and maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

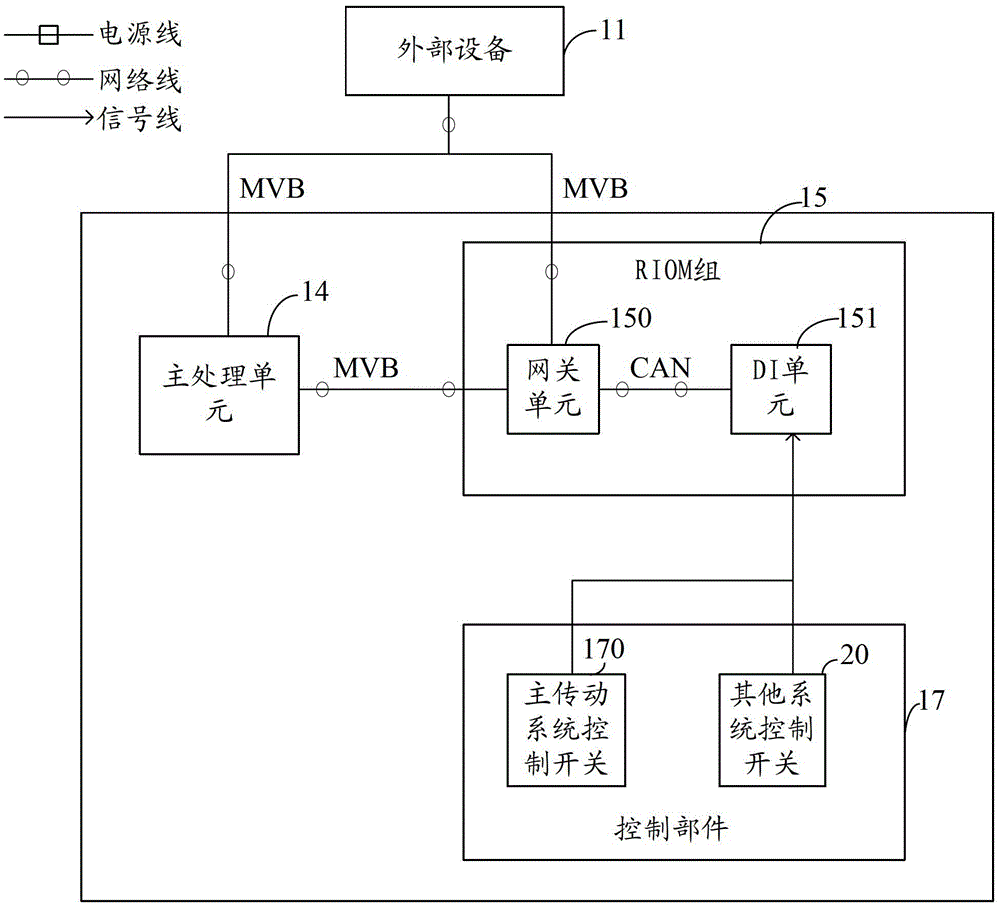

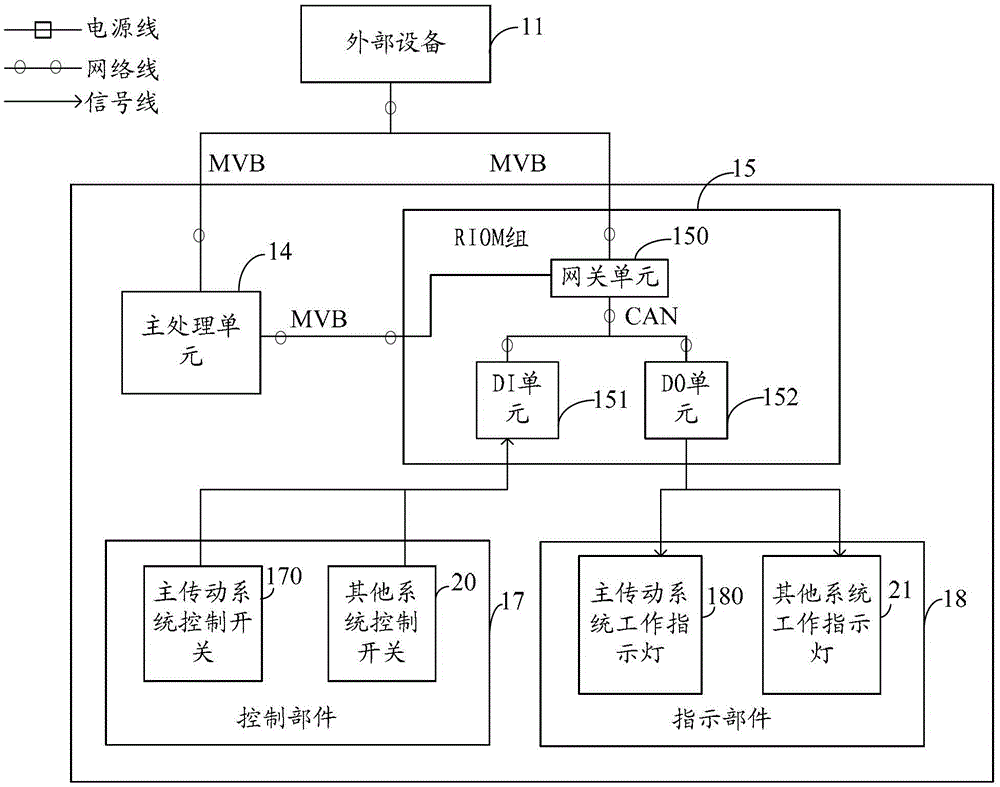

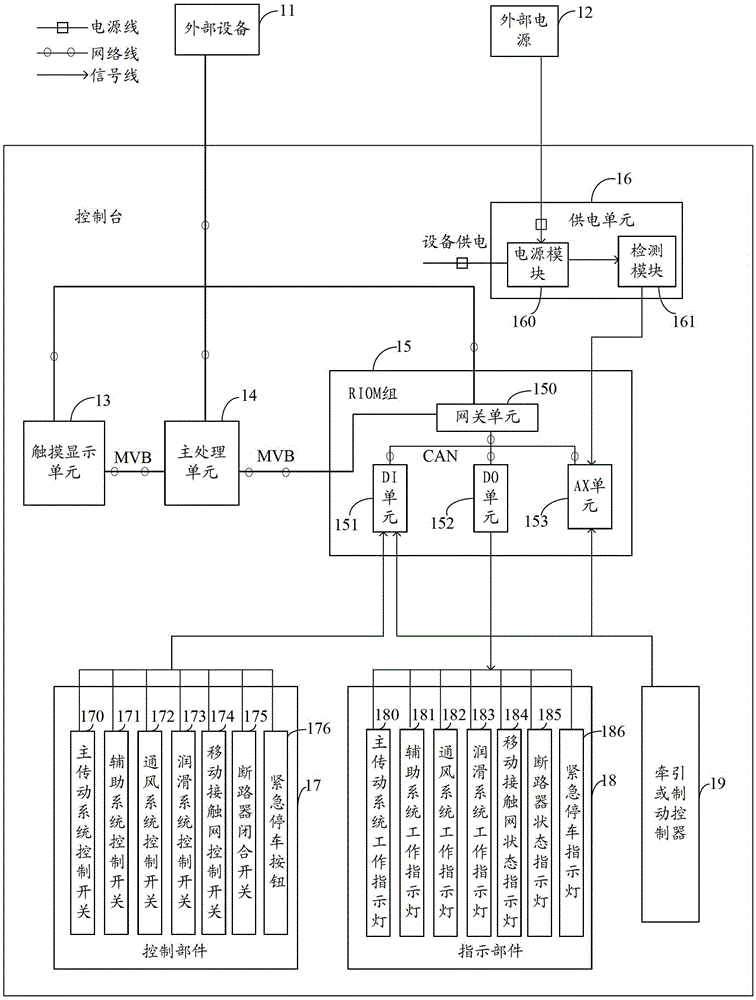

[0028] figure 1 It is a structural schematic diagram of Embodiment 1 of the remote control system used in the locomotive rolling table test of the present invention, as figure 1 As shown, the device of this embodiment may include a console on which a main processing unit 14, a RIOM group 15 and a control unit 17 are arranged; the remote input and output module (RemoteInputOutputModule, hereinafter referred to as: RIOM) group 15 includes a (DigitalInput, hereinafter referred to as DI) unit 151 and gateway unit 150, the control unit 17 includes a main transmission system control switch 170 and other system control switches 20 related to the experiment.

[0029] Further, the main drive system control switch 170 and other system control switches 20 are connected to the DI unit 151, and the DI unit 151 is connected to the gateway unit 150 through a controller area network (ControllerAreaNetwork, hereinafter referred to as CAN) network interface, and the gateway unit 150 is The bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com