High-efficiency helical material pushing apparatus of horizontal helical centrifuge

A horizontal screw centrifuge and screw pusher technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of incomplete solid-liquid separation, unfavorable liquid phase flow separation, etc., and achieve solid-liquid separation Thorough, improve the effect of separation, improve the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

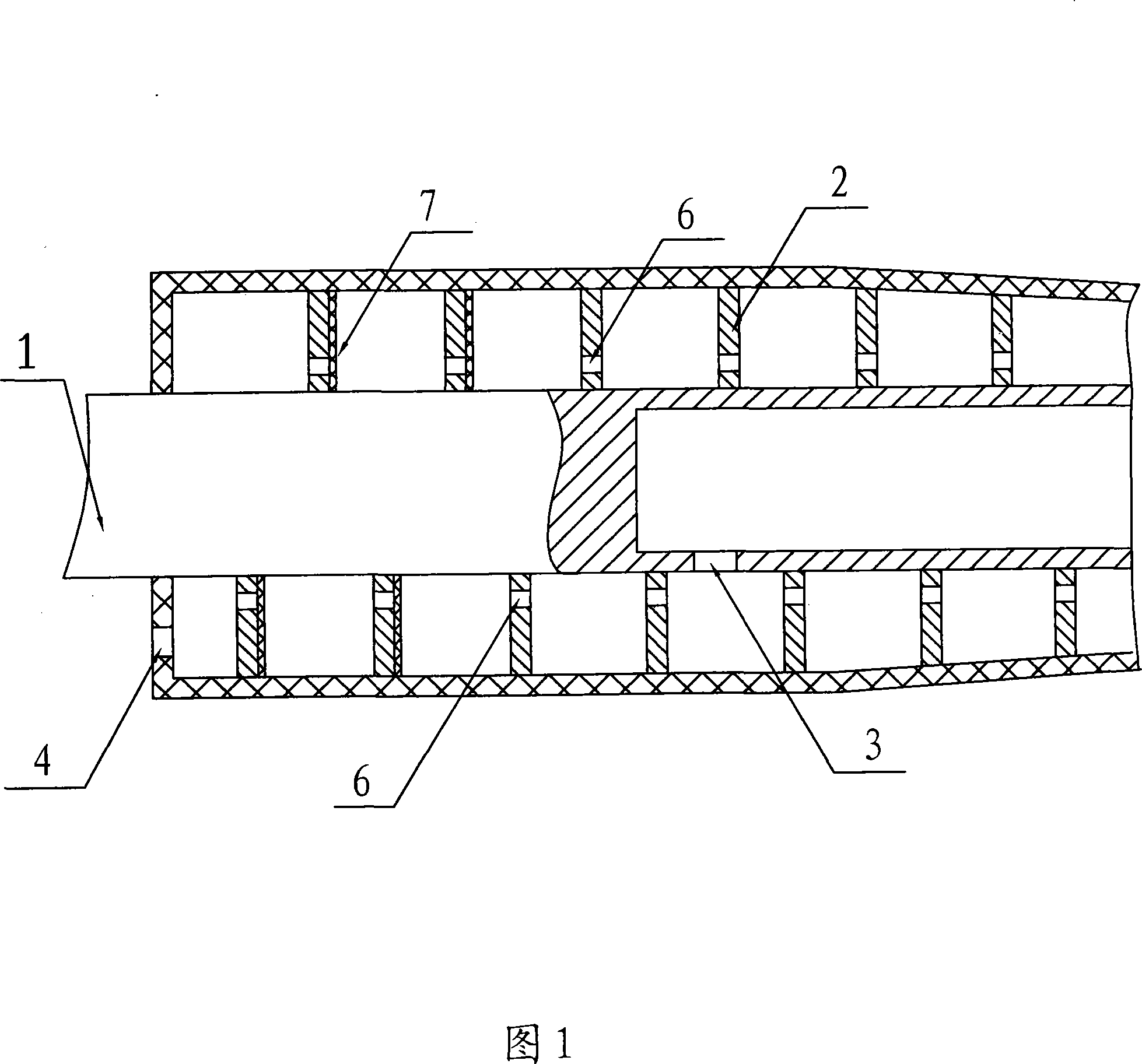

[0013] Embodiment 1: As shown in Figure 1, the high-efficiency screw pusher of the decanter centrifuge includes a main shaft 1 and a spiral pushing sheet 2, and the spiral pushing sheet 2 is distributed on the outer surface of the main shaft 1 with equal leads , in the settling area, the spiral pushing sheet 2 is distributed on the outer circle, and the main shaft 1 of this section is provided with a discharge port 3, and the leftmost end of the settling area is provided with a liquid phase outlet 4; in the drying area, the spiral pushing sheet 2 is conical. Shaped distribution, a solid phase outlet 5 is provided at the extreme end of the drying zone, and a liquid phase guide hole 6 is provided on the screw pushing sheet 2. The liquid-phase guide holes 6 are distributed on the inner side of the screw pushing plate 2, that is, on the side close to the main shaft 1, and the diameter of the liquid-phase guide holes 6 is 0.1-1.5 mm. A microporous gasket 7 is provided on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com