Underground gas-liquid hydrocyclone separation device

A cyclone separation device and gas-liquid separation technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of affecting the gas phase volume fraction, poor separation effect, difficult repair, etc., to improve utilization High efficiency, good separation effect, and the effect of reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

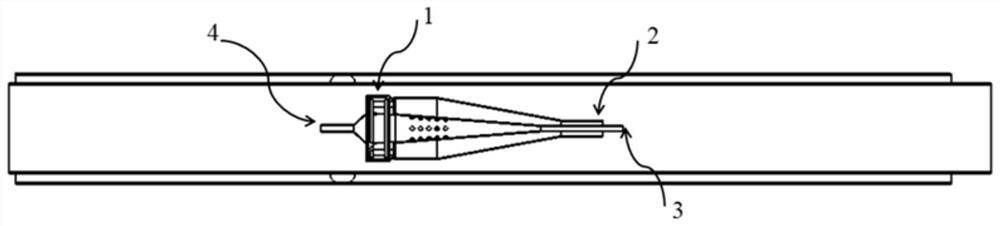

[0034] First of all, with reference to the accompanying drawings, an overall description will be made of a novel downhole gas-liquid cyclone separation device according to the present invention: the appearance of the new downhole gas-liquid cyclone separation device is a cylindrical casing structure such as figure 1 As shown, there is an incoming gas inlet 1, a primary liquid phase outlet 2, a multi-stage liquid phase outlet 3, and a gas phase outlet 4. The mixed phase enters the gas inlet 1 of the cyclone from the gas pipeline and enters the inside of the separation device. After multi-stage separation, the water phase is discharged from the device through the first-level liquid phase outlet 2 or the second-level liquid phase outlet 3, and the gas phase is separated from the gas phase outlet. 4 discharge.

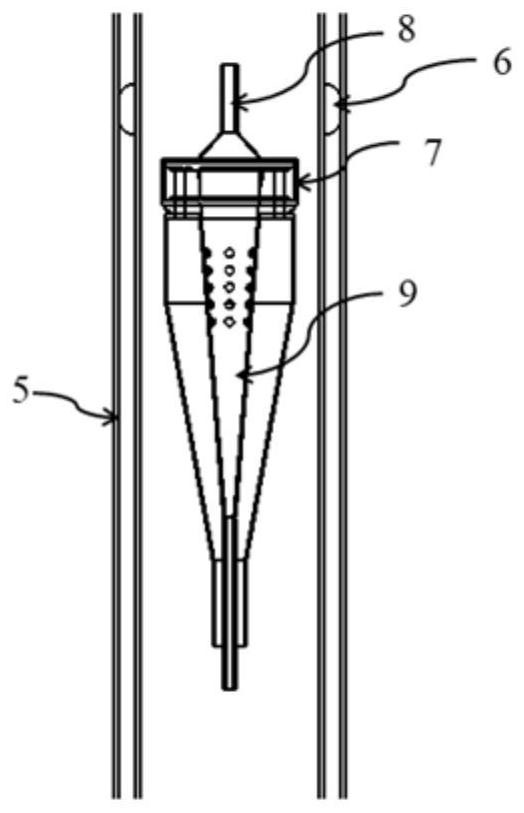

[0035] combine figure 2 , image 3 , Figure 4 , after sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com