Damp cavity sealed type jogged dissepiment strainer plate and sealing method thereof

A membrane filter plate, sealed technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of inability to form a self-sealing structure, and achieve low manufacturing costs, lower production costs, and lower liquid content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

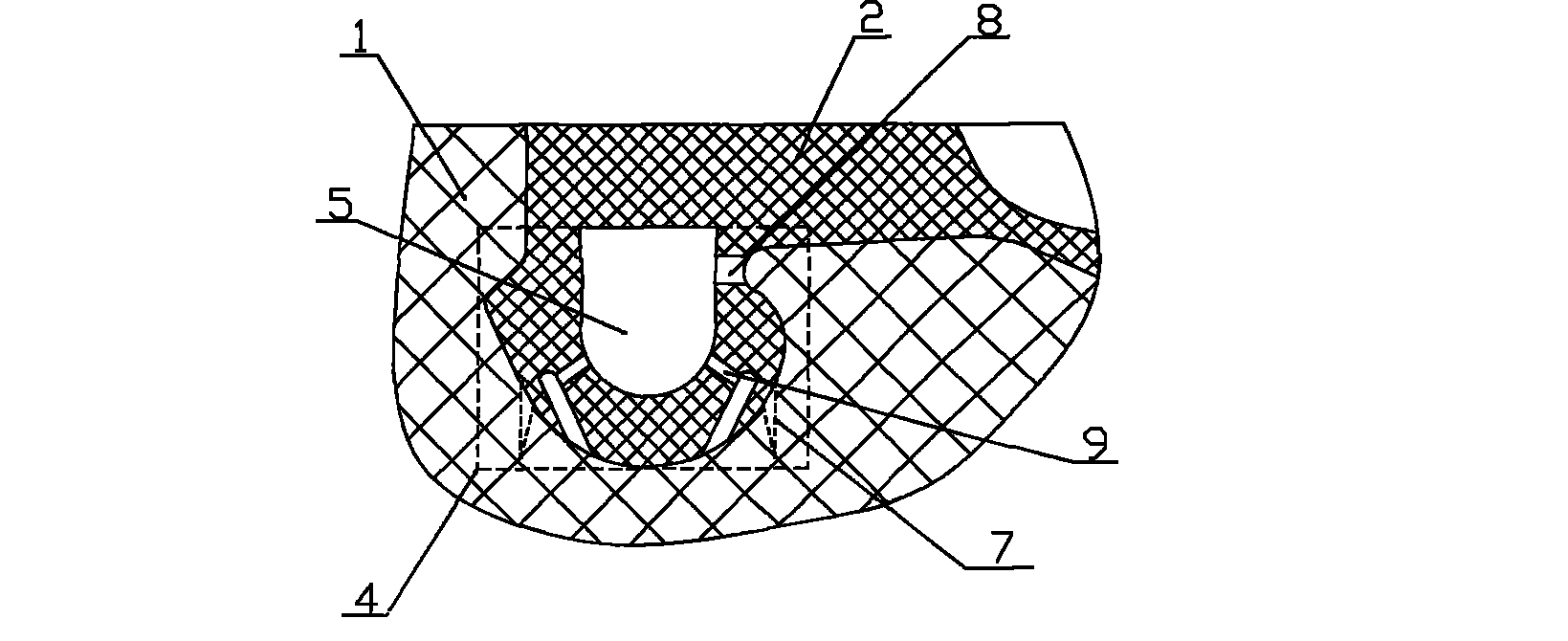

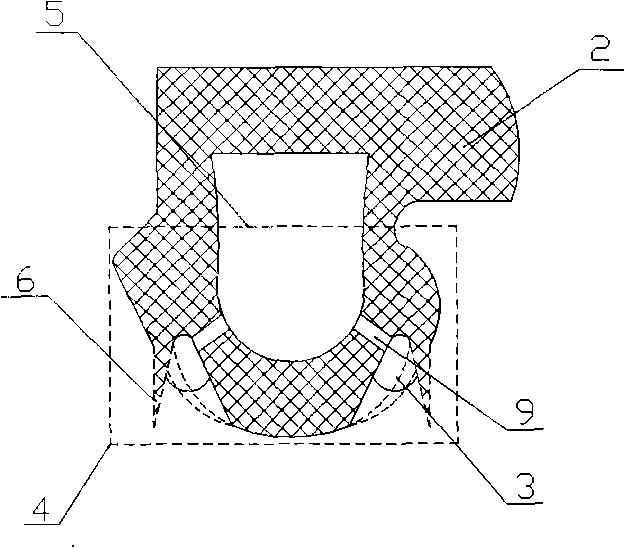

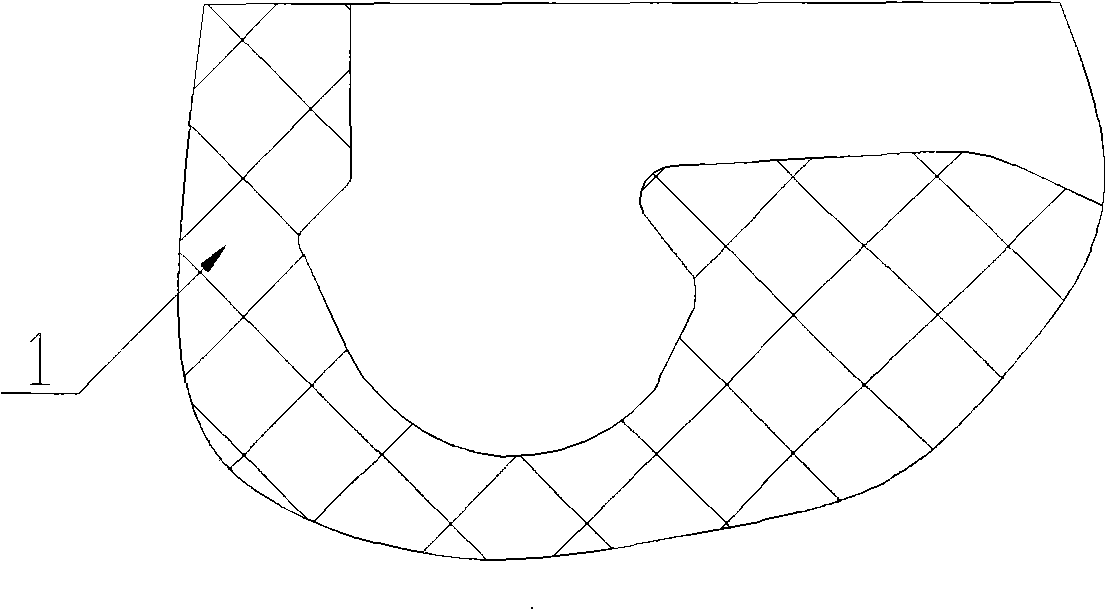

[0011] Embodiment 1: with reference to attached Figure 1~3 . The damping and sealing type embedded diaphragm filter plate includes a filter plate 1 and a diaphragm 2, and the production of the filter plate 1 and the diaphragm 2 is a prior art, and will not be described here. The loop inlaid portion in the diaphragm 2 has a boss 4, the bottom of the boss 4 has one or more circles of lips 6, and the diaphragm portion adjacent to one or more circles of lips 6 has a groove 3 and is connected to one or more circles of lips 6 respectively. Ring lip 6 constitutes an open damping cavity 7, see attached figure 2 . The boss 4 is a hollow boss sleeve 5, and the hollow boss sleeve 5 surrounds the inlay part of the diaphragm. See attached figure 2 . Hollow boss cover 5 adopts prior art to make (as compression molding, molding welding molding etc.), do not describe here. There are a plurality of fluid inlet holes 8 around the root of the hollow boss sleeve 5, and a plurality of flu...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the sealing method of the damping and sealing type fitted diaphragm filter plate, the ring line hollow boss sleeve of the diaphragm inlay part is embedded in the ring line sealing groove in the filter plate and is connected with the ring line of the filter plate The groove is sealed and matched. After one or more circles of lips at the bottom of the annular hollow boss sleeve in the diaphragm inlay part are embedded in the filter plate groove, one or more circles of lips form a self-sealing with the filter plate groove surface Damping cavity or line-sealed damping cavity, when the diaphragm is tympanic, the fluid enters the cavity of the ring-line hollow boss sleeve through multiple fluid inlet holes located at the root of the hollow boss sleeve, and as the fluid pressure increases, the fluid flows from Multiple fluid outlet holes around the bottom of the self-sealing damping chamber or line-sealing damping chamber enter the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com