A packing self-sealing component and method thereof for ultra-low temperature conditions

A self-sealing, ultra-low temperature technology, used in shaft seals, engine components, valve details, etc., can solve problems such as rising maintenance costs, and achieve the effect of extending service life and achieving self-sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

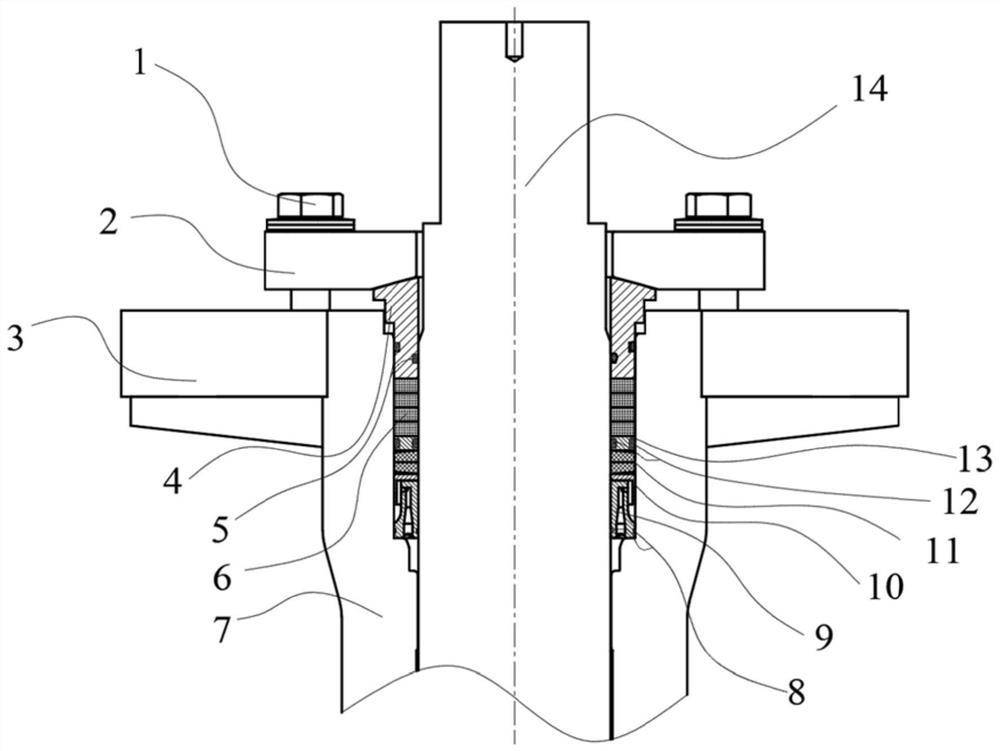

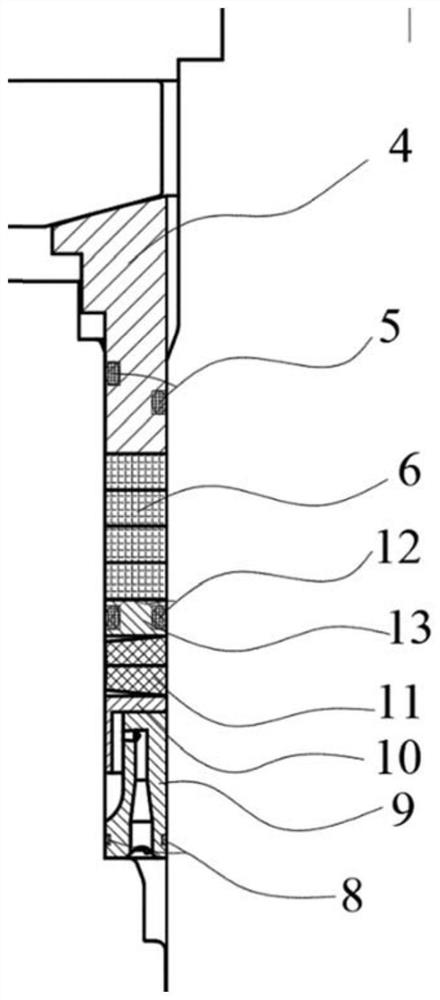

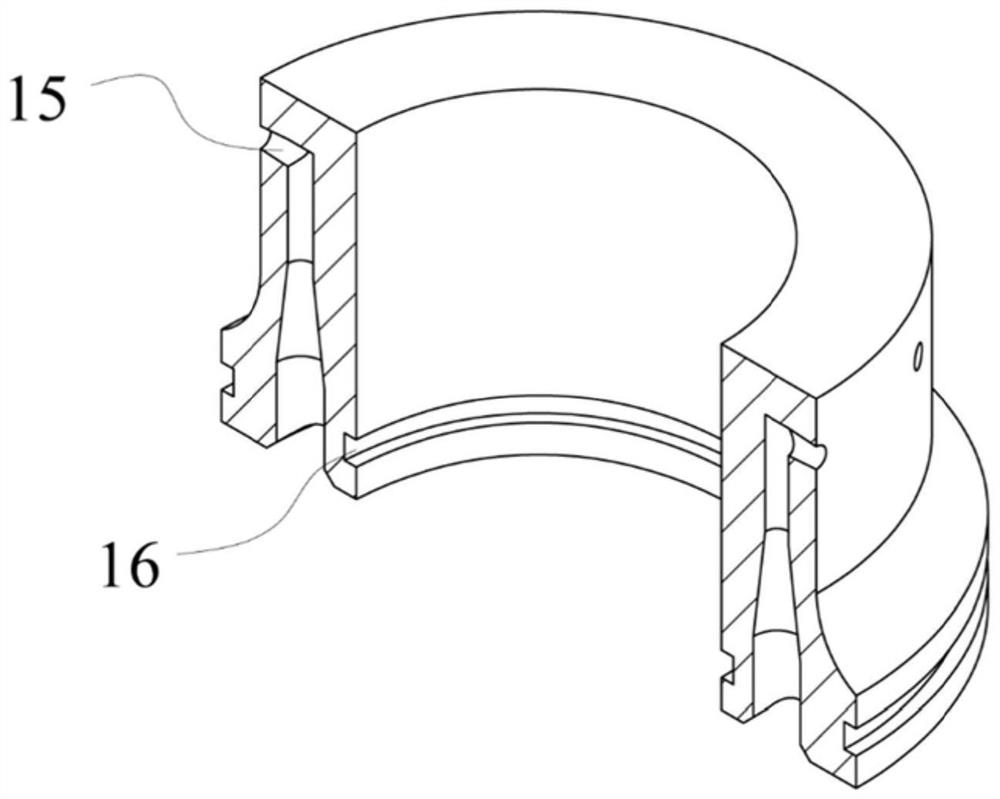

[0029] Such as figure 1 Shown is a packing self-sealing assembly for ultra-low temperature conditions of the present invention, which includes a valve cover 7, a first pressure plate 2 and a self-sealing module. Wherein, the bonnet 7 is sleeved on the valve stem 14 of the target valve body, the bonnet 7 can be fixedly connected with the target valve stem 14 through the flange group 3, and a first groove is opened on the upper inner wall of the bonnet 7, the first The groove is ring-shaped and arranged around the outer wall of the valve stem 14, and the first groove is used for placing the self-sealing module. The self-sealing module is also annular, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com