Patents

Literature

76 results about "Diaphragm Part" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Any component of the fibromuscular tissue that separates the thoracic from the abdominal cavity.

Thermal Flowmeter

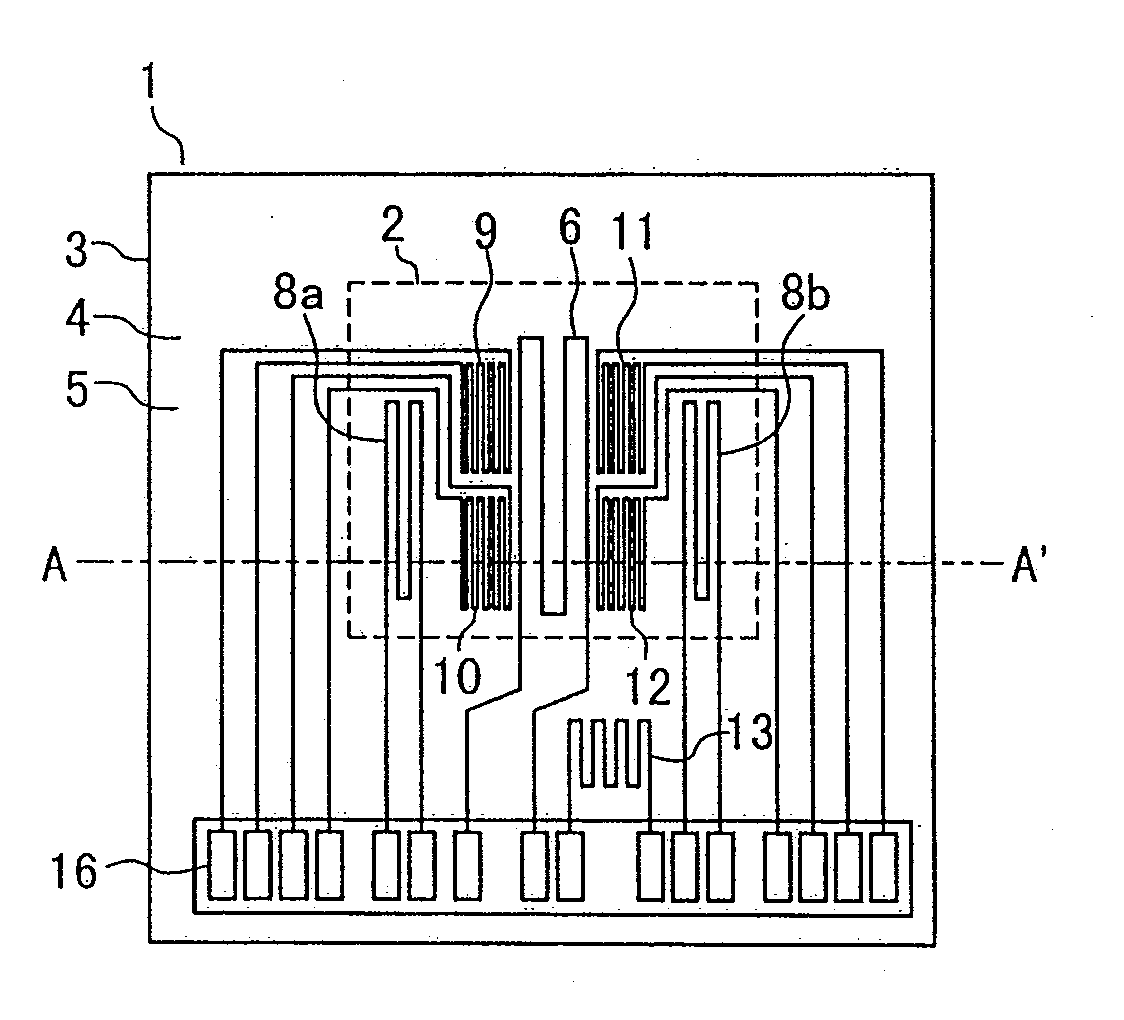

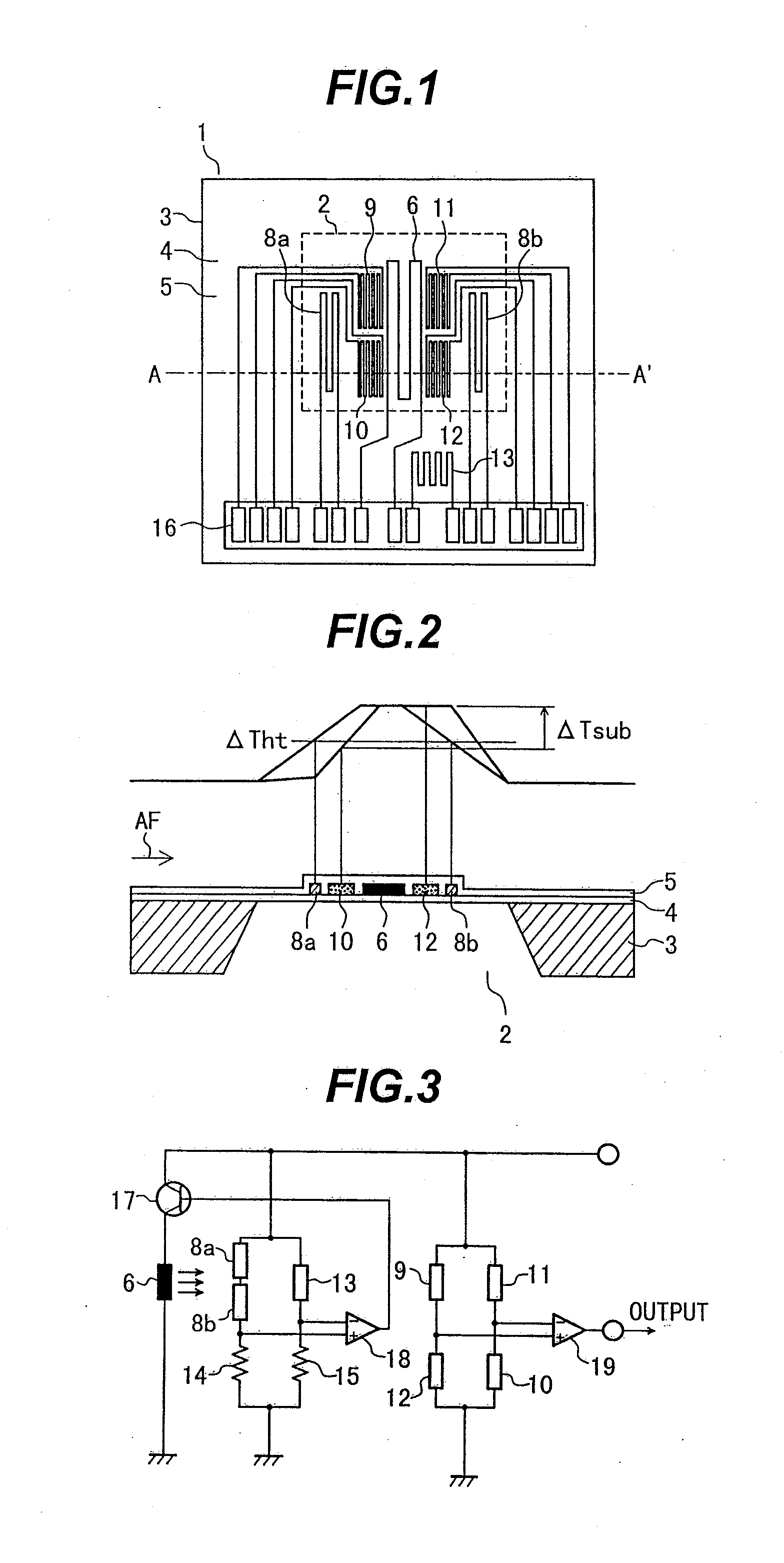

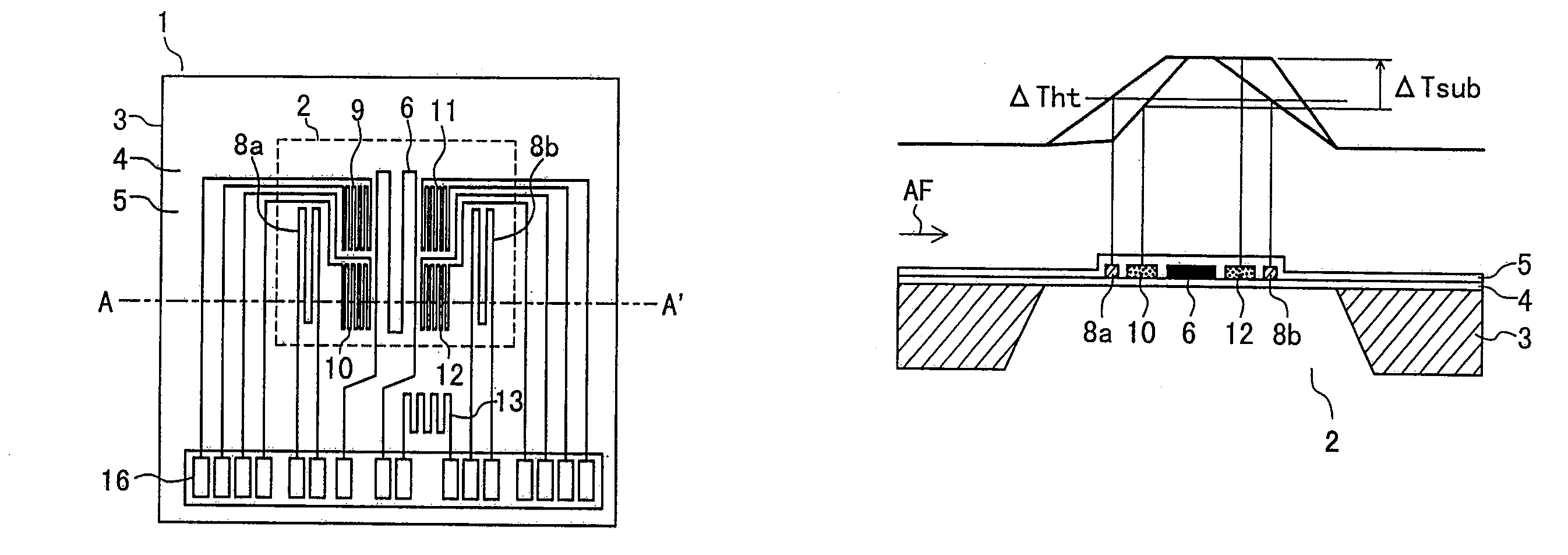

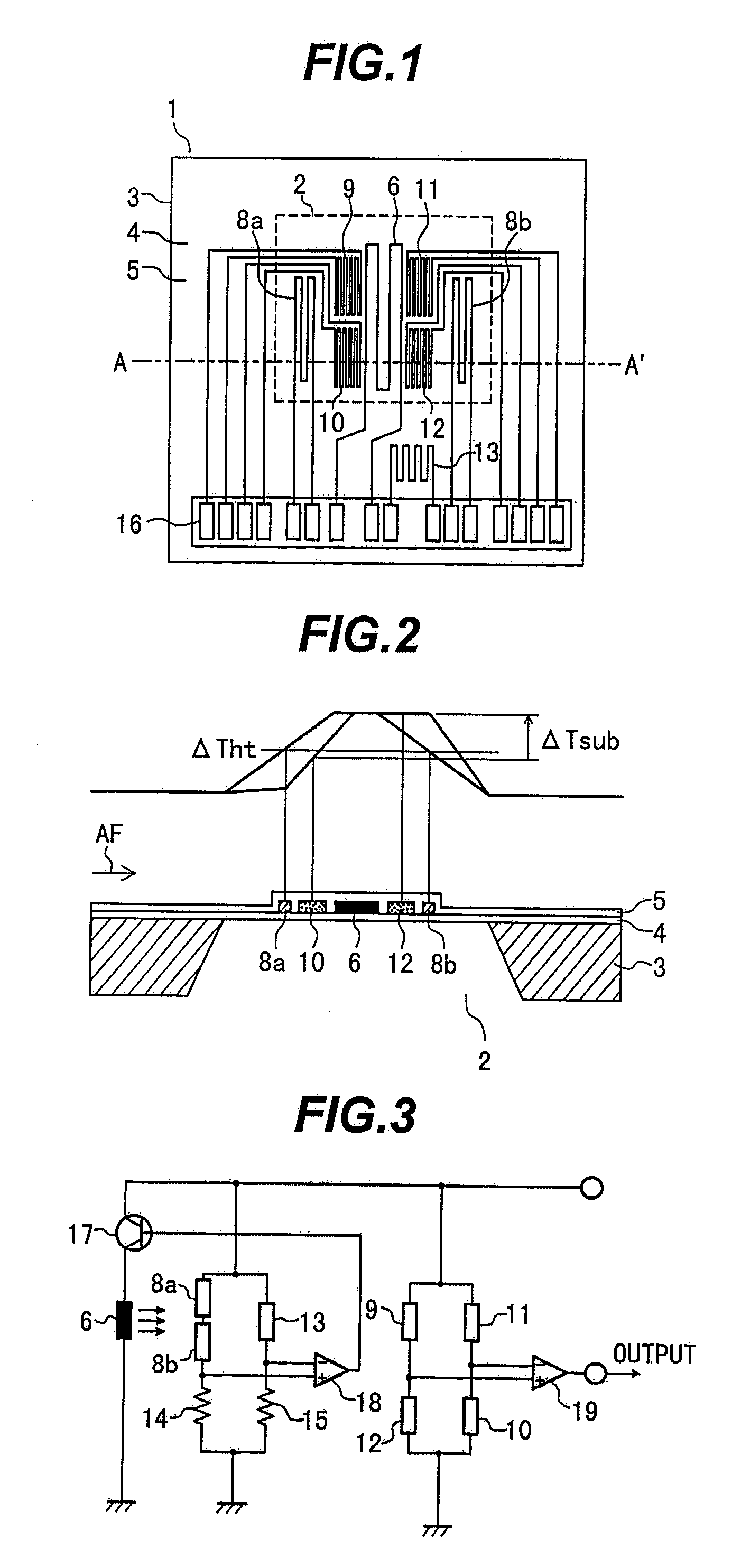

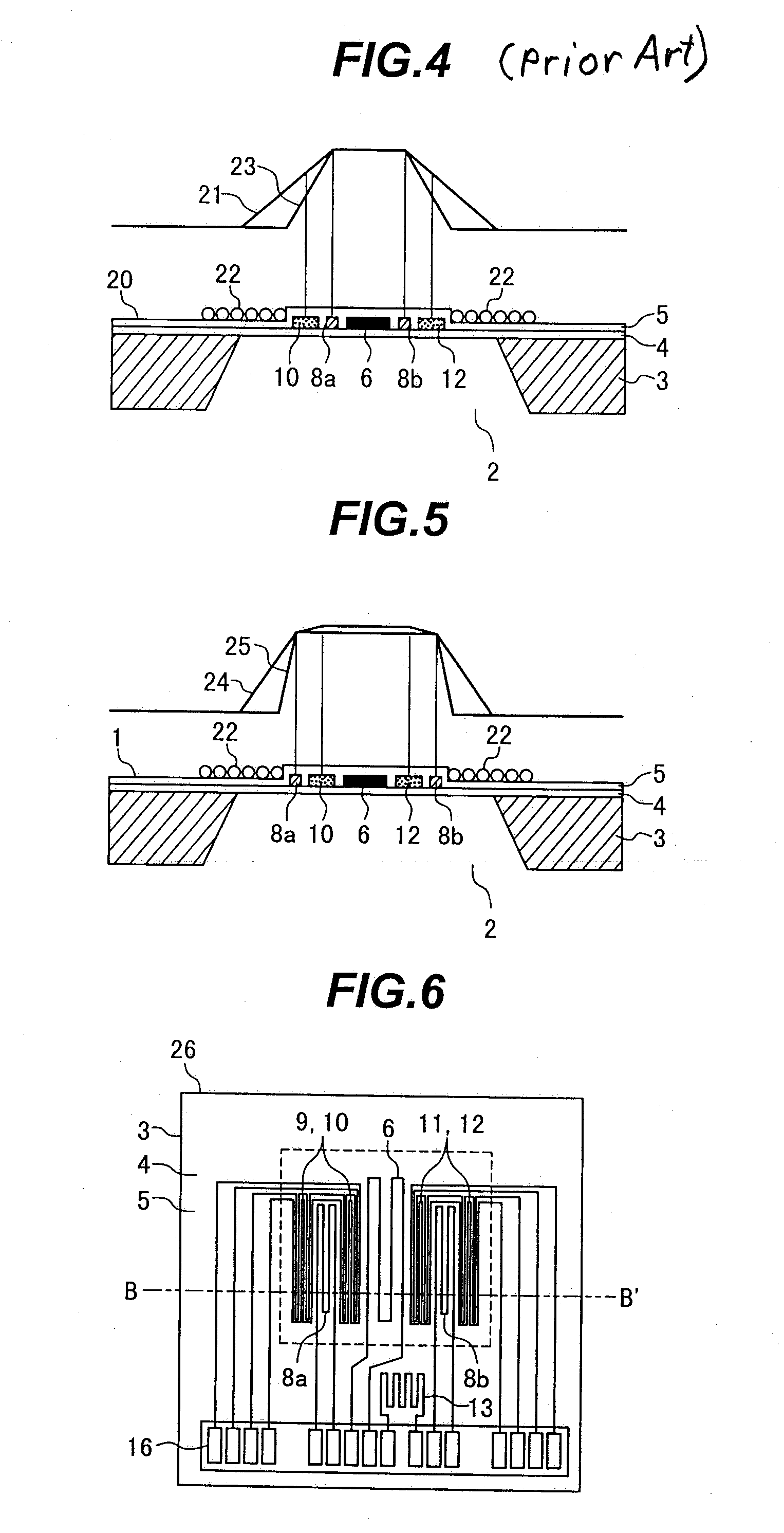

ActiveUS20080282791A1High measurement accuracyPrevent degradationVolume/mass flow by thermal effectsVolume flow proportion measurementTemperature differenceEngineering

A simply configured thermal flowmeter can provide high measurement accuracy over a long period of time by suppressing the characteristics degradation due to adhering contaminants. On the surface of a diaphragm part, a heater resistor is formed. Temperature difference sensors through are disposed on the two sides of the heater resistor (upstream and downstream sides in the flow direction of an air stream). The temperature difference sensors are disposed upstream of the heater resistor while the temperature difference sensors are disposed downstream of the heater resistor. Outside the temperature difference sensors, heating temperature sensors are formed. Control is performed so that the temperature of the heating temperature sensors is set higher than the air stream temperature by a certain degree. Therefore, even if contaminants adhere to the sensor device, the temperature of the heating temperature sensors is held constant. Since the temperature difference sensors to detect the flow rate is located between the heating temperature sensors, the temperature change due to the contamination is small. This suppresses the characteristics degradation, making it possible to provide high measurement accuracy over a long period of time.

Owner:HITACHI ASTEMO LTD

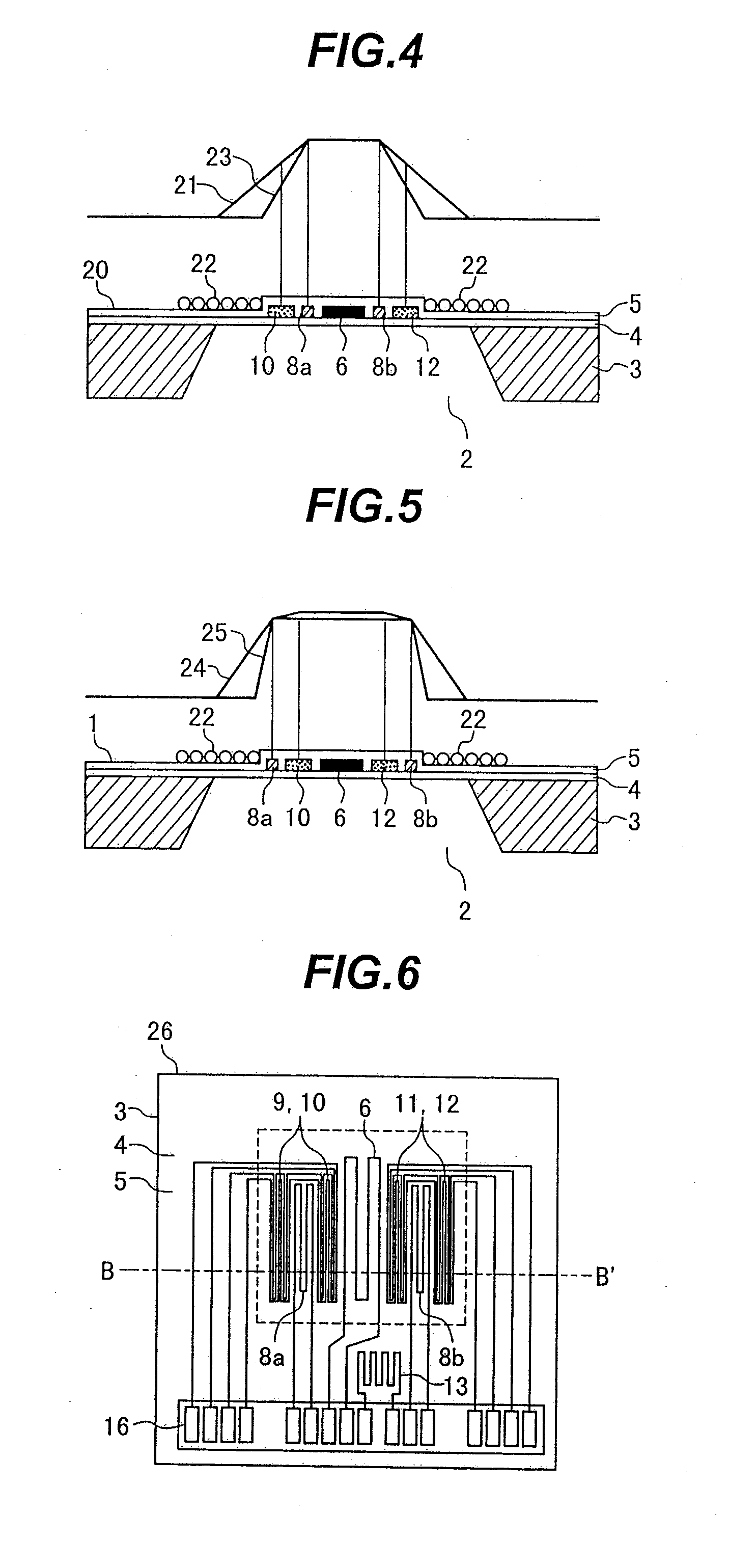

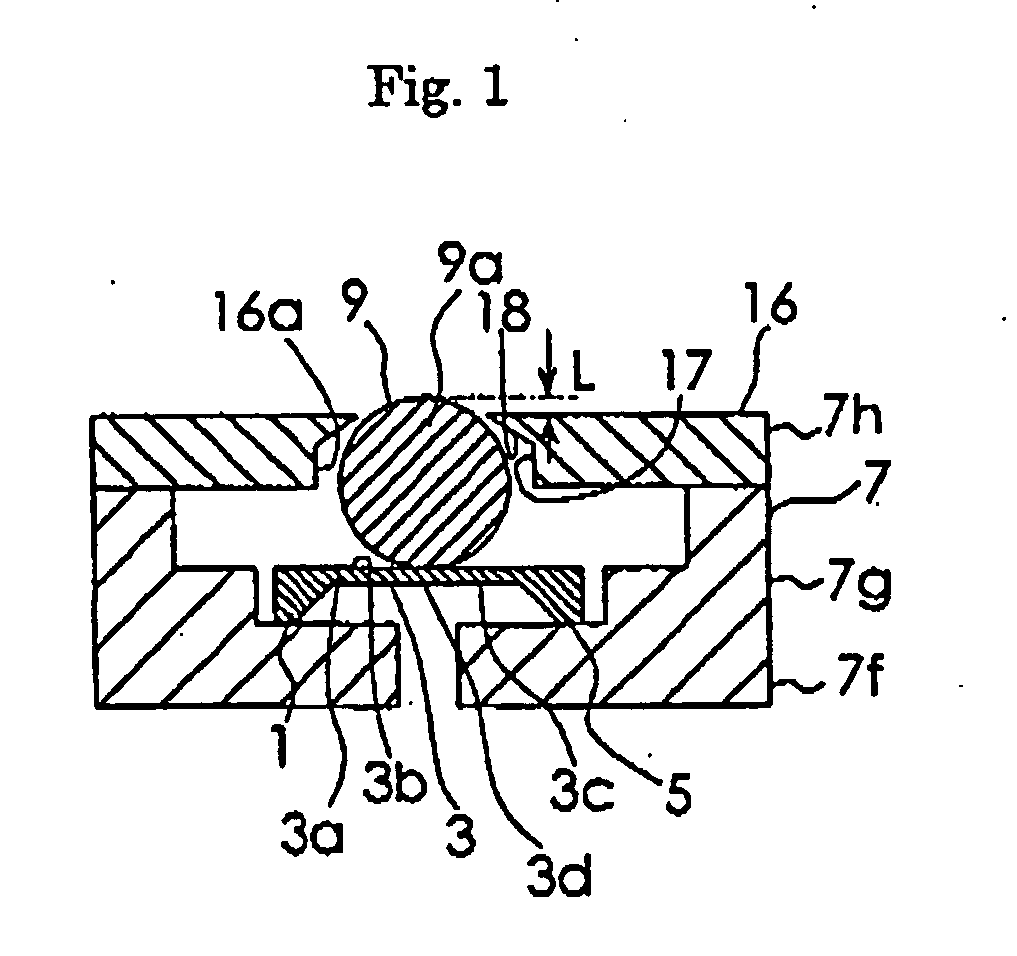

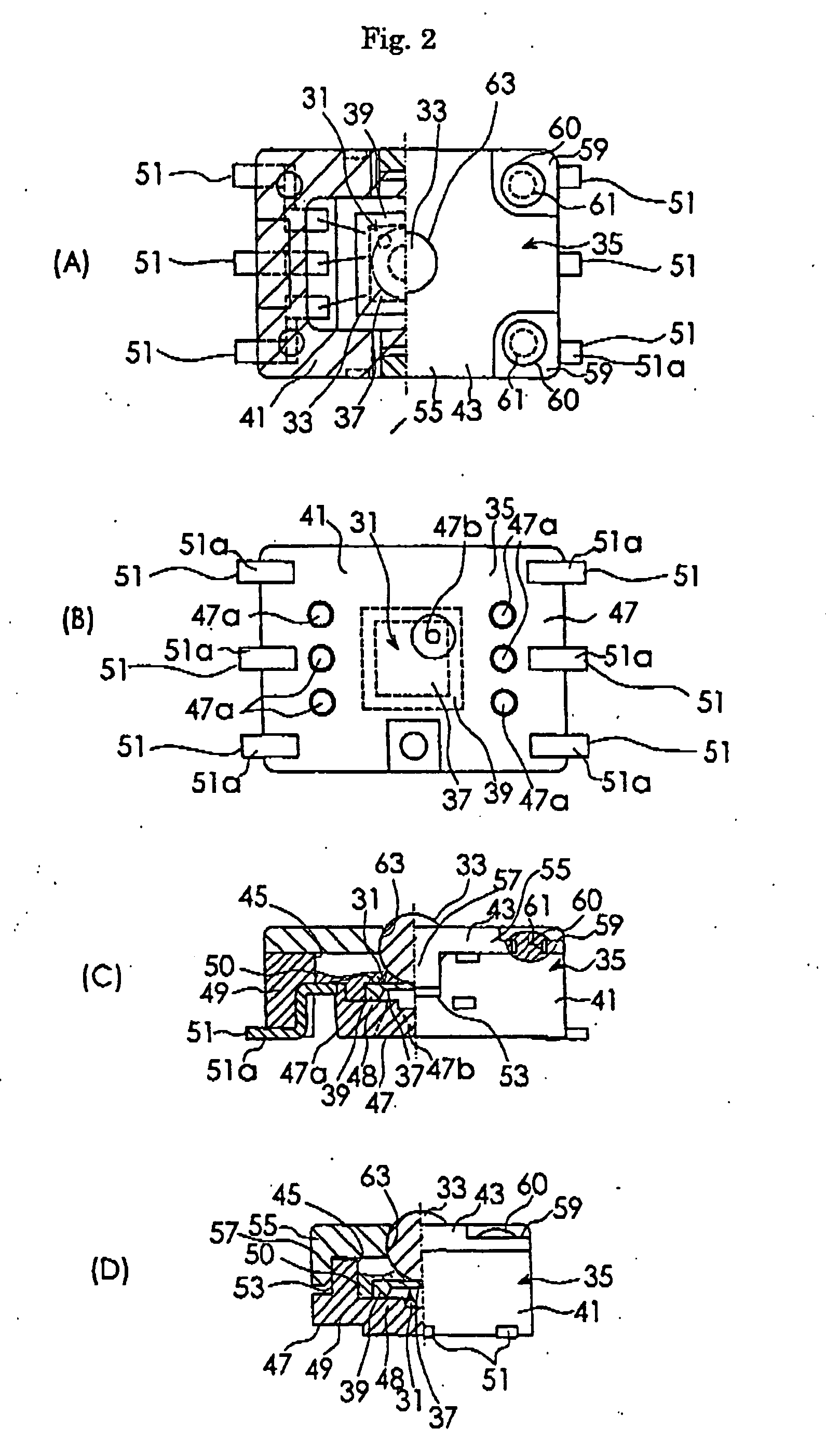

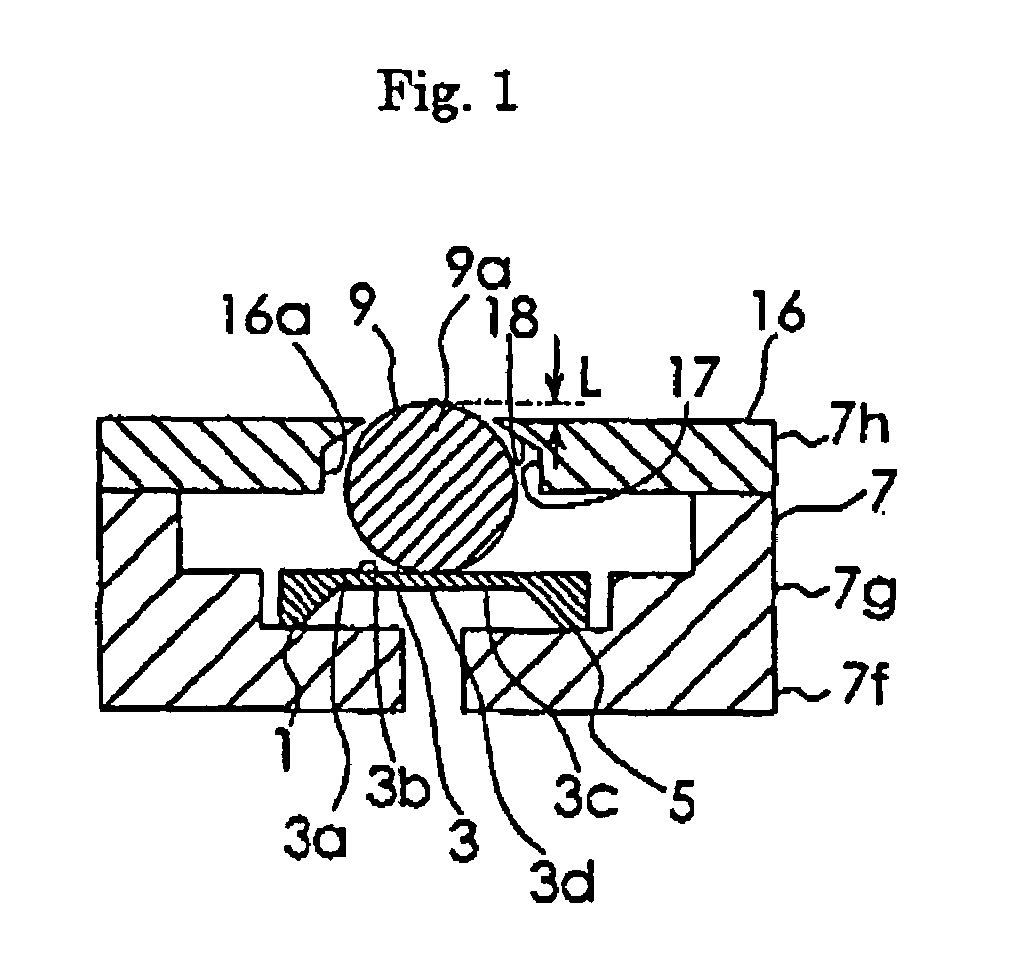

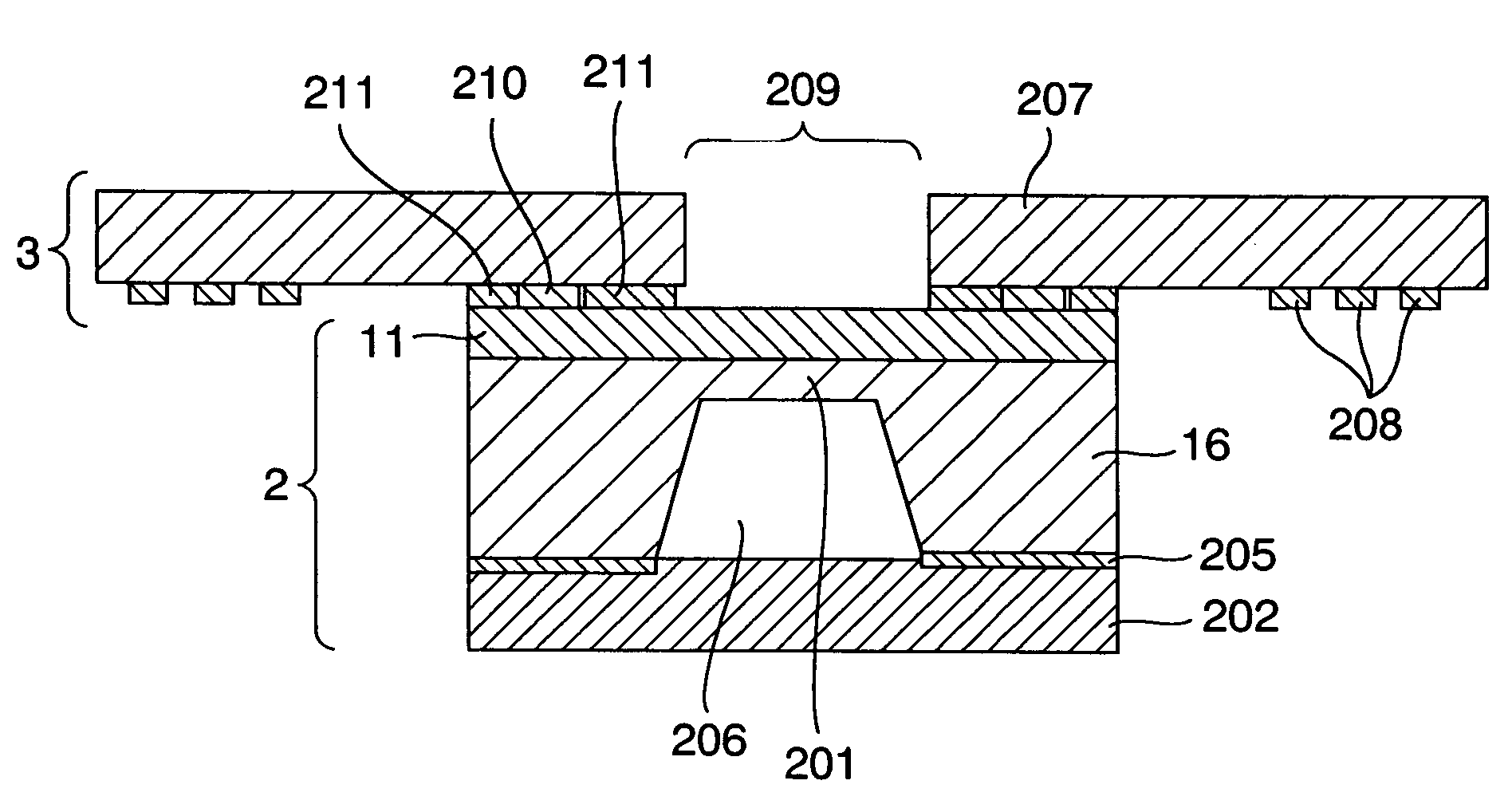

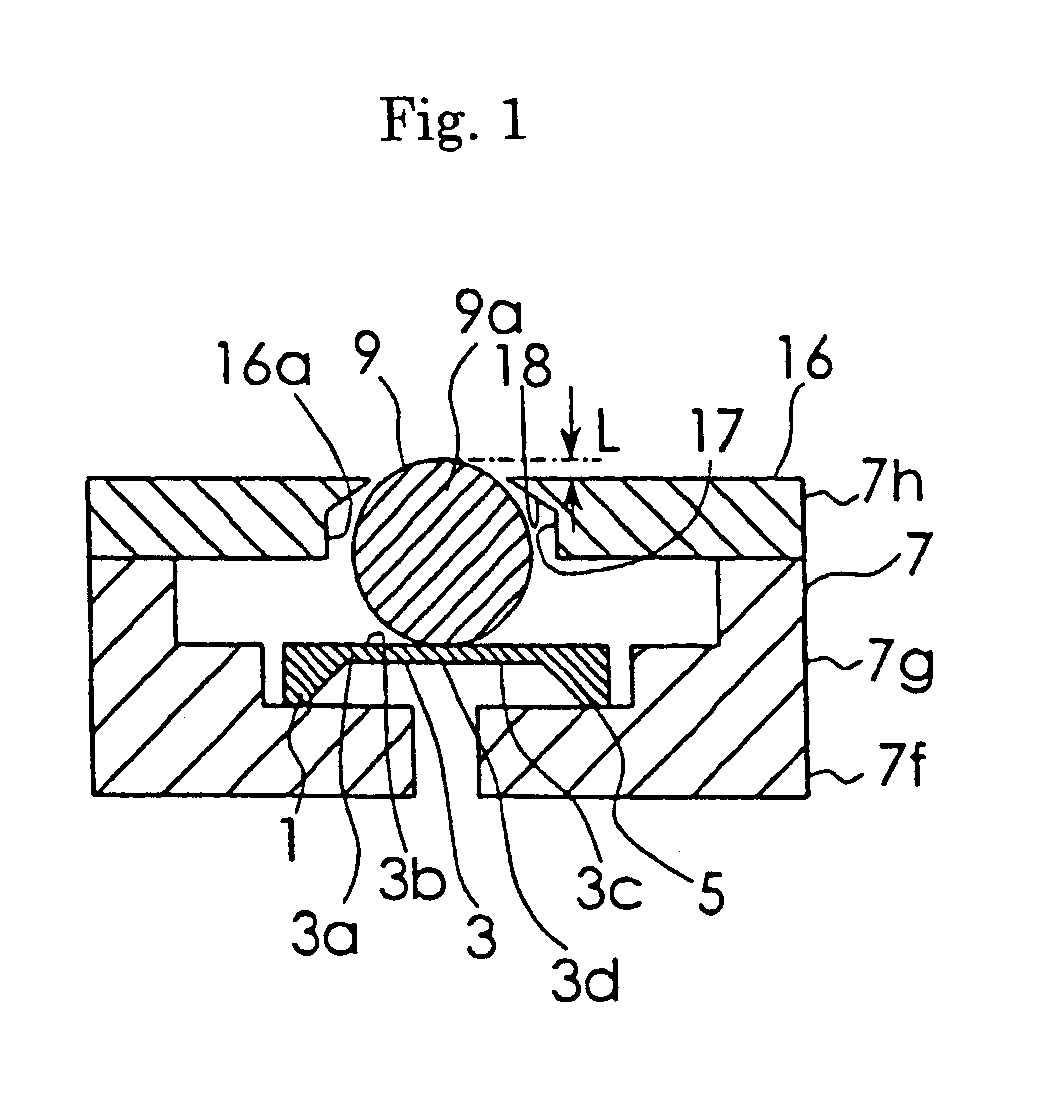

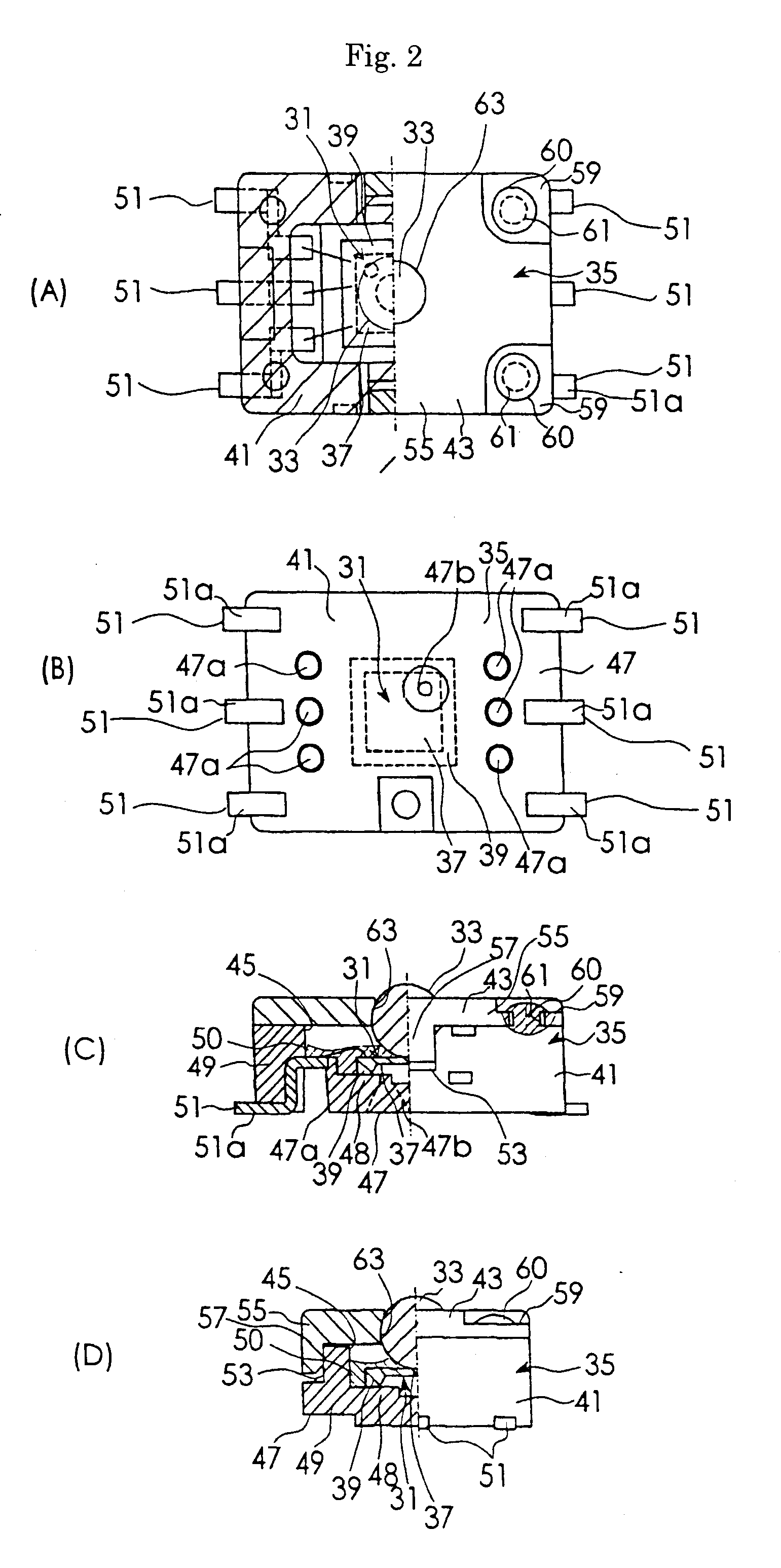

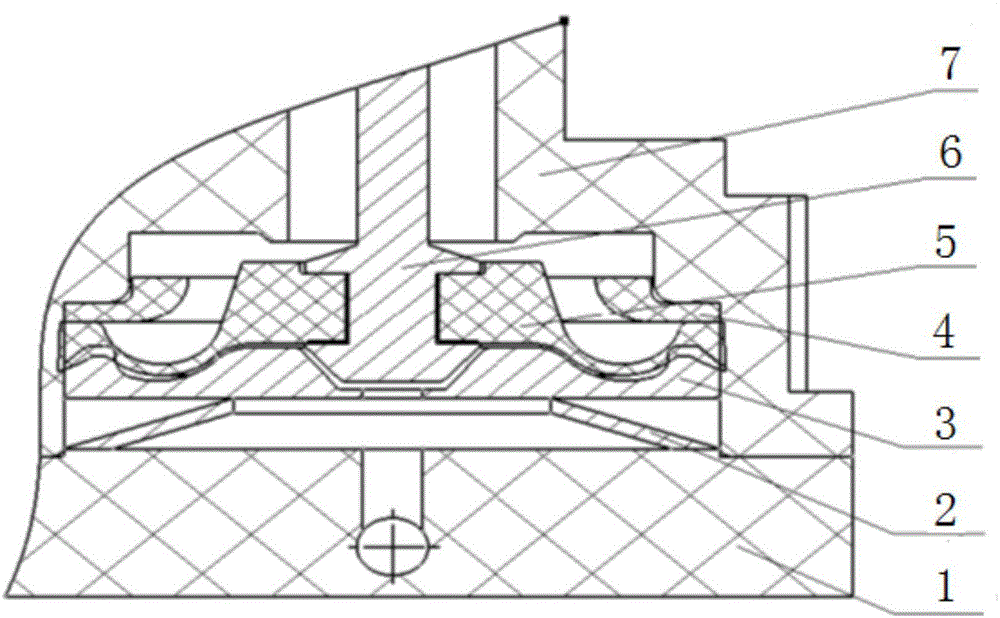

Semiconductor force sensor

ActiveUS20050217386A1Precise positioningWell formedTesting/calibration apparatusUsing electrical meansEngineeringForce sensor

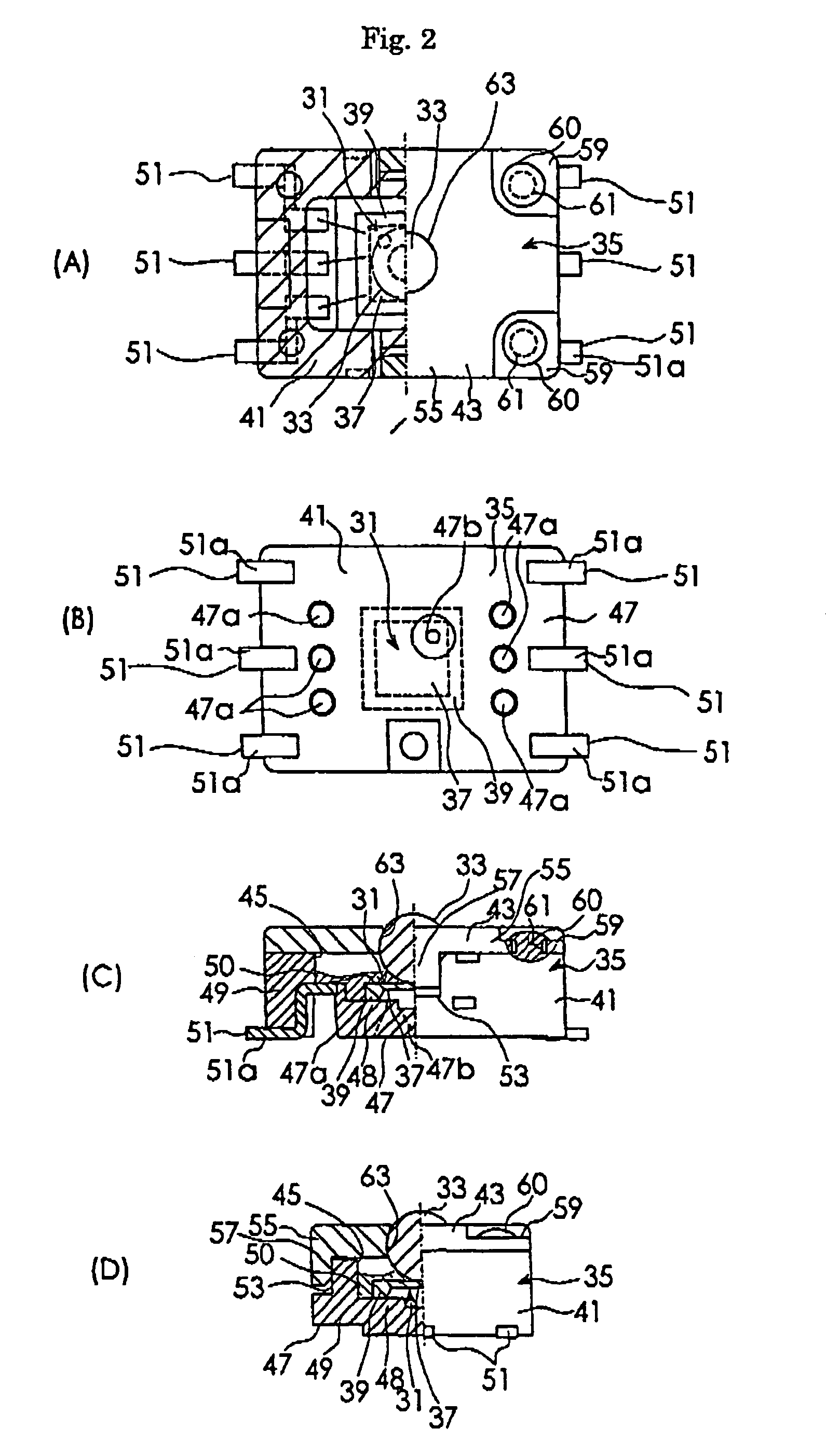

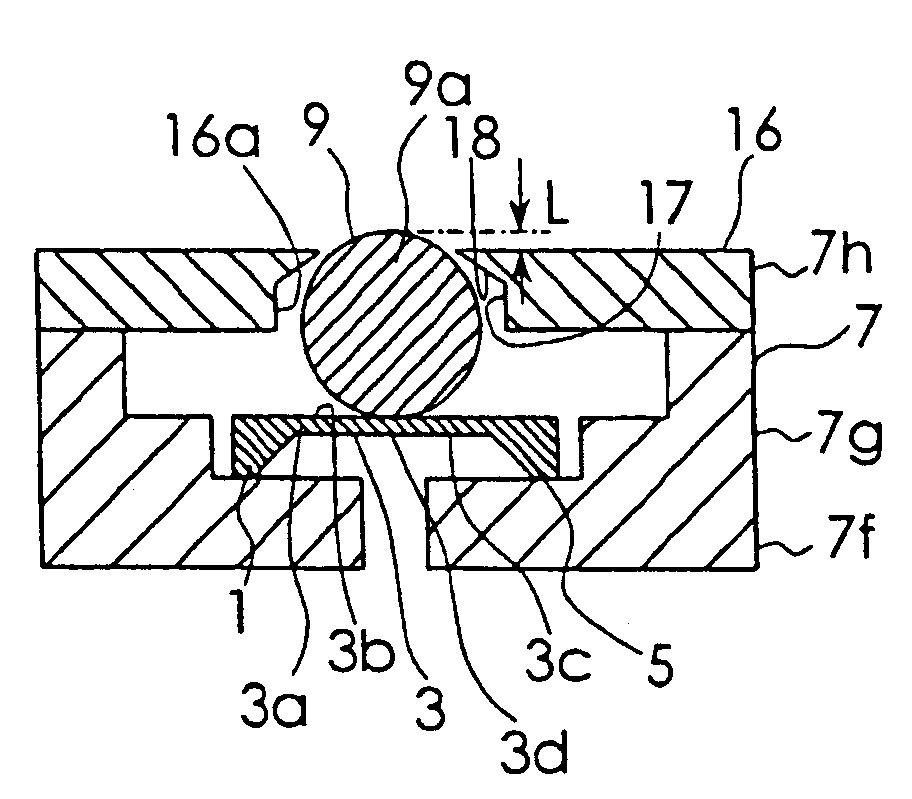

A semiconductor force sensor capable of preventing a diaphragm part (37) from being broken and accurately measuring a force applied thereto in a direction orthogonal to the diaphragm part (37), wherein a force transmitting means for applying a measured force to the diaphragm part (37) of a semiconductor force sensor element (31) is formed of a sphere (33) having a rigidity, and a through hole (63) passing through an opposed wall part (55) toward the diaphragm (37) is formed in the opposed wall parts (55) at a position opposed to the center part of the diaphragm part (37) so that a part of the sphere (33) can face the outside of the opposed wall part (55) and stores a part of the remaining part of the sphere (33) to allow the sphere (33) to be moved only in a direction orthogonal to the diaphragm part (37) and rotated on the center part of the diaphragm part (37).

Owner:HOKURIKU ELECTRIC INDS

Semiconductor force sensor

ActiveUS7234359B2Application of undue force can be preventedAccurate measurementTesting/calibration apparatusUsing electrical meansEngineeringForce sensor

A semiconductor force sensor capable of preventing a diaphragm part (37) from being broken and accurately measuring a force applied thereto in a direction orthogonal to the diaphragm part (37), wherein a force transmitting means for applying a measured force to the diaphragm part (37) of a semiconductor force sensor element (31) is formed of a sphere (33) having a rigidity, and a through hole (63) passing through an opposed wall part (55) toward the diaphragm (37) is formed in the opposed wall parts (55) at a position opposed to the center part of the diaphragm part (37) so that a part of the sphere (33) can face the outside of the opposed wall part (55) and stores a part of the remaining part of the sphere (33) to allow the sphere (33) to be moved only in a direction orthogonal to the diaphragm part (37) and rotated on the center part of the diaphragm part (37).

Owner:HOKURIKU ELECTRIC INDS

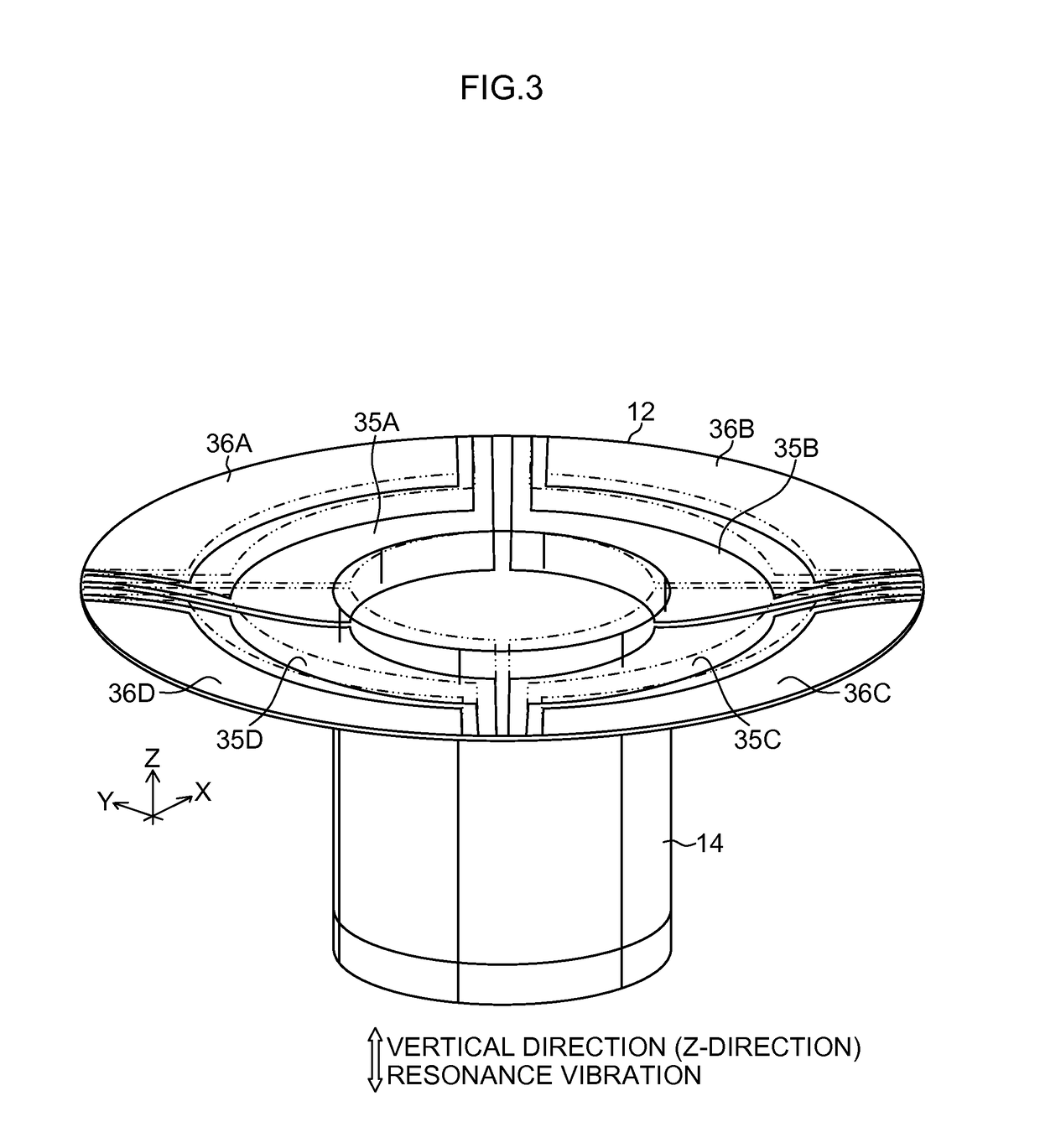

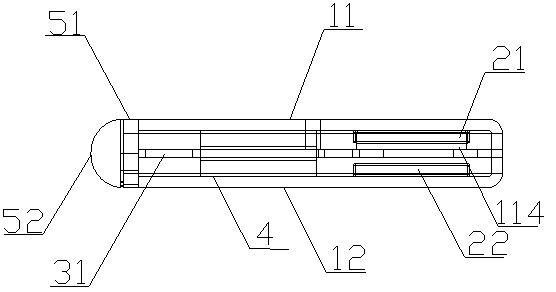

Ultra-thin telephone receiver

ActiveCN103067806AReduce thicknessReduced anterior chamber spaceEarpiece/earphone attachmentsAlloyEngineering

The invention discloses an ultra-thin telephone receiver. A driving mechanism of the ultra-thin telephone receiver comprises an armature section and a coil section, wherein the armature section is E-shaped and comprises a base portion, two wing portions and a middle portion, the base portion, the two wing portions and the middle portion are formed in an integrated mode, the middle portion comprises a root part located on the base portion, the root part extends forward to form a vibrating diaphragm part, and the coil section is arranged on the root part in a sleeved mode at intervals. A shell of the ultra-thin telephone receiver comprises an upper shell and a lower shell, wherein the upper shell is arranged at the top of the driving mechanism in a covered mode, and comprises a cover plate and cover edges which are formed by extending downward from the periphery of the cover plate, a first magnet is fixedly connected to the inner wall, covered at the top of the vibrating diaphragm part, of a section of the cover plate, the upper shell is made of magnetically soft alloy, the lower shell is arranged at the bottom of the driving mechanism in a covered mode relative to the upper shell, a second magnet is fixedly connected to the inner wall of the lower shell relative to the first magnet, the lower shell is made of magnetically soft alloy, and a sounding hole is formed in the upper shell or the lower shell. According to the ultra-thin telephone receiver, the thickness of an existing telephone receiver is reduced to the largest extent, and the ultra-thin telephone receiver is more suitable for the structure of a mobile phone with a narrow frame or a mobile phone which is nearly frameless.

Owner:SUZHOU YICHUAN TECH CO LTD

Thermal flowmeter

ActiveUS8069718B2High measurement accuracyPrevent degradationVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringTemperature difference

A simply configured thermal flowmeter can provide high measurement accuracy over a long period of time by suppressing the characteristics degradation due to adhering contaminants. On the surface of a diaphragm part, a heater resistor is formed. Temperature difference sensors through are disposed on the two sides of the heater resistor (upstream and downstream sides in the flow direction of an air stream). The temperature difference sensors are disposed upstream of the heater resistor while the temperature difference sensors are disposed downstream of the heater resistor. Outside the temperature difference sensors, heating temperature sensors are formed. Control is performed so that the temperature of the heating temperature sensors is set higher than the air stream temperature by a certain degree. Therefore, even if contaminants adhere to the sensor device, the temperature of the heating temperature sensors is held constant. Since the temperature difference sensors to detect the flow rate is located between the heating temperature sensors, the temperature change due to the contamination is small. This suppresses the characteristics degradation, making it possible to provide high measurement accuracy over a long period of time.

Owner:HITACHI ASTEMO LTD

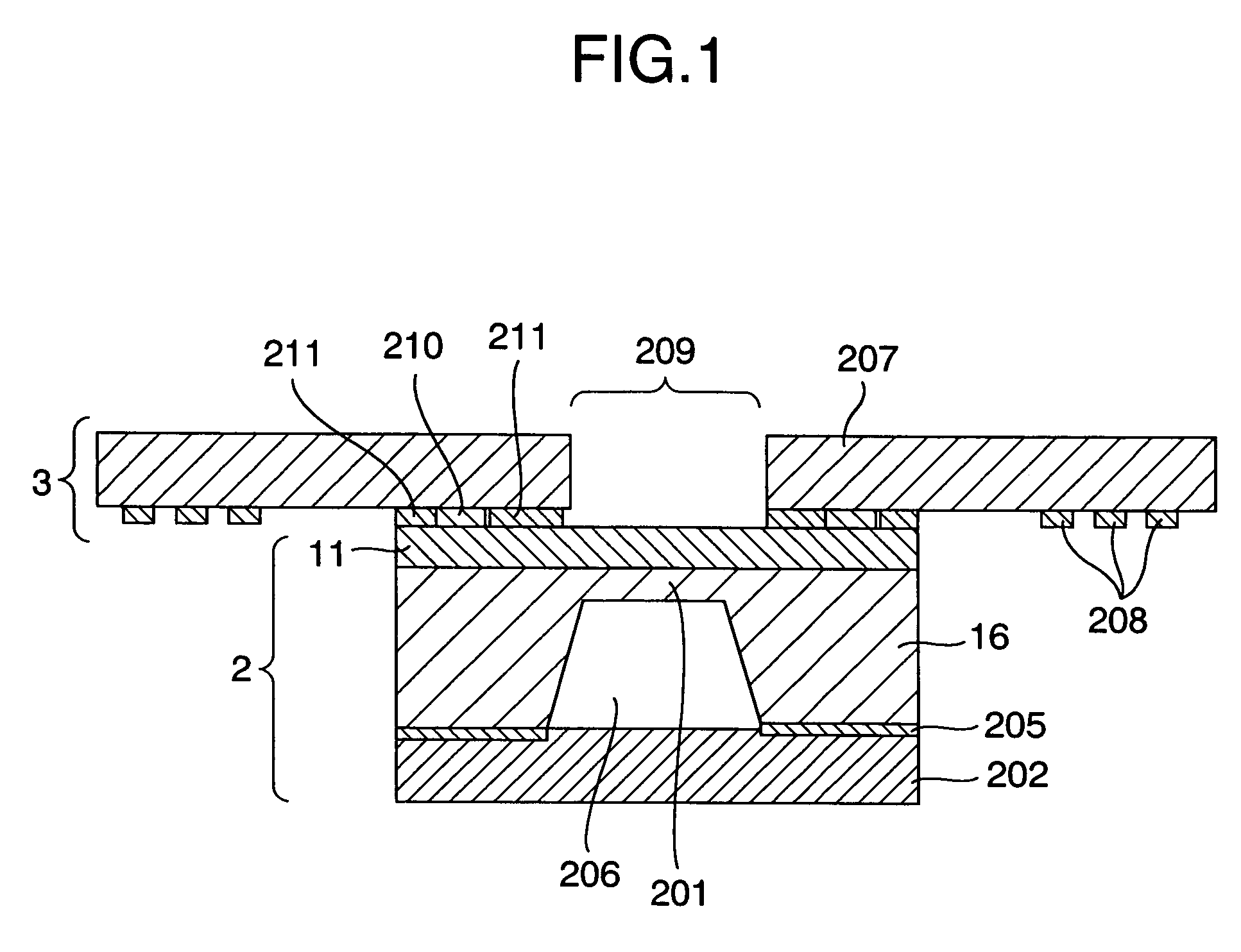

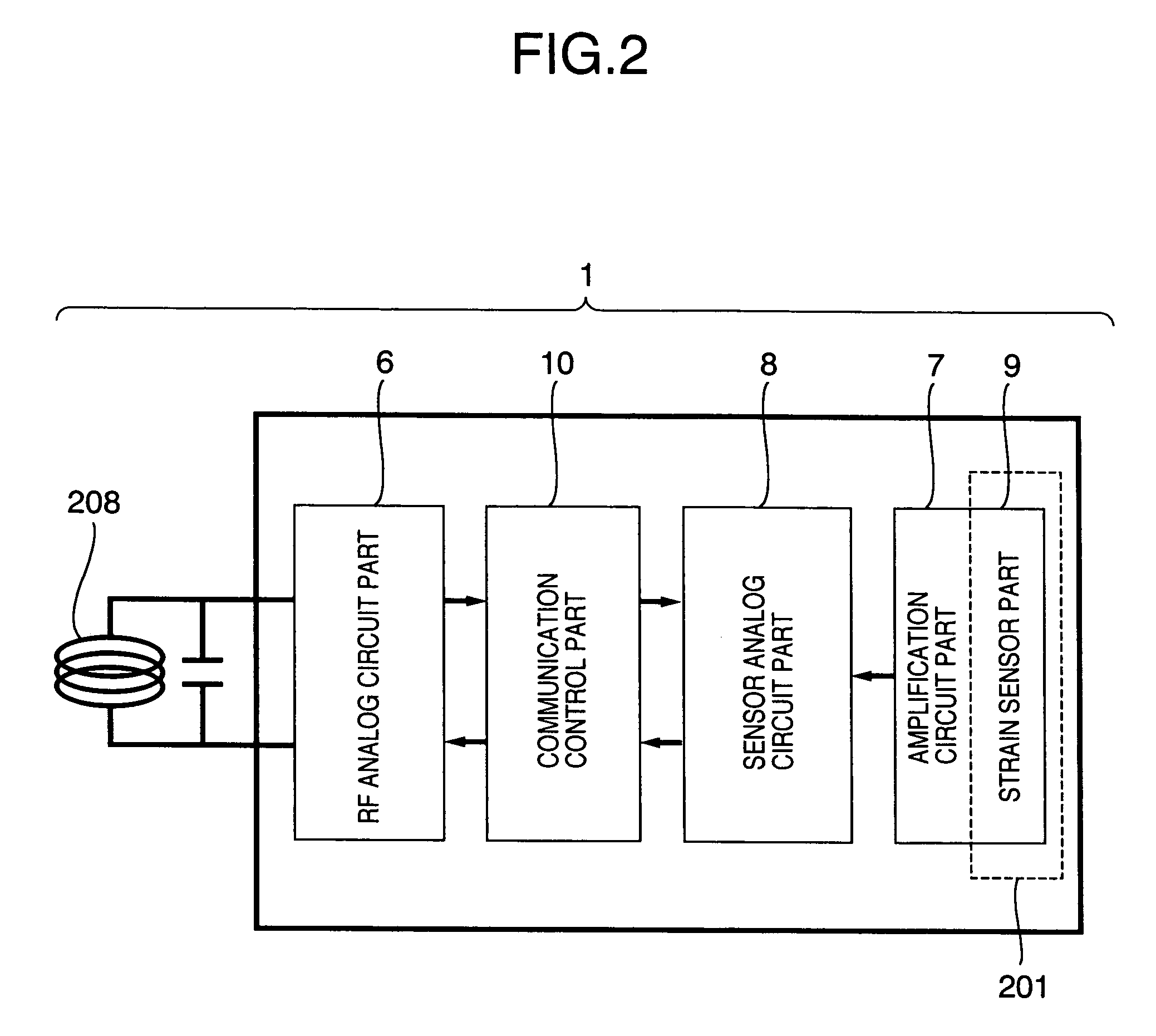

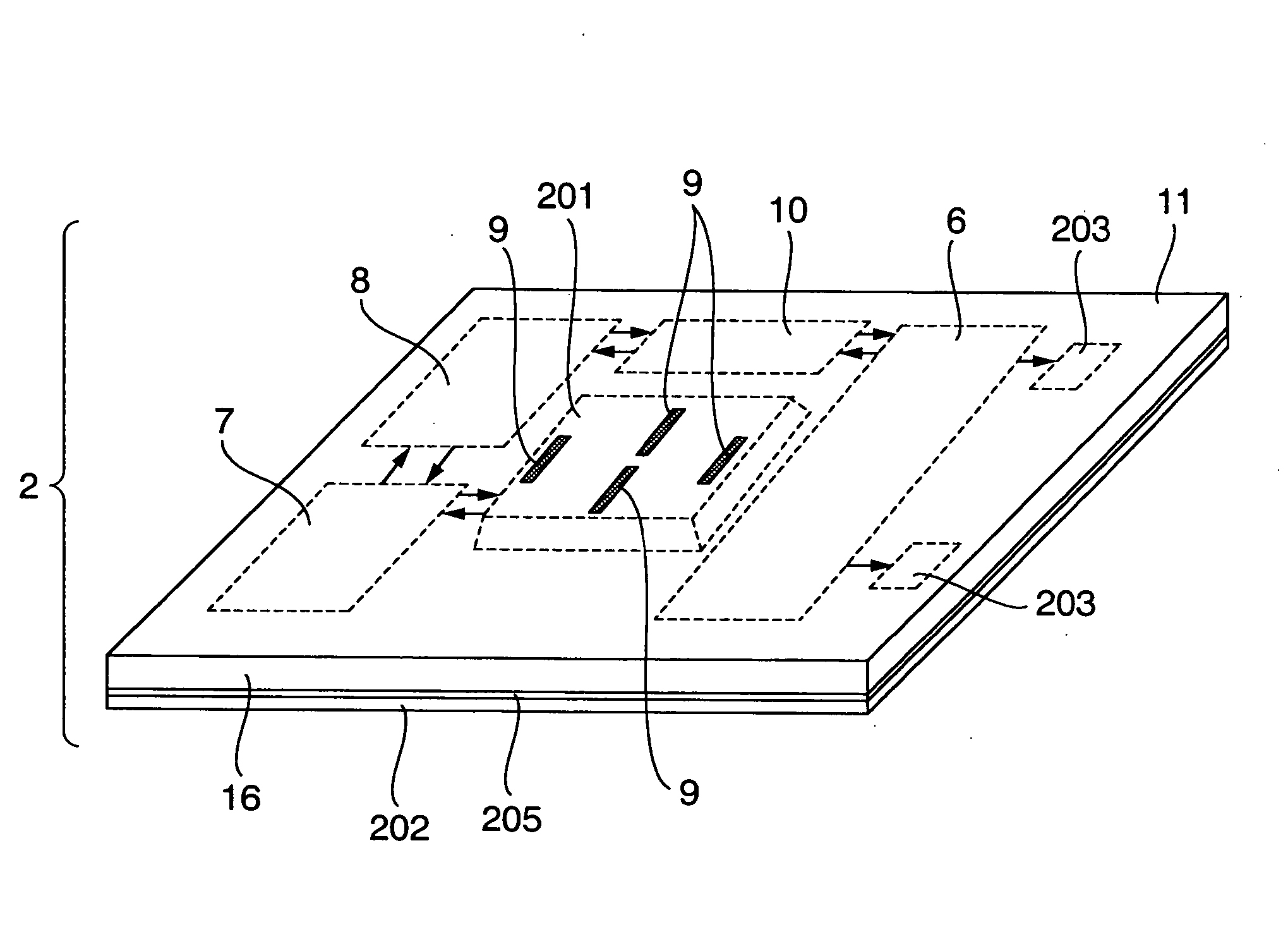

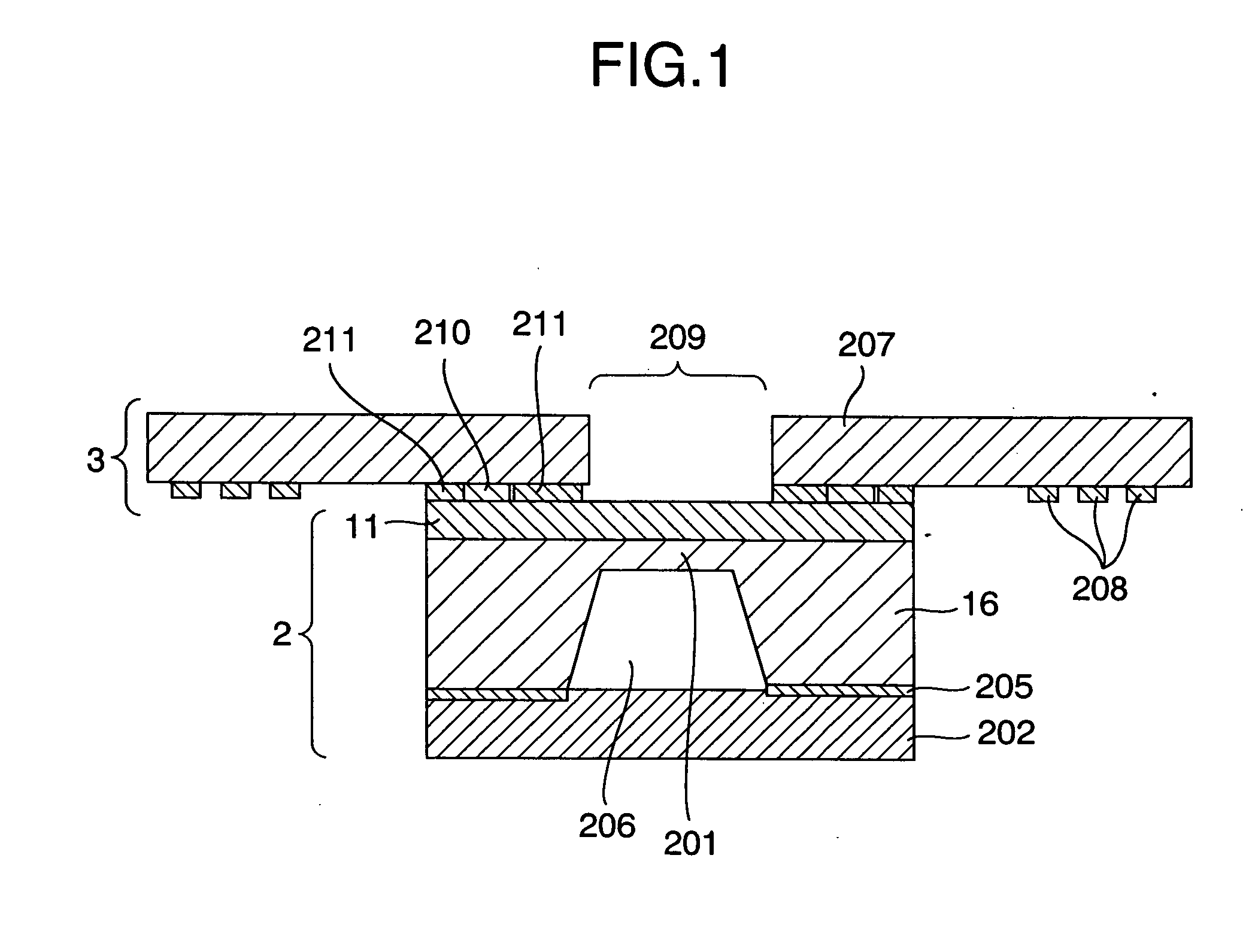

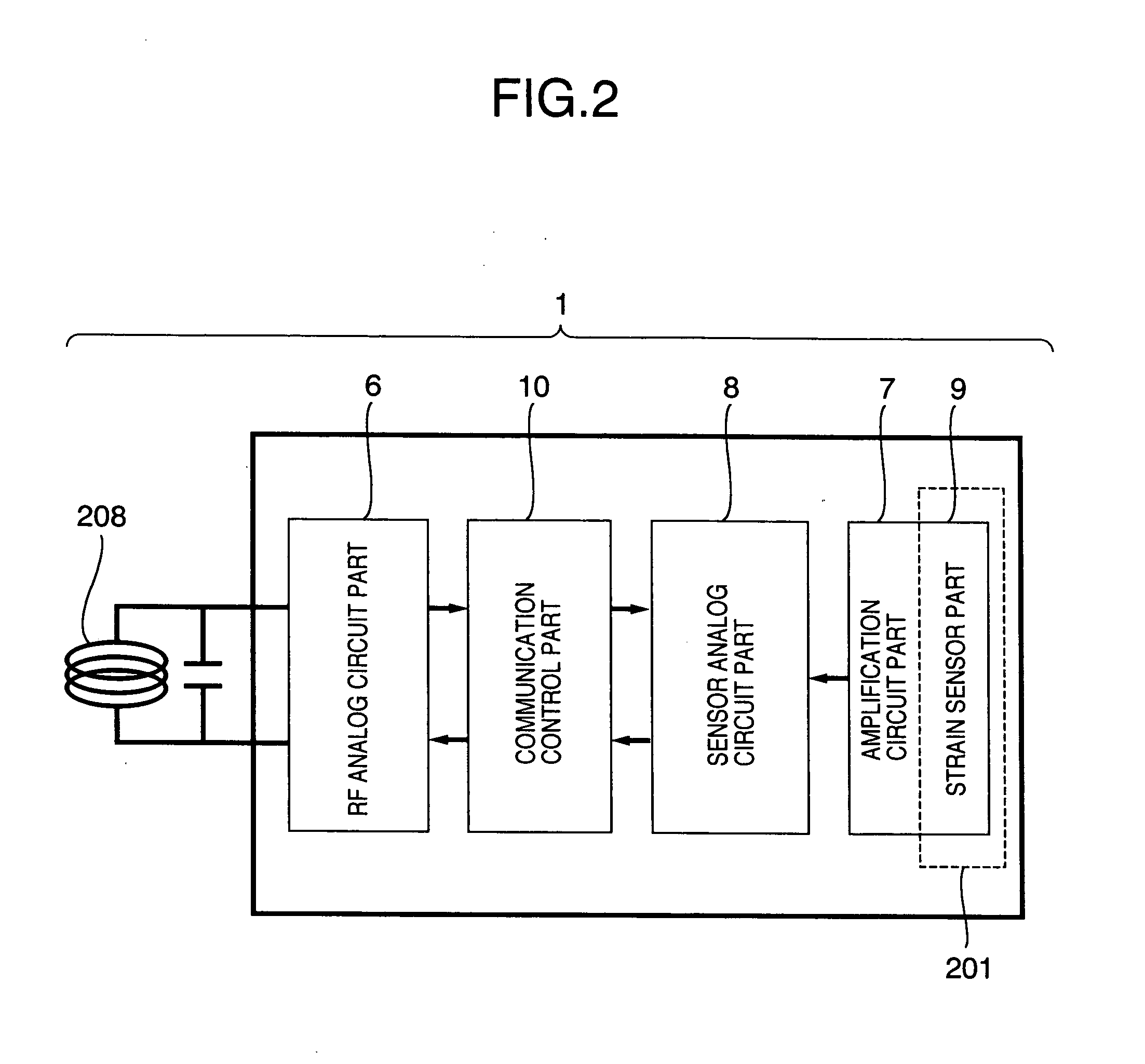

Pressure sensor system with semiconductor chip and antenna member

ActiveUS7252010B2Improve accuracyFluid pressure measurement by electric/magnetic elementsSemiconductor chipEngineering

In order to realize a compact wireless pressure sensor system which transmits an accurate pressure value, the present invention provides a pressure sensor system constructed at least by a silicon chip on which a circuit operated by electromagnetic wave energy is mounted, and a film which supports an antenna, in which film a through-hole is provided in the vicinity of a diaphragm part.

Owner:HITACHI LTD

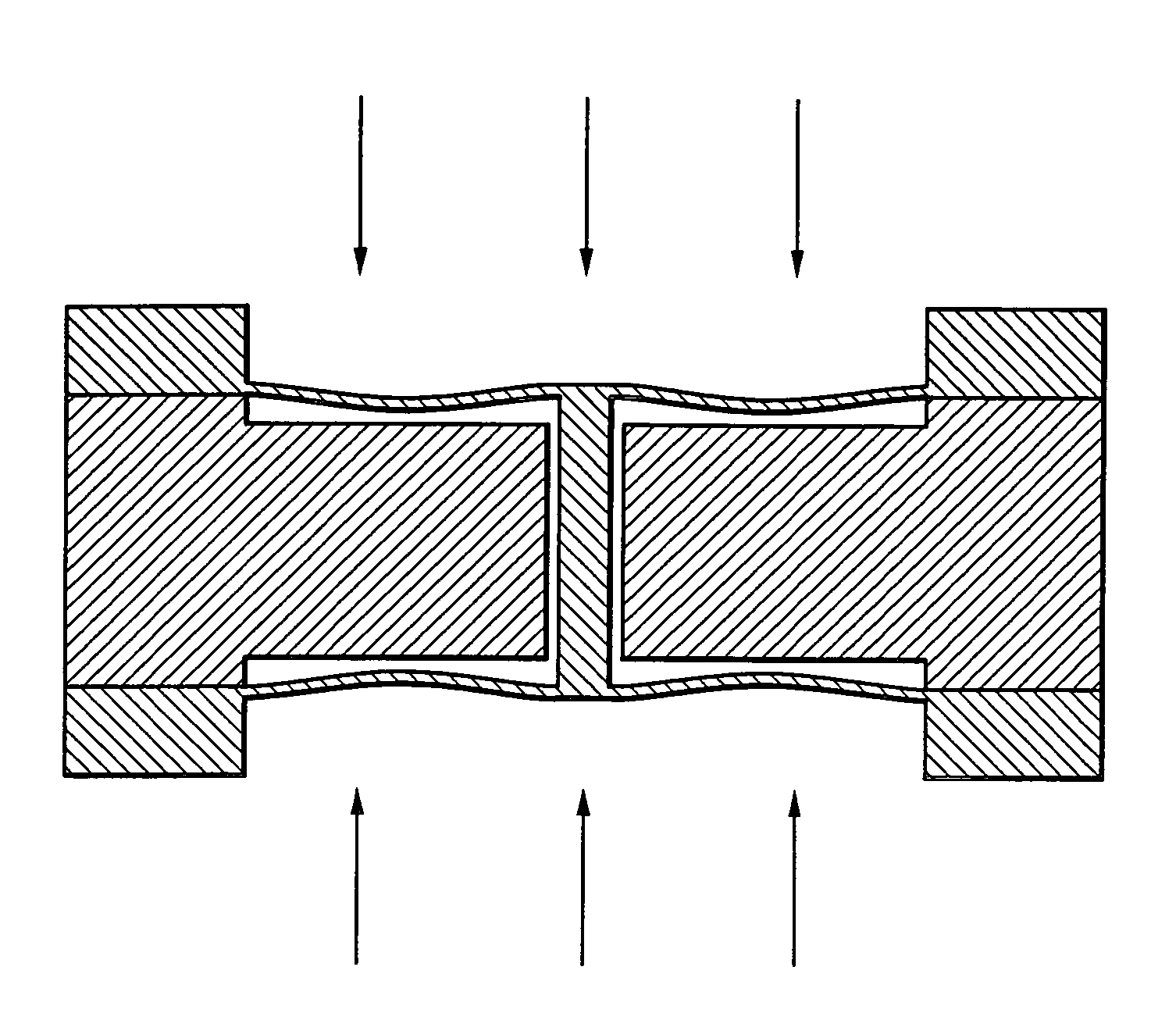

Differential pressure sensor

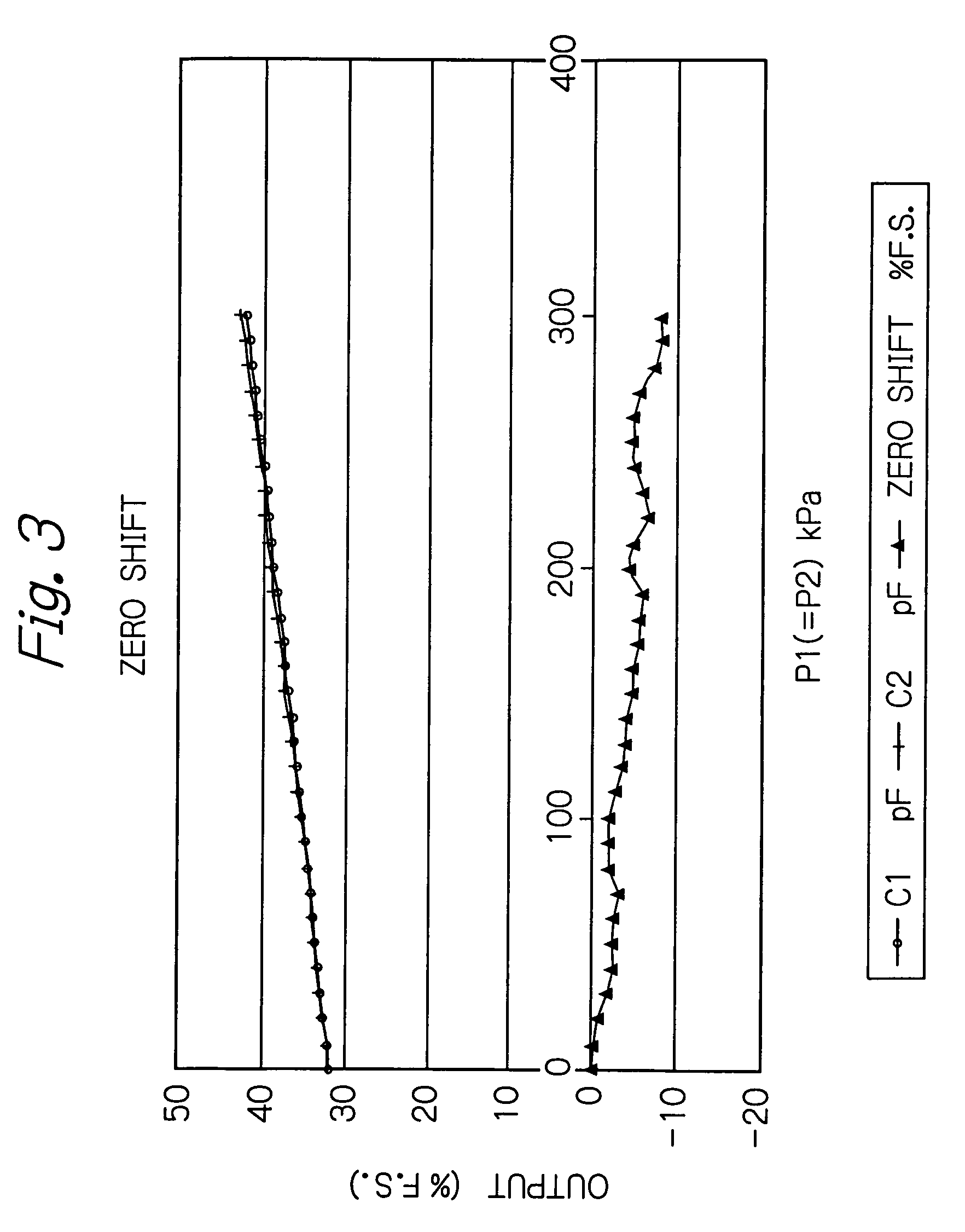

InactiveUS7219551B2Sensitive and accurate detectionApparatus for force/torque/work measurementPressure difference measurement between multiple valvesCapacitanceDifferential pressure

According to the present invention, there is provided a high-precision differential pressure sensor which is not affected by a considerable change in baseline pressure. A differential pressure sensor of the present invention includes: a pair of diaphragms, each including a diaphragm portion capable of being deformed due to application of a pressure and a support portion for holding an outer peripheral edge of the diaphragm portion; a pair of fixed electrodes in disk-like form fixed to the support portions of the diaphragms; and a movable electrode including a disk-like electrode portion and shaft-like projections extending in opposite directions from a central portion of the electrode portion. The shaft-like projections extend at a right angle relative to the electrode portion, and the movable electrode is secured to central portions of the diaphragms through the shaft-like projections so that the electrode portion faces each of the fixed electrodes in a predetermined spaced relationship. The movable electrode is capable of moving so as to allow a distance between the electrode portion and each of the fixed electrodes to vary according to a difference between fluid pressures acting on the respective diaphragm portions of the diaphragms. A capacitance generated between the electrode portion and each of the fixed electrode changes due to a variance in the distance between the electrode portion and each of the fixed electrode, and a differential pressure is detected, based on this change in capacitance.

Owner:MKS JAPAN INC

Pressure sensor system

ActiveUS20060219022A1Improve accuracyHigh precision measurementFluid pressure measurement by electric/magnetic elementsEngineeringSilicon chip

In order to realize a compact wireless pressure sensor system which transmits an accurate pressure value, the present invention provides a pressure sensor system constructed at least by a silicon chip on which a circuit operated by electromagnetic wave energy is mounted, and a film which supports an antenna, in which film a through-hole is provided in the vicinity of a diaphragm part.

Owner:HITACHI LTD

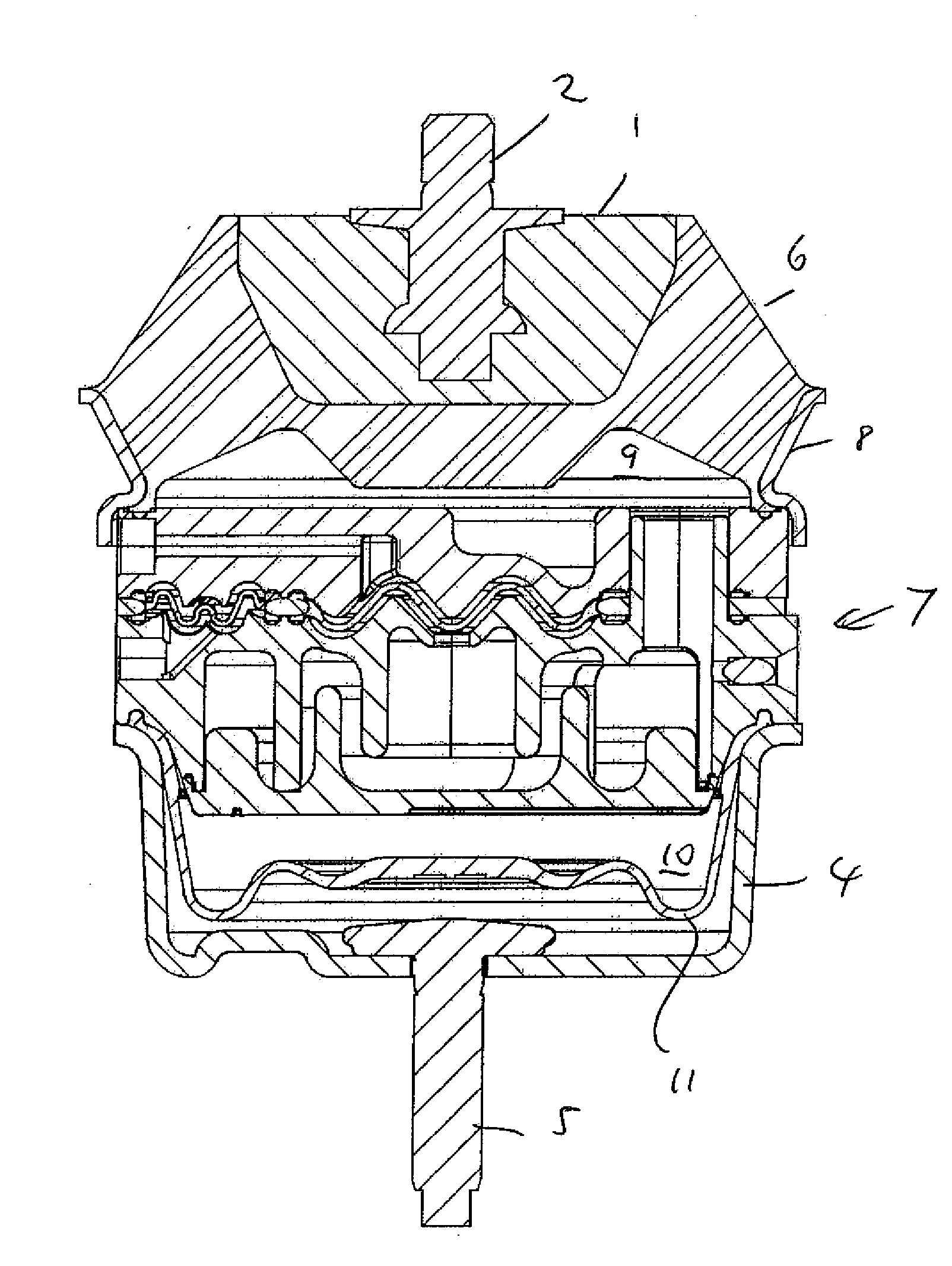

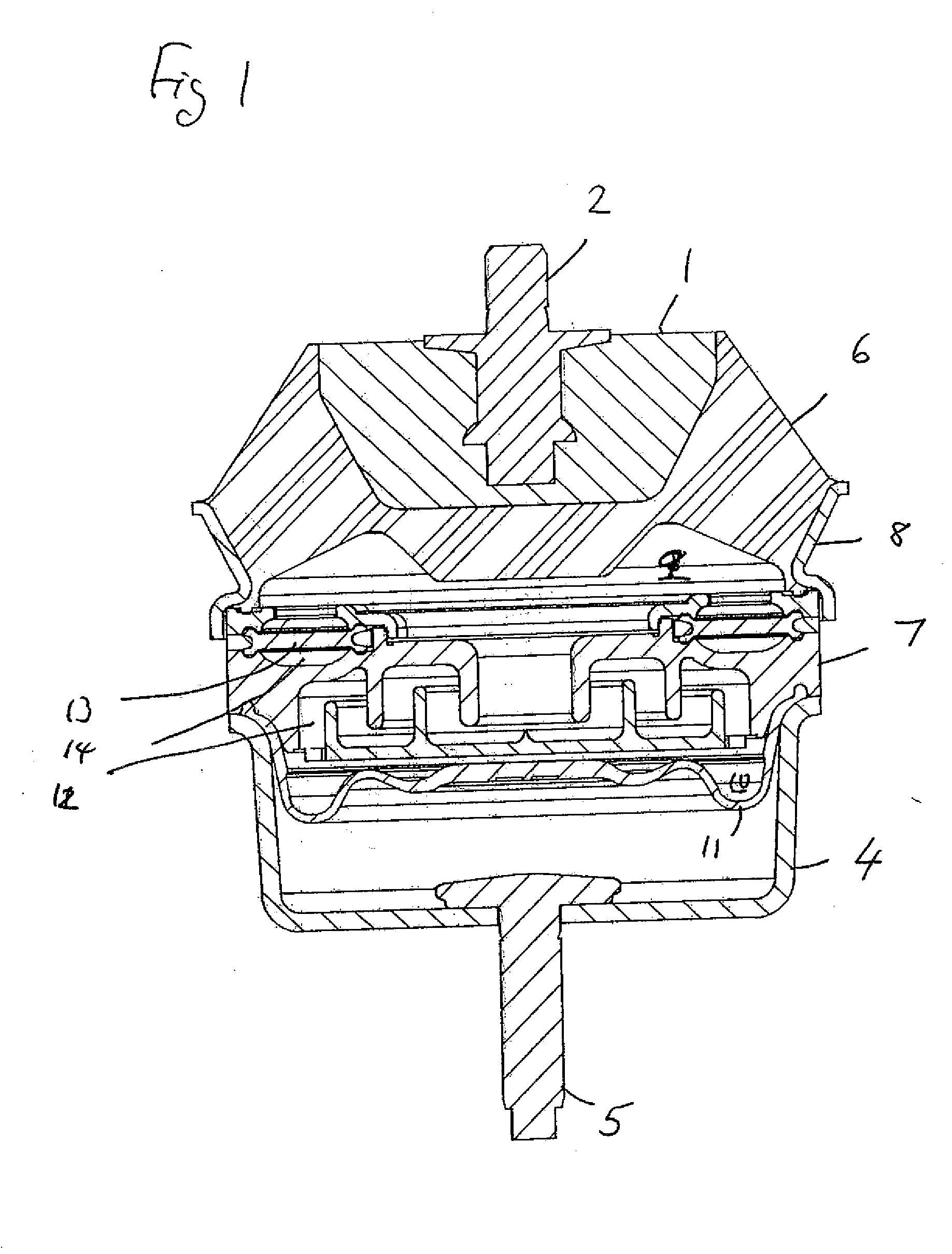

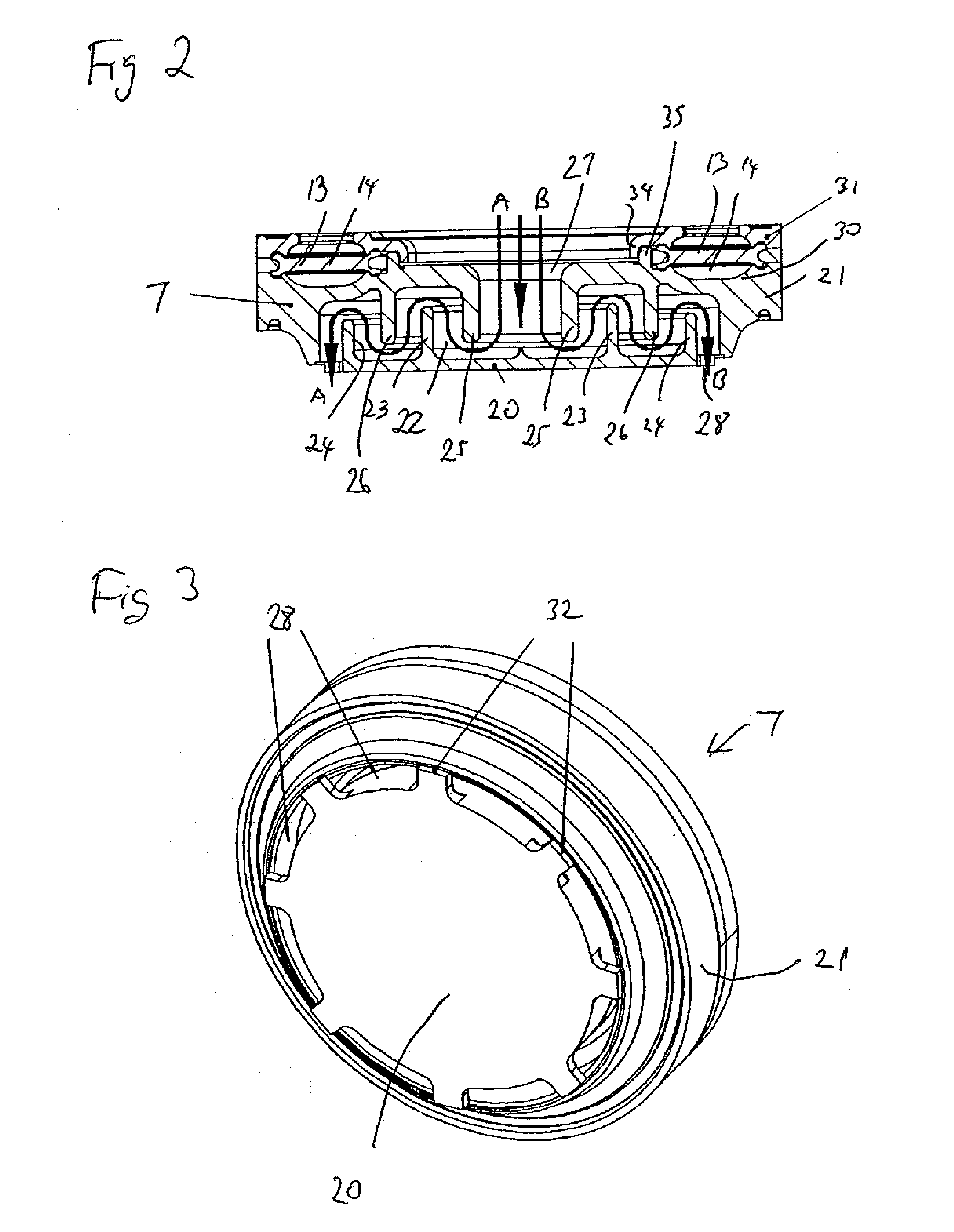

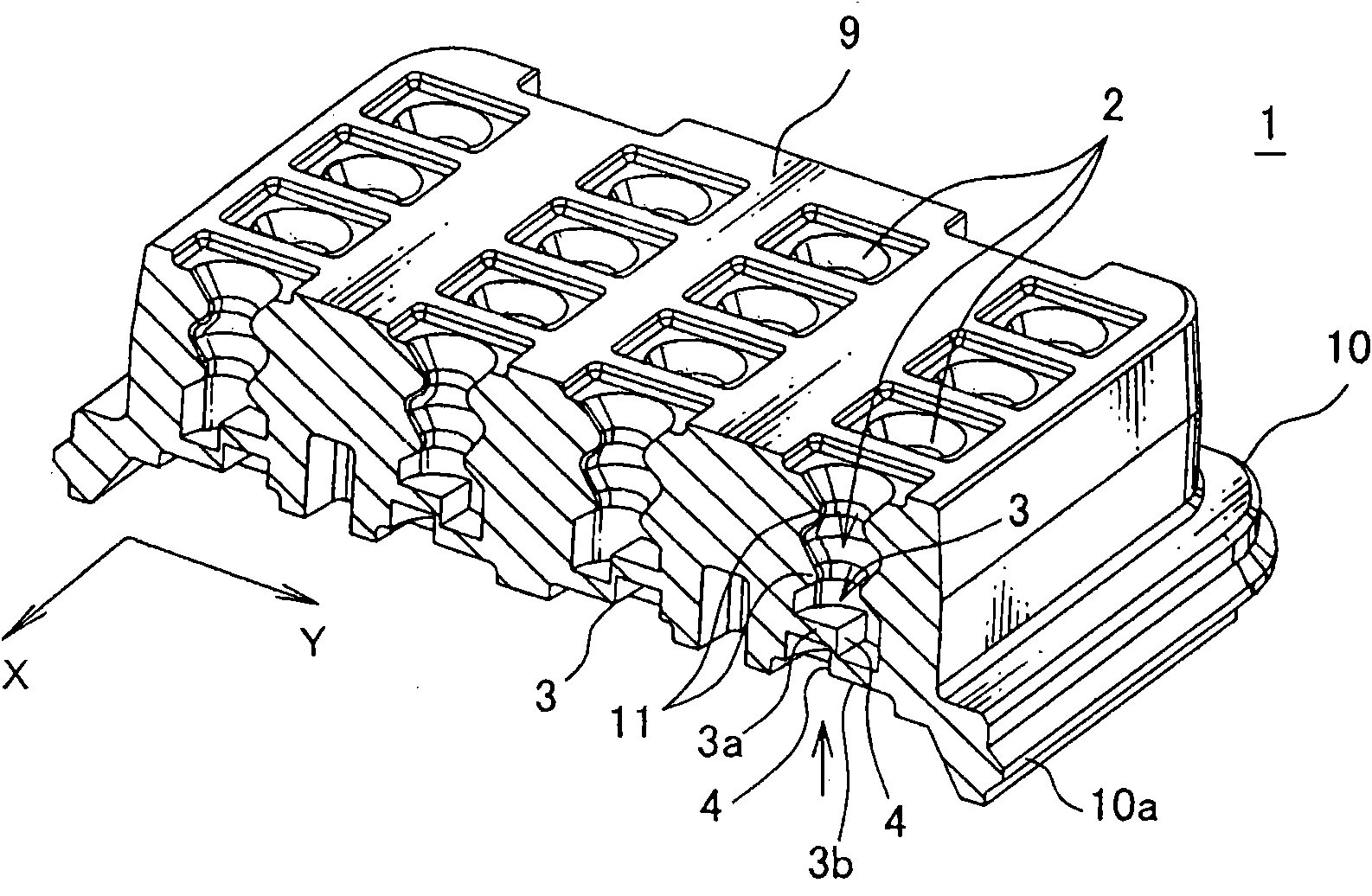

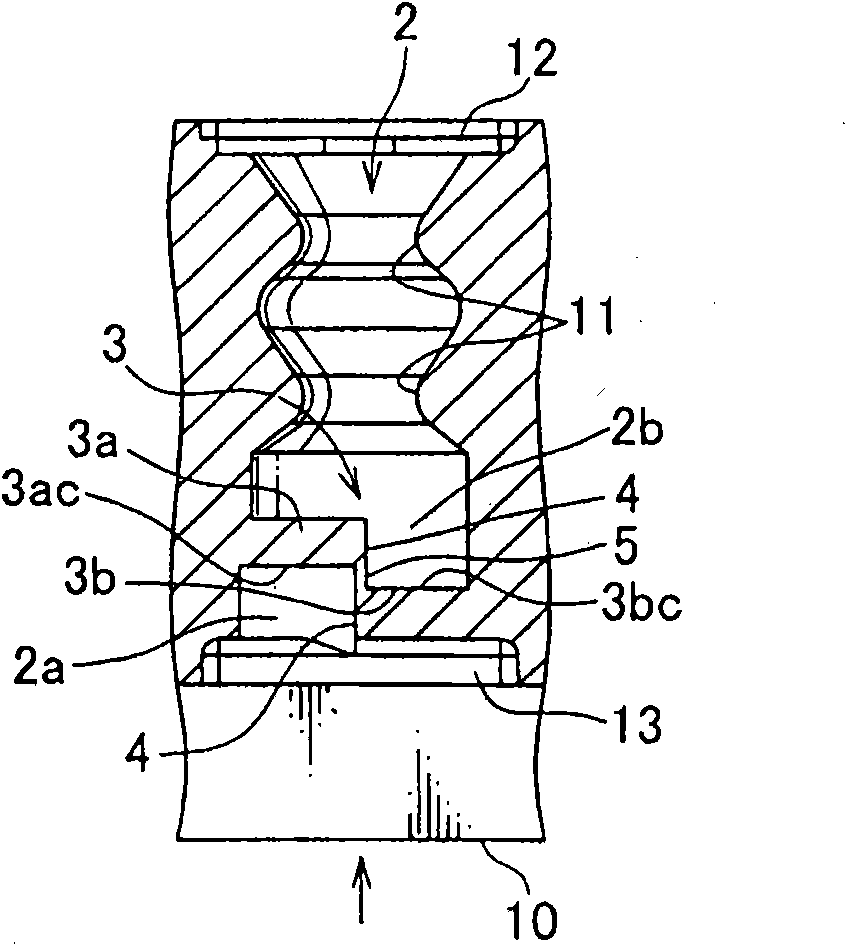

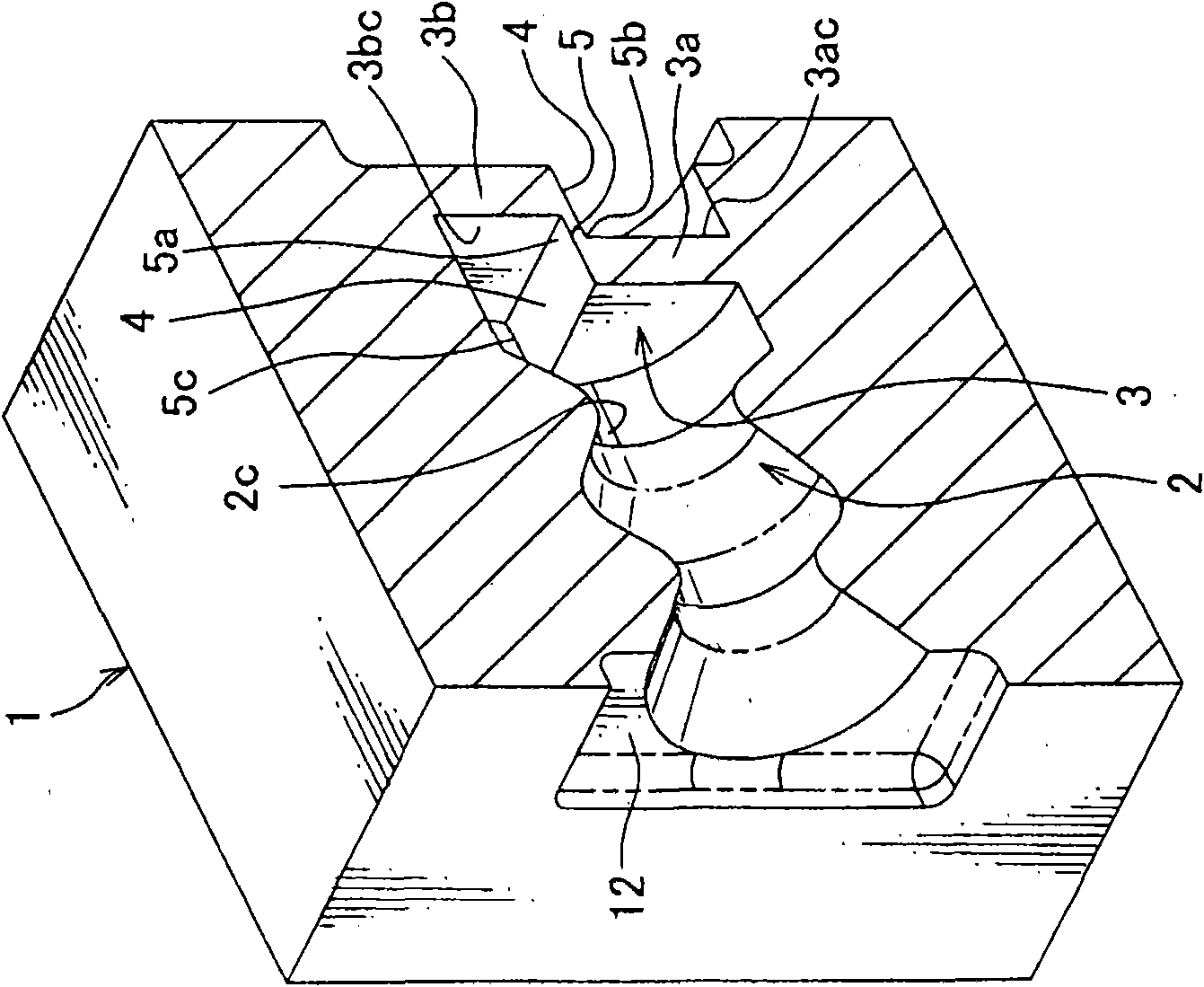

Hydraulically damped mounting device

A hydraulically damped mounting device has two anchor parts connected by deformable wall. A partition is associated with one of the anchor parts and defines, together with the deformable wall a working chamber for hydraulic fluid. The working chamber is connected via a passageway to a compensation chamber partially bounded by another deformable wall. The partition separates the working and compensation chambers, and the device has a diaphragm being a barrier between the hydraulic fluid and a gas. In one arrangement at least part of the passageway is formed within a cavity in the partition in which there are projections which are arranged to overlap, and so define a convoluted path for the hydraulic fluid around the projections. In another arrangement a duct to a diaphragm part is at least partially formed by a cavity within the partition, which cavity has cylindrical projections arranged one within the other and overlapping to form a convoluted path for hydraulic fluid. In a third arrangement the passageway has a branch to the diaphragm, which branch is convoluted as it passages through a cavity in the partition containing cylindrical projections.

Owner:DTR VMS LTD

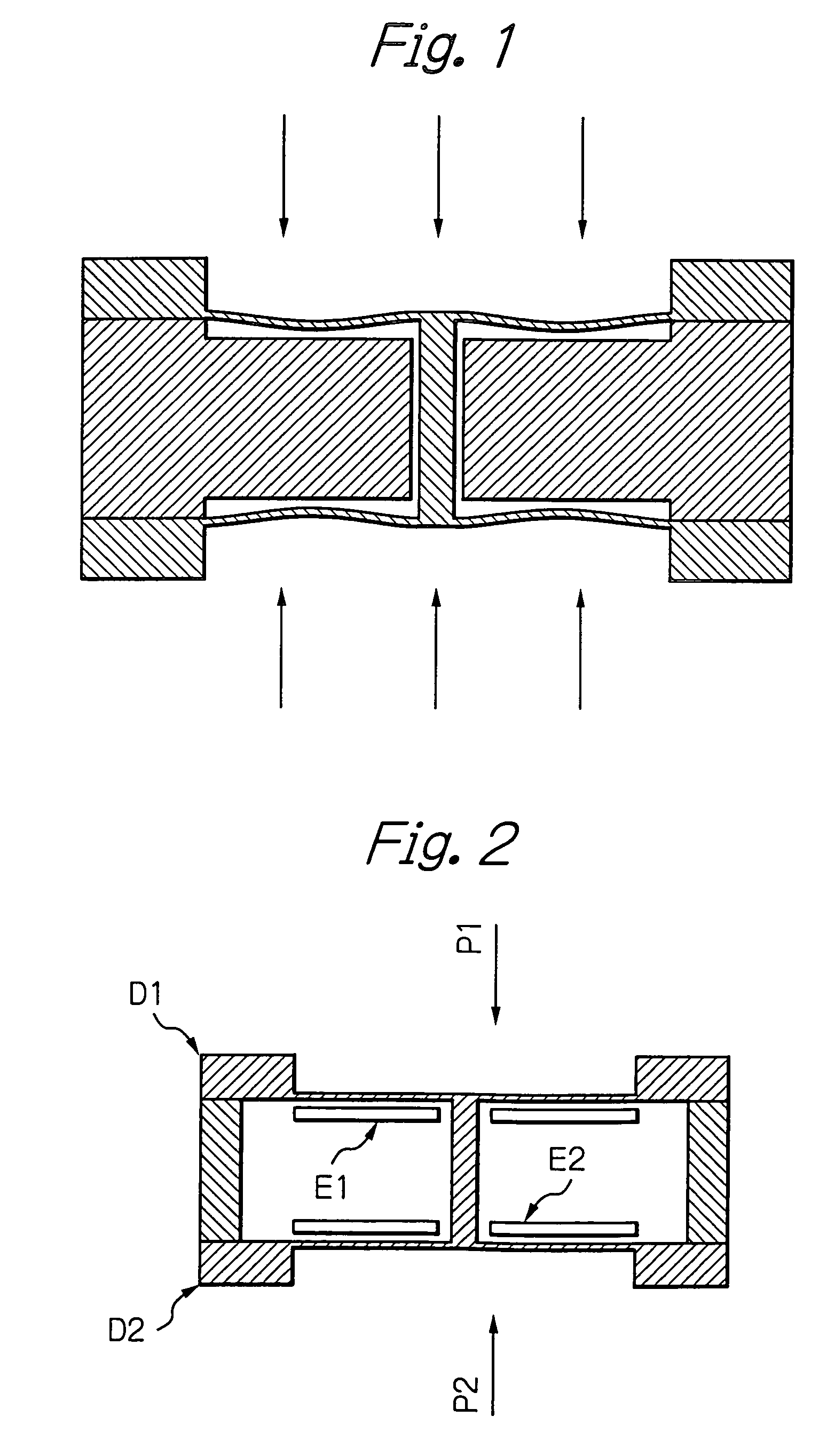

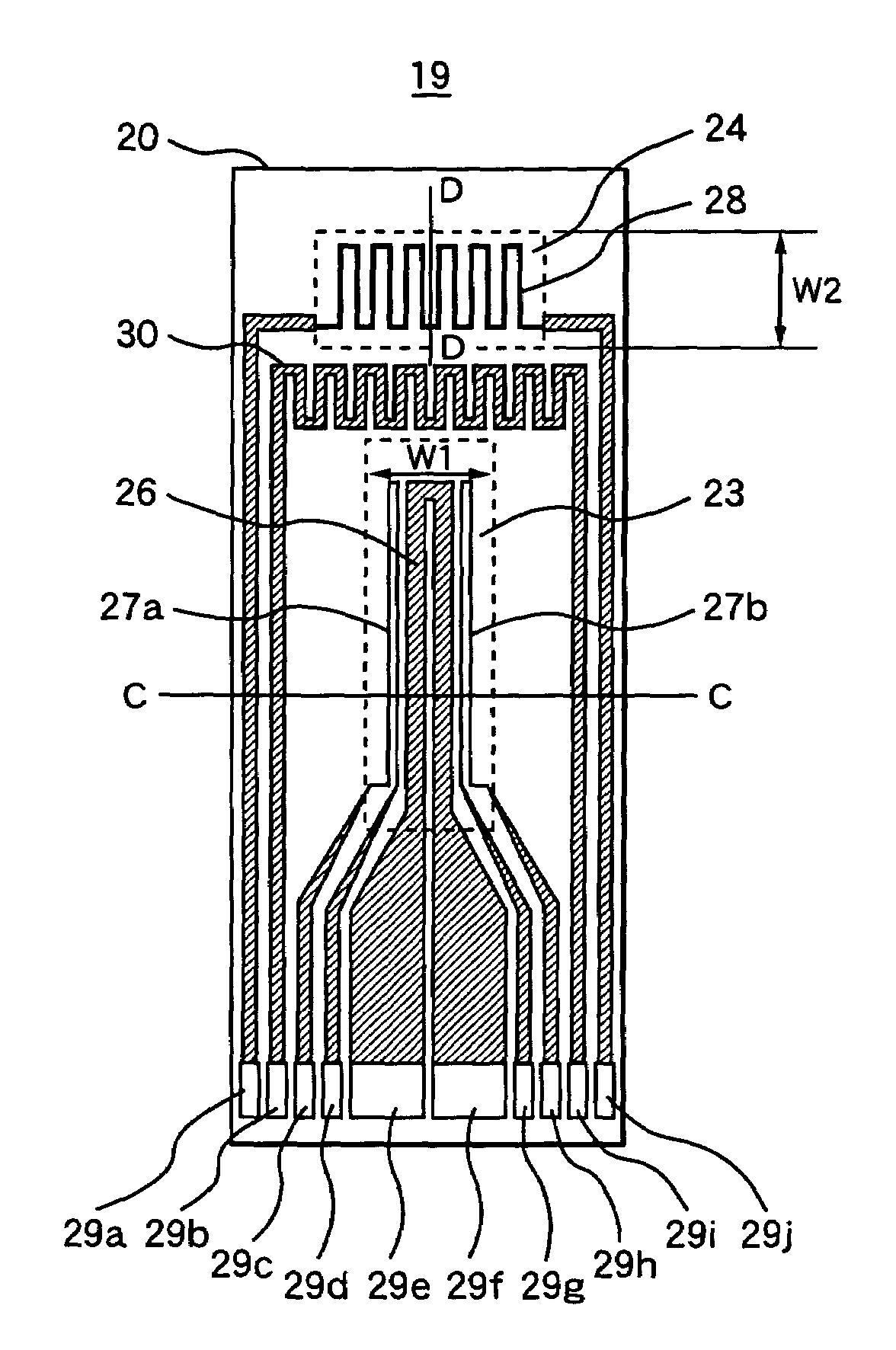

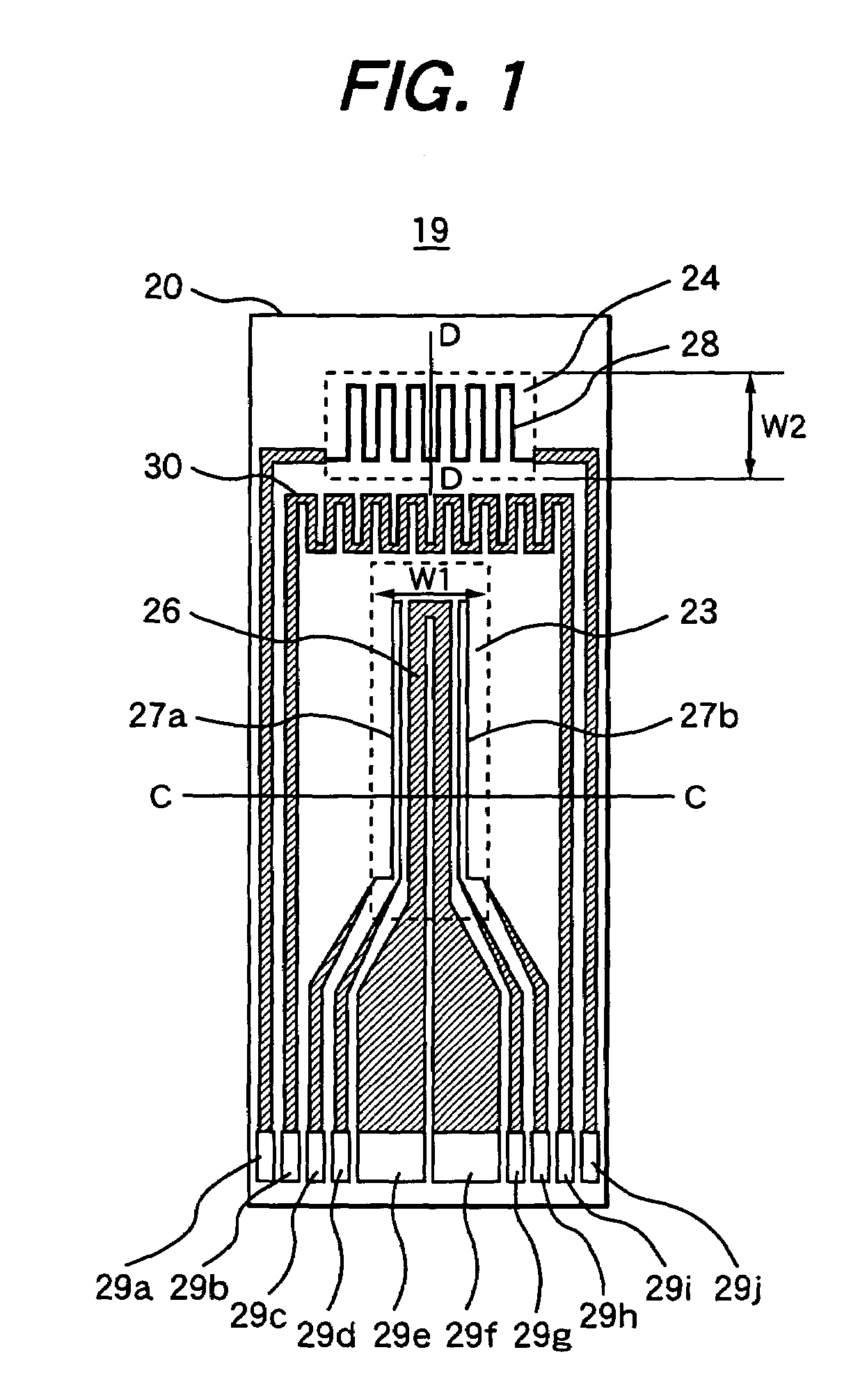

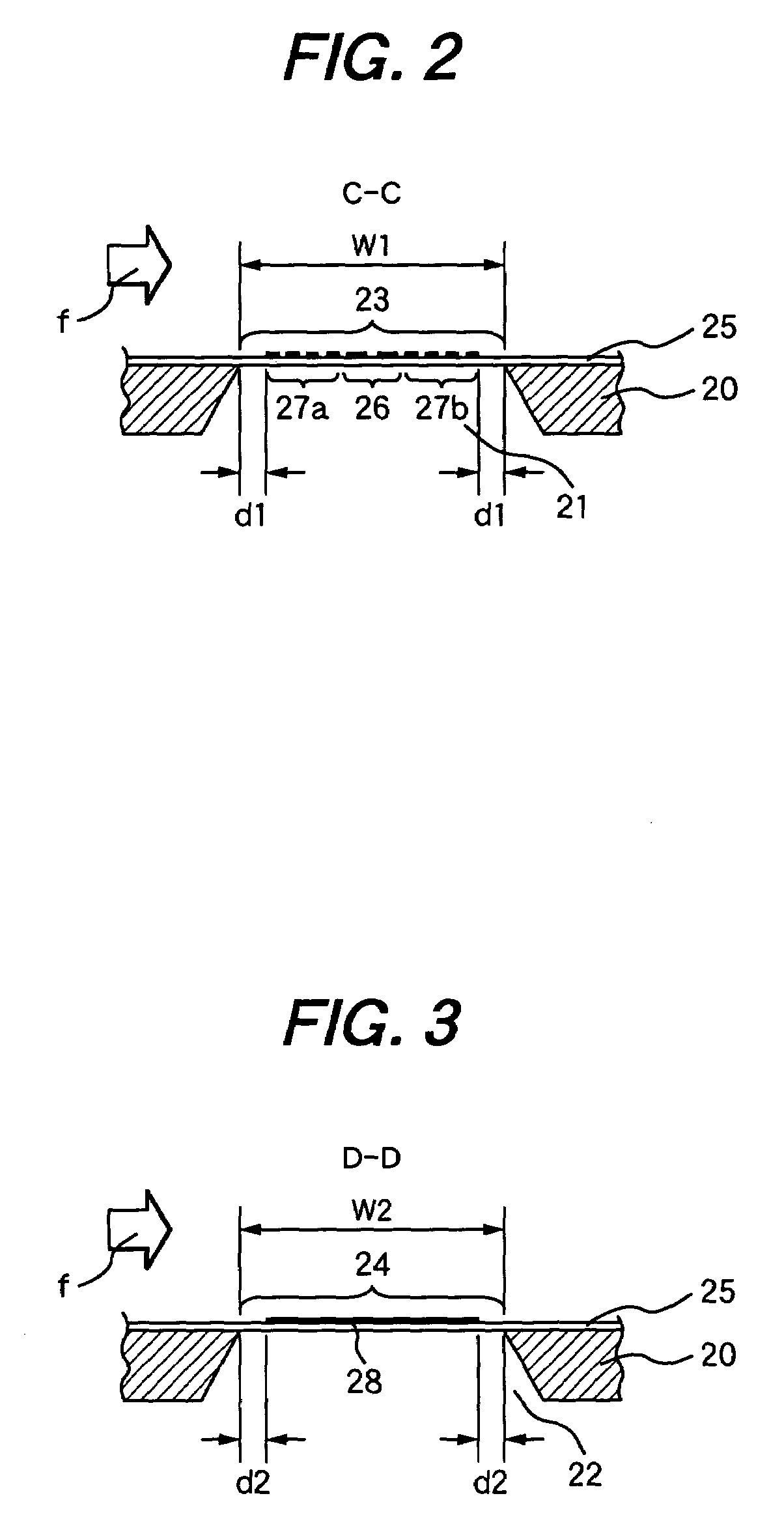

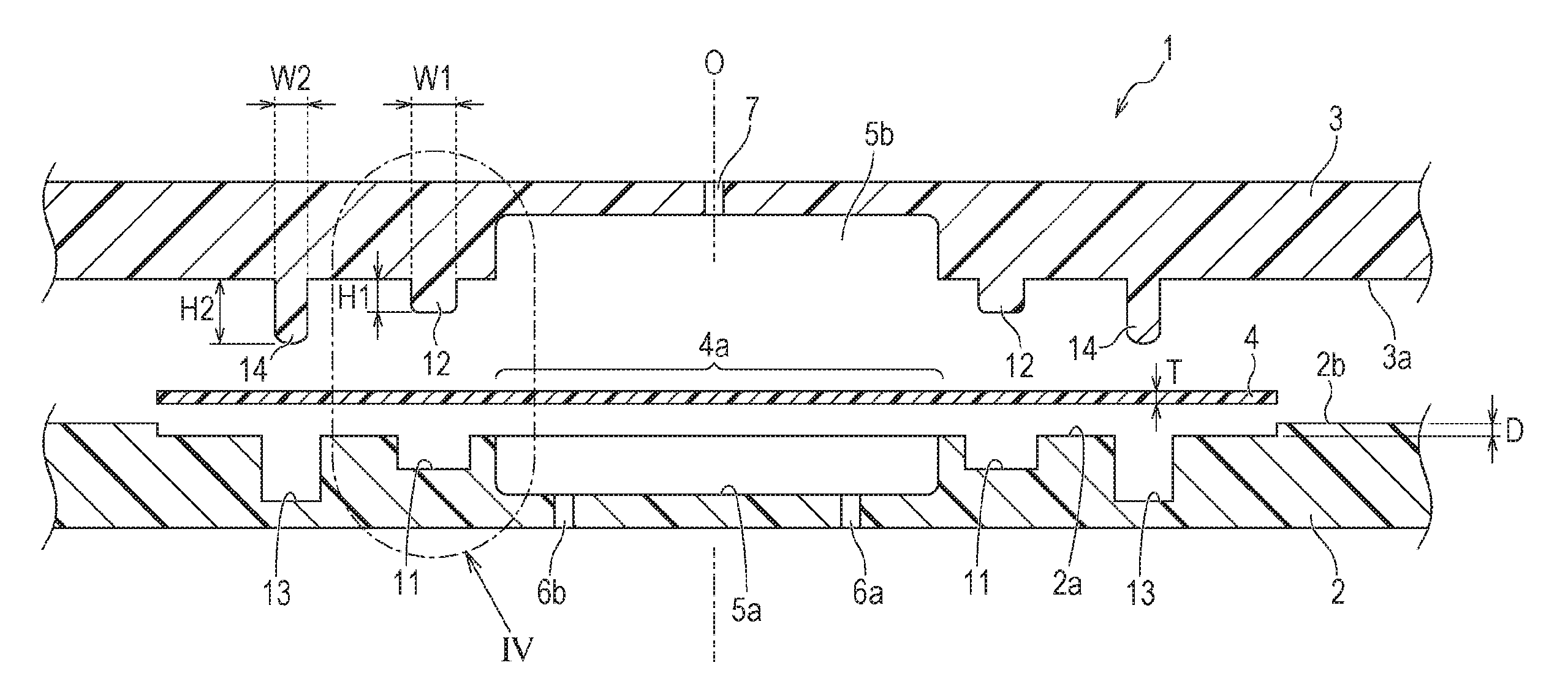

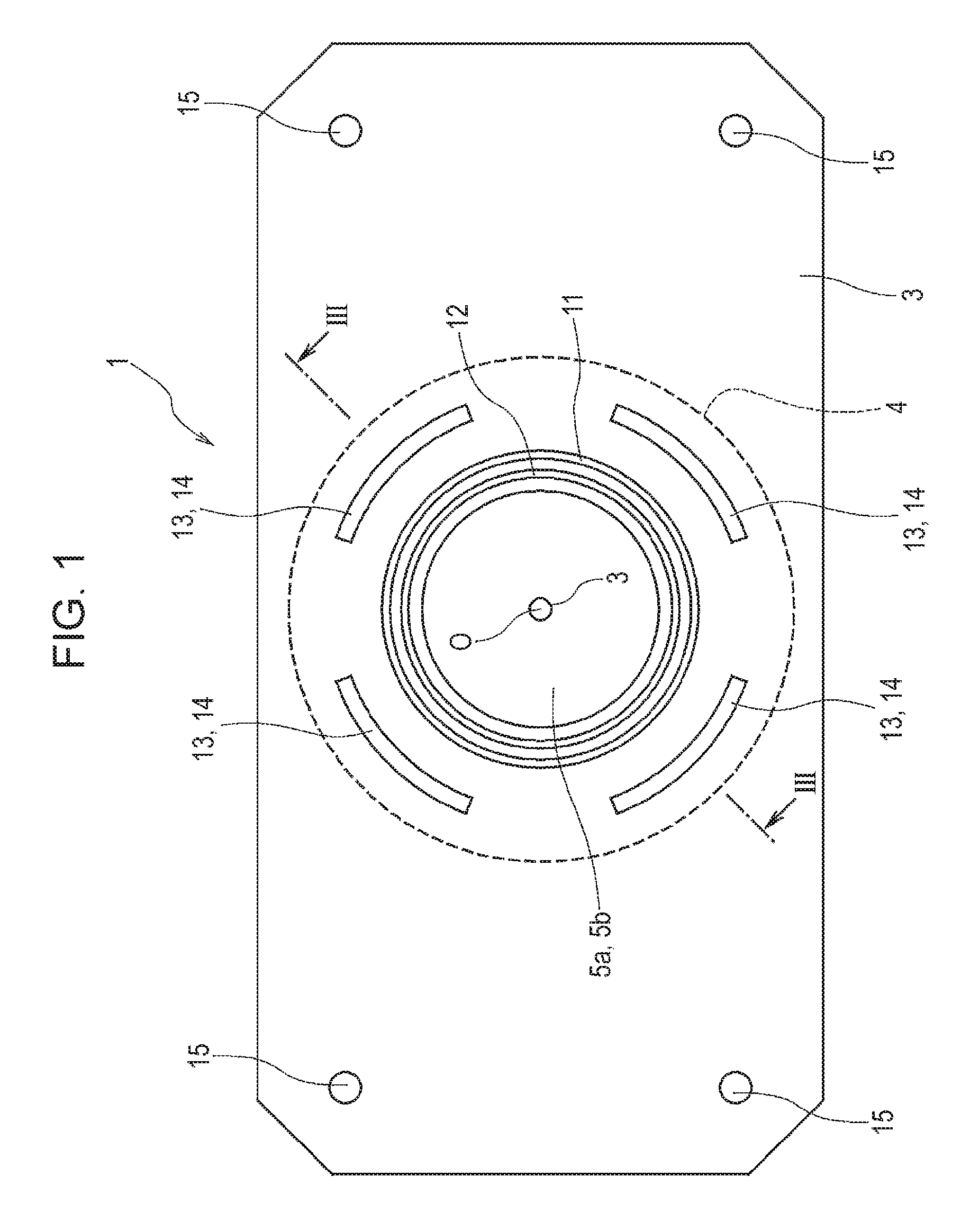

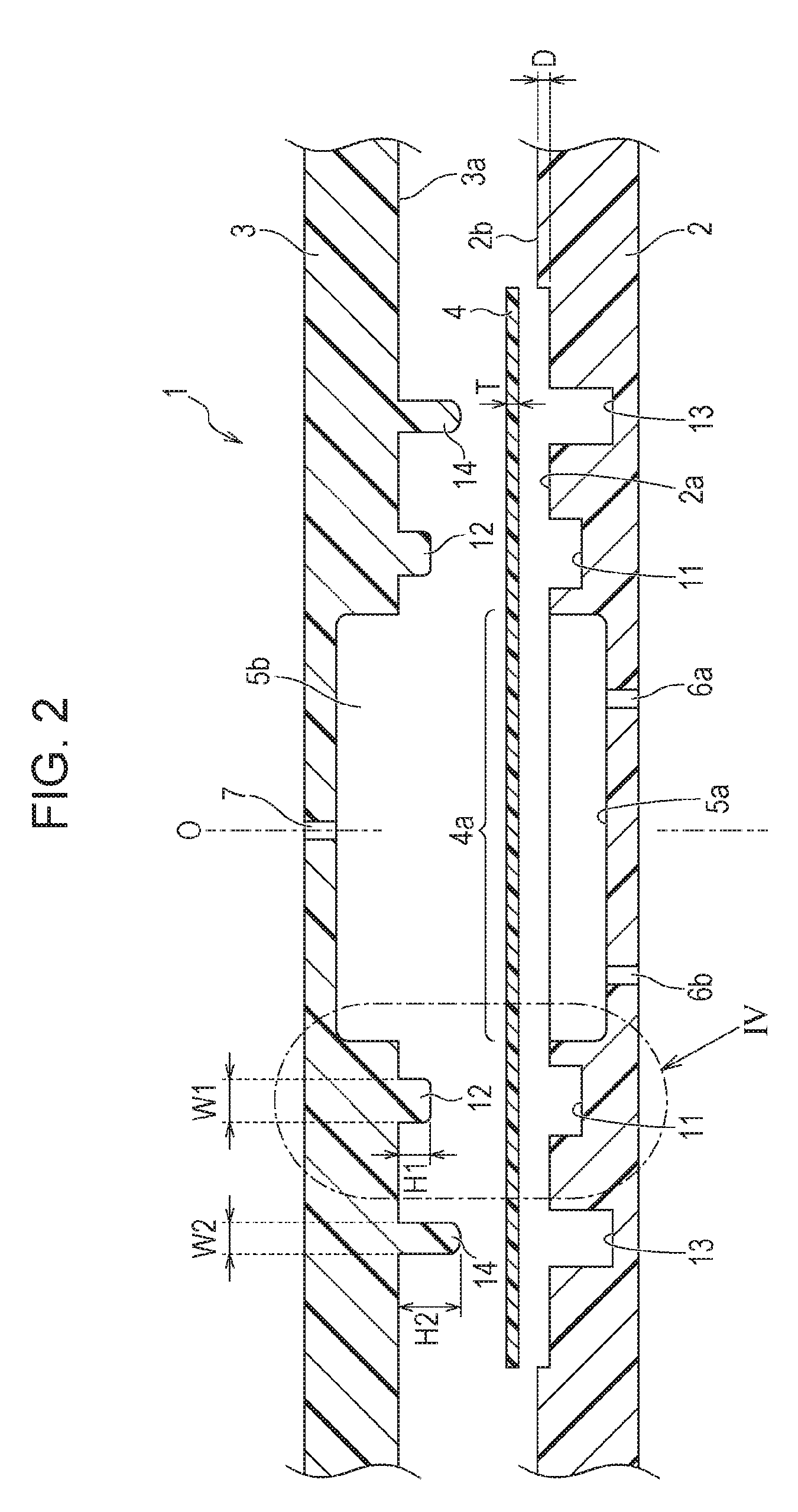

Thermal type air flow meter having semiconductor sensor elements with similar diaphragm sizes

InactiveUS7360415B2Excellent in mass productivity and reliability and measurement accuracyVolume/mass flow by thermal effectsEngine testingElectricitySemiconductor sensor

A thermal type air flow meter that makes it possible to precisely and easily determine whether a sensor element is a non-defective or a defective by screening is provided. First and second diaphragm sections composed of an electrical insulating film are formed in a semiconductor substrate. A heating resistor and a resistor for intake air temperature sensor are disposed on them to obtain a sensor element for thermal type air flow meters. The length of the short sides W1 of the rectangular first diaphragm section is made substantially equal to the length of the short sides of the second diaphragm section rectangular as well. Thus, the pressures applied to each of the diaphragm sections are substantially identical with each other in pressurization during screening.

Owner:HITACHI LTD

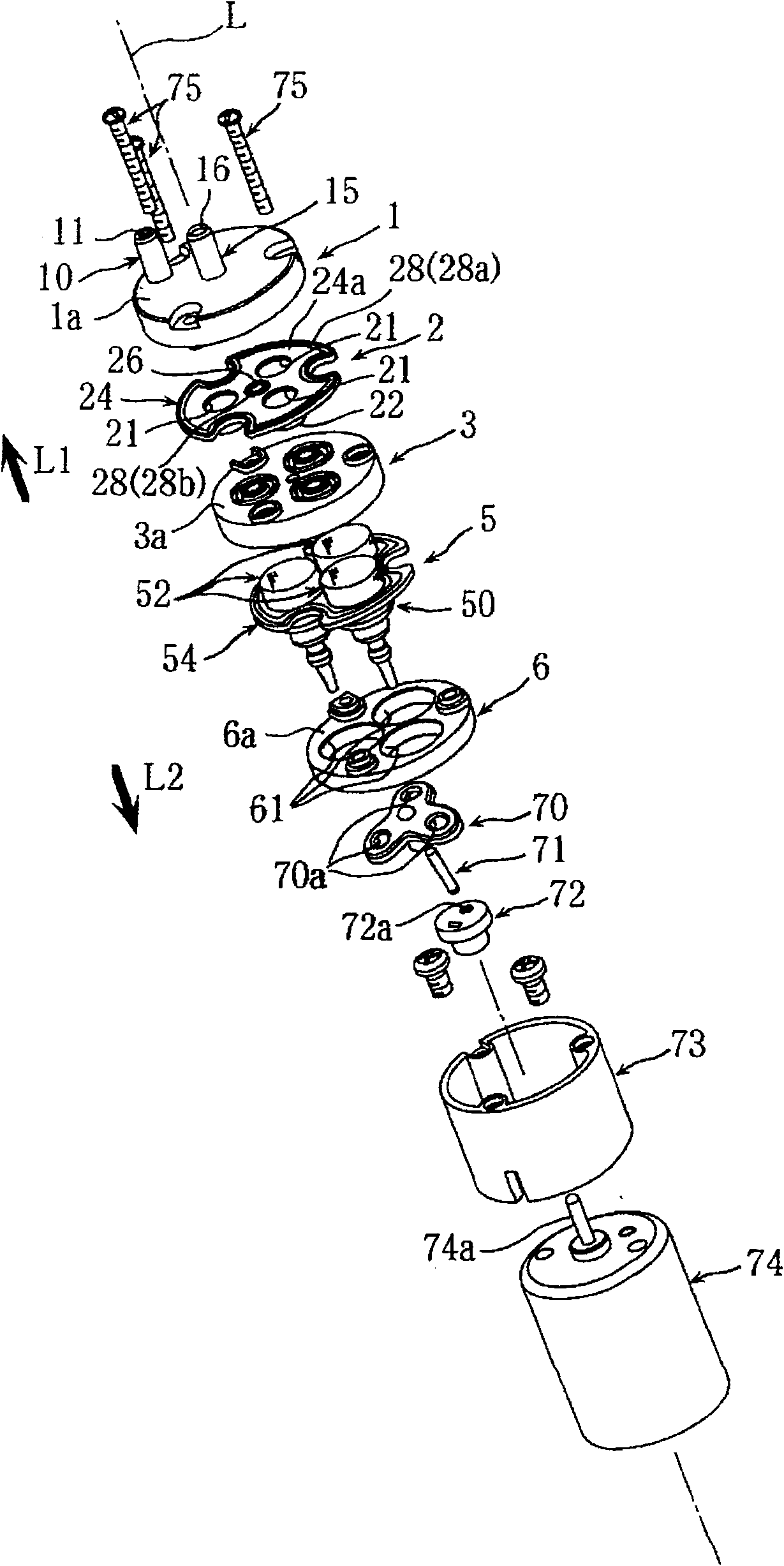

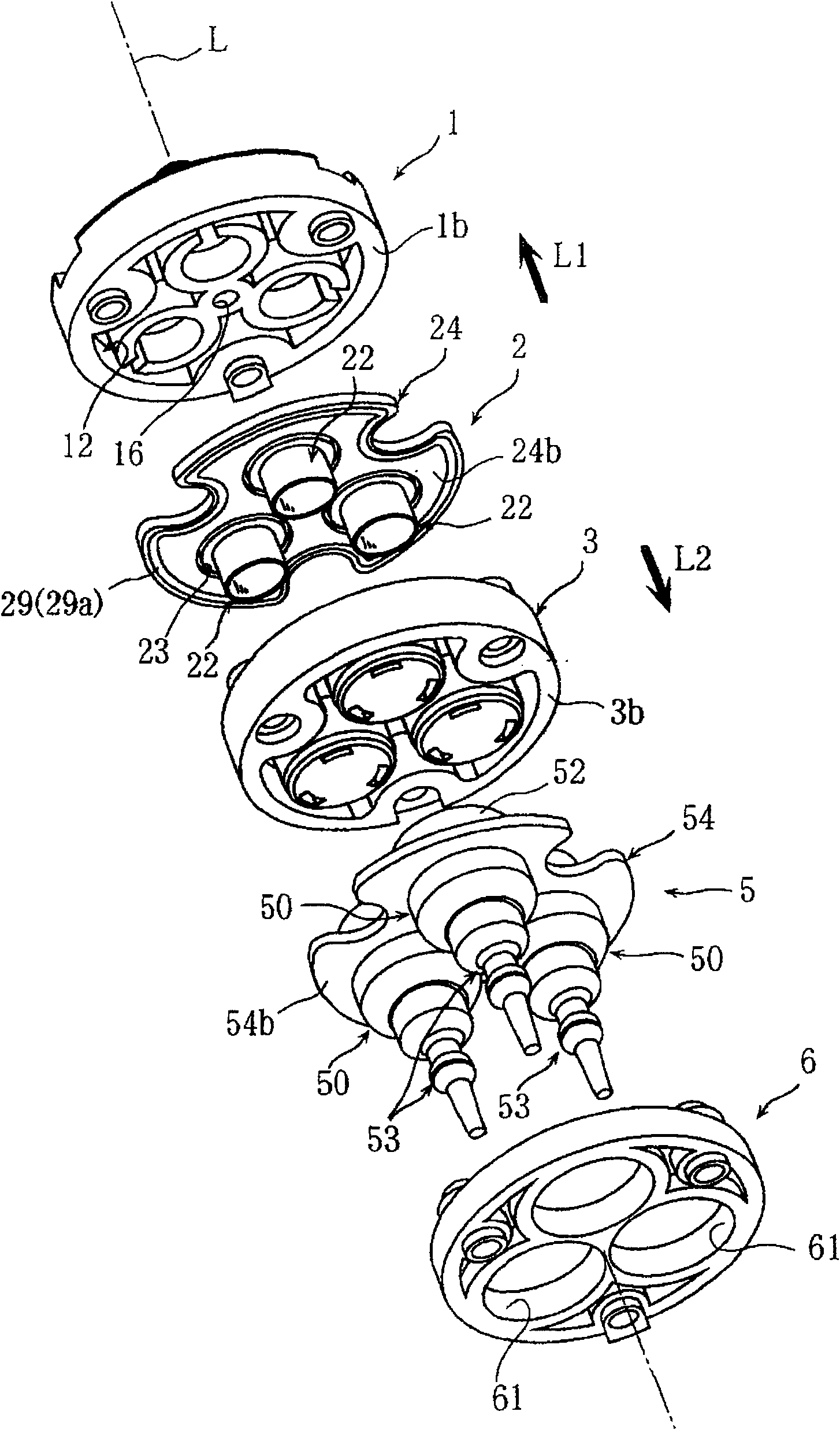

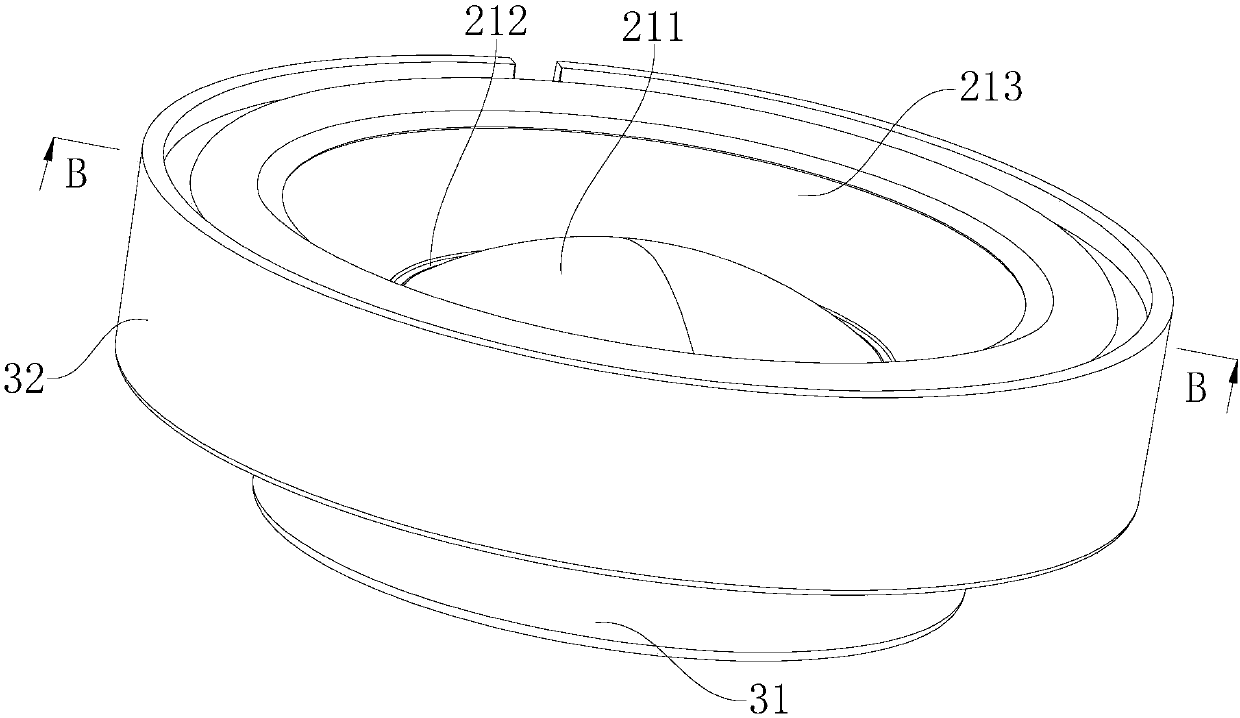

Diaphragm pump for fluid

InactiveCN102102655AShorten the lengthReduce noiseEngine manufacturePositive displacement pump componentsDiaphragm pumpEngineering

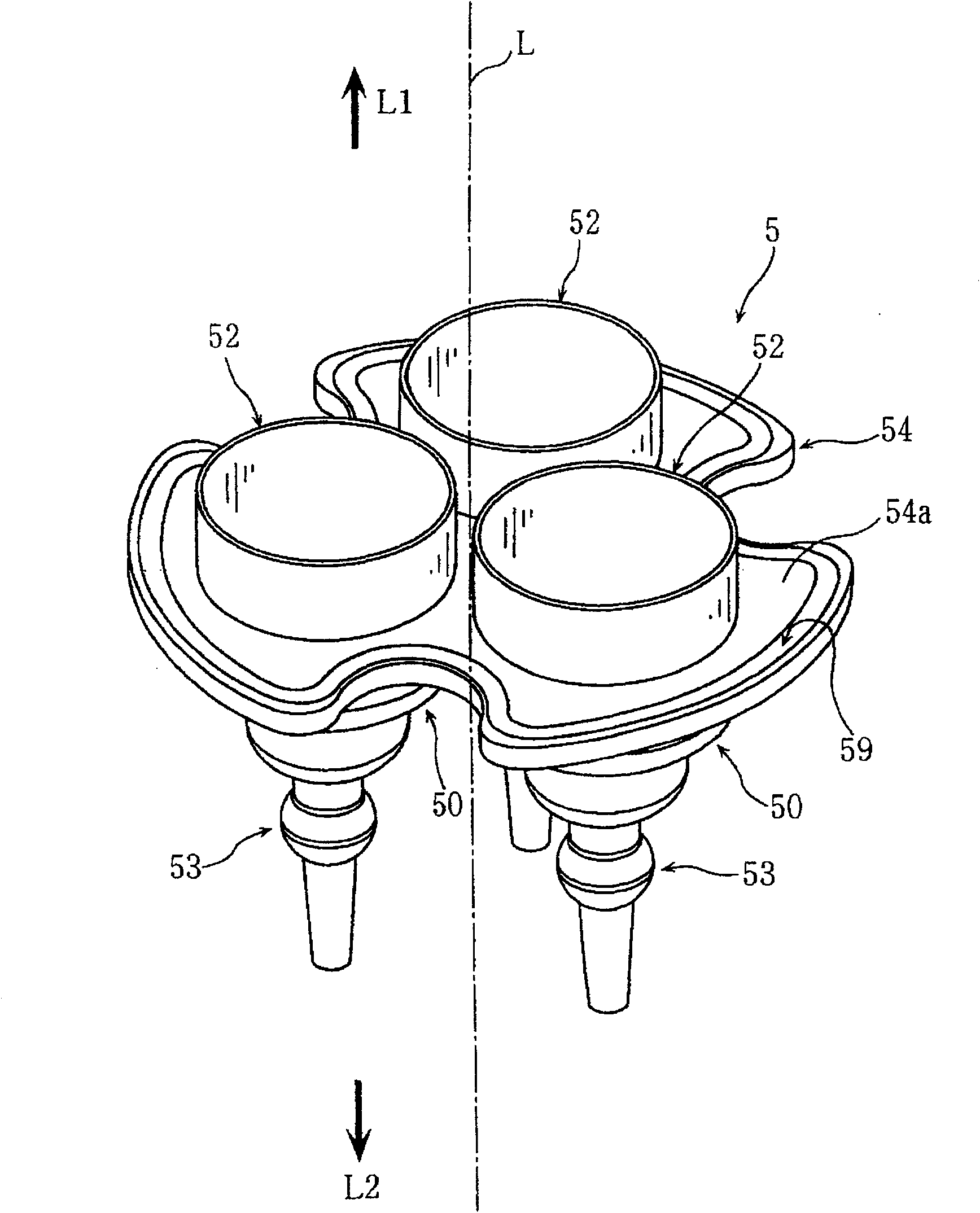

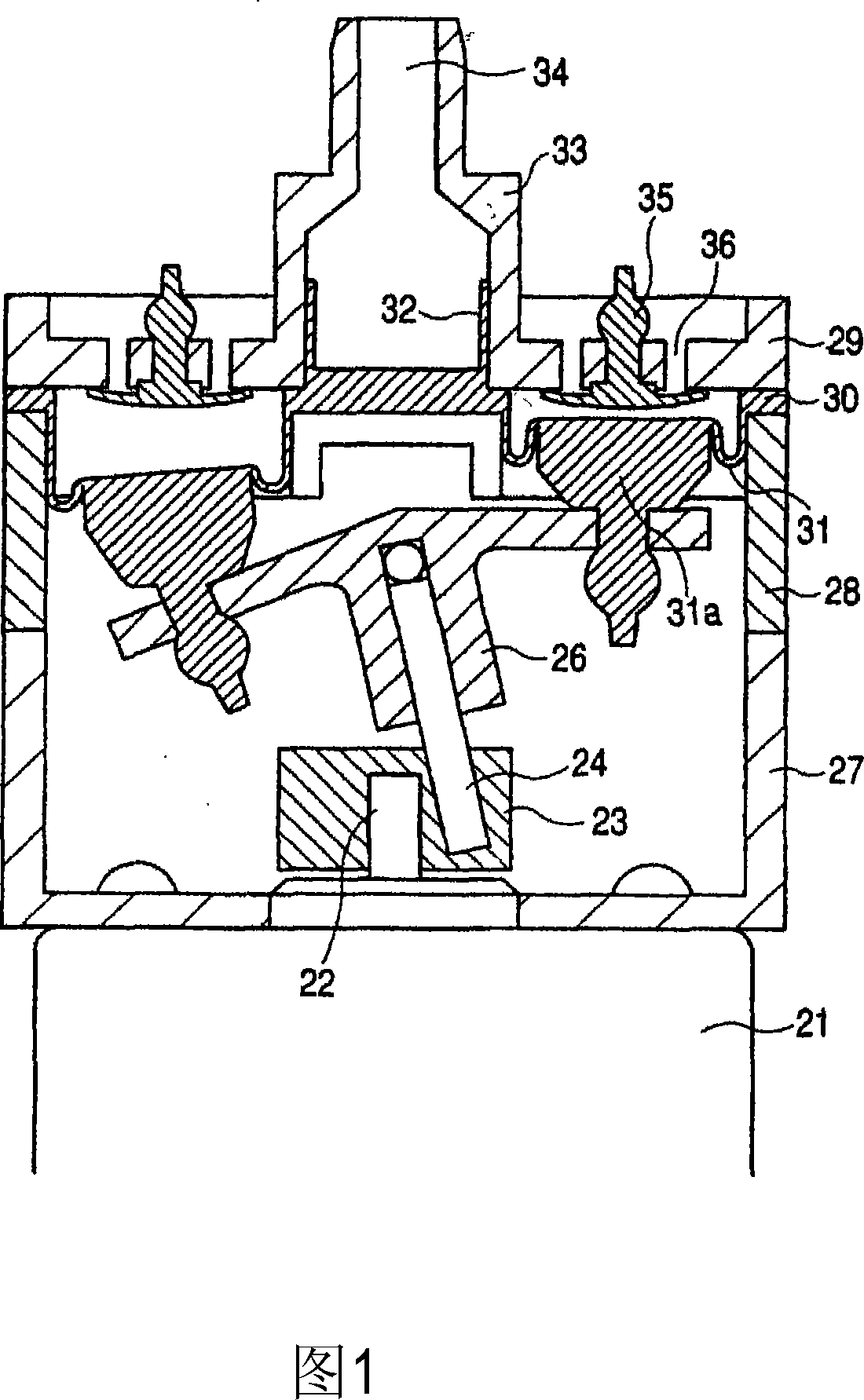

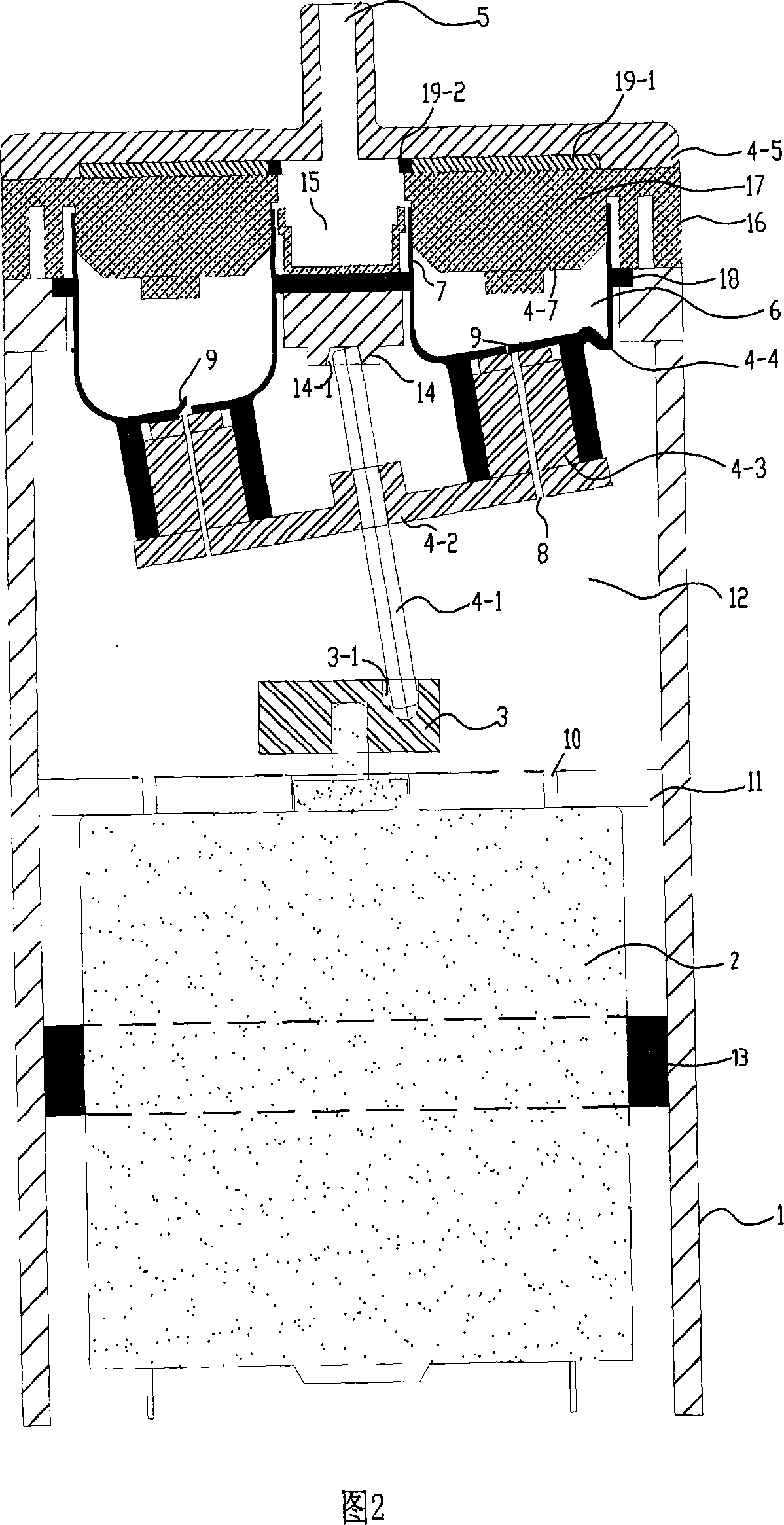

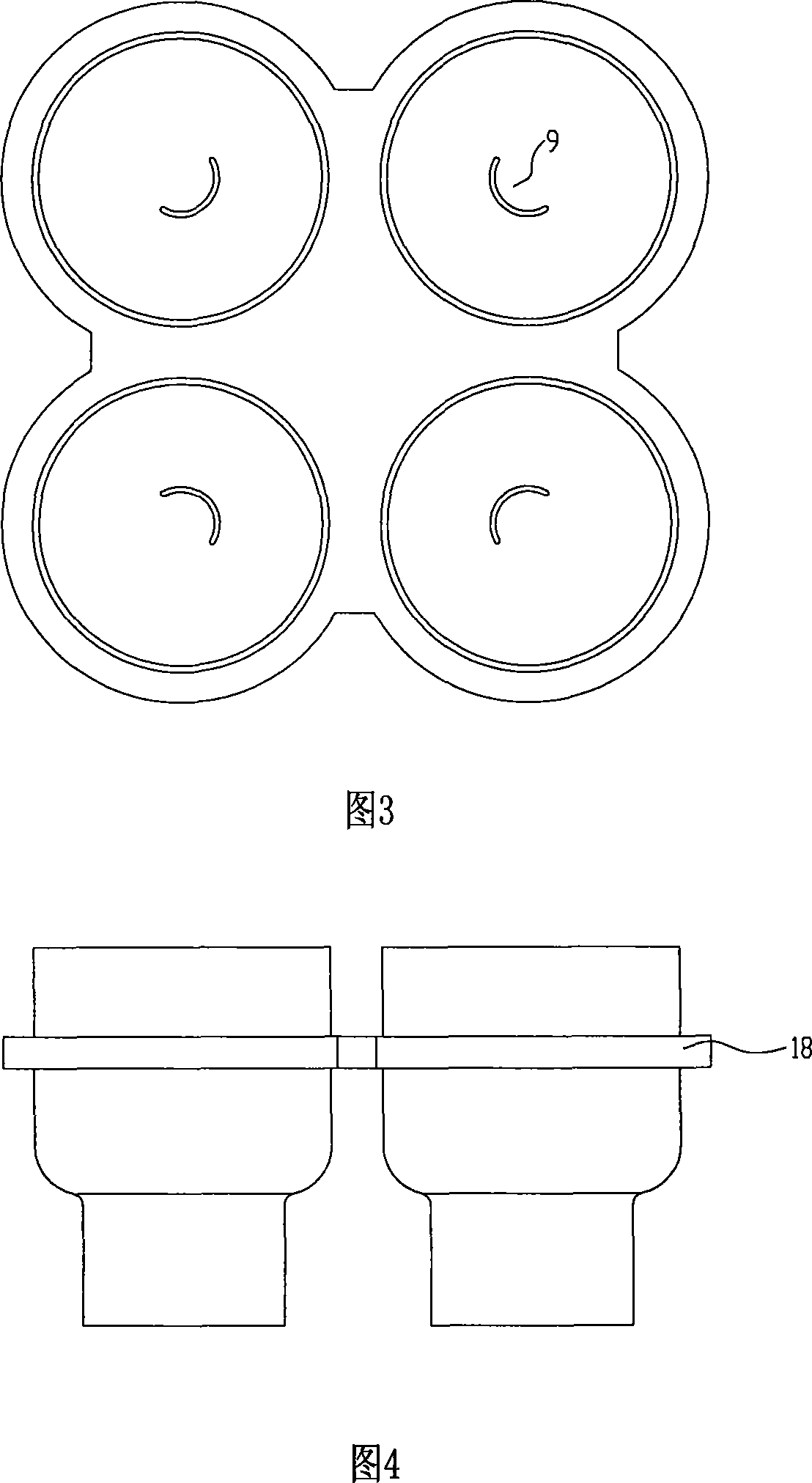

The present invention provides a diaphragm pump for fluid, which has a small number of components and is easily assembled. The diaphragm pump for fluid is provided with the following components: a diaphragm assembly (5) which comprises the components of: bowl-shaped diaphragms (50) that are respectively opened in an axis direction (L1), a short cylindrical discharge valve diaphragm part (52) which is formed through extending an open edge of the diaphragm (50) to an axial direction (L1), and an orthogonal planar transverse diaphragm part (54) which integrally connects a plurality of diaphragms (50) with equal distance on the circumference; a suction valve diaphragm assembly (2) which comprises the components of: an axially orthogonal planar flat plate part (24), and a plurality of short cylindrical suction valve diaphragms (22) which project from the flat plate part (24) to the other axial direction (L2) with equal distance on the circumference; a middle cover body (3) which is provided with a cylindrical discharging valve seat part (35) that is provided between the diaphragm assembly (5) and the suction valve diaphragm assembly (2) and has a discharge valve diaphragm part (52) that clings to and detachably contacts with an outer circumferential surface; and a circular suction valve seat part (32) which is configured coaxially with the discharging valve seat part (35) and has a suction valve diaphragm (22) that clings to and detachably contacts with the outer circumferential surface.

Owner:DATA PLASTIC INDAL

Diaphragm pump

ActiveCN101100989ADelay agingExtended service lifeFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpPump chamber

This invention relates to gas variable displacement mechanical field, especially a diaphragm pump. It has machine case, in which is arranged with diaphragm pump components. The back side of machine case is set with electric engine which drives diaphragm pump components. Boss, diaphragm part and driving part form a gas absorbing and exhausting function element. At the interior of machine case, the air flow passes air inlet opening, semicircular air inlet valve, pump chamber, barrel type air outlet valve and air outlet opening in turn. This invention reduces energy consumption and working noise.

Owner:CHANGZHOU FULING & CEIEC

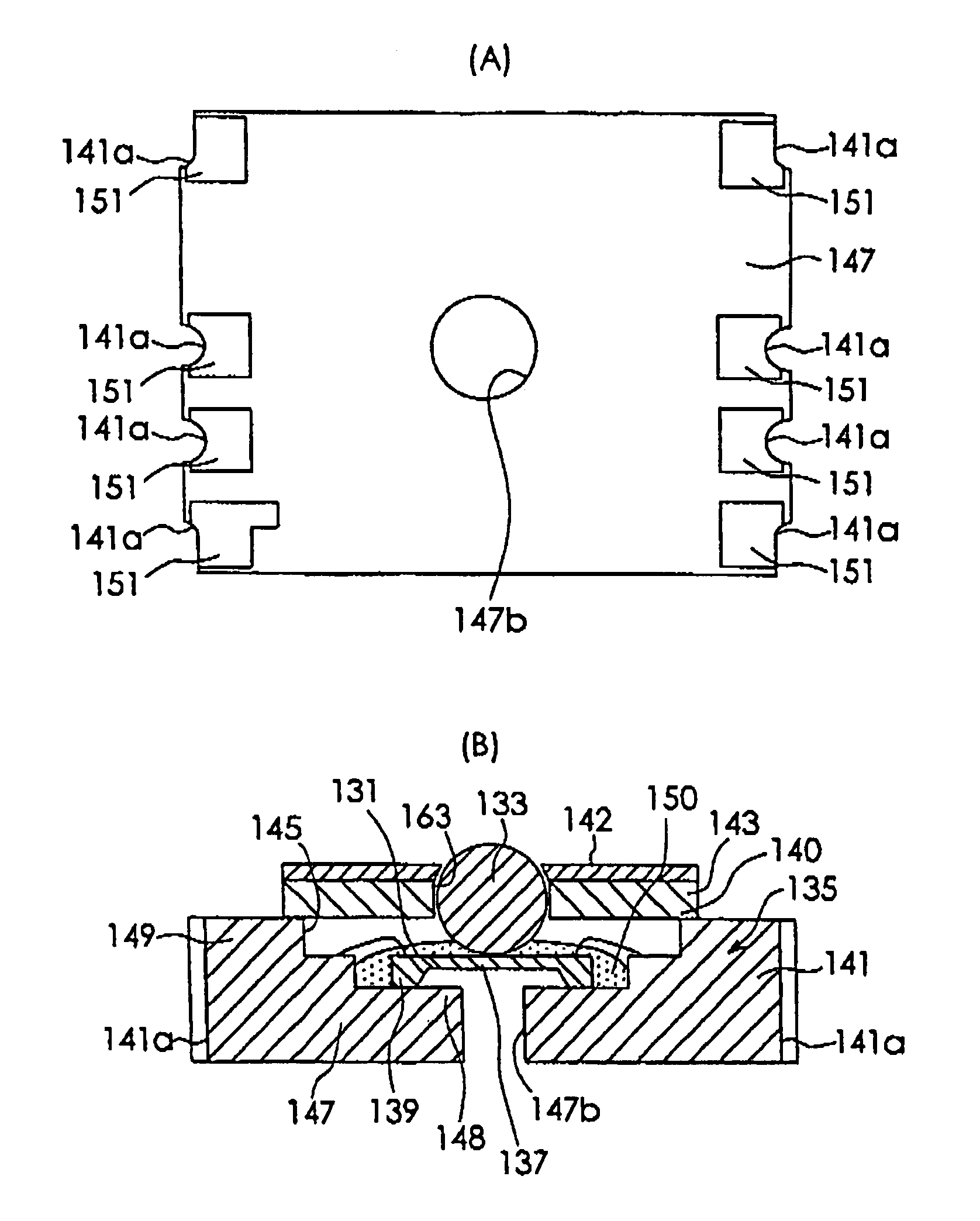

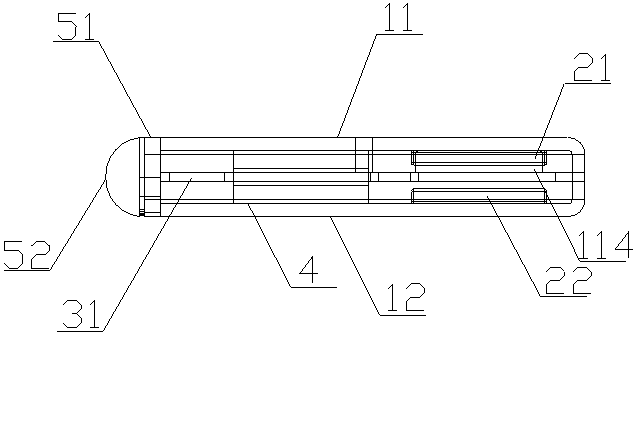

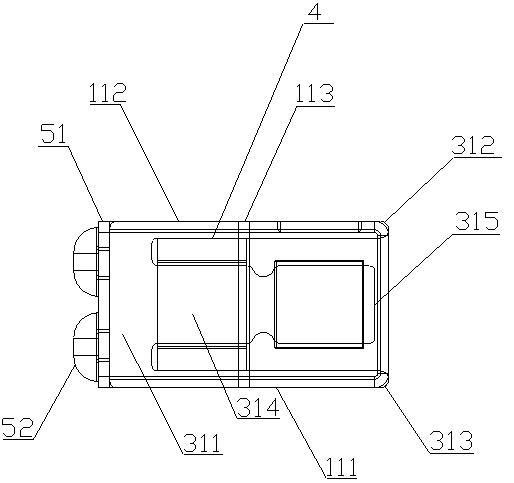

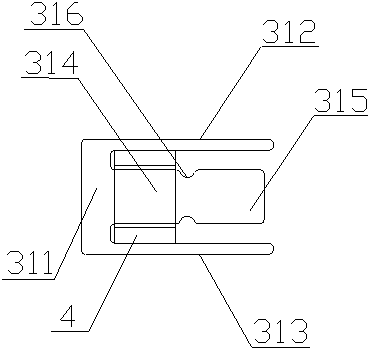

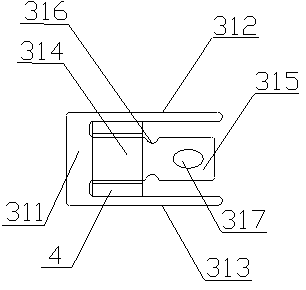

A connector sealing element

The invention provides a connector sealing element and allows the inspection of the existence of the opening which is not correctly formed in terminal insertion holes of the connector sealing part. The connector sealing element comprises a sealing part body and a plurality of terminal insertion holes each of which is provided with an upper diaphragm part and a lower diaphragm part which are mutually separated and which are connected through a thin layer. Preferably, the terminal insertion holes are provided with diaphragms and comprise an approximately bent groove and an approximately bent thin layer. Preferably, the terminal insertion holes are provided with diaphragms with thin layers which are located in the direction which is coincident with a diagonal of a rectangular cross section of the terminals so as to cause the angles of the terminals to collide against the correspondent ends of the thin layers.

Owner:YAZAKI CORP

Semiconductor force sensor

InactiveUS20070234827A1Application of undue force can be preventedAccurate measurementUsing electrical meansForce measurement using piezo-resistive materialsEngineeringForce sensor

A semiconductor force sensor capable of preventing a diaphragm part from being broken and accurately measuring a force applied thereto in a direction orthogonal to the diaphragm part, wherein a force transmitting device for applying a measured force to the diaphragm part of a semiconductor force sensor element is formed of a sphere having a rigidity, and a through hole passing through an opposed wall part toward the diaphragm is formed in the opposed wall parts at a position opposed to the center part of the diaphragm part so that a part of the sphere can face the outside of the opposed wall part and stores a part of the remaining part of the sphere to allow the sphere to be moved only in a direction orthogonal to the diaphragm part and rotated on the center part of the diaphragm part.

Owner:HOKURIKU ELECTRIC INDS

Voice coil diaphragm integrated structure and manufacturing method thereof

The invention discloses a voice coil diaphragm integrated structure and a manufacturing method thereof. The voice coil diaphragm integrated structure comprises a main body and a spherical top, wherein the main body comprises an annular diaphragm part and a tubular voice coil part; and the spherical top is fixed on the outer surface of the annular diaphragm part and covers the outer end opening of the tubular voice coil part. The inner annular edge of the inner surface of the annular diaphragm part integratedly extends inwardly to form the tubular voice coil, a first leading line formed and etched on the outer surface of the annular diaphragm part is matched, a second leading line is formed and etched on the inner surface of the annular diaphragm part, a first voice coil line is etched and formed on the inner surface of the tubular voice coil part, and a second voice coil line is etched and formed on the outer surface of the tubular voice coil part. A traditional split assembly mode is replaced, the voice coil and the diaphragm are firmly combined together, a break-off phenomenon does not happen, the quality of the product can be effectively ensured, the assembly difficulty of the product is greatly reduced, and the production efficiency of the product is improved.

Owner:DONGGUAN TRANSOUND ELECTRONICS

Loudspeaker and terminal equipment

InactiveCN110505557AImprove sound qualityPiezoelectric/electrostrictive transducersTerminal equipmentEngineering

The embodiment of the invention provides a loudspeaker and terminal equipment, relates to the technical field of communication, and aims at solving the problem that the tone quality output by the loudspeaker in the existing terminal equipment is poor. The loudspeaker comprises a non-closed cavity, a vibrating diaphragm part arranged in the cavity and a piezoelectric part arranged on the first surface of the vibrating diaphragm part, the second surface of the vibrating diaphragm part and the first inner surface of the cavity are arranged at intervals, and the first surface of the piezoelectricpart and the second inner surface of the cavity are arranged at intervals; wherein the first surface and the second surface of the vibrating diaphragm component are two opposite surfaces on the vibrating diaphragm component, the first surface and the second surface of the piezoelectric component are two opposite surfaces on the piezoelectric component, and the second surface of the piezoelectric component is in contact with the first surface of the vibrating diaphragm component. The loudspeaker can be applied to the terminal equipment.

Owner:VIVO MOBILE COMM CO LTD

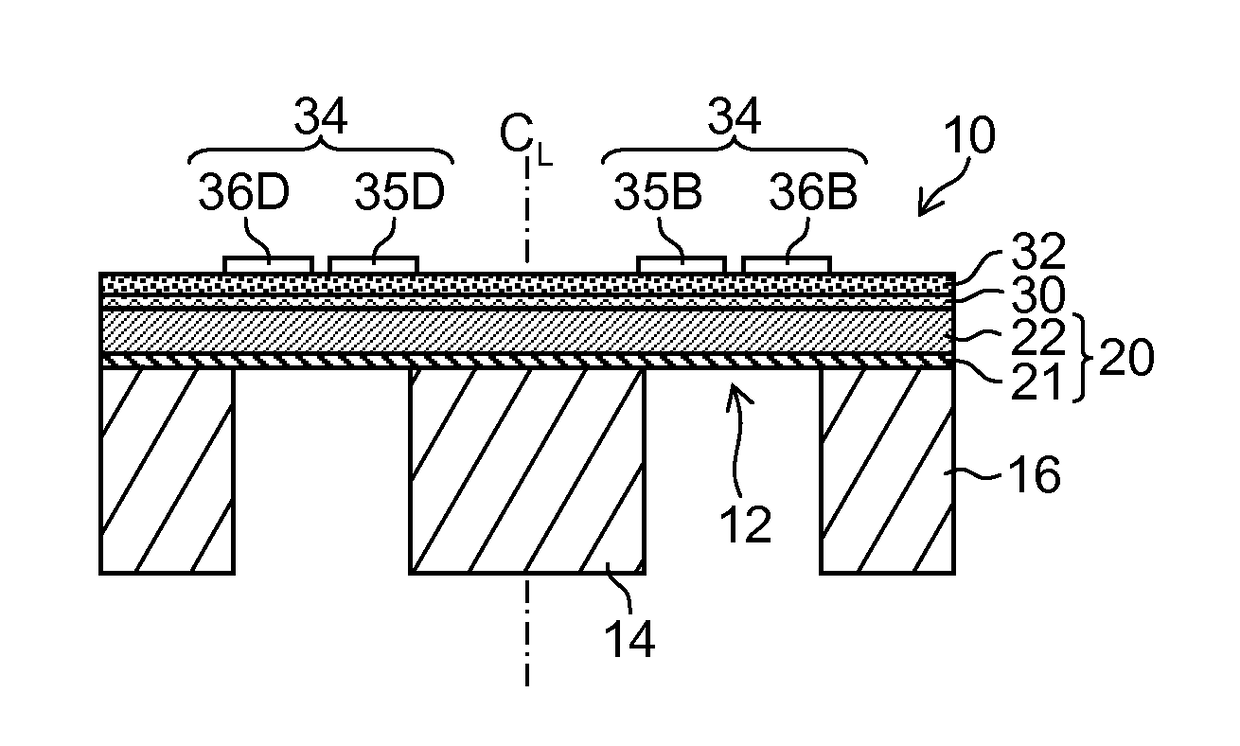

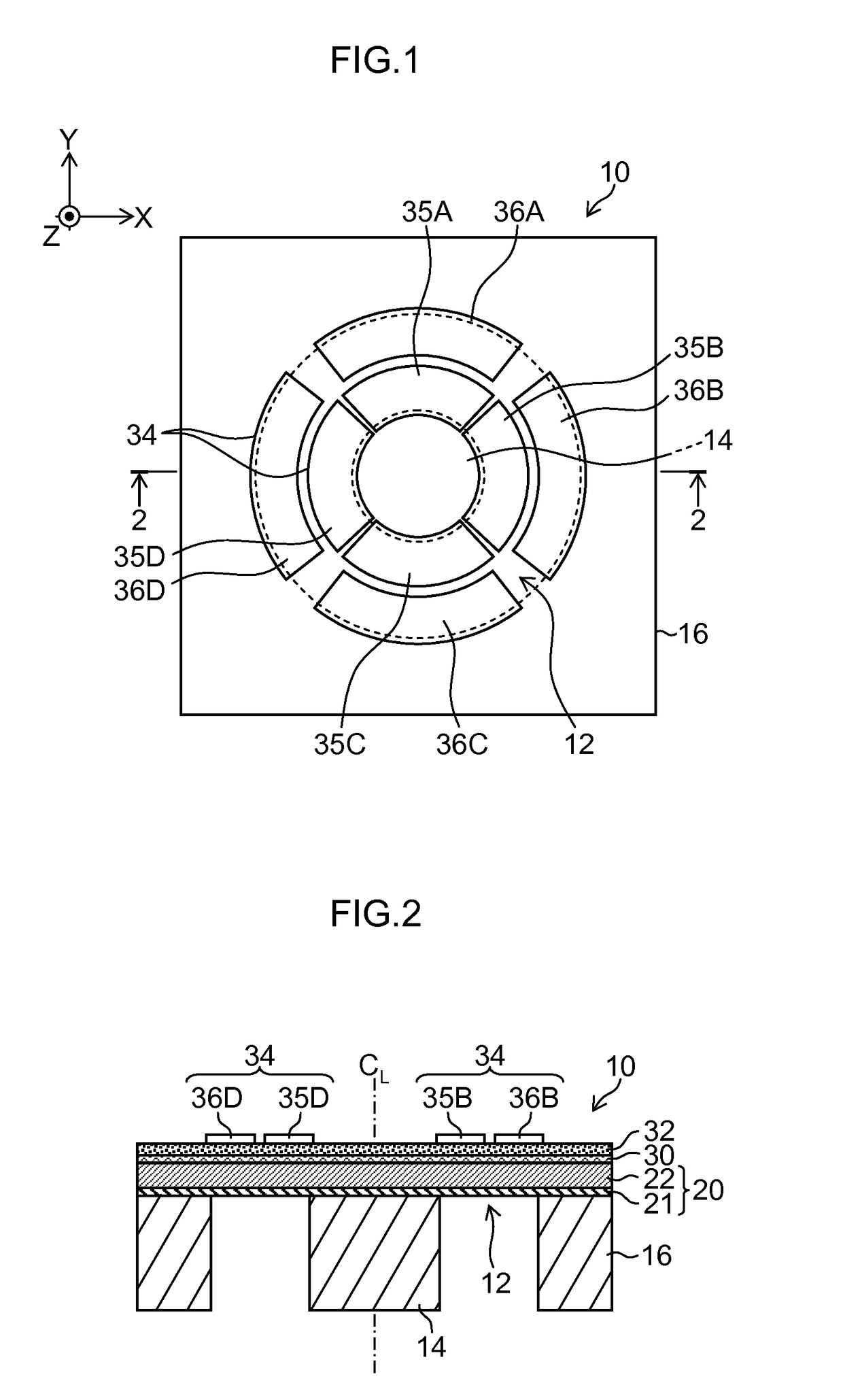

Angular velocity sensor and manufacturing method therefor

ActiveUS9702698B2Increase in costReduced dimensionAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocityResonance vibration

One or more vibration plate layers of a diaphragm part are formed by a thin film forming technique. When a resonance frequency in a resonance vibration mode calculated from dimensions of a structure of an angular velocity sensor and an elastic parameter of a material thereof is defined as f kilohertz, a mass of a weight part is defined as M milligrams, a circumference of the diaphragm part is defined as r meters, a stress applied to a piezoelectric layer is defined as σp pascals, a thickness thereof is defined as tp meters, a stress applied to an n-th layer from the weight part in a vibration plate portion constituted by a plurality of layers including a lower electrode and the vibration plate layers is defined as σn pascals, and a thickness thereof is defined as tn meters (where n is a natural number), Teff expressed by Teff=r(σptp+Σσntn) / M satisfies {(−0.36f2+210) / 33}≦Teff≦{(0.44f2+210) / 33}.

Owner:FUJIFILM CORP

Low-frequency ultra-thin telephone receiver

The invention discloses a low-frequency ultra-thin telephone receiver. A driving mechanism of the low-frequency ultra-thin telephone receiver comprises an armature section and a coil section, wherein the armature section is E-shaped and comprises a base portion, two wing portions and a middle portion, the base portion, the two wing portions and the middle portion are formed in an integrated mode, the middle portion comprises a root part located on the base portion, the root part extends forward to form a vibrating diaphragm part, at least one through hole is formed in the vibrating diaphragm part, and the coil section is arranged on the root part in a sleeved mode at intervals. A shell of the low-frequency ultra-thin telephone receiver comprises an upper shell and a lower shell, wherein the upper shell is arranged at the top of the driving mechanism in a covered mode, and comprises a cover plate and cover edges which are formed by extending downward from the periphery of the cover plate, a first magnet is fixedly connected to a section, covered at the top of the vibrating diaphragm part, of the inner wall of the cover plate, the upper shell is made of magnetically soft alloy, the lower shell is arranged at the bottom of the driving mechanism in a covered mode relative to the upper shell, a second magnet is fixedly connected to the inner wall of the lower shell relative to the first magnet, the lower shell is made of magnetically soft alloy, and a sounding hole is formed in the upper shell or the lower shell. According to the low-frequency ultra-thin telephone receiver, the low-frequency output can be enhanced, and the thickness of an existing telephone receiver is reduced to the largest extent.

Owner:SUZHOU YICHUAN TECH CO LTD

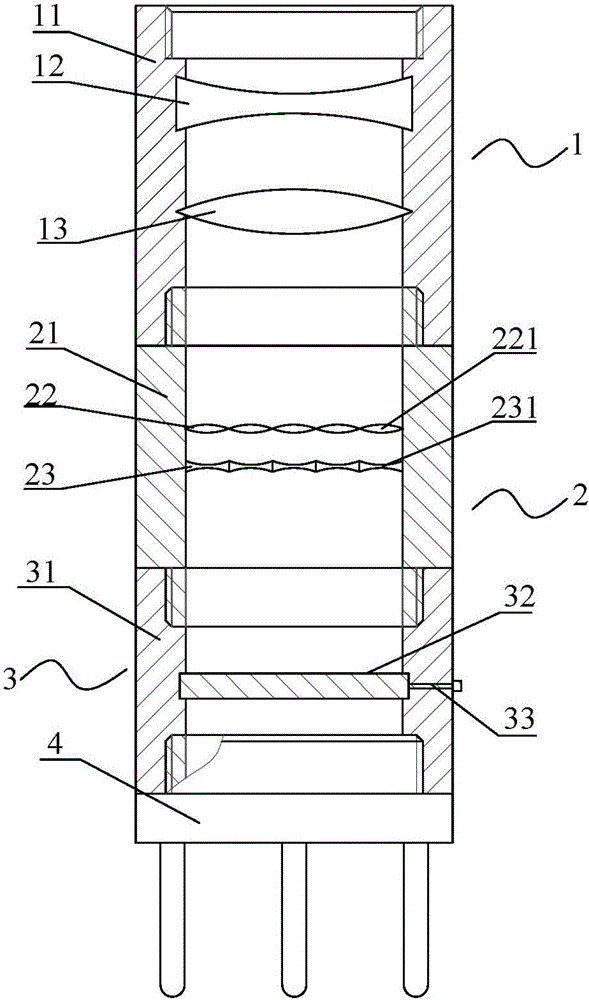

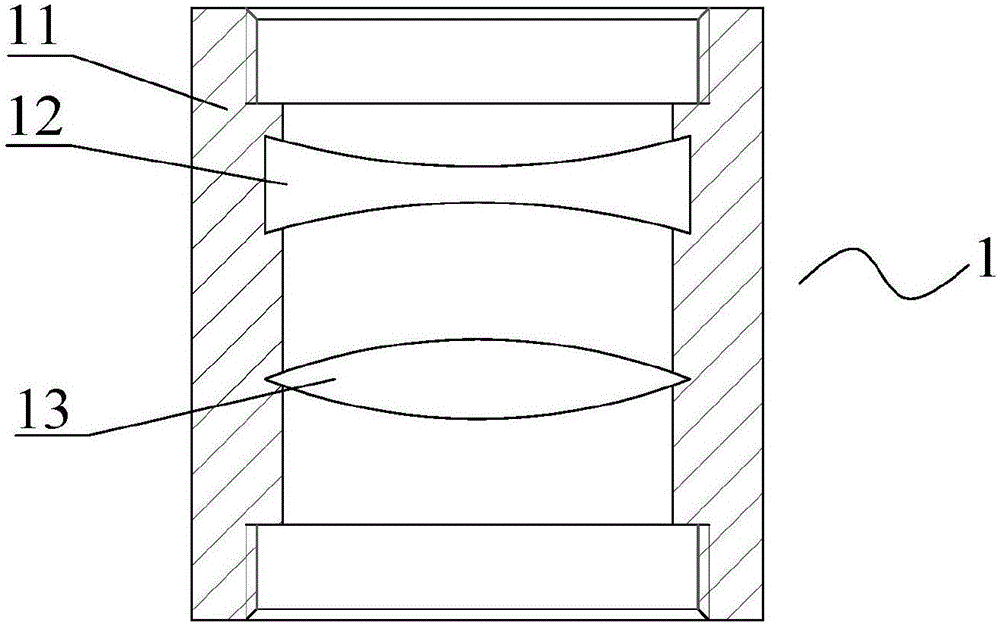

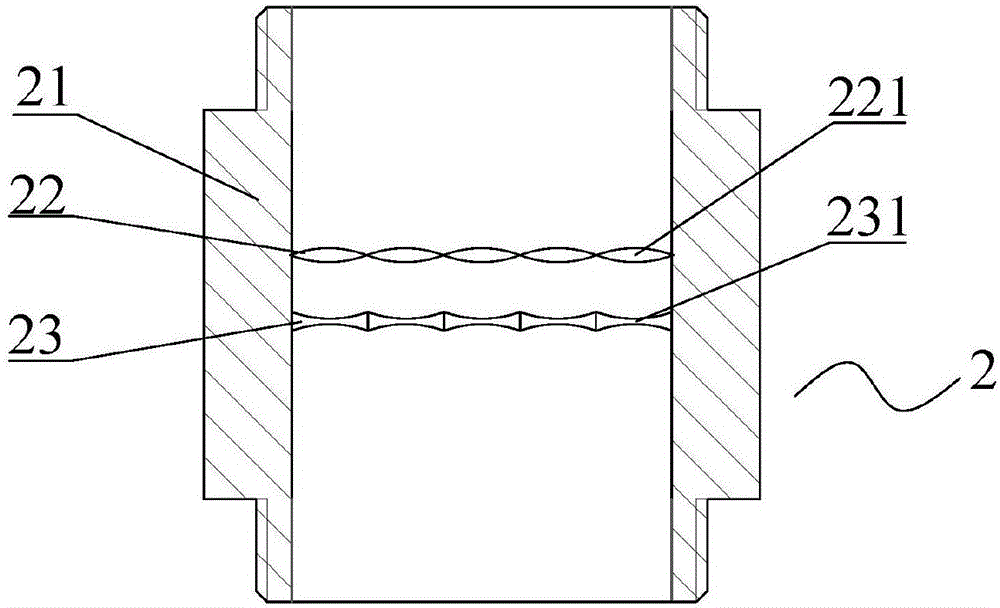

CO2 laser treating hand tool

ActiveCN106725845AUniform strengthNot easy to leave behindSurgical instrument detailsLight beamOptoelectronics

The invention discloses a CO2 laser treating hand tool. The CO2 laser treating hand tool comprises a beam parallel part, a beam dividing part and a diaphragm part connected in sequence from top to bottom, the beam parallel part comprises a first housing body and a beam parallel lens set, and an incident laser beam irradiates into the first housing and passes through the beam parallel lens set to become parallel beam; the beam dividing part comprises a second housing and a beam separating lends set, and a parallel beam irradiated by the beam parallel part irradiates into the second housing and passes through the beam separating lens set to become multiple parallel beams; the diaphragm part comprises a third housing and an iris diaphragm arranged in the third housing, the iris diaphragm is used for adjusting the area of an irradiated beam, and the first housing, the second housing and the third housing are connected in sequence and the upper ends and the lower ends of the first housing, the second housing and the third housing are all opened. The CO2 laser treating hand tool improves the operability of a treating doctor, achieves the purpose of accordingly adjusting the size of a CO2 laser beam facula according to angiomas with different sizes, avoids the unnecessary laser injury, and improves the treating effect.

Owner:HAIKOU REDUP COSMETIC +1

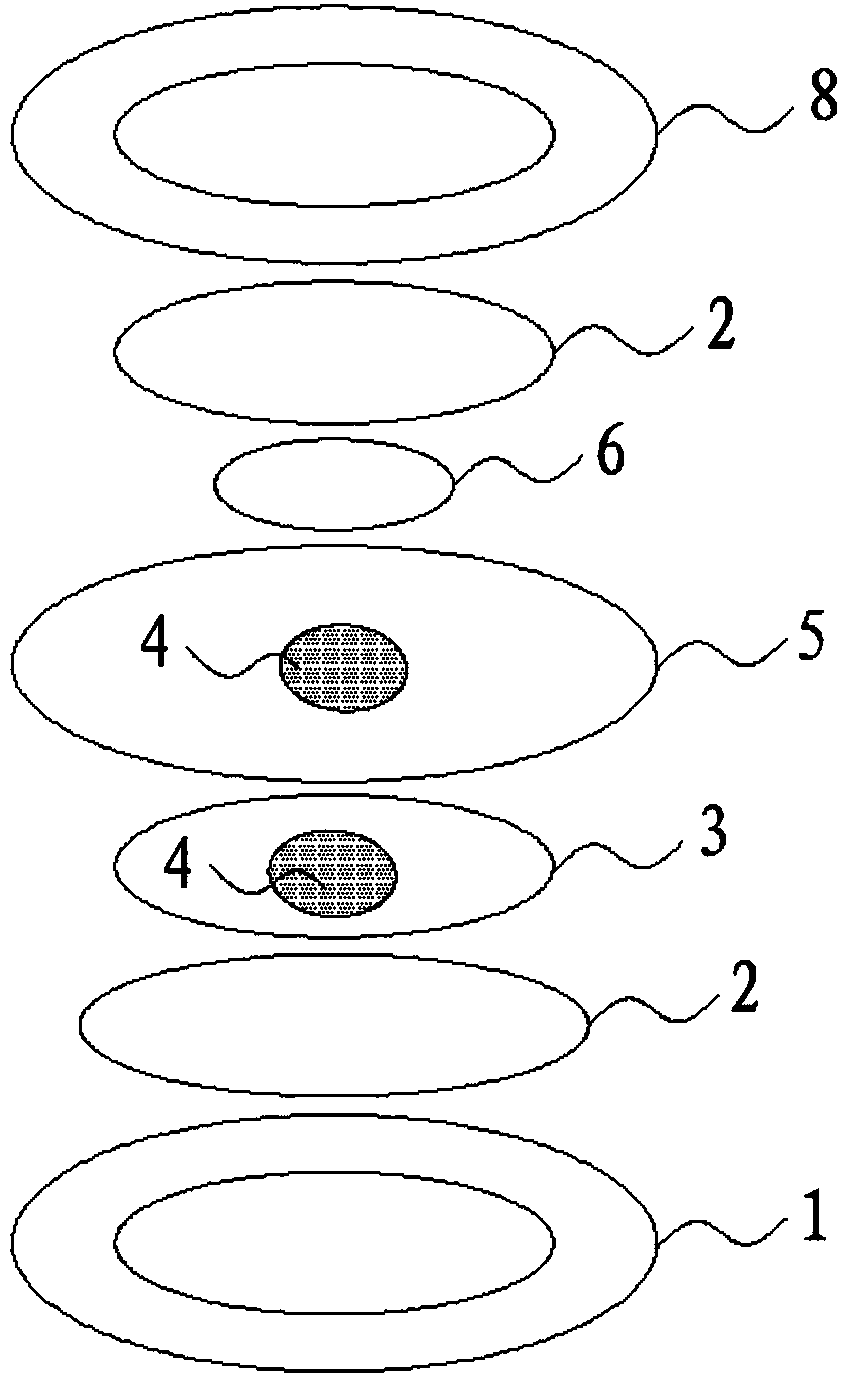

Assembling method for lithium-ion button type battery

InactiveCN108281696AQuick assemblyEfficient assemblyCell seperators/membranes/diaphragms/spacersFinal product manufacturePole pieceLithium-ion battery

The invention relates to the technical field of lithium-ion batteries, in particular to an assembling method for a lithium-ion button type battery. The assembling method for the lithium-ion button type battery comprises the following steps: clamping a diaphragm by using tweezers, slightly placing the diaphragm on a negative pole shell, and wetting a large diaphragm part and a small diaphragm partof a metal lithium piece by using electrolyte; adding a droplet of electrolyte on the diaphragm dropwise; clamping a pole piece by using the tweezers, and slightly placing the pole piece on the electrolyte on the diaphragm; clamping a gasket by using the tweezers, and slightly placing the gasket on the pole piece; clamping one side of a positive pole shell by using the tweezers, and slightly covering the negative pole shell with the positive pole shell; slightly pressing the positive pole shell by using the tweezers; clamping an assembled battery by using the tweezers, and placing the assembled battery in an electric sealing machine for sealing. According to the battery which is assembled by adopting the method provided by the invention, the lithium piece and the gasket of the negative pole shell cannot be in contact with the positive pole shell by only placing one gasket on each side of the positive pole shell and the negative pole shell without foam nickel and a spring piece, so thata short circuit in the battery is avoided; the battery assembling time is shortened; the assembling of a button type button can be completed quickly and efficiently; the accuracy and the consistencyof the button type battery are greatly improved; the assembling method for the lithium-ion button type battery is suitable for laboratory evaluation, and is very suitable for evaluating material performance by an electrochemical method.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

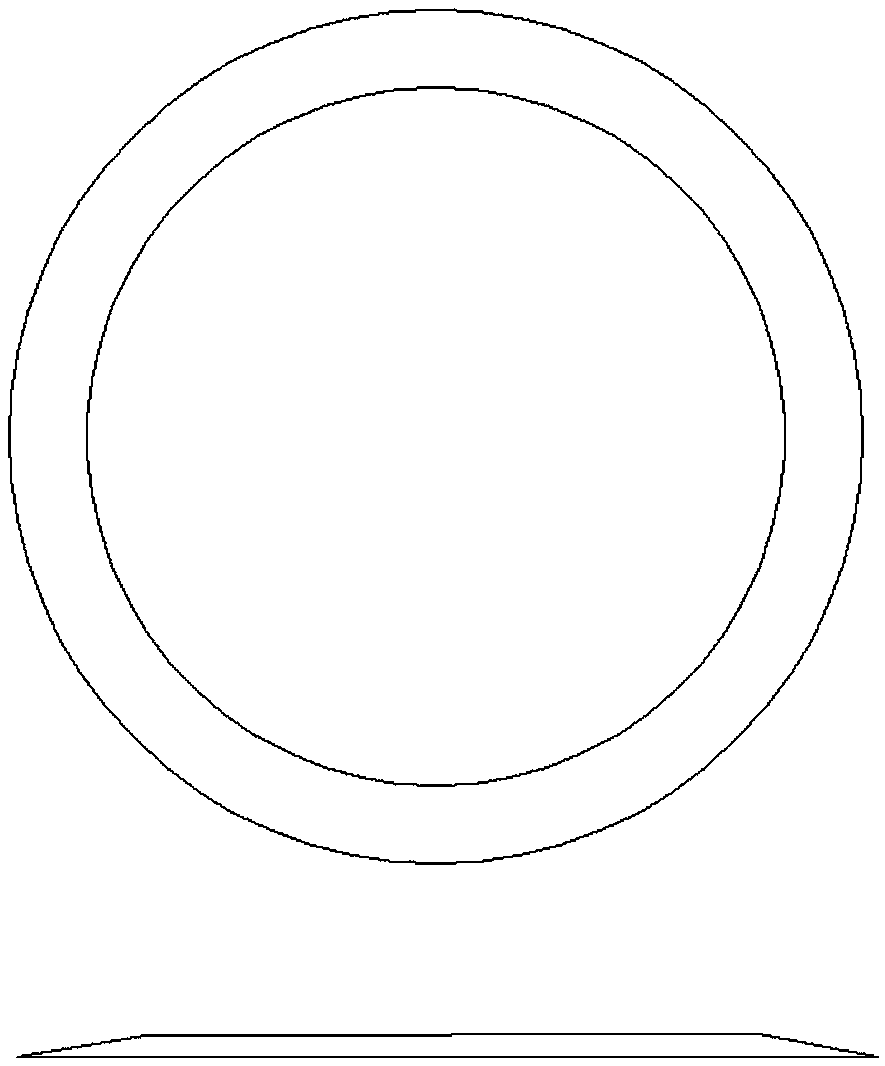

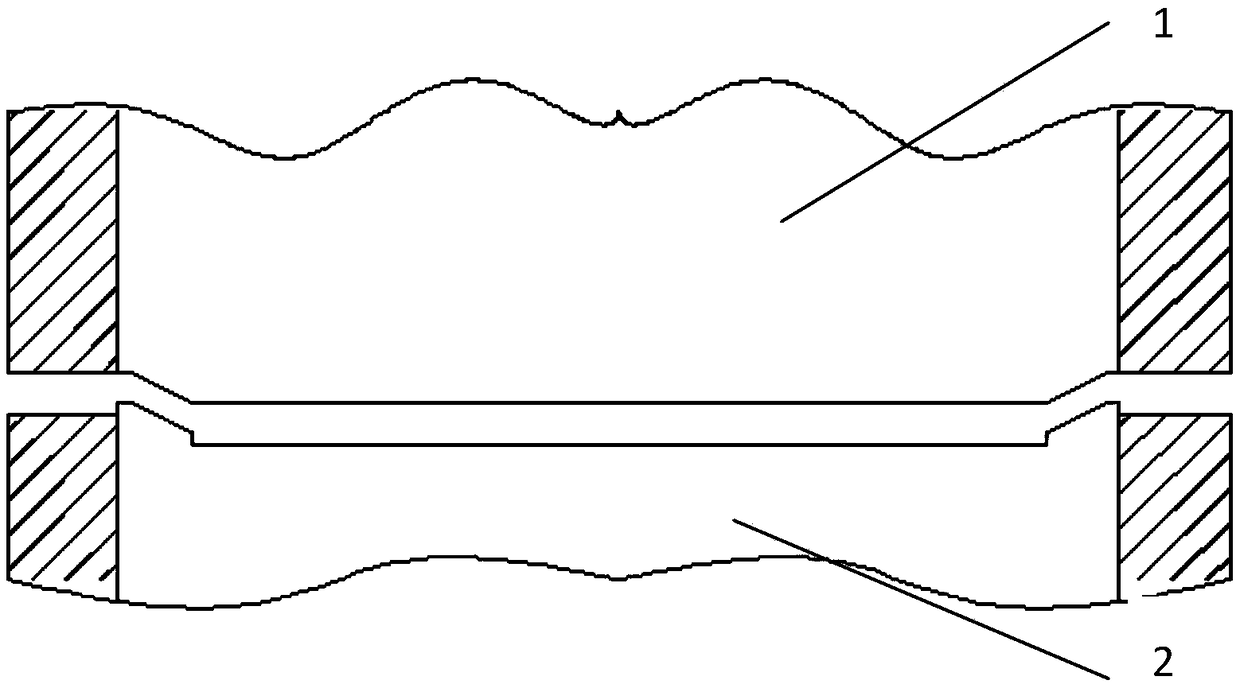

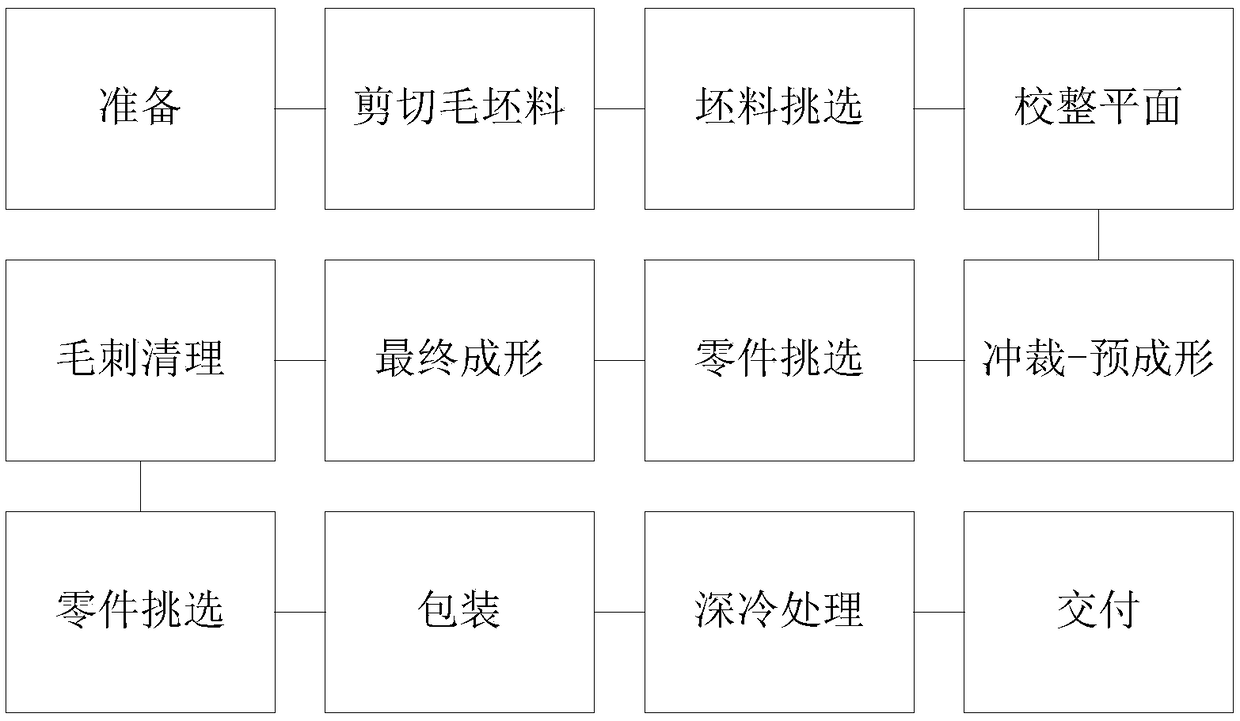

Optimized stamping forming process method of accumulator diaphragm capsule diaphragm

ActiveCN109332482AImprove flatnessGood stamping processMetal-working apparatusElement analysisEngineering

The invention relates to an optimized stamping forming process method of an accumulator diaphragm capsule diaphragm. The optimized stamping forming process method of the accumulator diaphragm capsulediaphragm comprises the following steps that (1) a stamping blank is optimized to improve the flatness of the blank; (2) a stamping process is optimized, forming is achieved in two steps; and (3) a reasonable rebound value of a die is determined. Before the parts are machined, bending angles of the parts in the two stages of blanking-pre-forming and final forming are reasonably distributed. Beforeforming, a finite element analysis tool can be used for simulation calculation to obtain a distribution value; and then the die test verification of the die is carried out, the test result is evaluated, and the die size is corrected appropriately. Through a series of iterative analysis, structural parameters of the die can be finally determined, mainly the bending springback angle value is determined. Through the corrected rebound, the final size of the diaphragm parts can be ensured.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

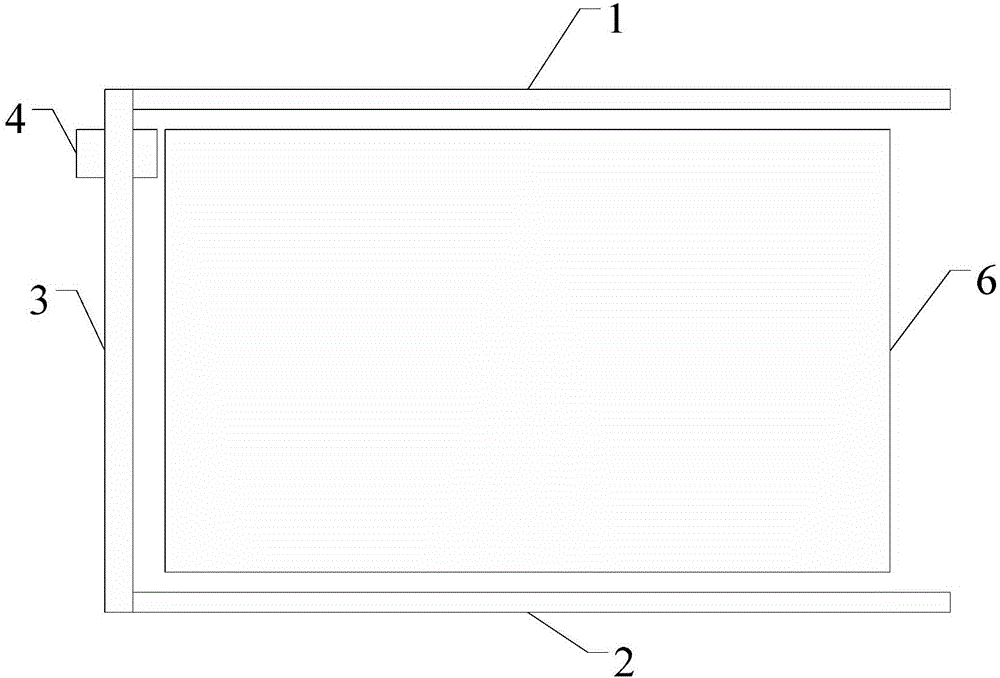

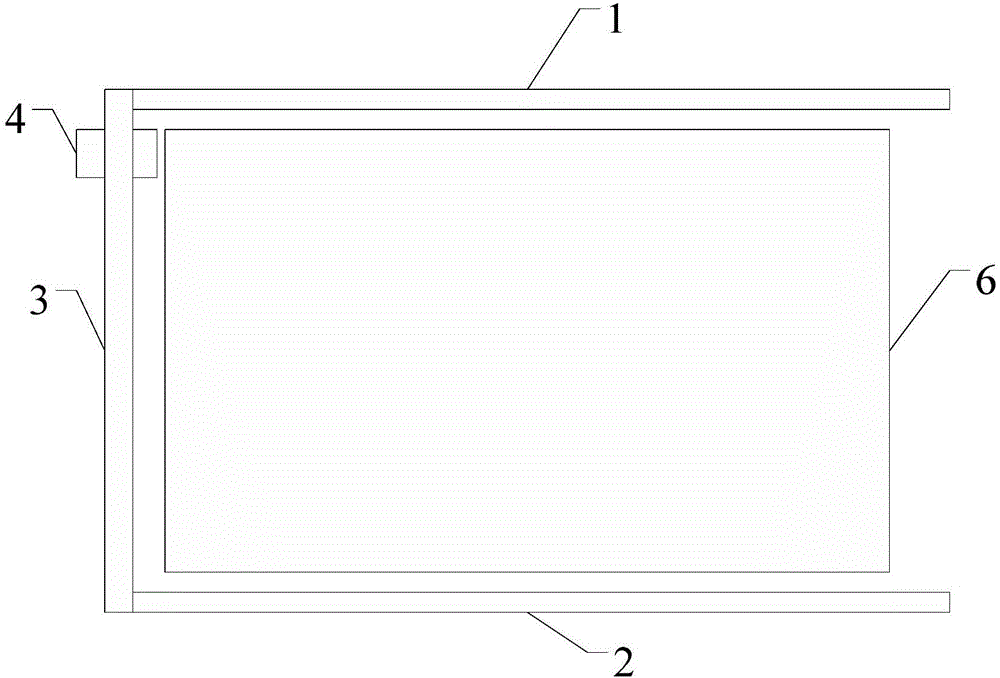

Blackboard with dust collecting function

ActiveCN106114010AReduce soaringAvoid flyingBoard cleaning devicesWriting boardsEngineeringRubber sheet

The invention discloses a blackboard with a dust collecting function. The blackboard comprises a blackboard body, a side framework, an eraser base, a collecting slot, a water storage cavity, an ejector rod, a first drive mechanism, a second drive mechanism and a control device; the bottom of the collecting slot is backwards extended with an inserting part; an insert slot is formed in the lower end part of the eraser base; the inserting part is inserted into the insert slot, so that the collecting slot is connected to the lower side part of the eraser base; the water storage cavity is formed inside the plate eraser base, a water penetrating hole is formed inside the lower side part of the eraser base; the water penetrating hole is equipped with a diaphragm part which is composed of a pair of rubber sheets; the middle parts of the pair of the rubber sheets are superposed with each other; the ejector rod is arranged in the collecting slot; the blackboard body abuts against one end of the ejector rod, and the other end of the ejector rod applies pressure to the diaphragm part, so that the middle parts of the pair of the rubber sheets are separated from each other; and the control device controls the first drive mechanism and the second drive mechanism to alternatively work. The blackboard realizes automatically erasing chalk writings on the blackboard body.

Owner:NANNING YUANZHUO NEW ENERGY TECH CO LTD

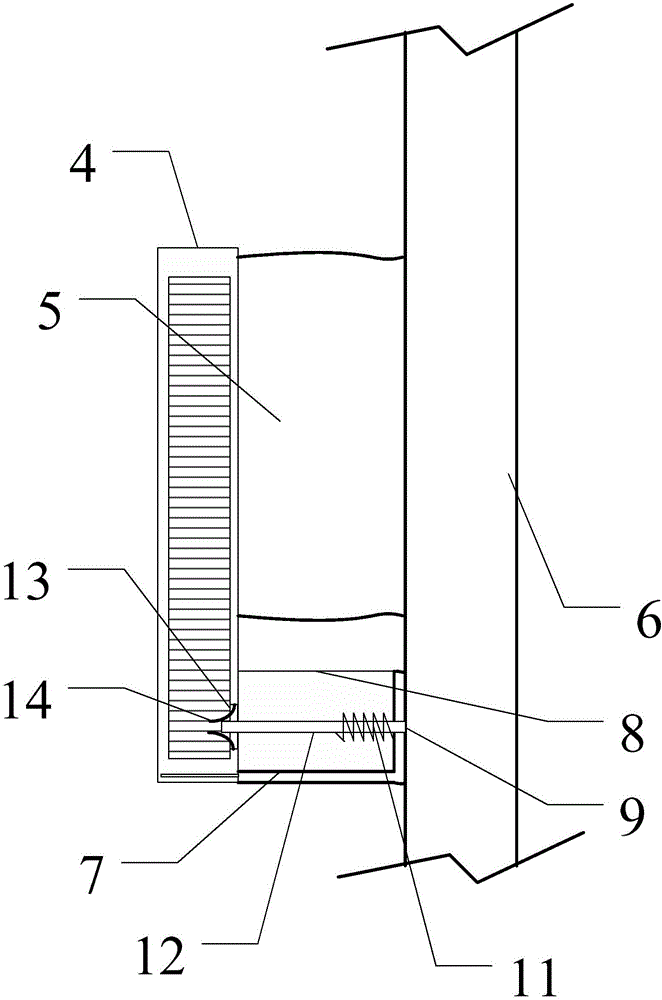

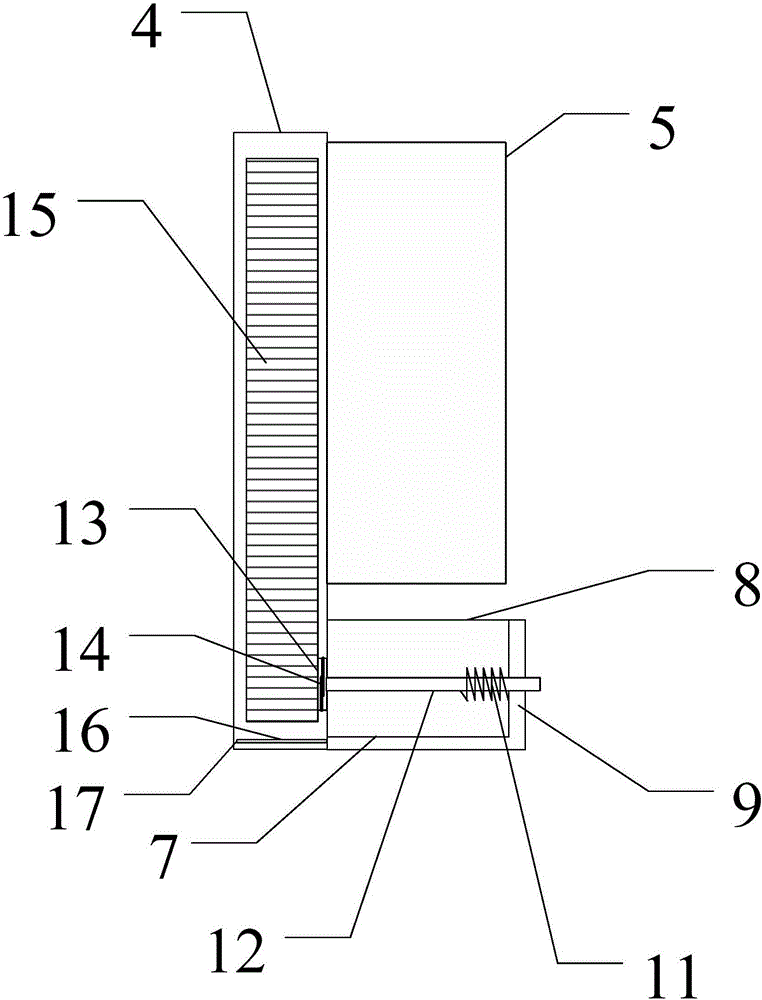

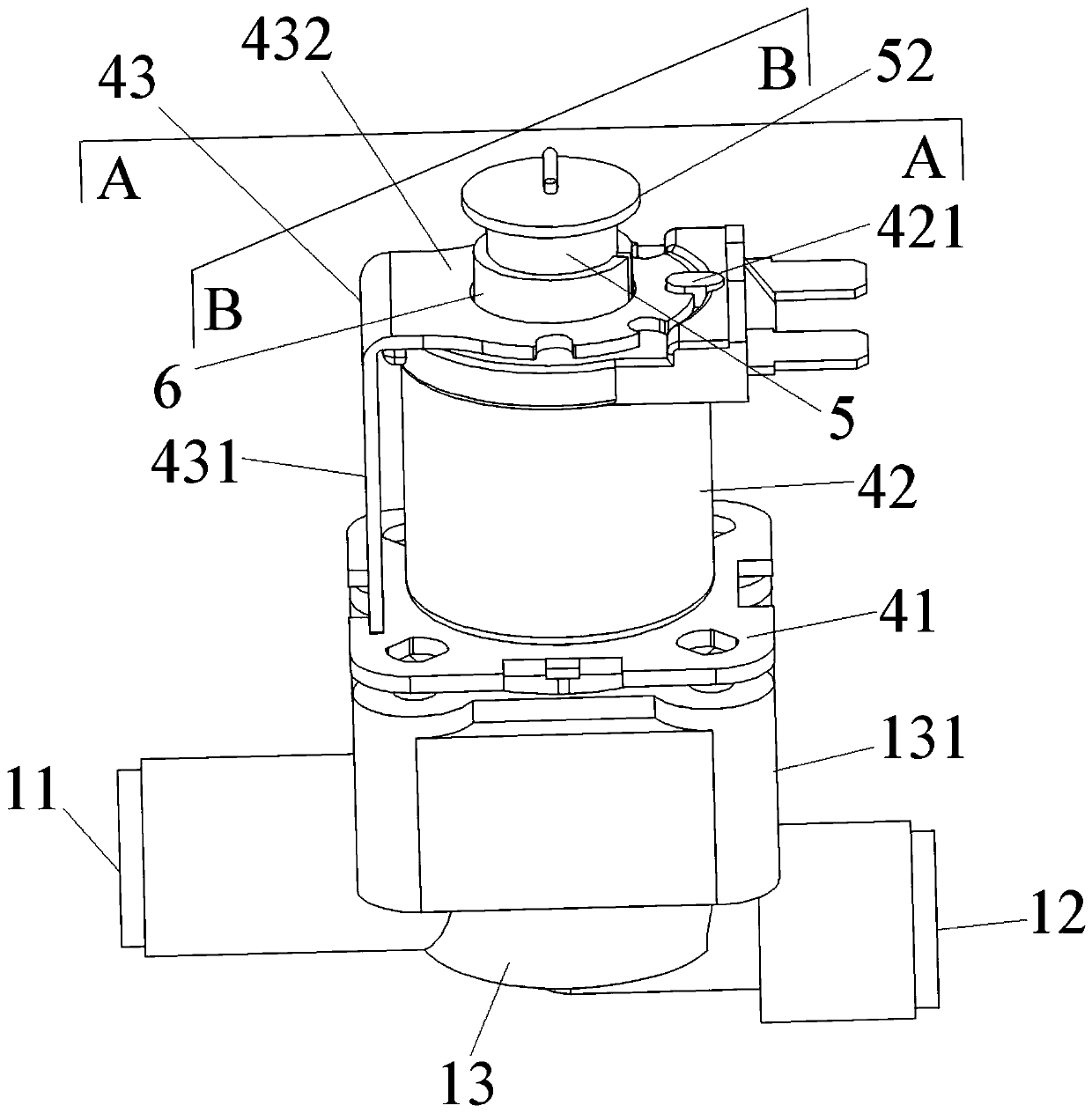

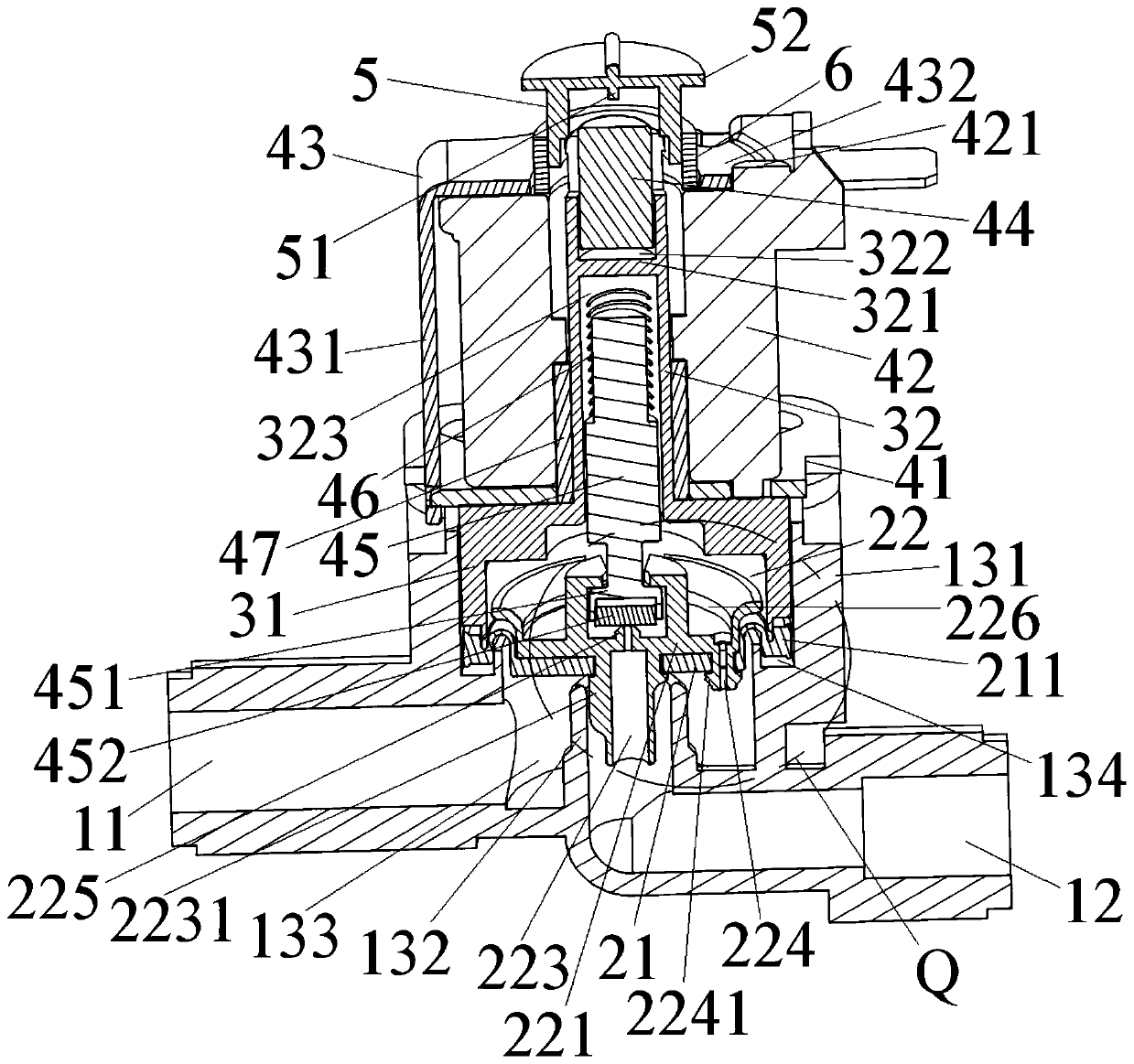

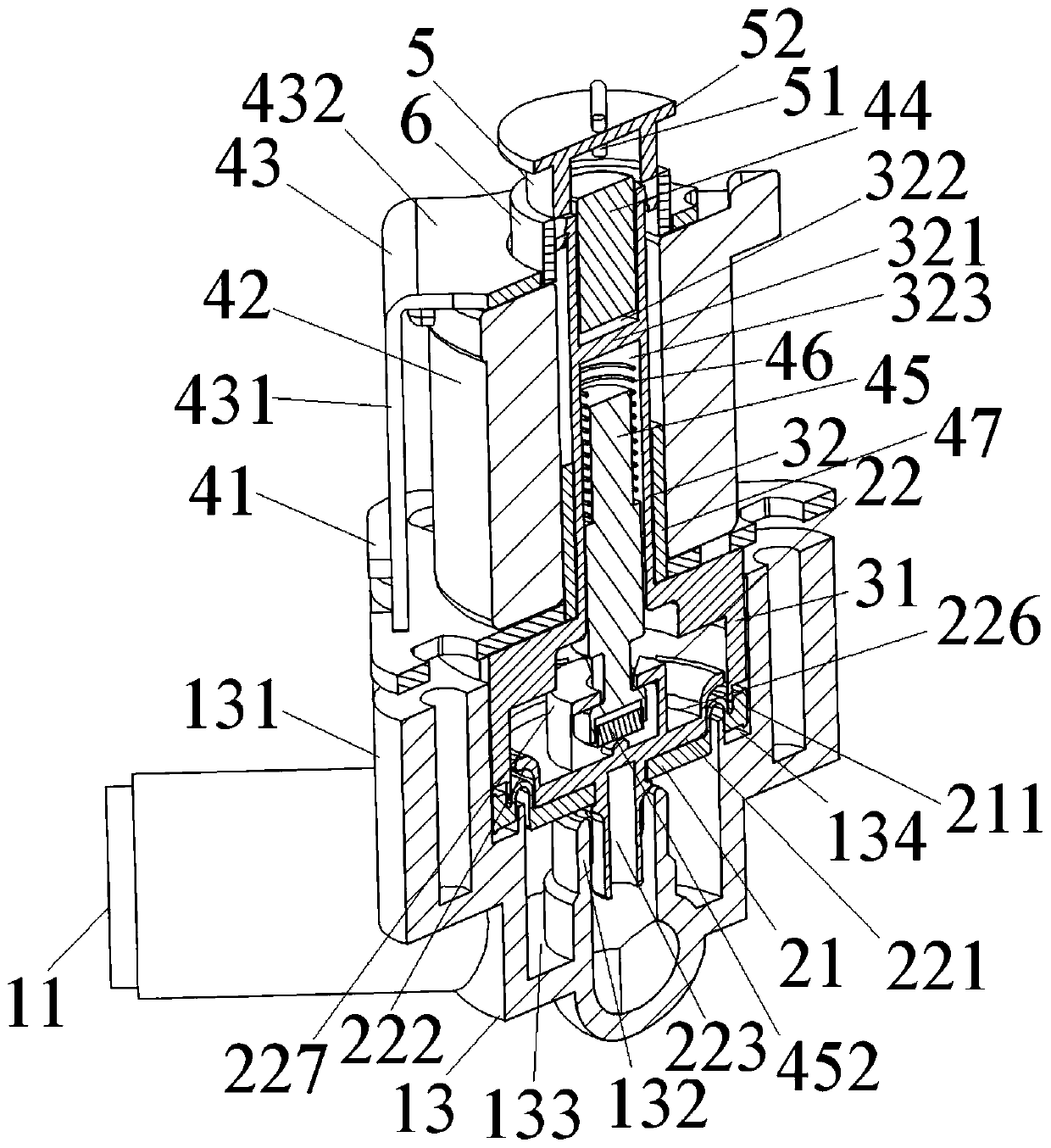

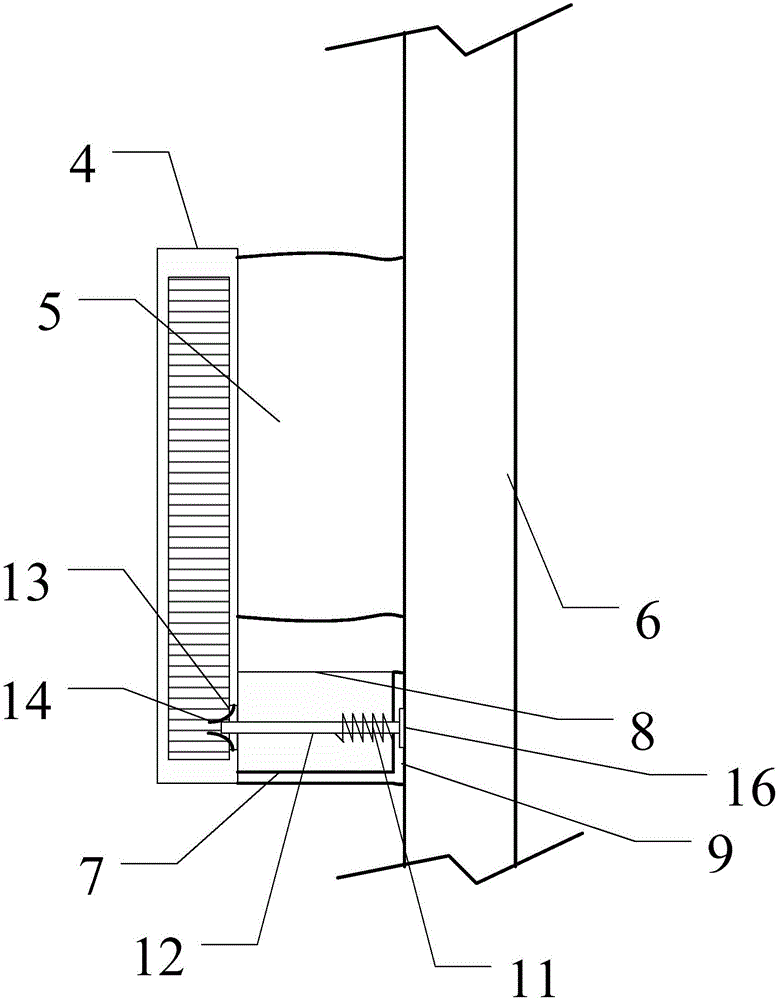

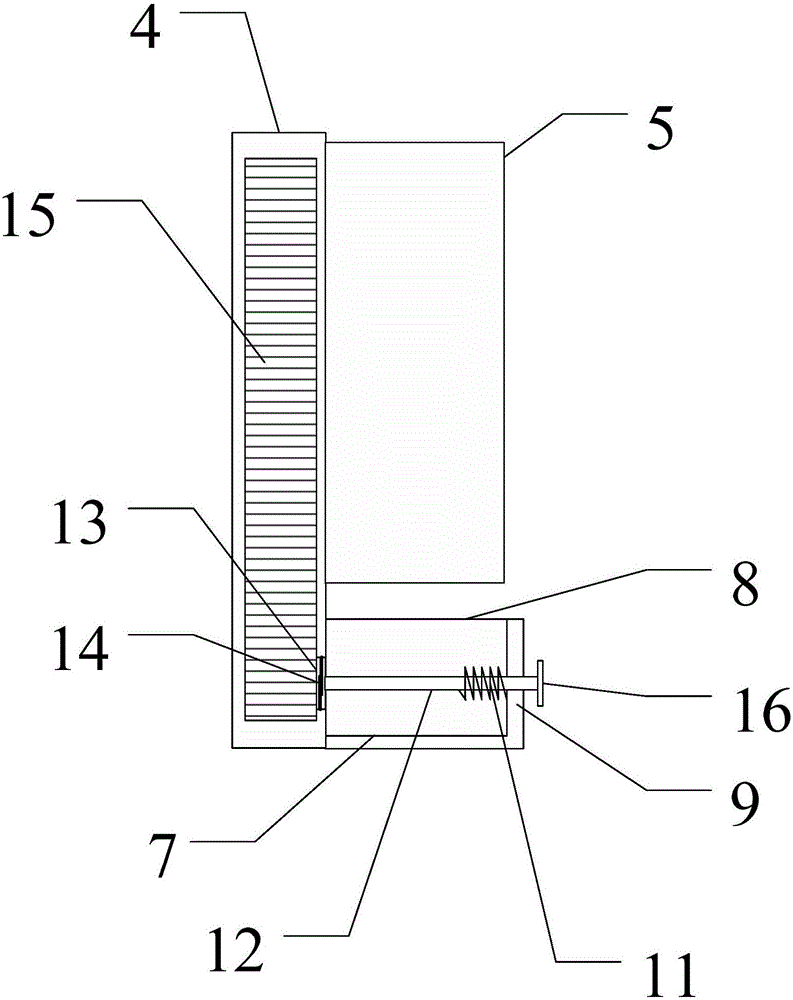

Solenoid valve diaphragm installation structure

InactiveCN106286951AAvoid damageSimple structureDiaphragm valvesOperating means/releasing devices for valvesElastic componentSolenoid valve

The invention discloses a solenoid valve diaphragm installation structure, which belongs to the technical field of electromagnetic relays, and comprises two opposite cover plates and a valve body arranged between the cover plates. A push rod is arranged in the valve body; upper diaphragms are arranged around the push rod; a support seat is arranged between the upper diaphragms and the cover plates; elastic components are arranged between the support seat and the cover plates; support brackets are arranged on edges between the upper diaphragms and the valve body. According to the technical scheme, the support seat is arranged between the cover plates and the upper diaphragms, so that the structure of each cover plate is simplified; the elastic components are arranged between the support seat and the cover plates, so that the pressure deformation borne by the push rod and the upper diaphragms is transferred to the elastic components on the lower parts; with diaphragm installation slot structures on the upper diaphragm parts, the push rod and the upper diaphragms are stressed in a balance way, so that the damage caused by pressure force on the diaphragms is reduced, and the service life of an electromagnetic relay is prolonged.

Owner:贵州新安航空机械有限责任公司

Fluid control device

Owner:ALPS ALPINE CO LTD

Low-pressure pulse electromagnetic valve

PendingCN111059340AReduce use costLess power consumptionOperating means/releasing devices for valvesLift valveTap waterEngineering

The invention relates to the technical field of electromagnetic valves. The low-pressure pulse electromagnetic valve aims to solve the problem that the water pressure of tap water in an old communityis unstable and the water pressure is small. The invention provides a low-pressure pulse electromagnetic valve, wherein a valve base is provided with an inner tube, a clamping groove and an overflow groove; a positioning convex ring on a diaphragm pad is clamped in the clamping groove, a diaphragm part is pressed on the diaphragm pad, and a water inlet tube and a water outlet tube are inserted into the overflow groove and the inner tube respectively, a positioning frame is inserted into the valve base and is pressed on the positioning convex ring, and a partition plate is arranged in a guide tube to form a magnet accommodating cavity and a piston accommodating cavity; a base plate sleeves the guide tube and is fixed at the top of the valve base, a coil is arranged on the guide tube in a sleeving manner and is inserted and fixed on the base plate, a coil clamping frame is connected with the coil and the base plate to fix the coil, a strip magnet is located in the magnet accommodating cavity, a piston is inserted into the piston accommodating cavity and can be pressed on an inlet pipe table, a blocking cap is arranged at the upper end of the guide tube in a sleeving manner, an iron column is arranged inside the blocking cap, and a magnet ring is sleeved outside blocking cap. According to the low-pressure pulse electromagnetic valve, the low-pressure water supply can be realized,and the power consumption is low.

Owner:上海肇民新材料科技股份有限公司

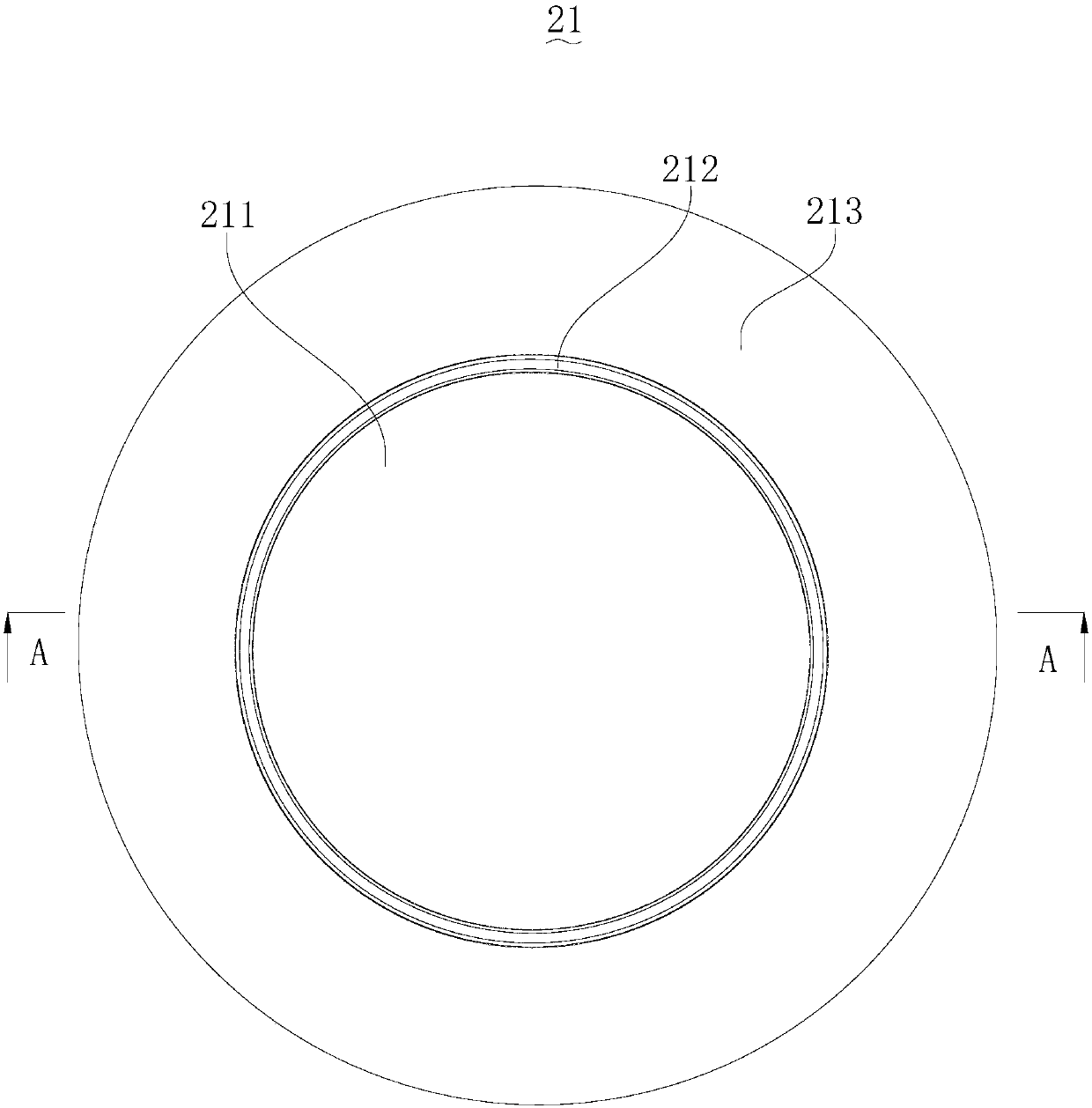

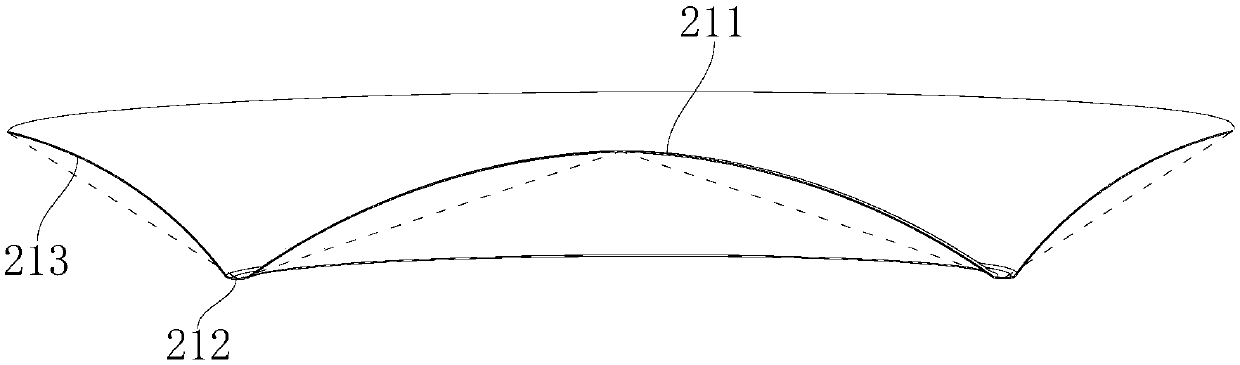

Metal vibrating diaphragm and loudspeaker

PendingCN110418248AAvoid deformationForce prevention of deformationNon-planar diaphragms/conesDiaphragm mounting/tensioningEngineeringLoudspeaker

The invention belongs to the field of electroacoustic products, and particularly relates to a metal vibrating diaphragm and a loudspeaker. The metal vibrating diaphragm comprises a dome-shaped hemispherical diaphragm part; the periphery of the semispherical film part extends in the horizontal direction to form an annular flat film part, the periphery of the annular flat film part is turned over inthe protruding direction of the semispherical film part and continues to extend away from the semispherical film part to form a horn-shaped film part, and the height of the outer periphery, away fromthe semispherical film part, of the horn-shaped film part is larger than that of the dome of the semispherical film part. When the metal vibrating diaphragm vibrates, the force which enables the metal vibrating diaphragm to deform can be partially or completely counteracted. The metal vibrating diaphragm is prevented from deforming, so that the rigidity of the metal vibrating diaphragm is improved, the thickness of the metal vibrating diaphragm is reduced and the damping characteristic of the metal vibrating diaphragm is improved under the condition of certain rigidity, the segmentation distortion of the metal vibrating diaphragm at high frequency is weakened, and the normal vibration sounding of the metal vibrating diaphragm is ensured.

Owner:SHENZHEN GRANDSUN ELECTRONICS CO LTD

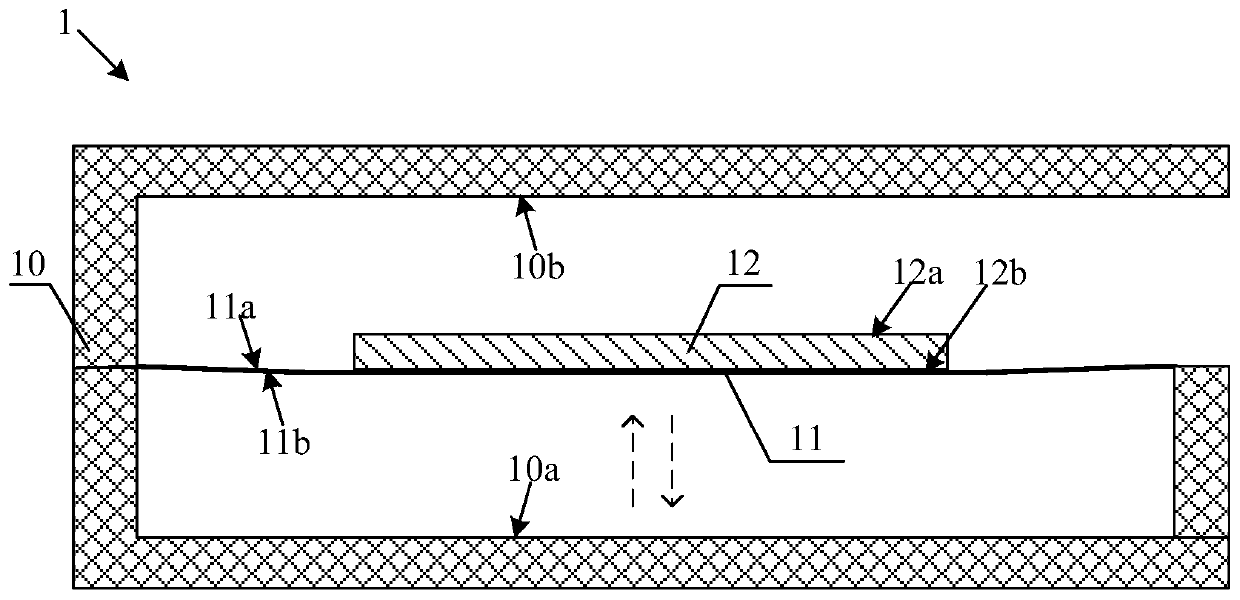

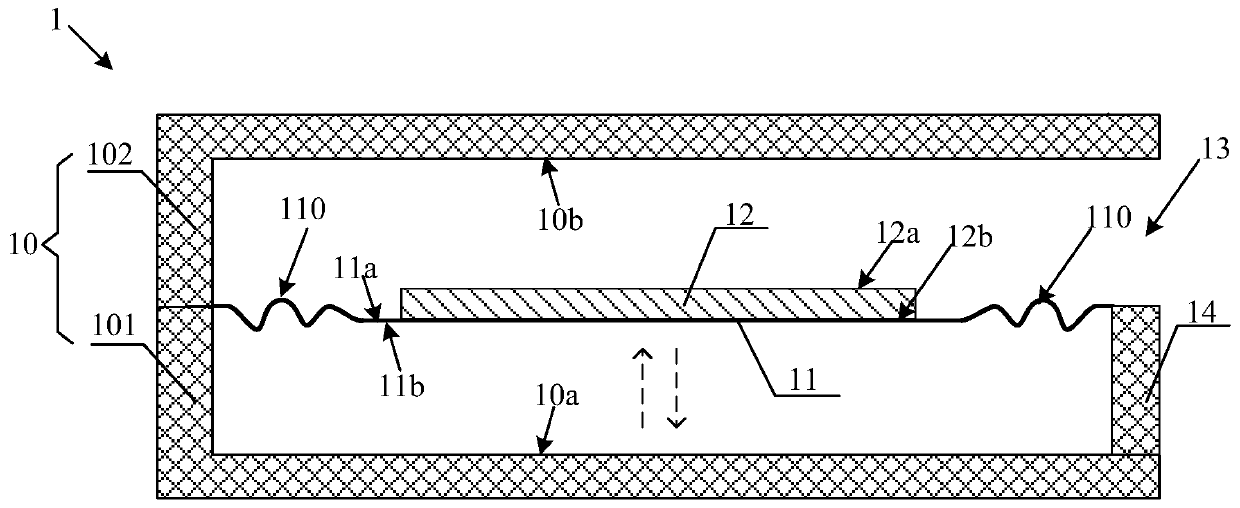

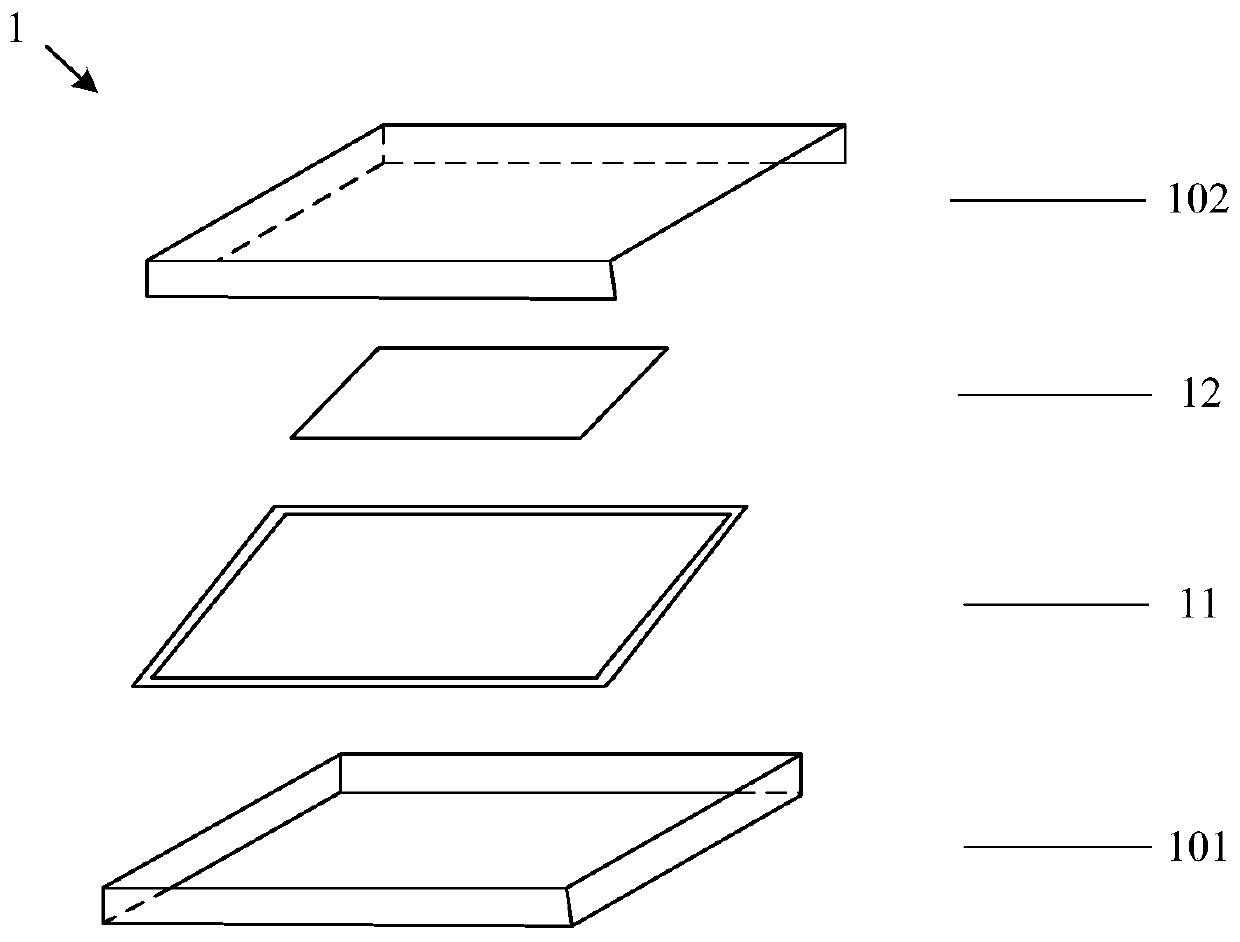

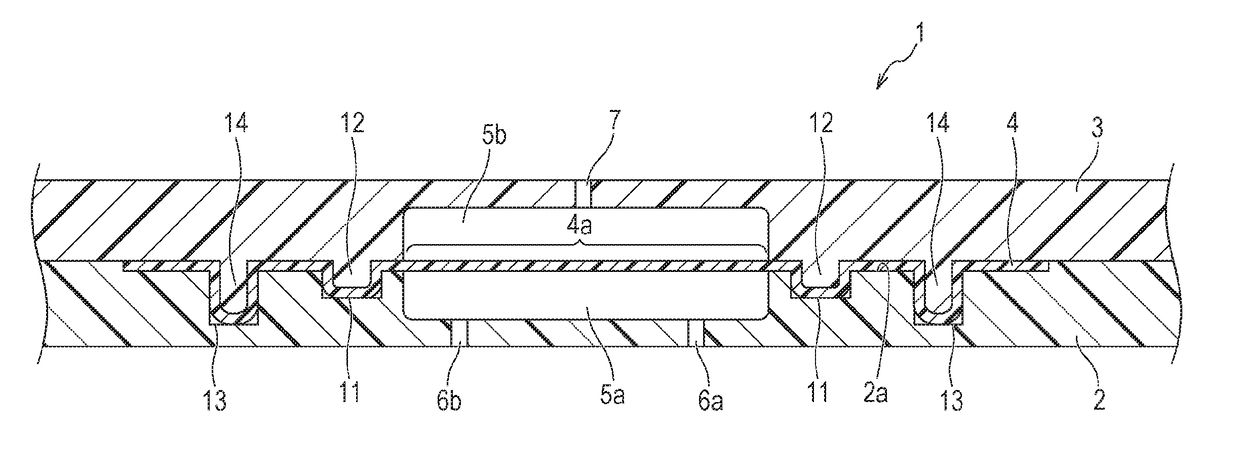

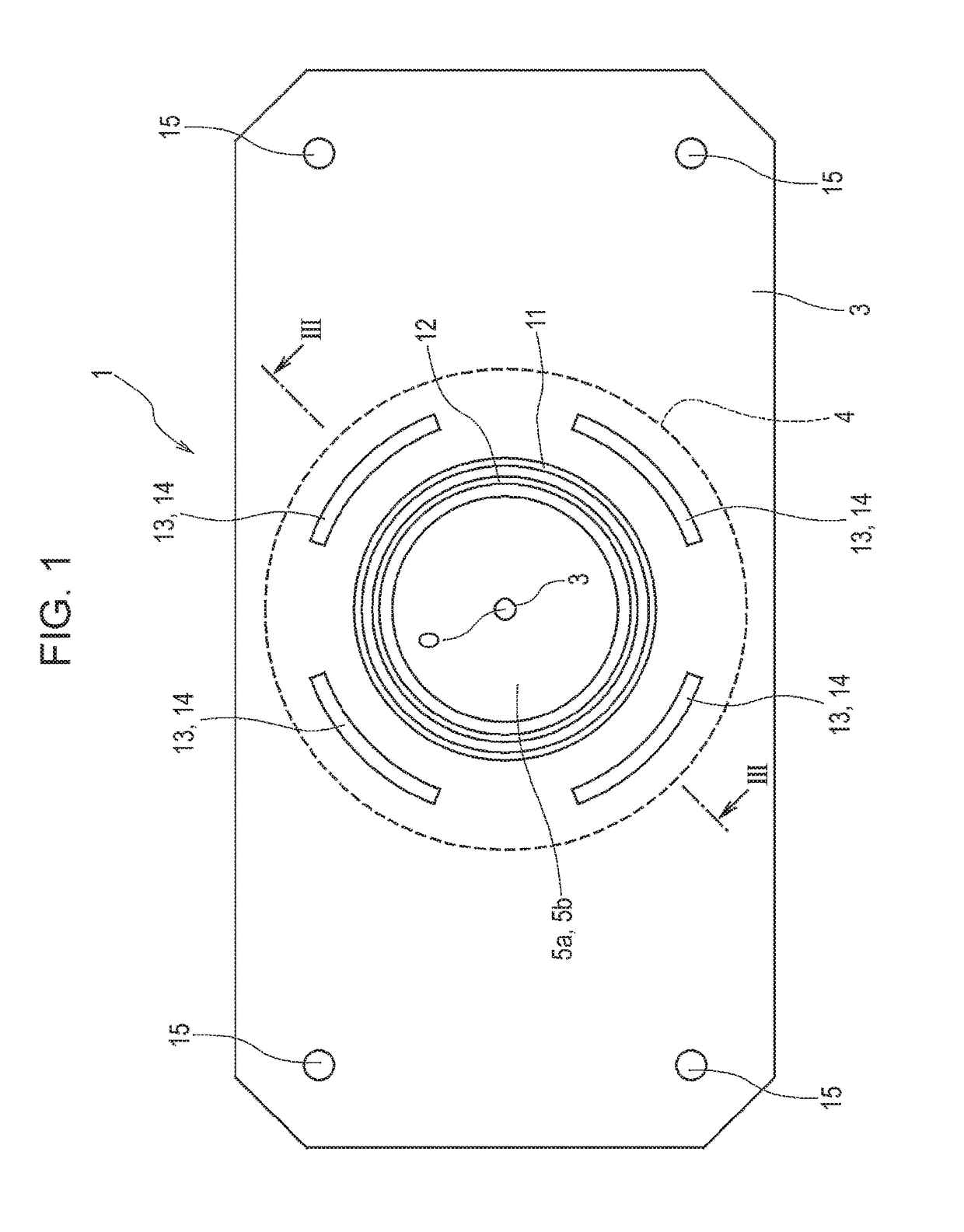

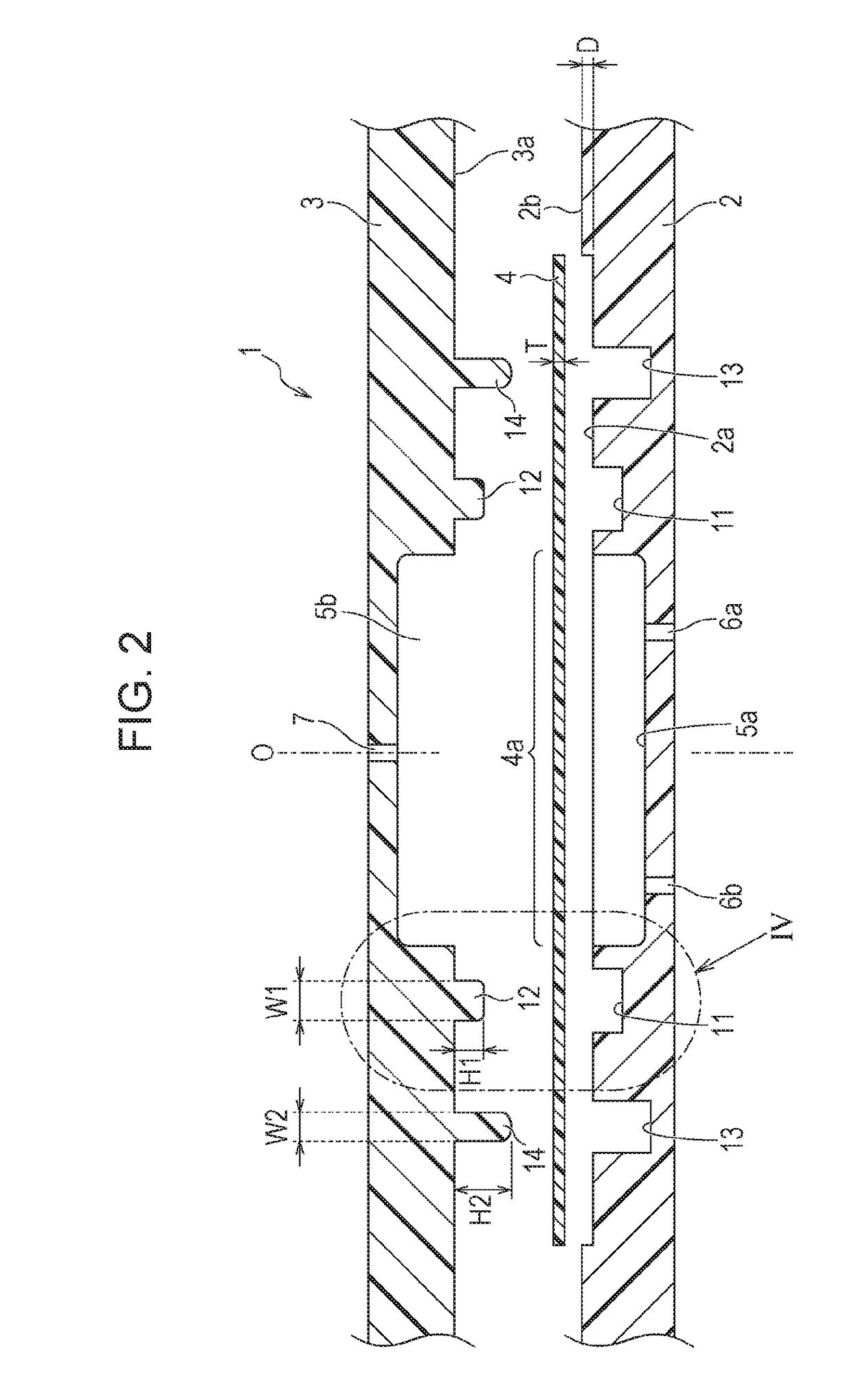

Fluid control device

A film is sandwiched between a first plate and a second plate. Outer convex parts formed on the second plate are formed so that their protrusion height dimension is larger than that of an inner convex part. Each outer convex part is formed so that its width dimension is smaller than the inner convex part. When the first plate and second plate are face-joined together, the film is sandwiched between outer concave parts and the outer convex parts, after which the film is sandwiched between an inner concave part and an inner convex part and a tension is applied to a diaphragm part stretched in concave flow paths.

Owner:ALPS ALPINE CO LTD

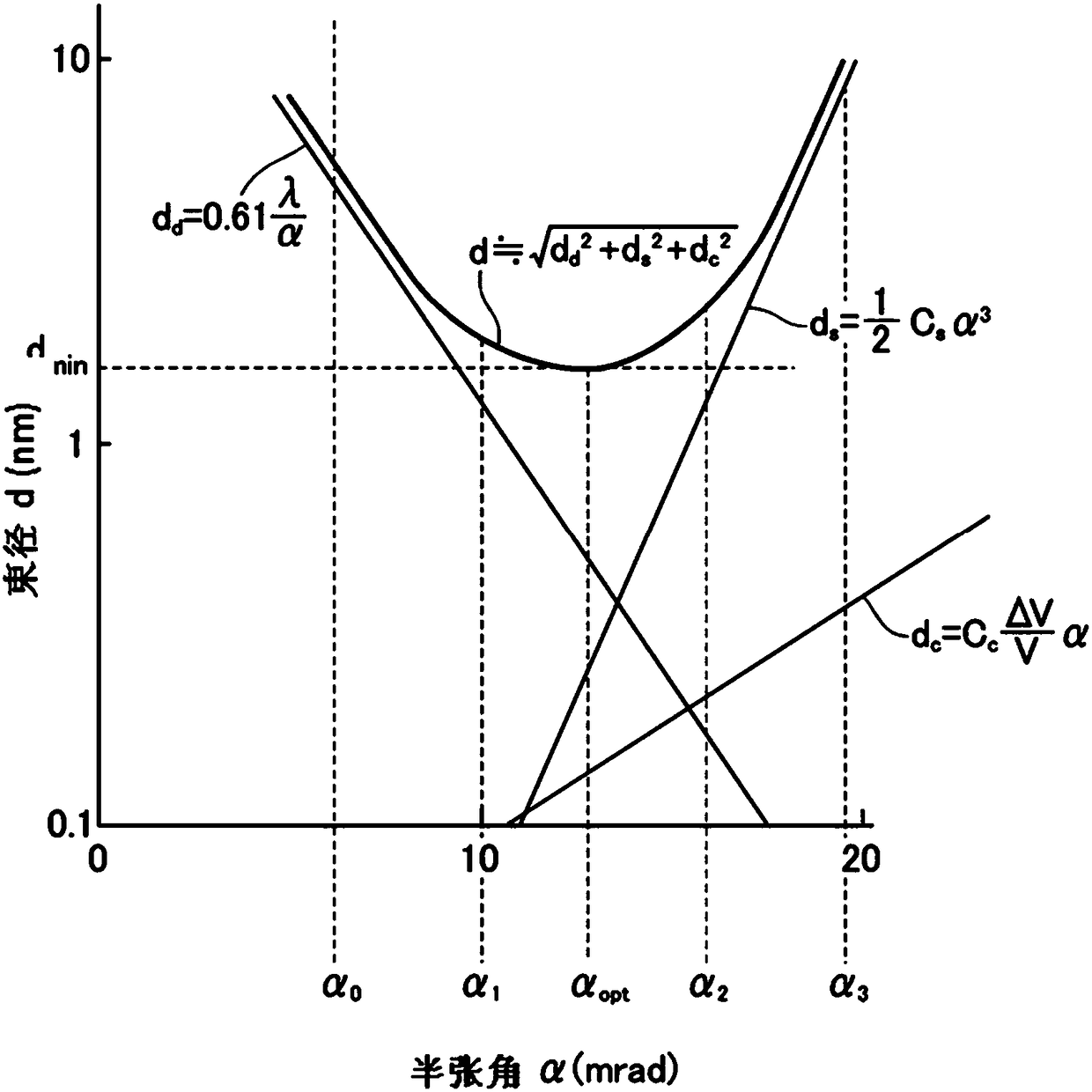

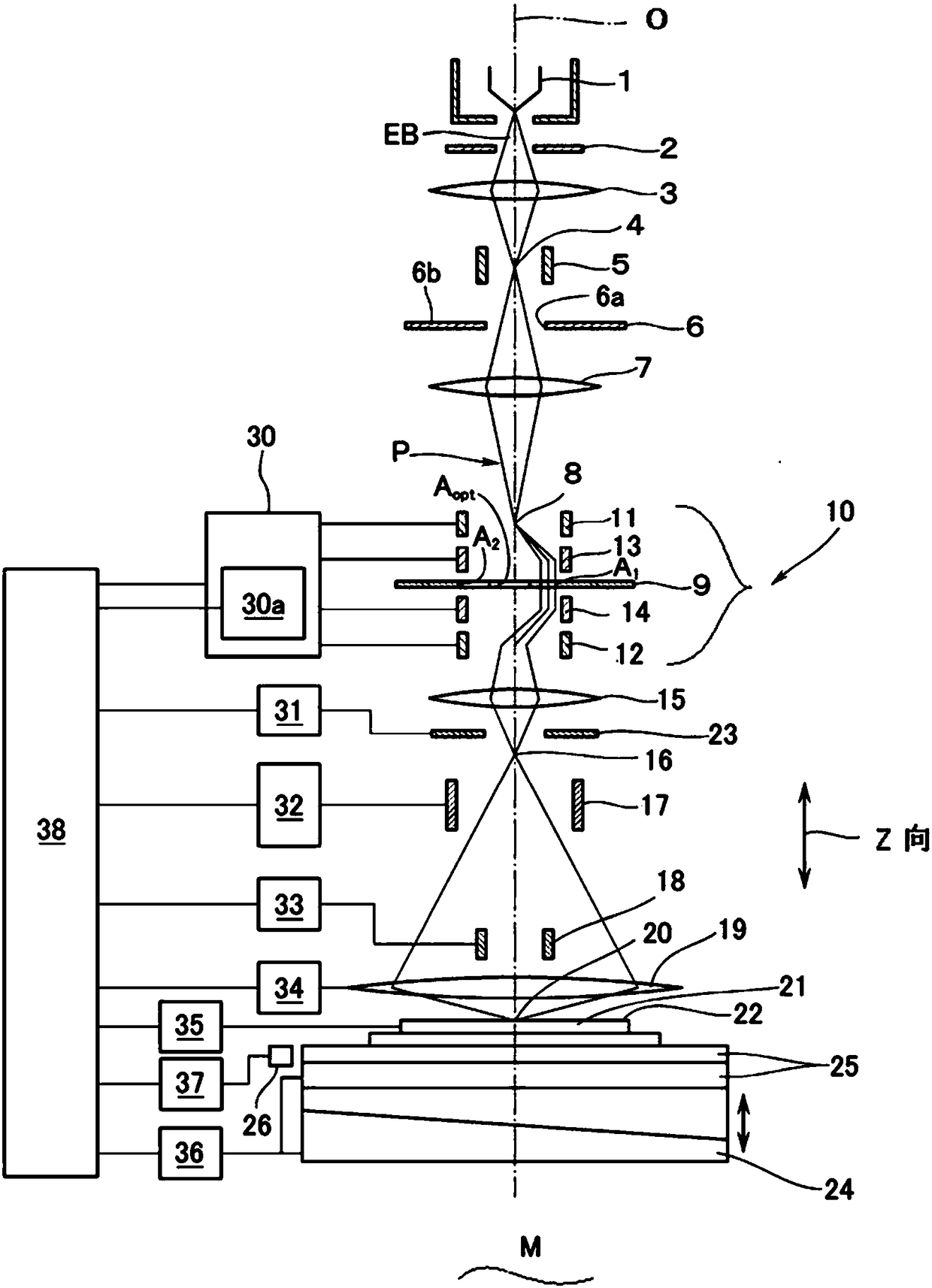

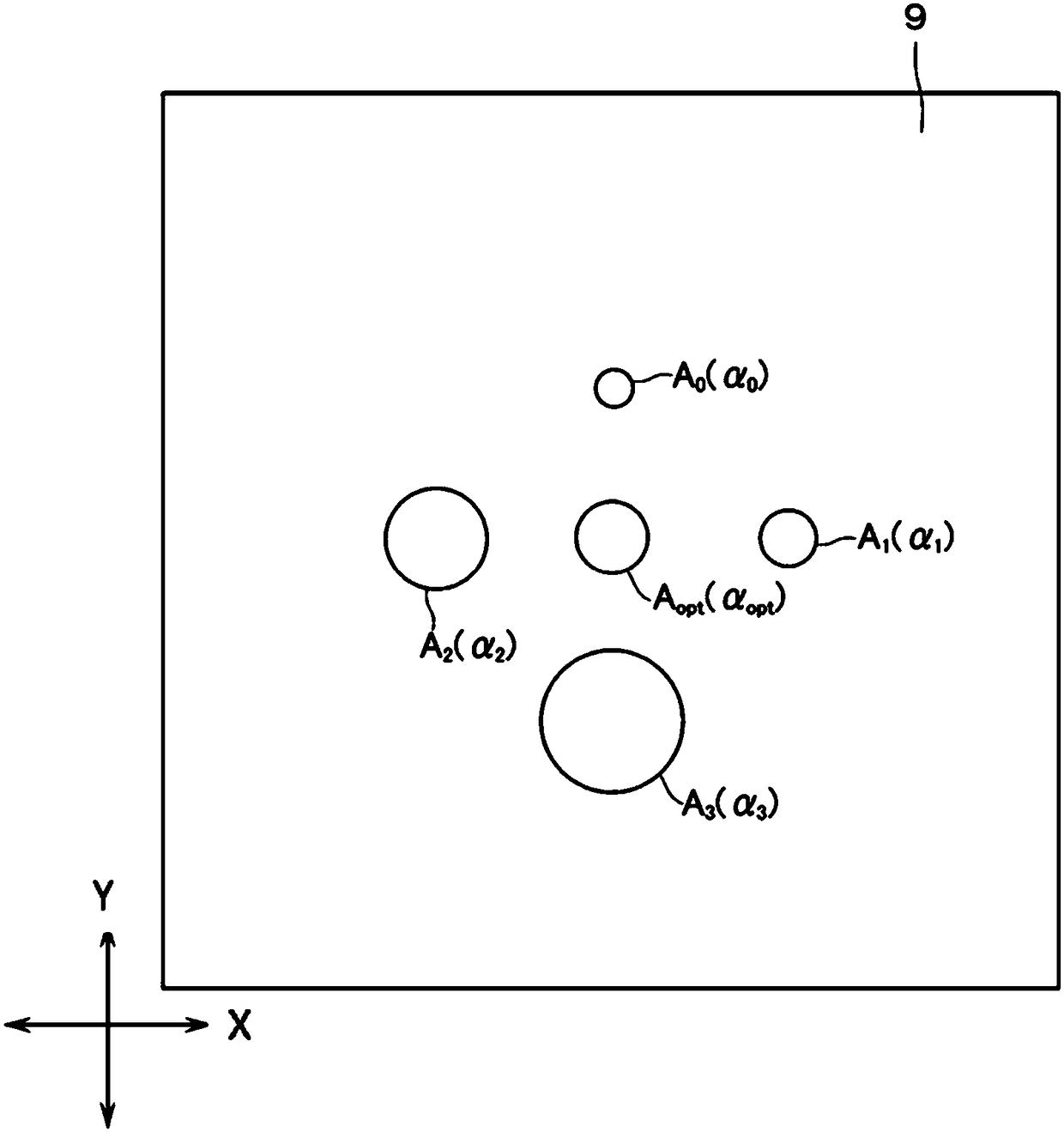

Electron beam control device and method, electron beam imaging module and electron beam detection device

ActiveCN109300760AElectric discharge tubesMaterial analysis by transmitting radiationDiaphragm PartElectron

The invention provides an electron beam control device for adjusting the size of an incident electron beam, a method, an electron beam imaging module and an electron beam detection device. The electron beam control device for adjusting the size of an incident electron beam comprises a diaphragm part; the diaphragm part is provided with multiple diaphragm openings arranged at intervals; the positions of the multiple diaphragm openings in the diaphragm part are determined to be corresponding to multiple different half angles of the incident electron beams and different sizes of the electron beams; and the size of each diaphragm opening is determined to be enough to enable the electron beam with the corresponding size to pass through, and thus, the size of the incident electron beam can be moved to the selected diaphragm opening in the multiple diaphragm openings to be adjusted through the electron beam.

Owner:DONGFANG JINGYUAN ELECTRON LTD

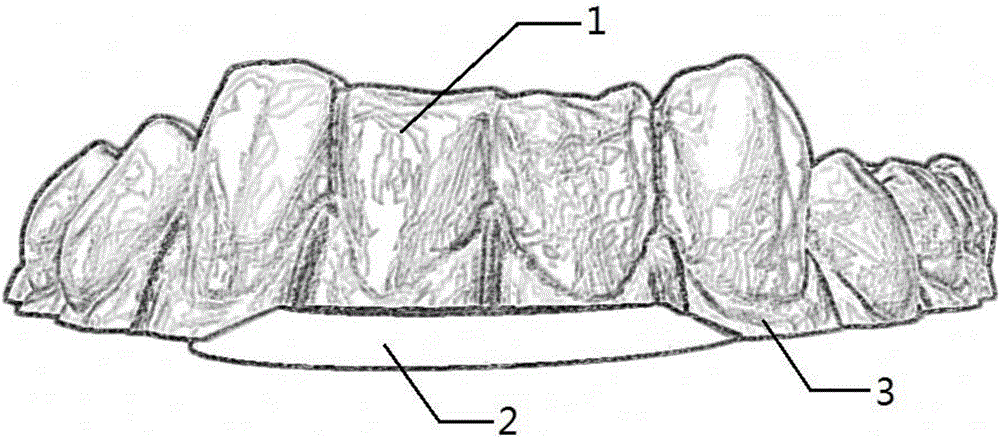

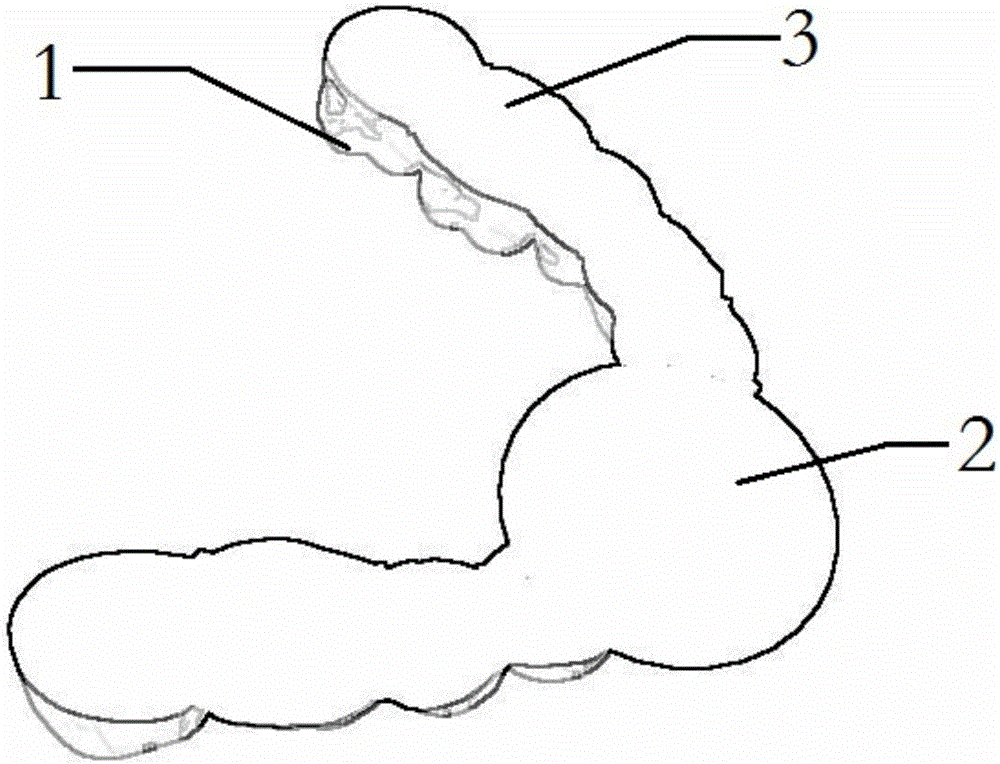

Teeth model and method for preparing concealed correcting device by utilizing model

InactiveCN106109028AAvoid difficultiesReduce the chance of damageOthrodonticsPrimary ToothEngineering

The invention relates to a teeth model. The teeth model comprises an upper dental crown part and a lower gingival part, wherein a truncated cone sheet is arranged below the gingival part, the upper bottom area of the truncated cone sheet is smaller than the lower bottom area, the diameter of the upper bottom is greater than the width of the gingival part, and the lower bottom is leveled to the bottom of the gingival part. A method for preparing a concealed correcting device by utilizing the teeth model comprises the following steps: (1) obtaining the teeth model with the truncated cone sheet on the bottom by virtue of three-dimensional modeling and three-dimensional printing; (2) placing the teeth model on a metal plate of a film pressing machine, and carrying out the film pressing; (3) after the film pressing is ended, separating a diaphragm from the teeth model, slightly bending the hot-pressed diaphragm part, enabling the truncated cone sheet to be warped, holding, by a hand, the truncated cone sheet, and vigorously turning upwards the diaphragm, thus obtaining a primary tooth socket template; and (4) further processing to obtain the concealed correcting device. The method is simple and practical, the operation speed is high, the efficiency is improved, the cost is reduced, and the damage probability of the macromolecular diaphragm when in demolding can also be maximally reduced.

Owner:QINGDAO LANXIN MEDICAL TECH CO LTD

Blackboard capable of automatically supplying water

ActiveCN106142923AErase completelyWipe cleanBoard cleaning devicesWriting boardsWater storageEngineering

The invention discloses a blackboard capable of automatically supplying water. The blackboard comprises a blackboard body, a slide frame, an eraser base, an eraser body, a collecting tank, a water storage cavity, an ejector rod and a control device, wherein the water storage cavity is formed in the eraser base; a water passing hole is formed in the lower side part of the eraser base, and is provided with a diaphragm part; the diaphragm part consists of a pair of rubber pieces; the middle parts of the pair of rubber pieces are overlapped with each other; the ejector rod is arranged in the collecting tank, and is a through hollow structure; a water outlet part has a cavity; multiple water outlet holes communicated with the cavity are formed in the front end part of the water outlet part; when the front side wall is tightly contacted with the blackboard body, the blackboard body is butted against one end of the ejector rod, and the other end of the ejector rod applies pressure to the diaphragm part, so that the middle parts of the pair of rubber pieces are separated, and the water storage cavity is communicated with the water outlet part through the ejector rod; and the control device controls a first driving mechanism and a second driving mechanism to alternately work. The blackboard realizes automatic erasing of chalk writing on the blackboard body.

Owner:NANNING YUANZHUO NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com