Metal vibrating diaphragm and loudspeaker

A loudspeaker and metal technology, applied in the direction of non-planar diaphragm/paper cone, diaphragm fixation/tightening, sensor, etc., can solve the problem that the diaphragm rigidity of the speaker is not enough to split the vibration, etc., to ensure normal vibration and sound, improve Sensitivity, the effect of weakening segmentation distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

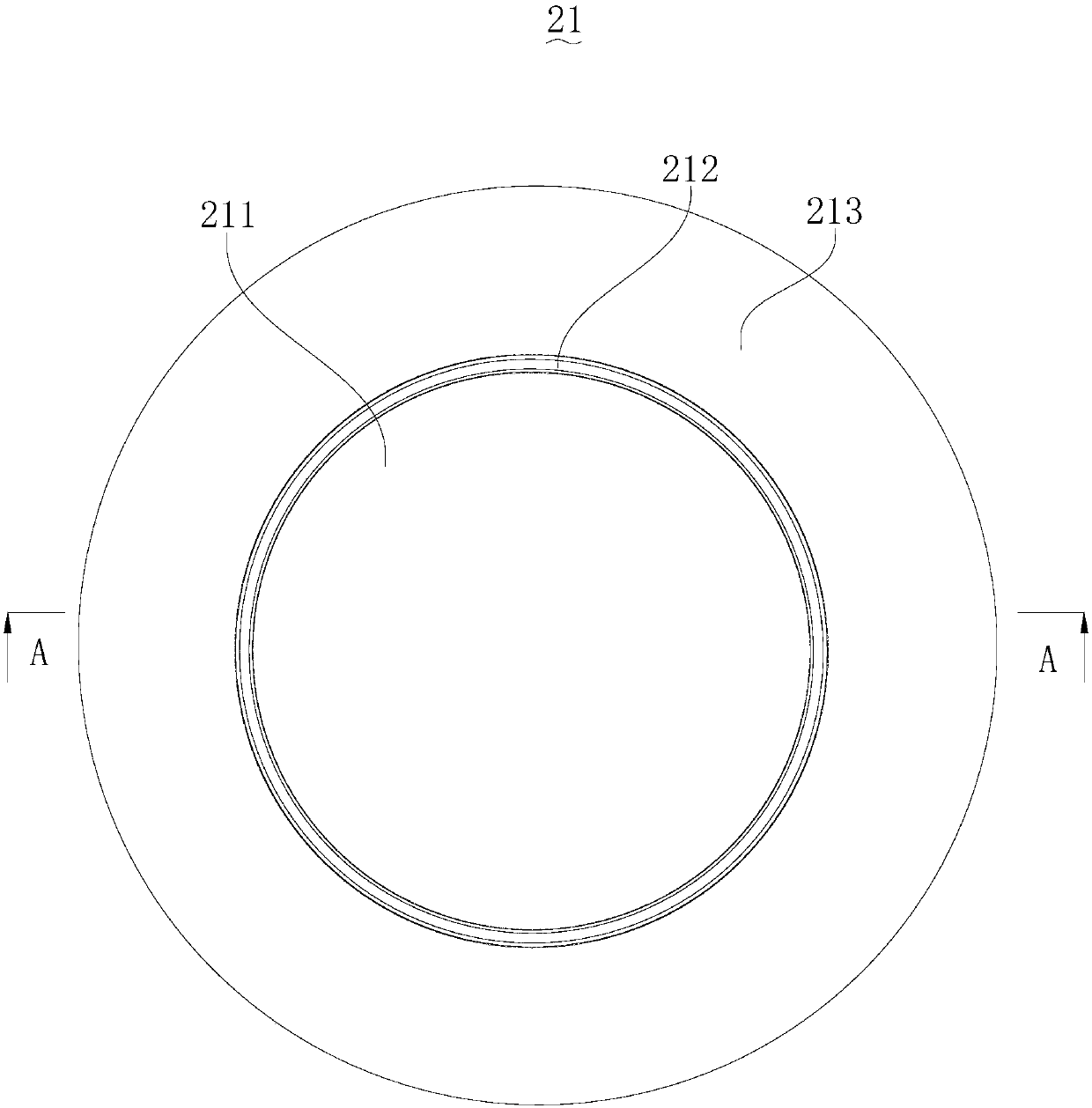

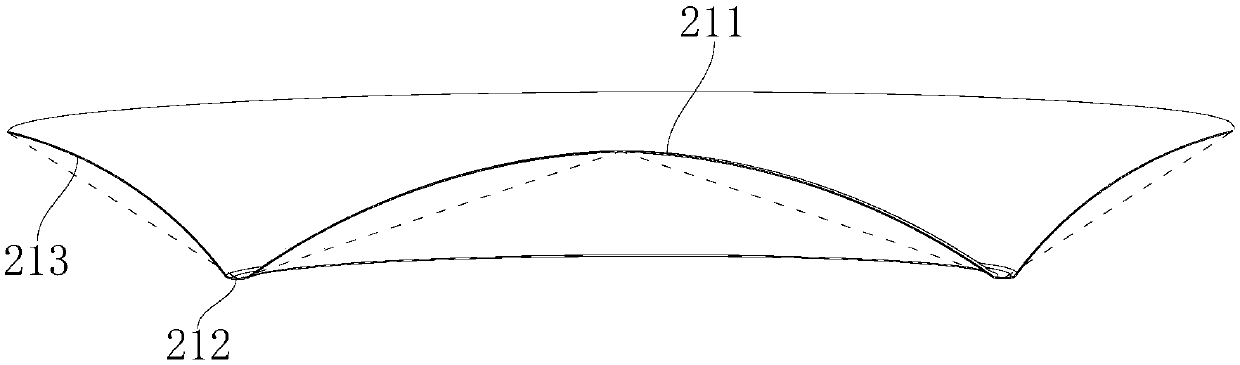

[0042] Such as Figure 1~6 As shown, Embodiment 1 of the present invention provides a metal diaphragm 21, which includes a hemispherical film part 211 with a convex middle part. The periphery of the hemispherical film part 211 extends along the horizontal direction to form an annular flat film part 212. The peripheral edge of the membrane portion 212 is folded toward the convex direction of the hemispherical membrane portion 211 and extends away from the hemispherical membrane portion 211 to form a trumpet-shaped membrane portion 213. The height of the spherical top of the film-shaped portion 211.

[0043]The metal diaphragm 21 of this embodiment, because its hemispherical film part 211 is the hemispherical structure that the central part protrudes outward, when the metal diaphragm 21 vibrates, the hemispherical film part 211 will vibrate and act on the ring in the middle. Shaped flat film portion 212 deviates from the first force of the hemispherical film portion 211; at the...

Embodiment 2

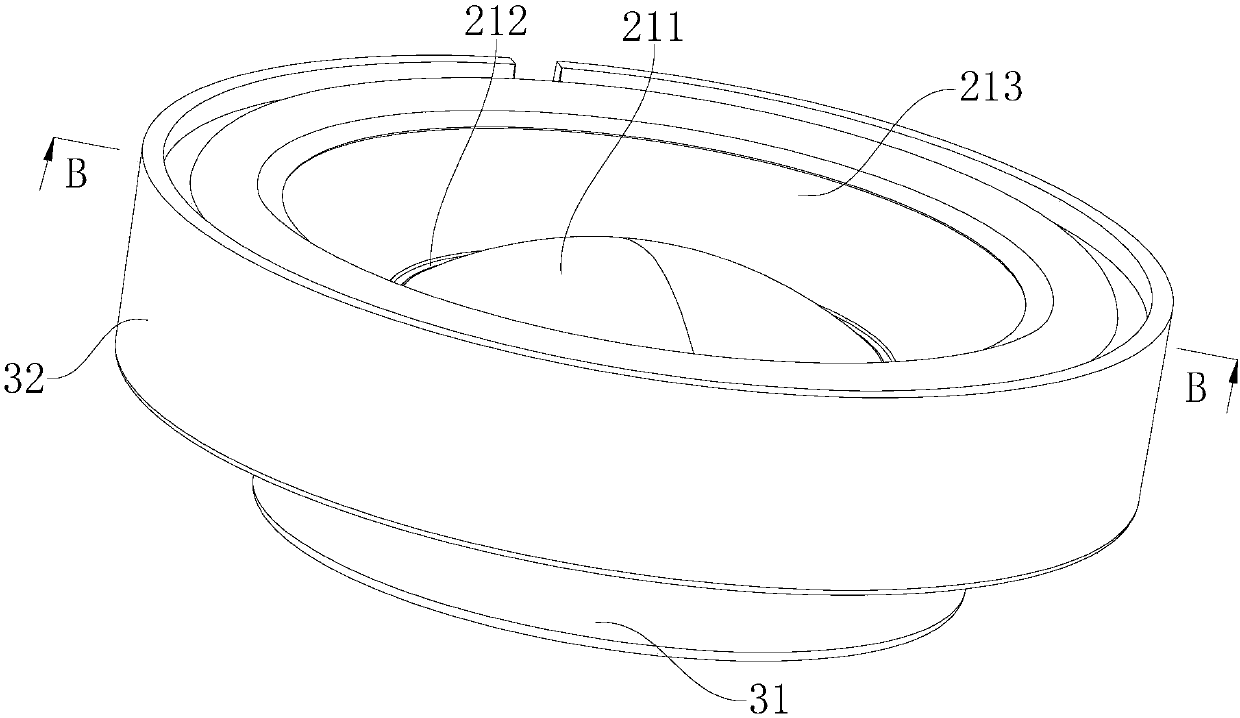

[0053] Such as Figure 3-6 As shown, Embodiment 2 of the present invention provides a speaker. The speaker of this embodiment includes a magnetic circuit system 10, a vibration system 20, a speaker bracket 30, and the metal diaphragm 21 in the first embodiment above. The speaker bracket 30 includes a basin frame 32 and U cup 31, the basin frame 32 and U cup 31 are fastened and connected with each other and form an installation cavity together, the magnetic circuit system 10 and the vibration system 20 are fixed in the installation cavity, and the trumpet-shaped membrane part of the metal diaphragm 21 The peripheral edge of 213 away from the hemispherical membrane part 211 is fixedly connected with the frame 32 .

[0054] The loudspeaker of this embodiment uses the above-mentioned metal diaphragm 21, the split vibration at high frequencies is reduced, and the high-frequency curve becomes smoother, which improves the sensitivity of the sound of the loudspeaker and improves the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com