Diaphragm pump

A diaphragm pump and diaphragm technology, which is used in pumps, pumps with flexible working elements, and liquid variable-capacity machines, etc., can solve the problems of rapid and unstable airflow in and out, the motor directly bears a large load, and the structure of the intake valve is complex. To achieve the effect of good air outlet, low cost and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

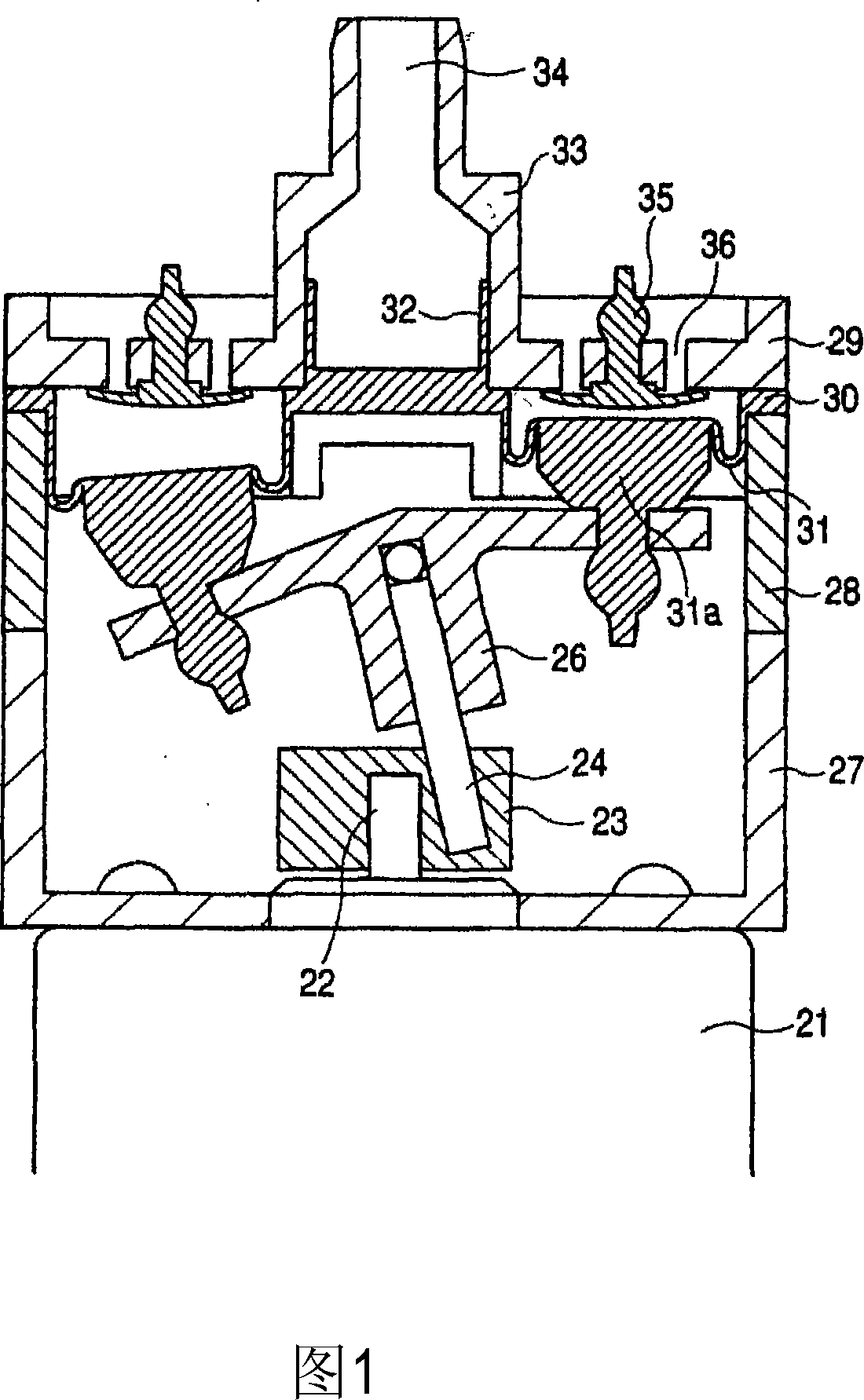

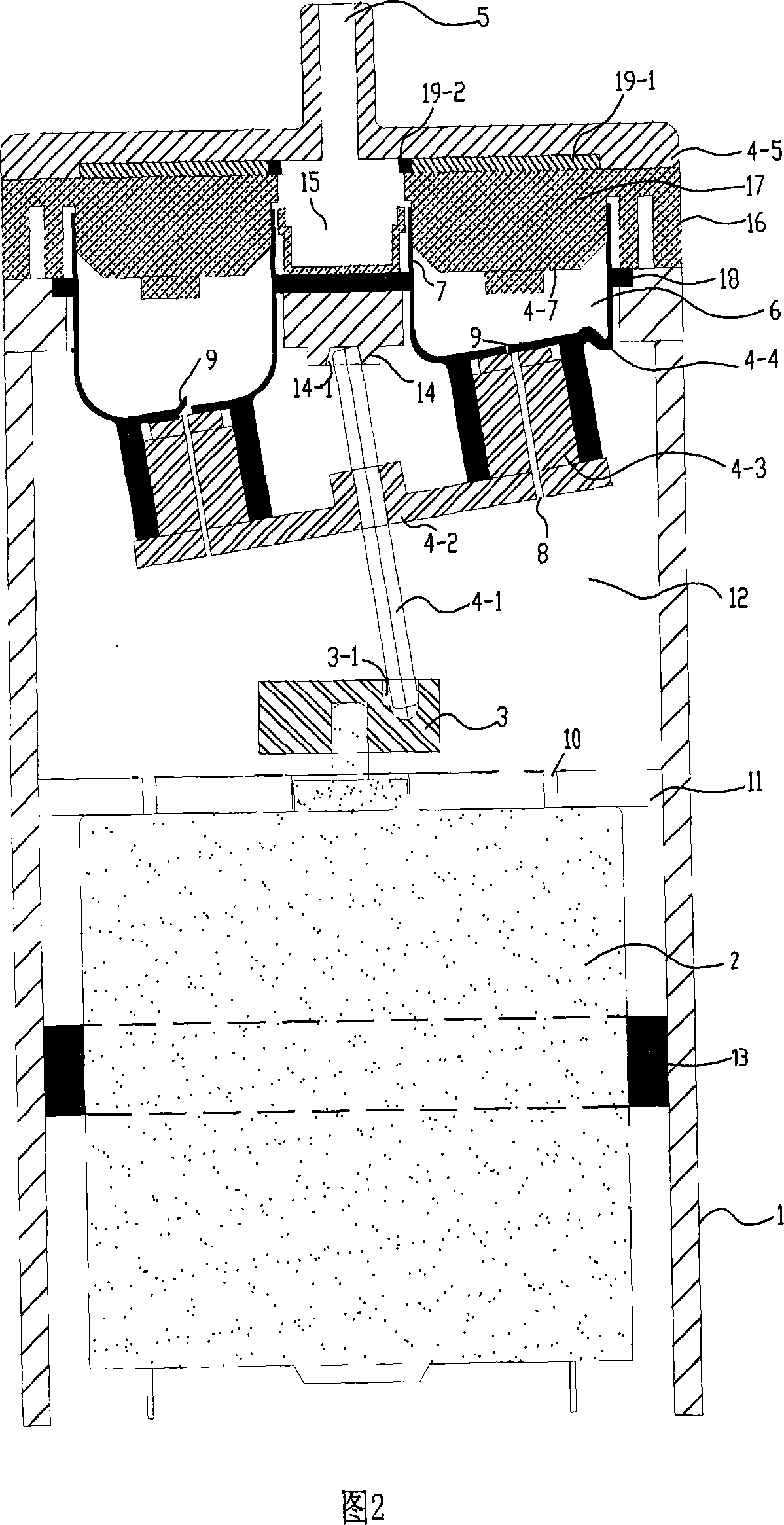

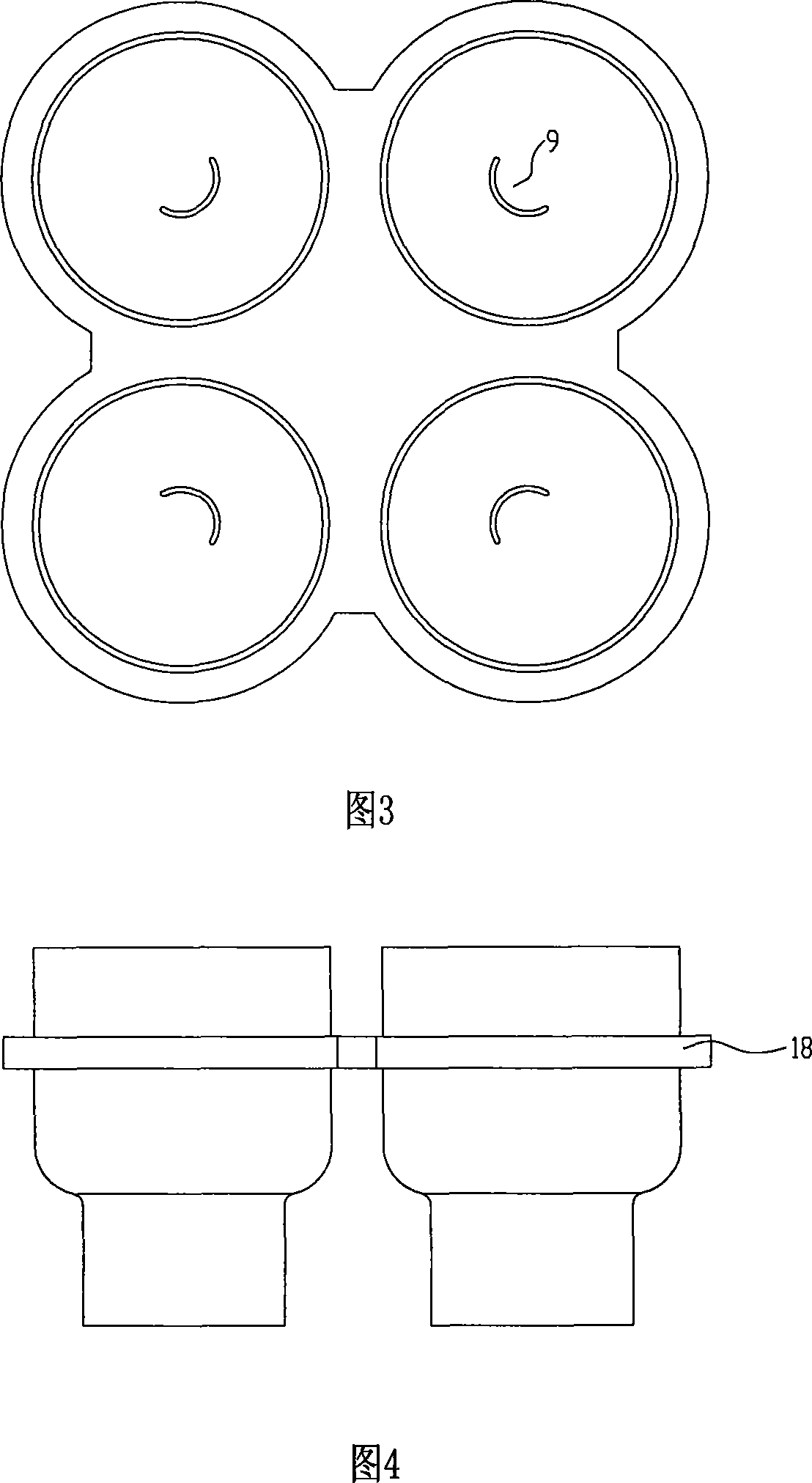

[0025] A diaphragm pump as shown in Figure 2 has a casing 1, a diaphragm pump assembly is arranged in the casing 1, and a motor 2 for driving the diaphragm pump assembly is arranged at the rear end; a rotating shaft is fixedly arranged on the output shaft of the motor 2 wheel 3; the diaphragm pump assembly includes a connecting rod 4-1 eccentrically connected to the runner 3, a rotating frame 4-2 fixedly connected to the connecting rod 4-1, and a driving part 4 arranged on the upper surface of the rotating frame 4-2 -3. The diaphragm part 4-4 connected with the driving part 4-3, and the air outlet cover 4-5 connected with the casing 1 and provided with the air outlet 5, the diaphragm pump assembly also includes the diaphragm part 4-4 The upper boss 4-7, the diaphragm part 4-4 is a cylindrical structure with one end open, and the open end is elastically wrapped on the outer circumferential surface of the boss 4-7 to form a pump chamber 6 inside the diaphragm part 4-4 , a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com