Voice coil diaphragm integrated structure and manufacturing method thereof

A one-piece, voice coil technology, applied to electrical components, sensors, etc., can solve the problems of unguaranteed assembly quality, difficult assembly of voice coil and diaphragm, etc., to reduce assembly difficulty, improve production efficiency, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

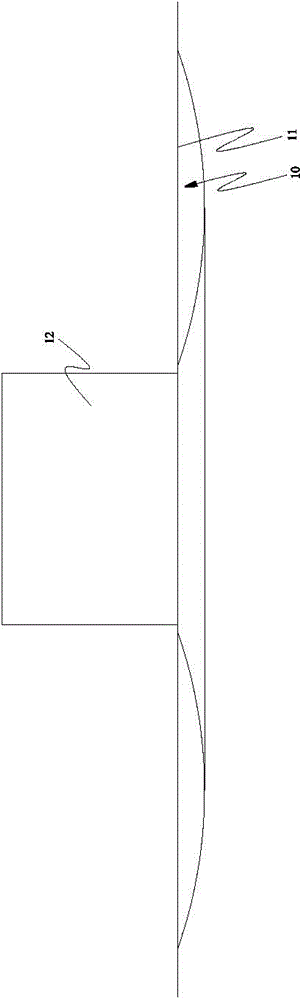

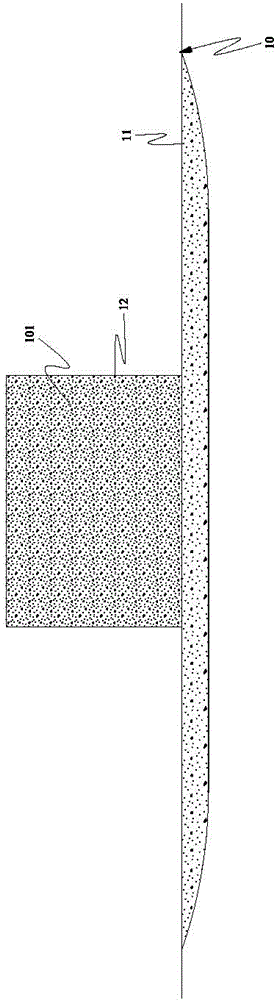

[0030] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the main body 10 and the dome 20 .

[0031] The main body 10 includes a ring-shaped diaphragm part 11 and a cylindrical voice coil part 12; the outer surface of the ring-shaped diaphragm part 11 is formed with a first lead-out line 30 by electroplating, vacuum evaporation or spraying. The surface is formed with a second lead-out line 40 by electroplating, vacuum evaporation or spraying; the cylindrical voice coil portion 12 extends inwardly from the inner ring edge of the inner surface of the annular diaphragm portion 11 as a whole, and the cylindrical voice coil portion 12 The inner surface of the cylindrical voice coil portion 12 is formed with a first voice coil circuit 50 by electroplating, vacuum evaporation or spraying, and the outer end of the first voice coil circuit 50 is connected to the first lead-out circuit 30. A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com