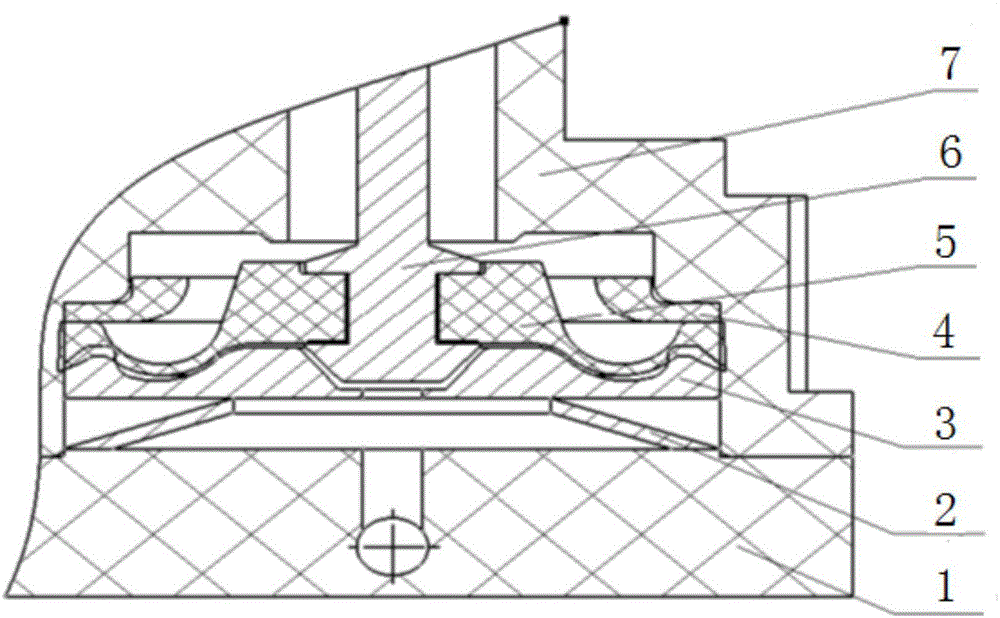

Solenoid valve diaphragm installation structure

An installation structure, solenoid valve technology, applied in the valve device, valve operation/release device, diaphragm and other directions, can solve the problems of diaphragm tear, relay failure, damage, etc., to simplify the structure, prolong the service life, reduce the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The arrangement of the elastic element 2 transfers the thrust of the push rod 6 and the pressure on the upper diaphragm 5 to the elastic element 2, and the elastic deformation of the elastic element 2 protects the upper diaphragm 5 from tearing. The butterfly spring adopted in the technical solution has an initial elastic force of zero and relatively high stiffness, ranging from 130N / mm to 150N / mm. The support seat 3 corresponds to the structure of the upper diaphragm 5 and the end of the push rod 6. The diaphragm installation groove supports and protects the upper diaphragm 5. The support frame 4 between the upper diaphragm 5 and the valve body 7 can The edge of upper diaphragm 5 is compressed.

[0020] When the relay is not working, the elastic element 2 has an initial elastic force of zero and is fixed between the cover plate 1 and the support base 3 . The push rod 6 is stressed, which generates pressure on the edge of the upper diaphragm 5, and the edge part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com