Assembling method for lithium-ion button type battery

A button battery and assembly method technology, applied in the field of lithium-ion batteries, can solve the problems affecting the accuracy and consistency of lithium-ion button battery testing, time-consuming pass rate, cumbersome procedures, etc., to shorten the time and avoid short circuit , accuracy and consistency improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

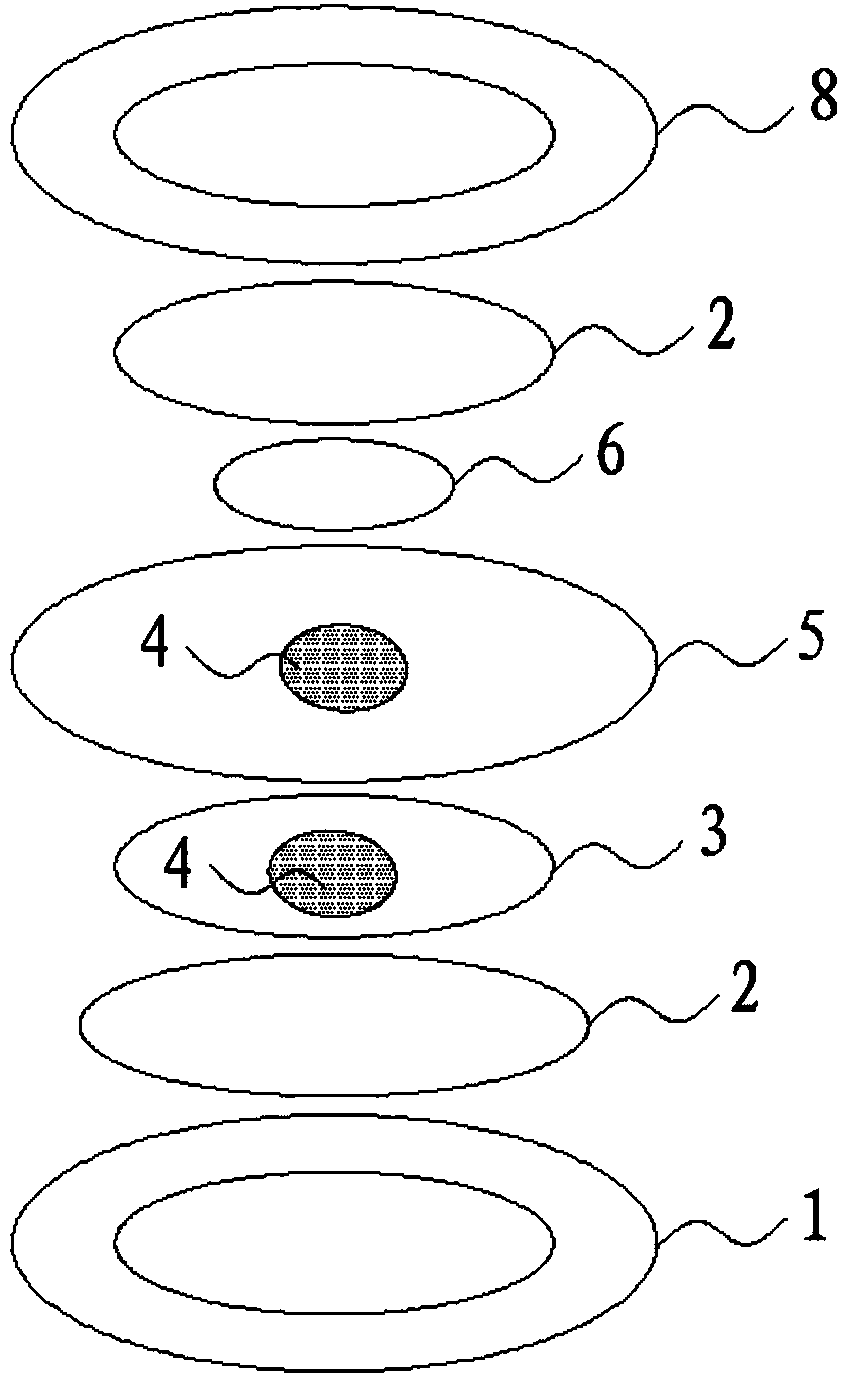

[0029] A method for assembling a lithium ion button battery, the technology provided by the invention is sequentially assembled in the order of negative electrode case 1, gasket 2, metal lithium sheet 3, electrolyte 4, diaphragm 5, electrolyte 4, pole piece 6, pad Sheet 2, positive electrode shell 7, the first step is to put the negative electrode shell 1 first; the second step is to put the metal lithium sheet 3 on the gasket 2, and remove the oxide on the surface of the metal lithium sheet 3 with a polishing rod; the third step is to put the gasket The sheet 2 and the metal lithium sheet 3 are placed together in the negative electrode case 1; the fourth step is to drop a drop of electrolyte 4 on the metal lithium sheet 3; the fifth step is to gently place the diaphragm 5 on the negative electrode case 1 with tweezers, and the The liquid 4 wets the metal lithium sheet 3 and the diaphragm 5; the sixth step is to drop a drop of electrolyte 4 on the diaphragm 5; the seventh step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com