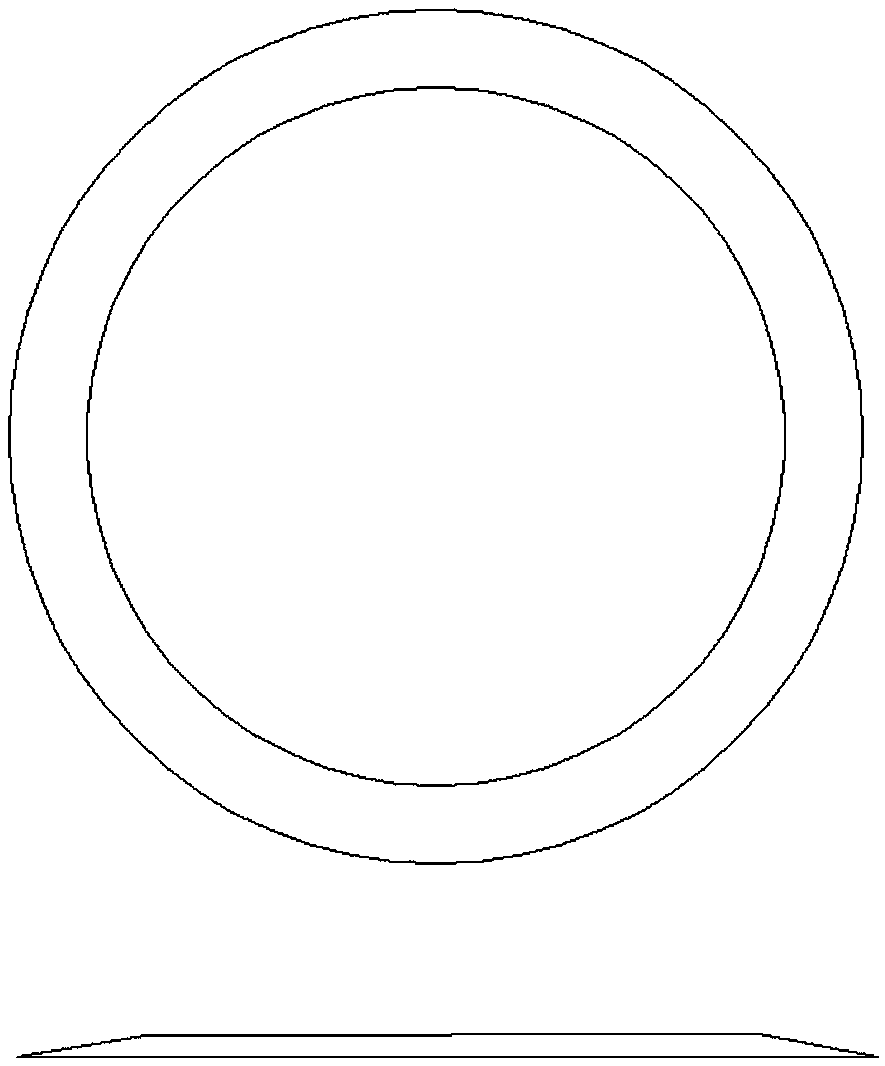

Optimized stamping forming process method of accumulator diaphragm capsule diaphragm

A stamping forming and process method technology, applied in the stamping and forming field, can solve the problems such as the height and size of the diaphragm parts being out of tolerance, and achieve the effect of reasonable distribution of the springback value and improvement of the flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Processing outer diameter the inside diameter of High temperature 1.5mm, thickness 0.3mm superalloy GH4169 diaphragm.

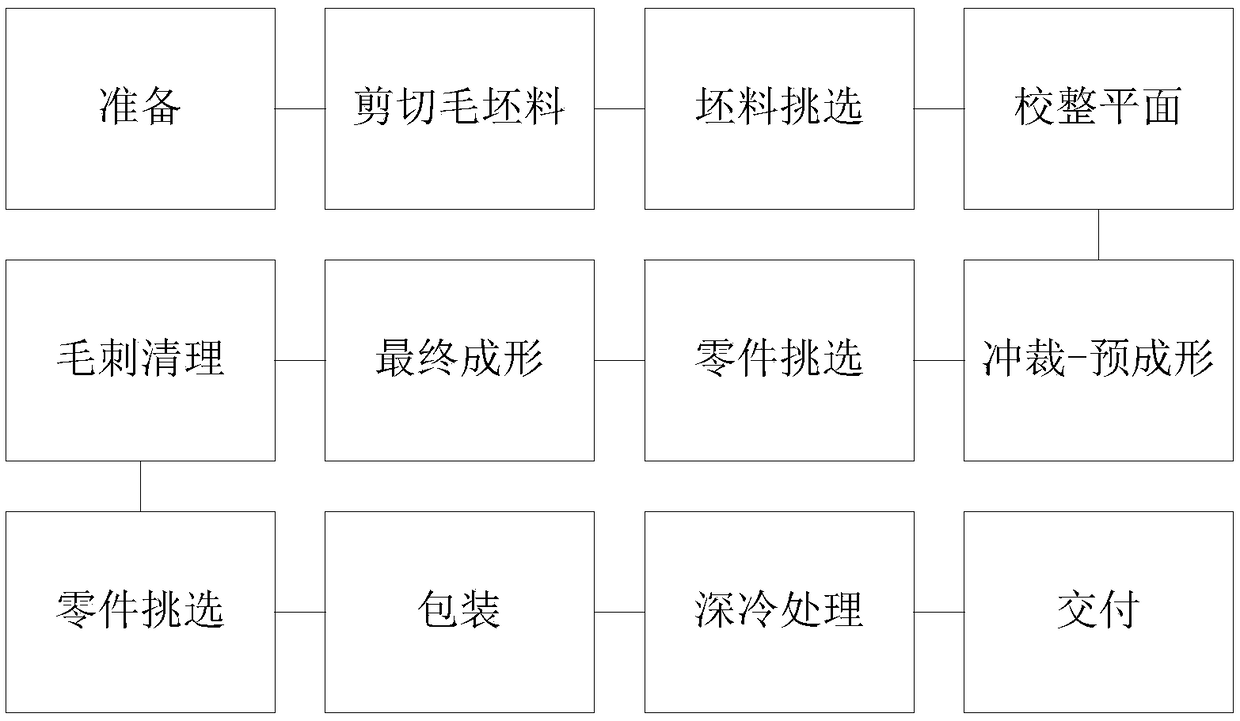

[0039] The processing flow chart is attached image 3 shown.

[0040] (1) Preparation of equipment and tooling

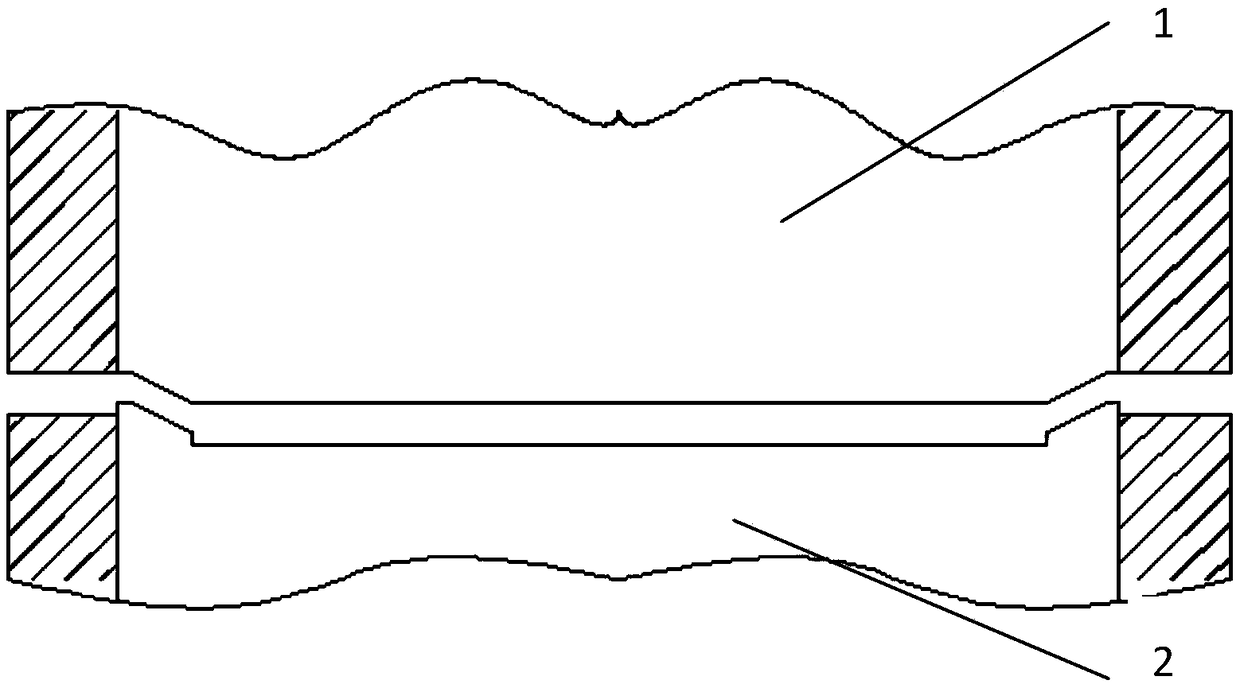

[0041] According to the forming requirements and actual conditions of the parts, select the appropriate stamping equipment, and it can be realized if the requirement is greater than 50T. According to the external dimension requirements of the diaphragm part, the initial forming mold design scheme is determined by using the finite element analysis tool, and the springback angle value of the mold is determined.

[0042] According to theoretical analysis and calculation results, the blanking-preforming height value is 1.2mm, and the final forming die height value is 2.0-2.1mm.

[0043] (2) Stamping blanks

[0044] Uncoil and cut 200×200mm rough blanks, check and select the surface quality of the cut rough blanks, and adjust the flatness...

Embodiment 2

[0055] Processing outer diameter the inside diameter of High temperature 1.5mm, thickness 0.2mm superalloy GH4169 diaphragm.

[0056] The processing flow chart is attached image 3 shown.

[0057] (1) Preparation of equipment and tooling

[0058] According to the forming requirements and actual conditions of the parts, select the appropriate stamping equipment, and it can be realized if the requirement is greater than 50T. According to the external dimension requirements of the diaphragm part, the initial forming mold design scheme is determined by using the finite element analysis tool, and the springback angle value of the mold is determined.

[0059] According to theoretical analysis and calculation results, the blanking-preforming height is 1.1mm, and the final forming die height is 1.8-2.0mm.

[0060] (2) Stamping blanks

[0061] Uncoil and cut 150×150mm rough blanks, check and select the surface quality of the cut rough blanks, and correct the flatness of the rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com