Ball jack-in method sealing

A flat sealing and jacking technology, which is applied in the direction of lift valves, engine components, mechanical equipment, etc., can solve problems such as leakage and reduced sealing effect, and achieve the effect of long service life and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

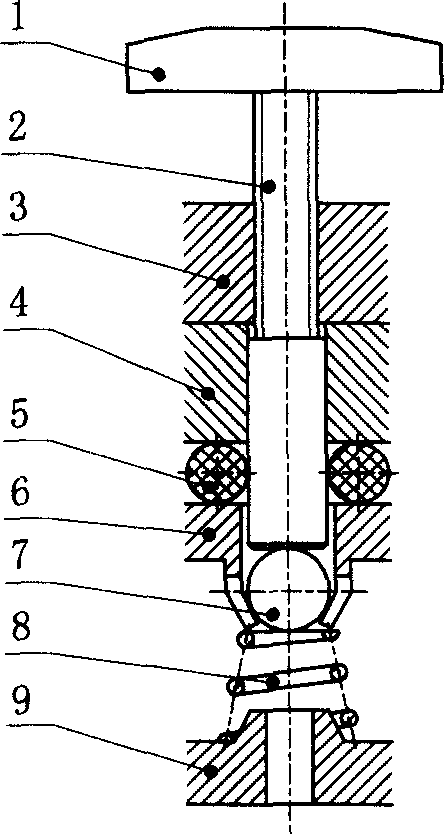

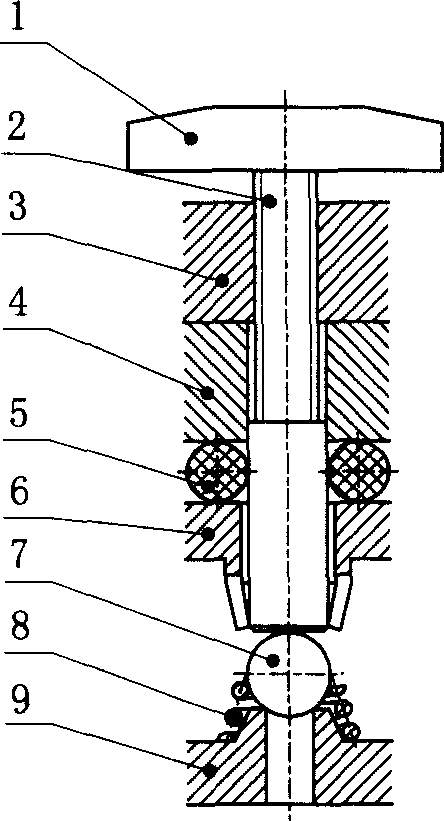

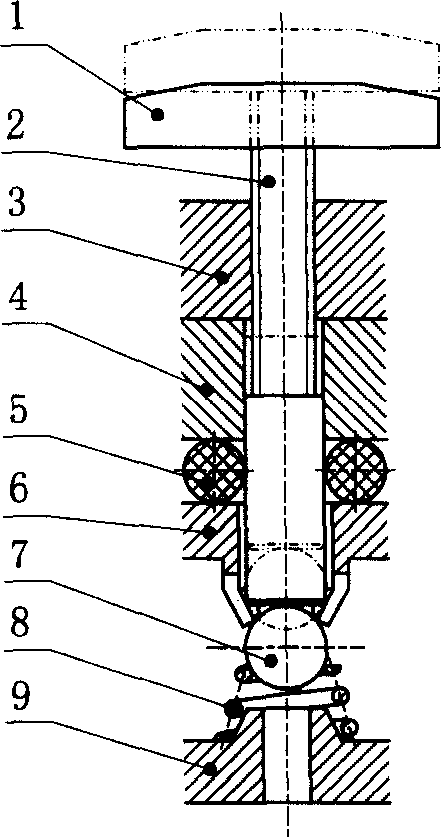

[0018] Figures 1 to 4 are implementations of general usage requirements.

[0019] In Fig. 1, the spherical body (7) is stuck in the card seat (6), and at this moment, the sealing seat (9) is opened.

[0020] In Fig. 2, the push rod (2) pushes the spherical body (7) out of the elastic clamping seat and presses against the sealing seat (9), at this time the sealing seat (9) is closed.

[0021] In Fig. 3, the push rod (2) is unscrewed upwards, the spherical body (7) leaves the sealing seat (9) under the action of the spring (8), and the sealing surface is opened. When the push rod (2) is fully unscrewed upwards, the spherical body (7) returns to the elastic clamping seat under the action of the spring (8), and the sealing seat is fully opened and the medium flux is maximum at this moment.

[0022] In Figure 4, the components can be combined into 1-N groups as needed.

[0023] Fig. 5 to Fig. 9 are implementations where secondary entry of the medium is not allowed in the applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com