Patents

Literature

86 results about "Method seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

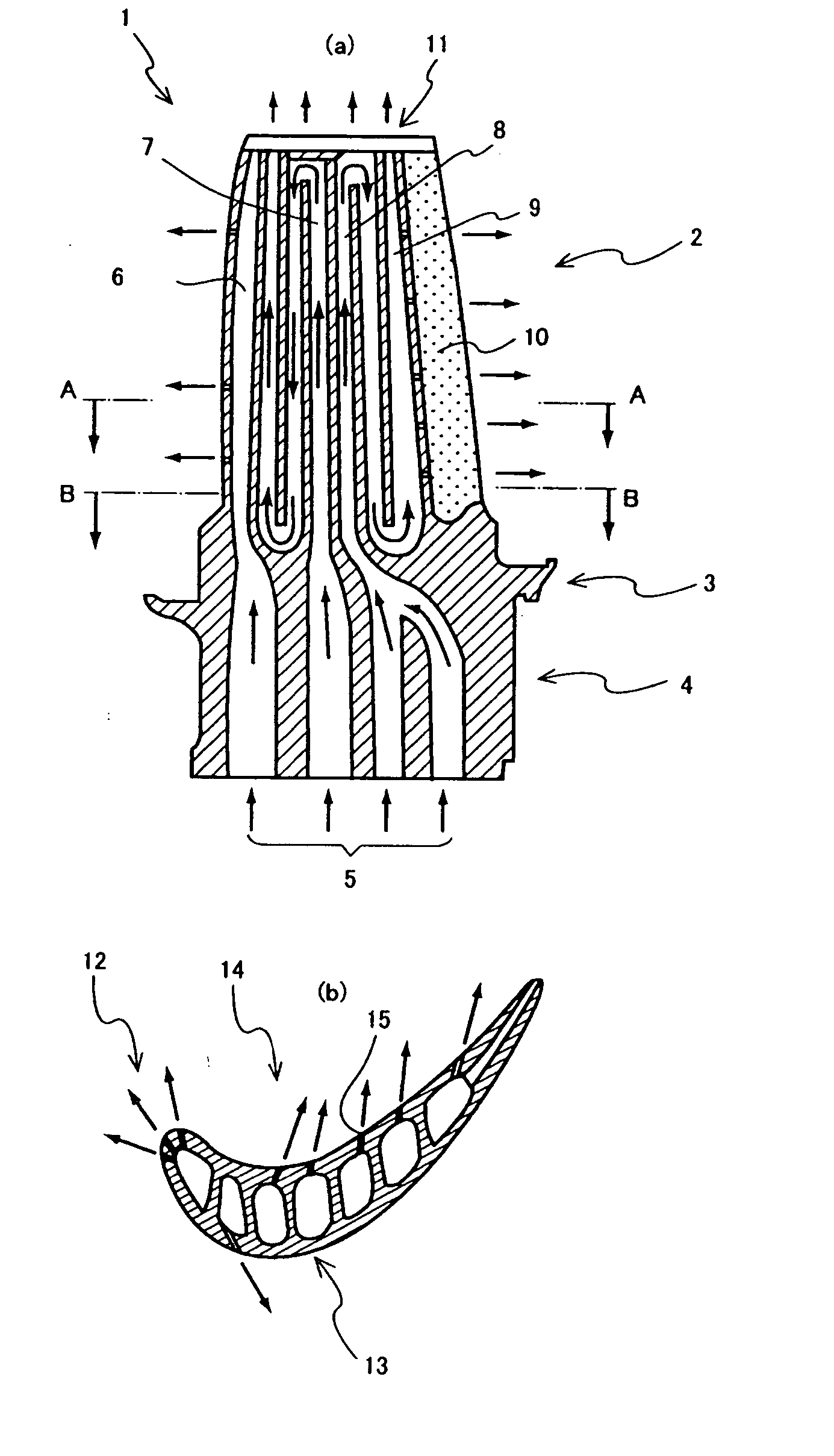

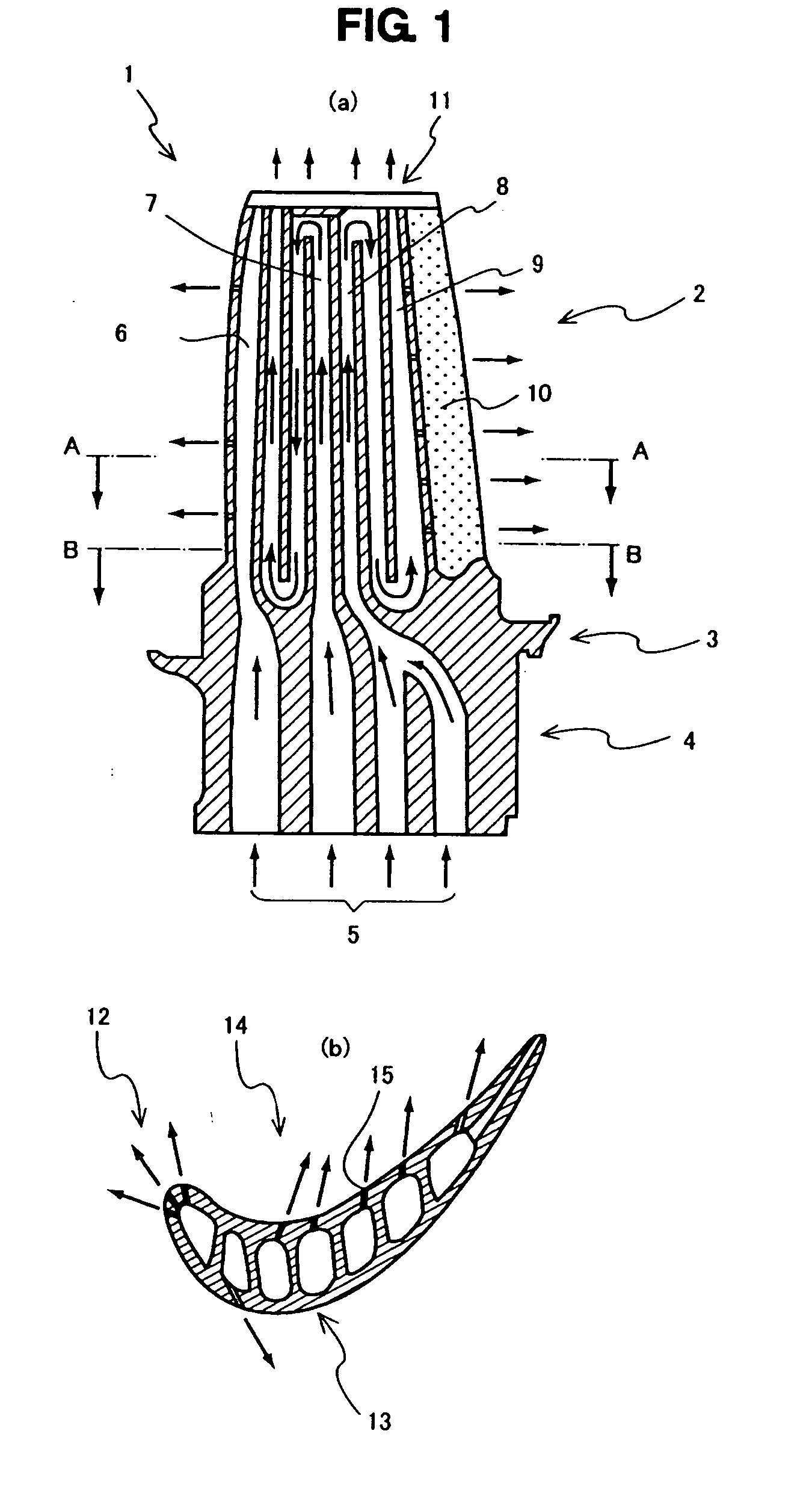

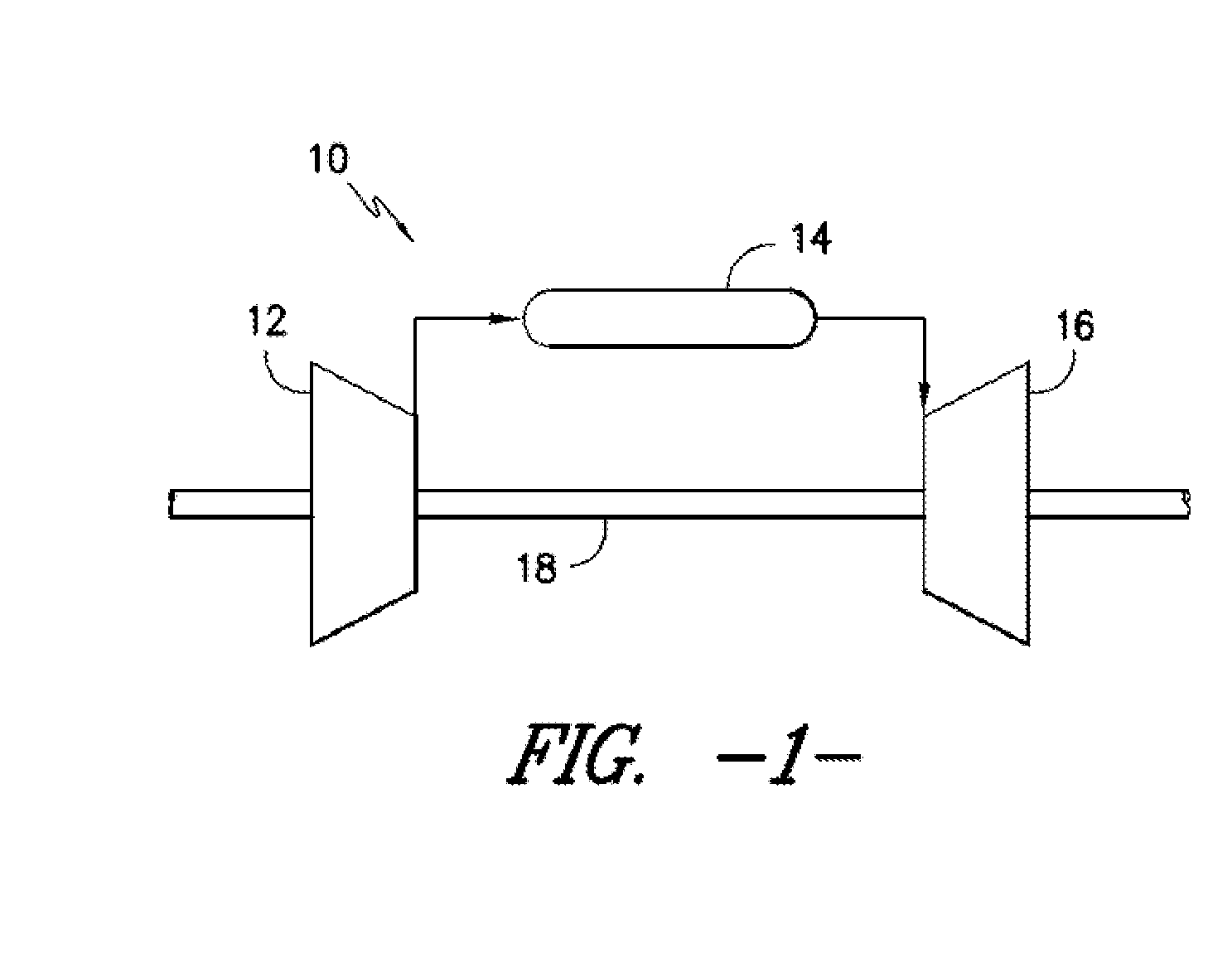

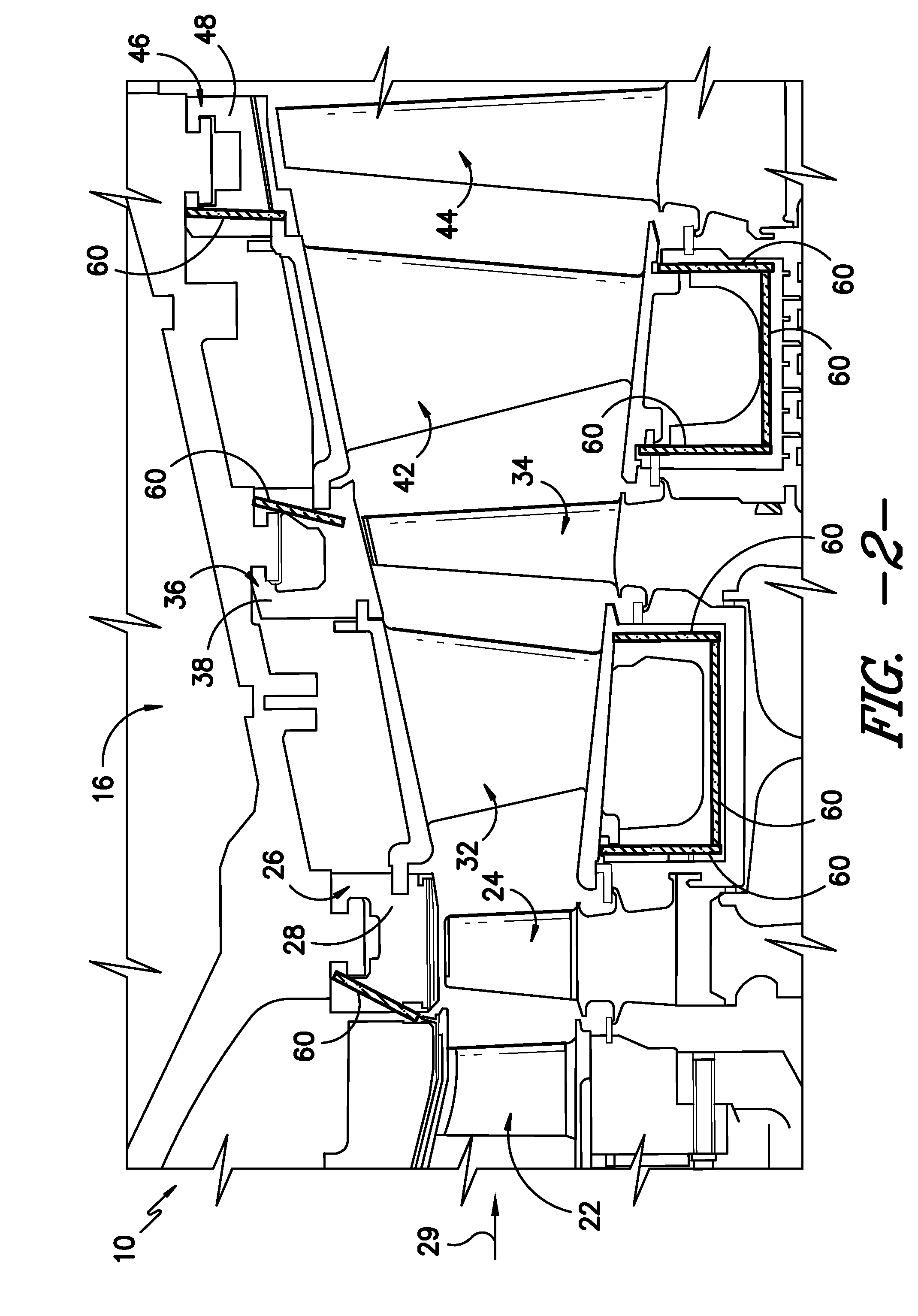

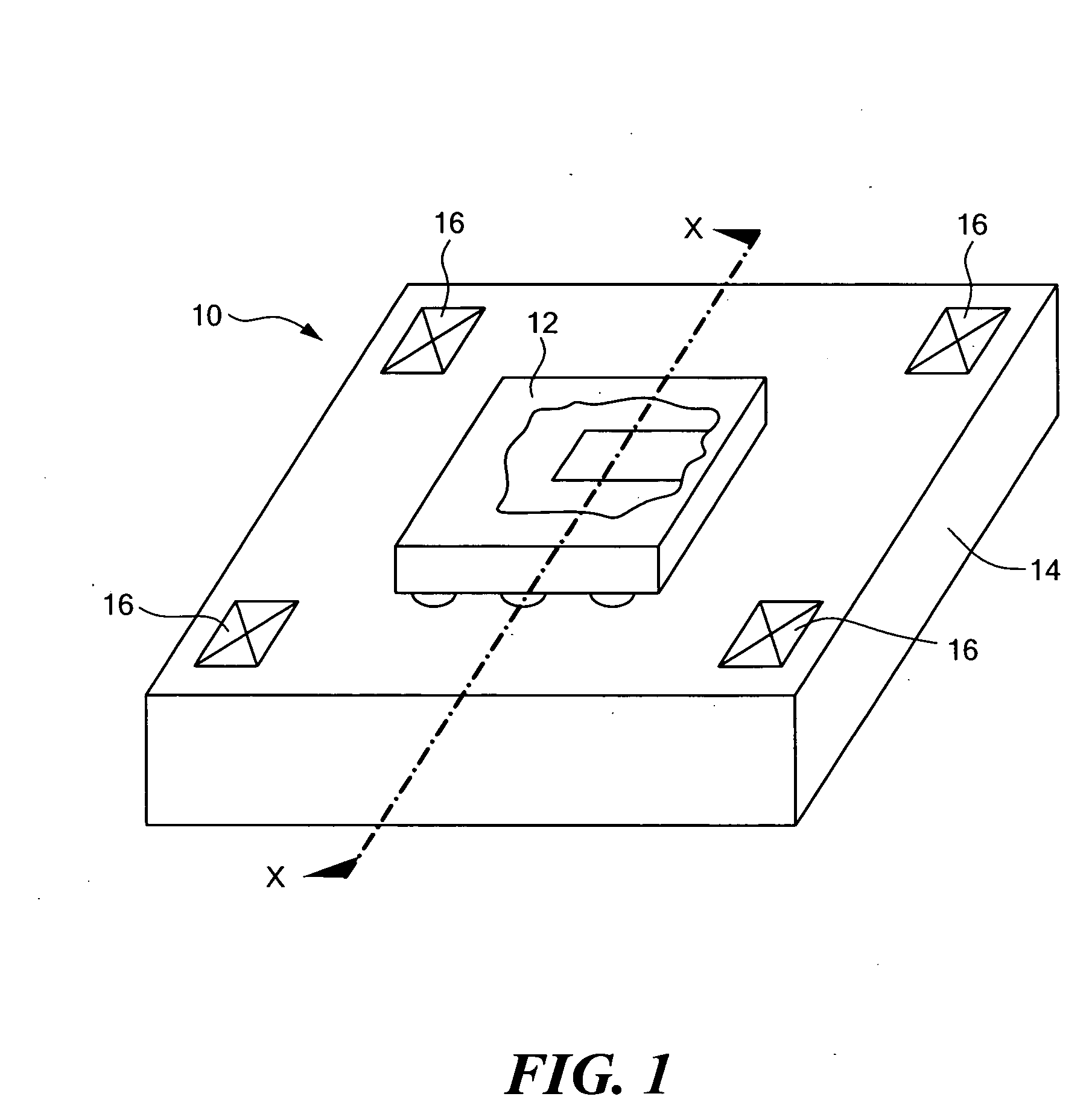

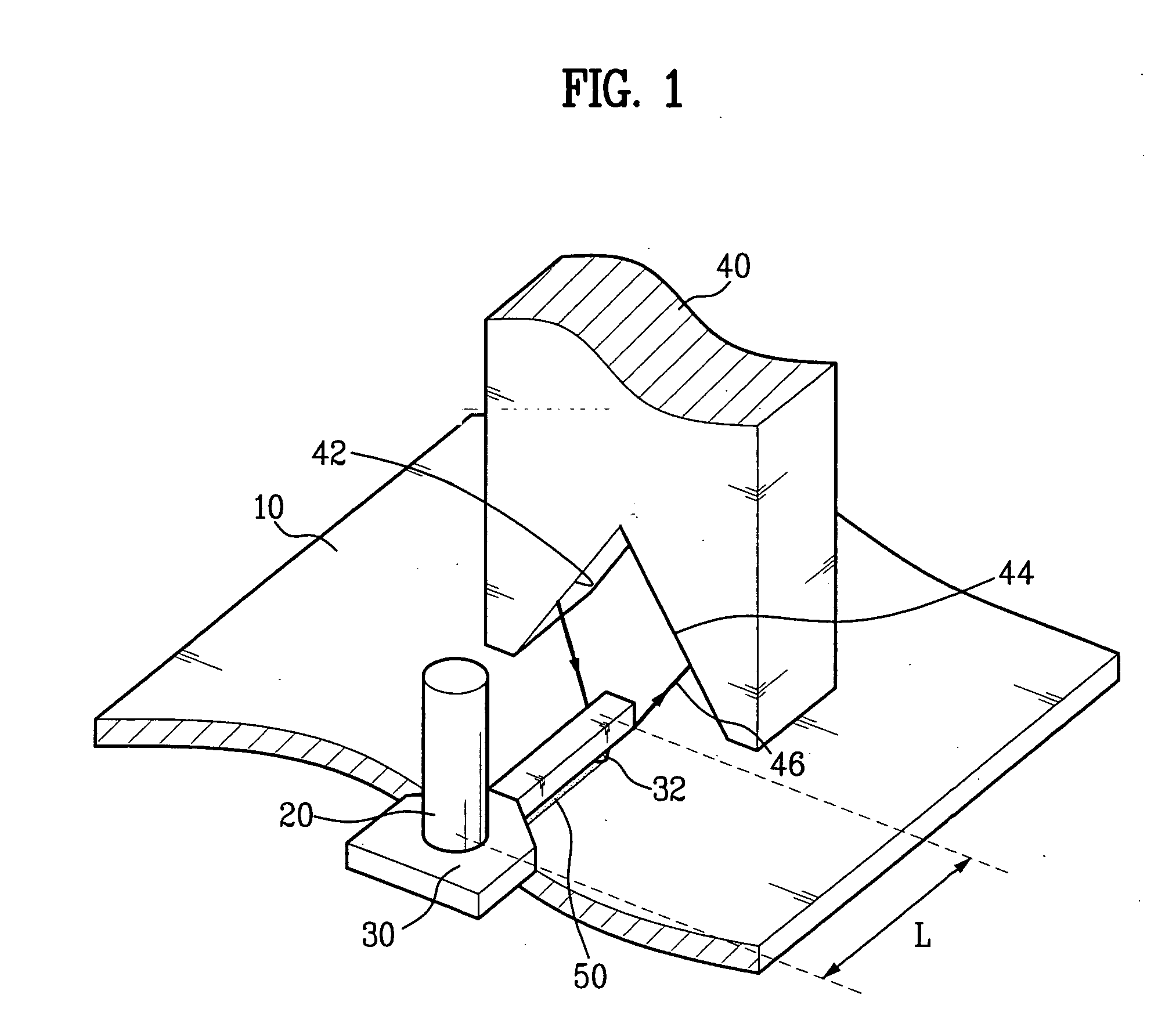

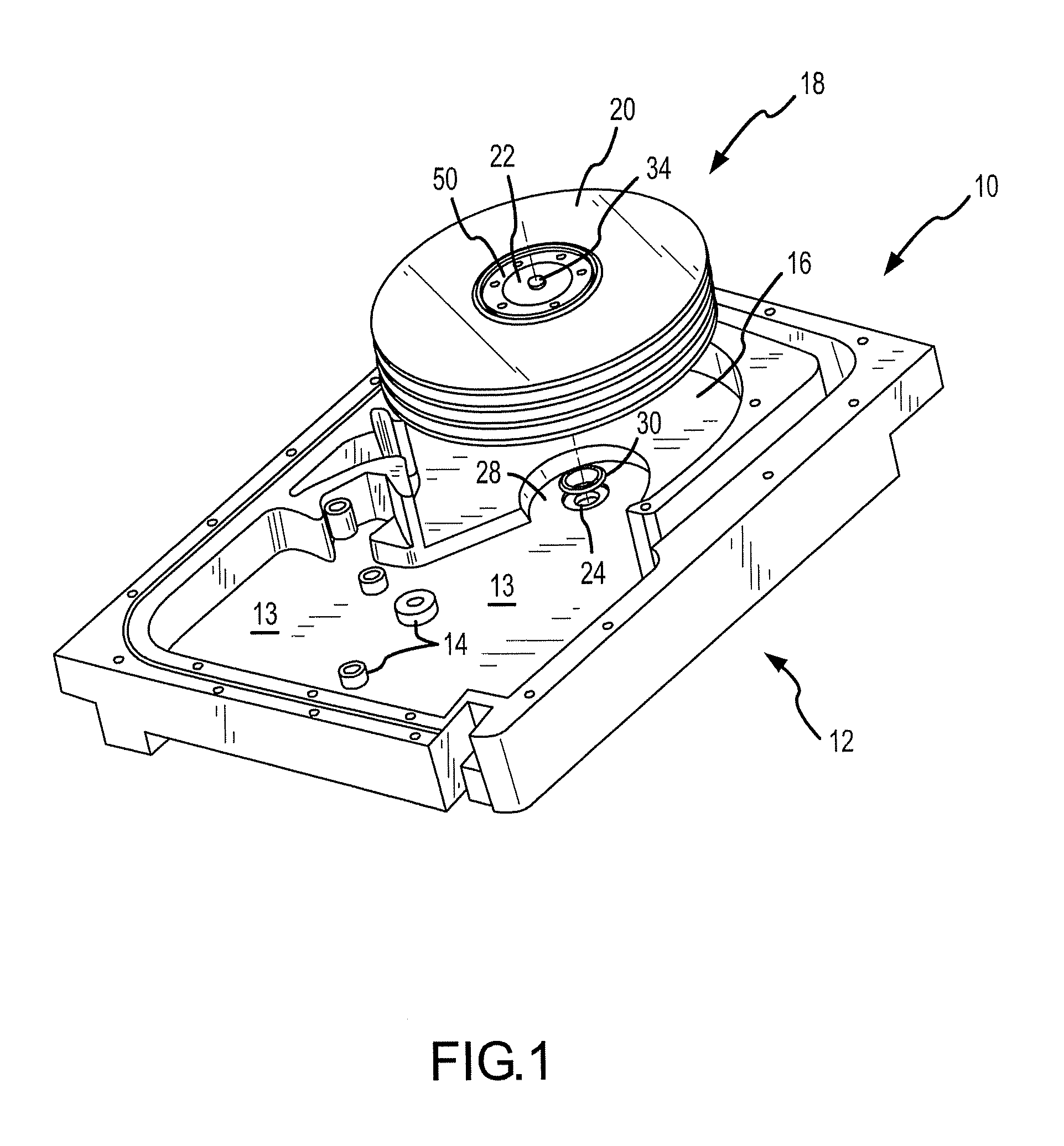

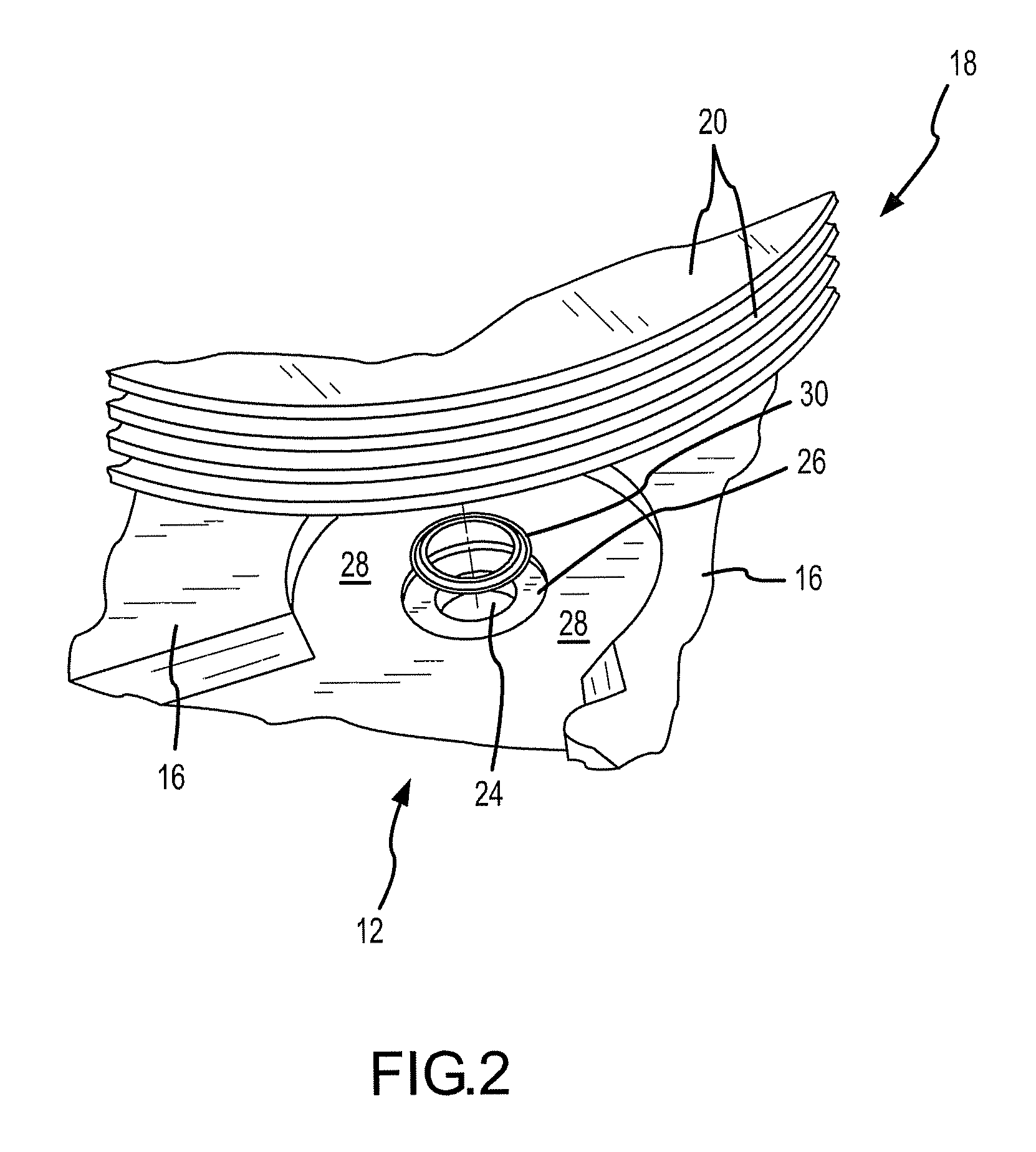

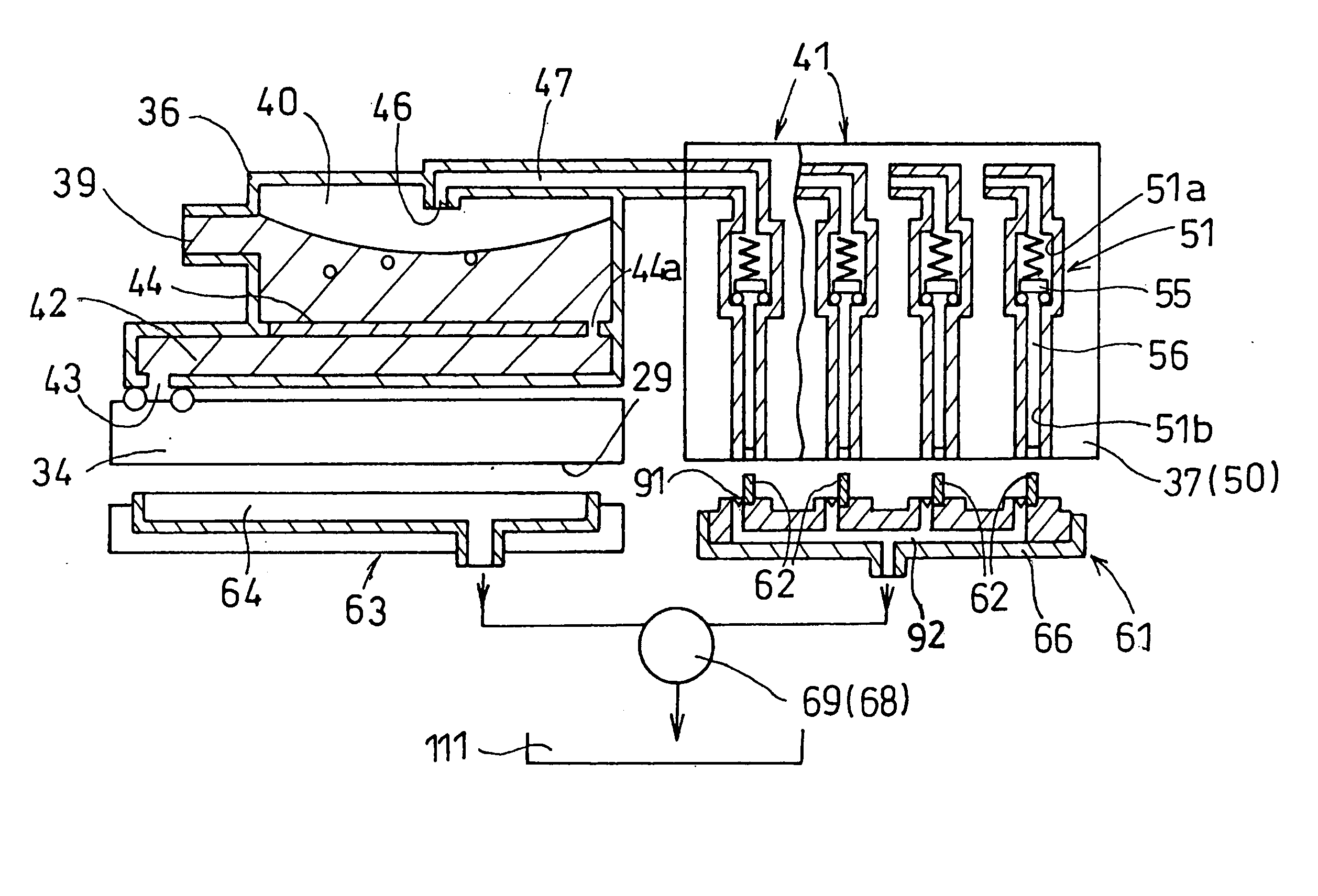

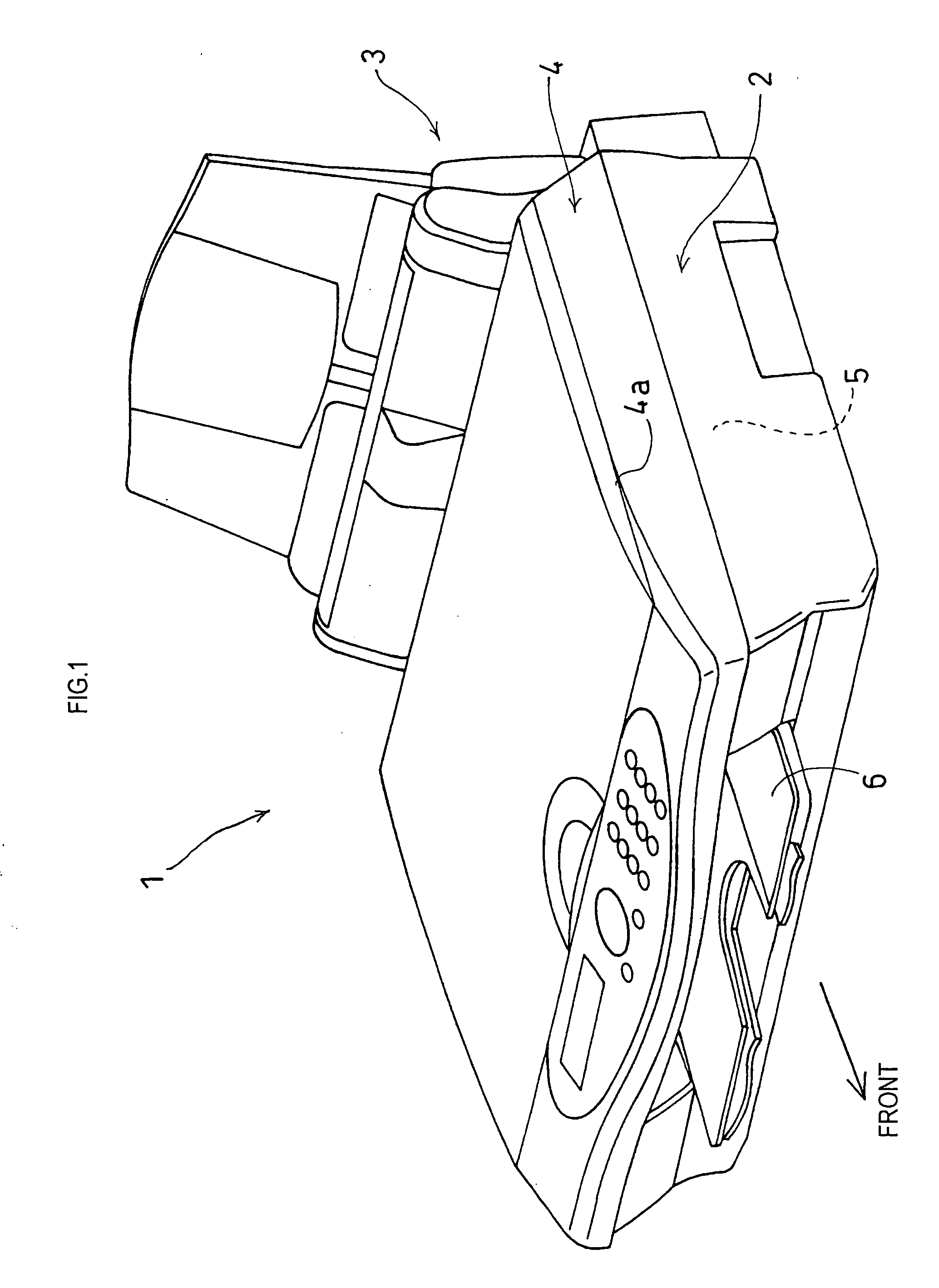

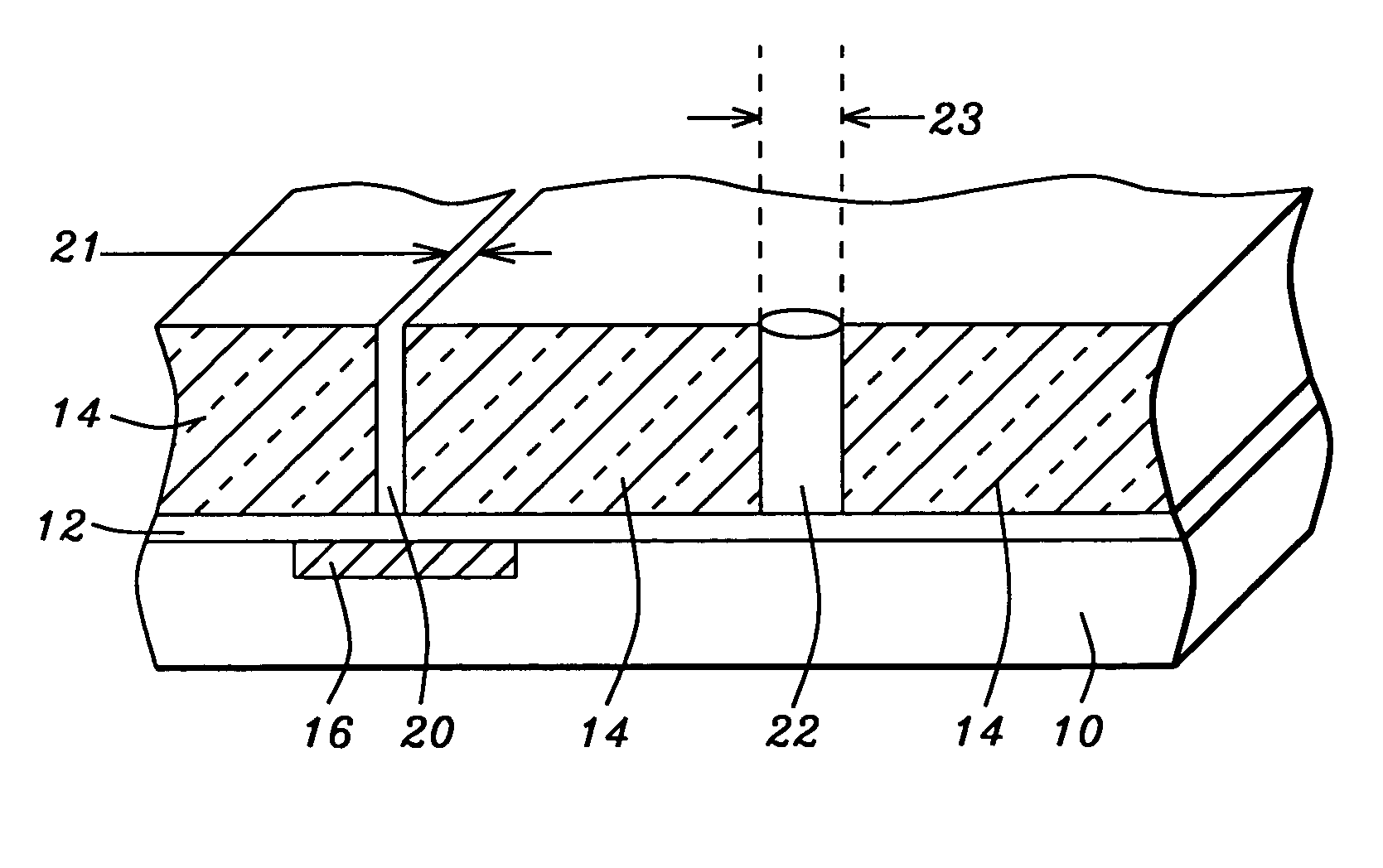

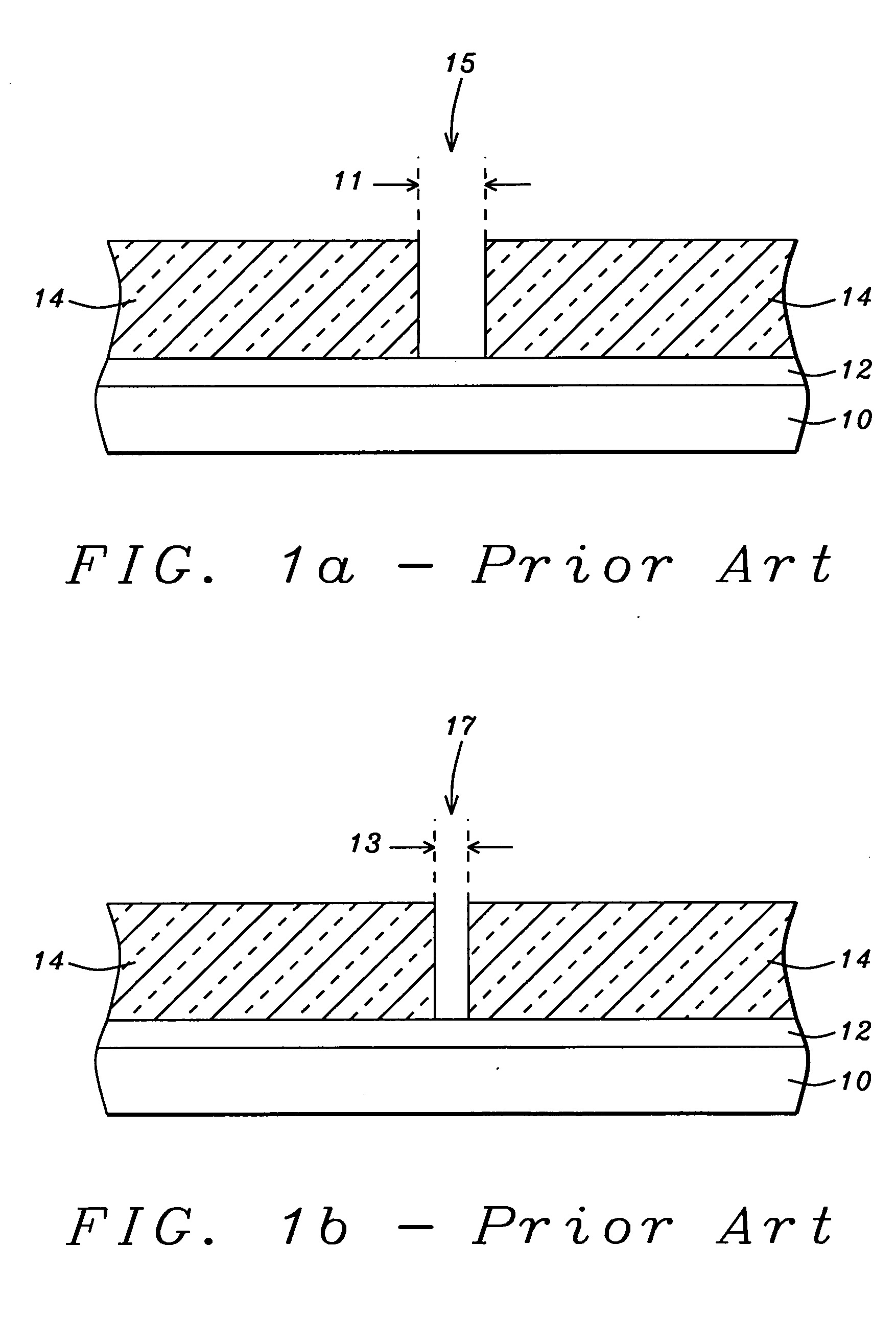

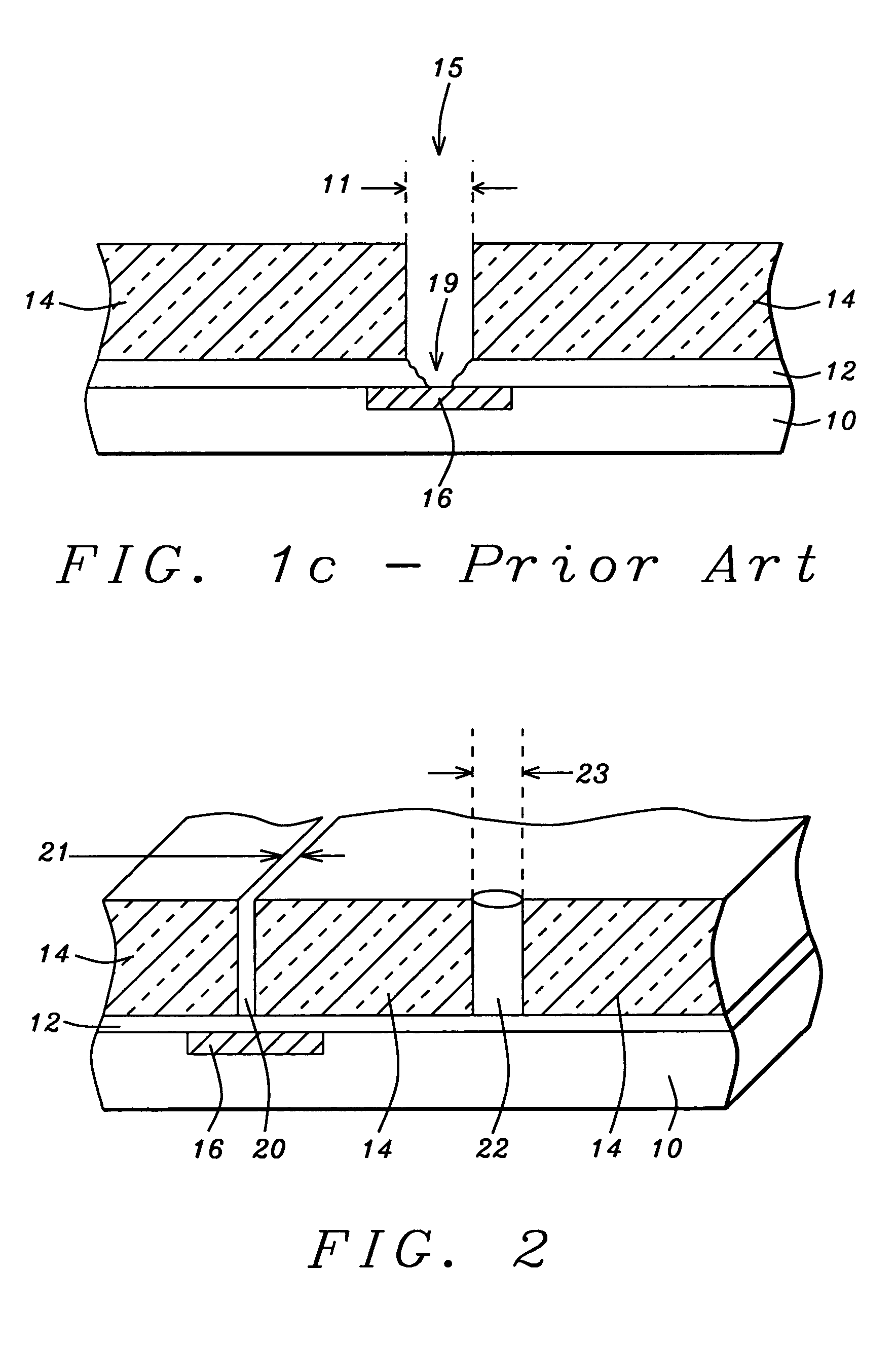

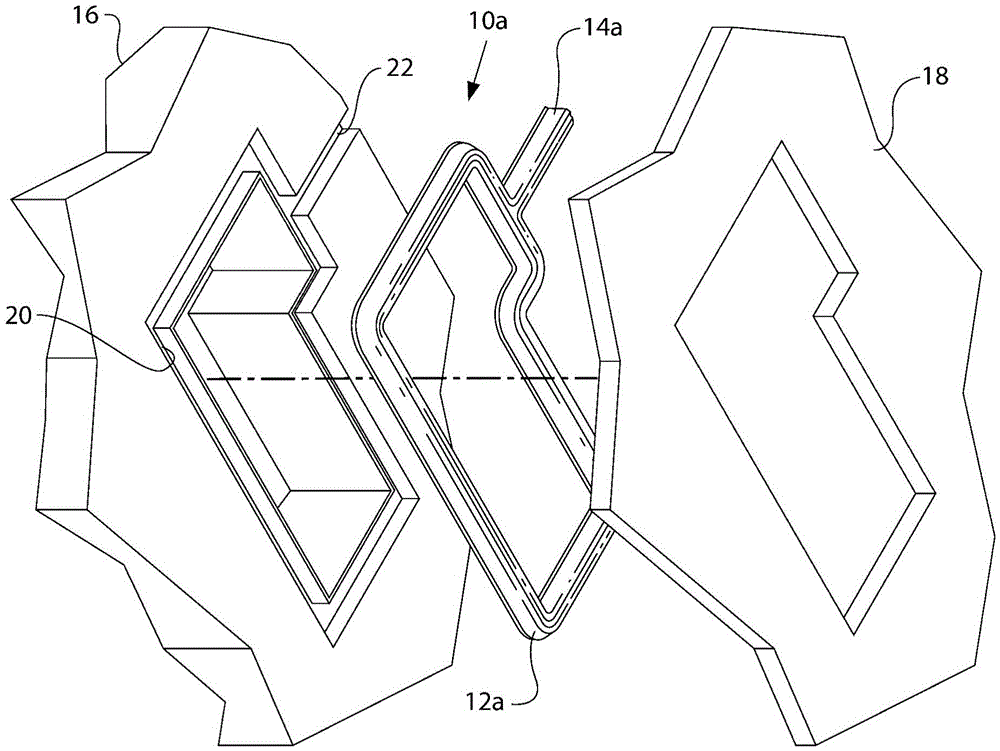

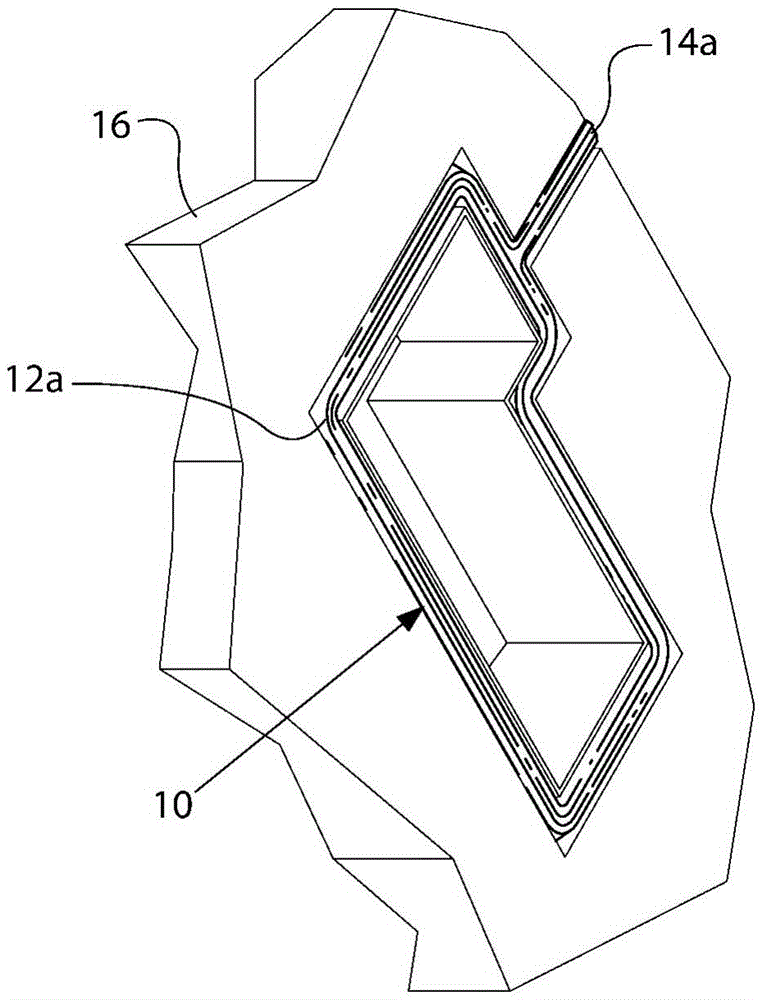

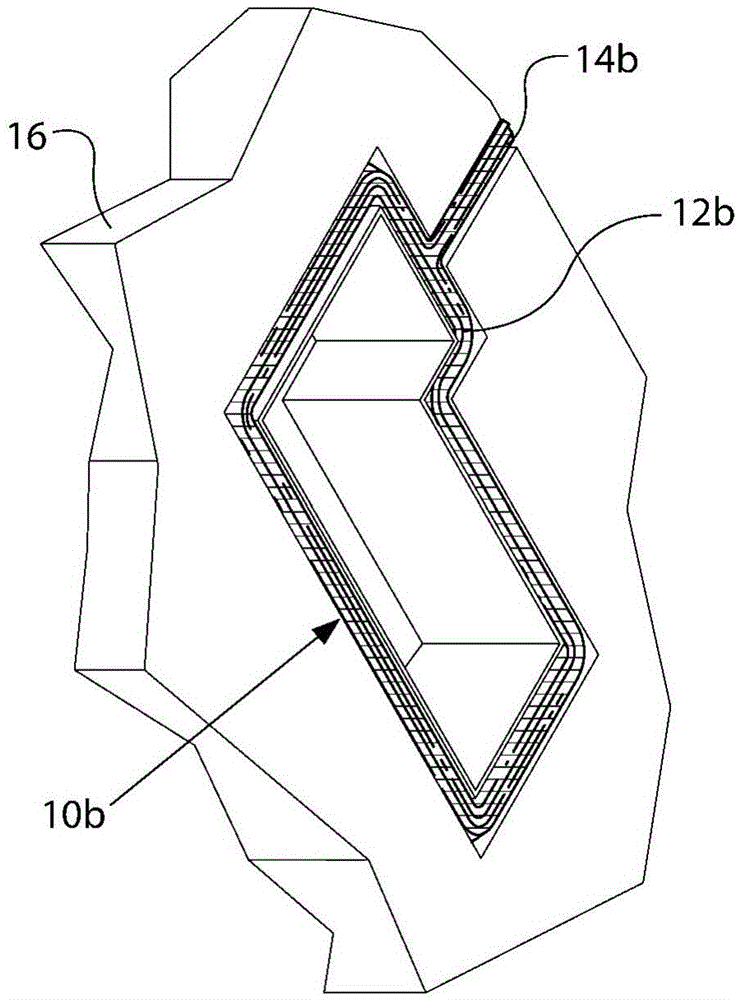

Gas turbine moving blade having a platform, a method of forming the moving blade, a sealing plate, and a gas turbine having these elements

InactiveUS20060269409A1Avoid temperature riseEasy to useEngine fuctionsBlade accessoriesGas turbinesBlow out

A platform of a gas turbine moving blade suppresses the effects of thermal elongation and thus improves cooling performance. A structure is constituted by a peripheral edge of a platform of a gas turbine moving blade, a bottom of the platform, and a shank of the moving blade. A cavity is blocked by disposing a sealing plate so as to seal the recessed section, while a supply route is formed for supplying air from cooling passages through an interior of the shank to the cavity, each of the passages being for air-cooling the interior of the gas turbine moving blade with air blown out from the cavity to a surface of the platform. A method of appropriately installing the sealing plate is also disclosed.

Owner:MITSUBISHI HEAVY IND LTD

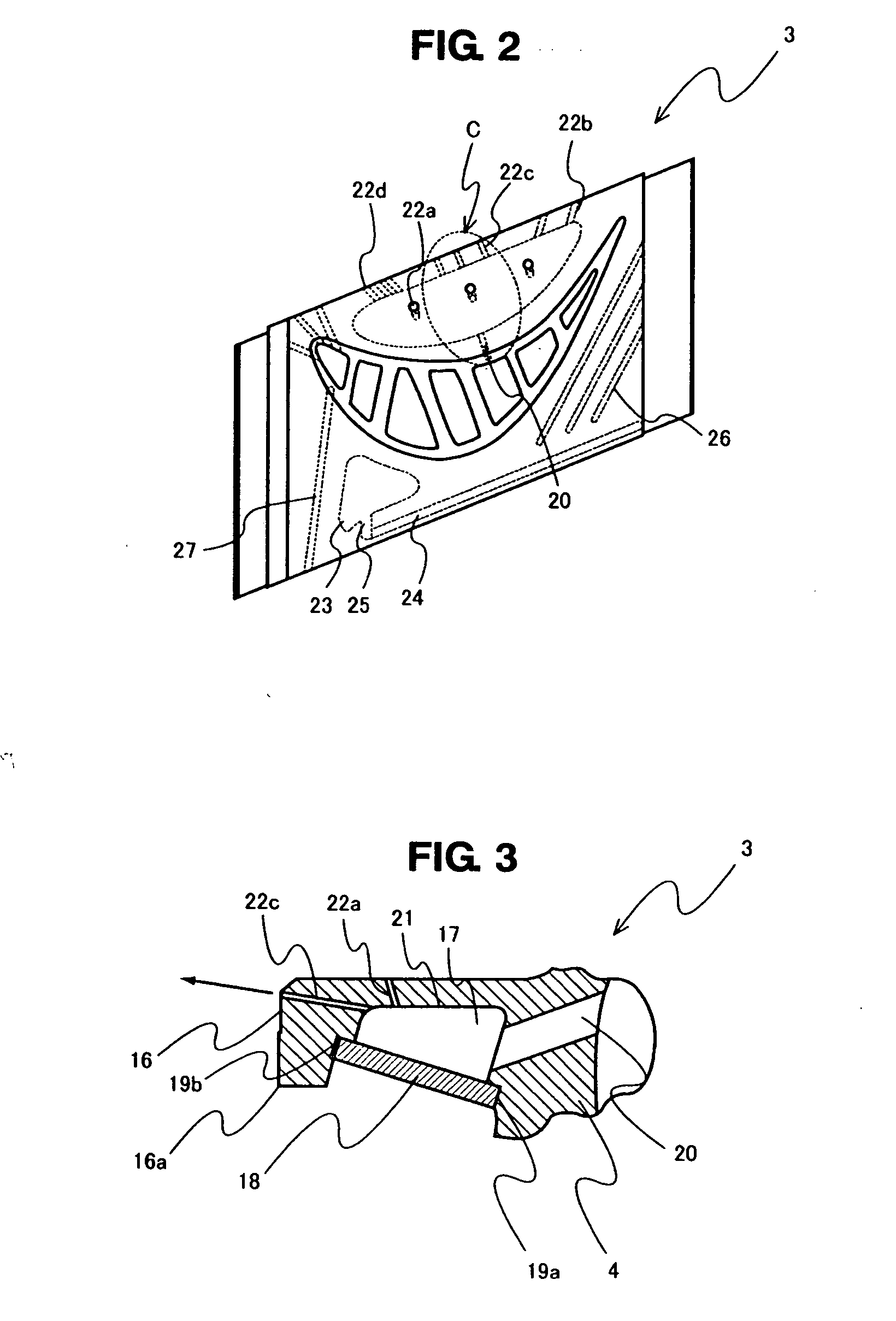

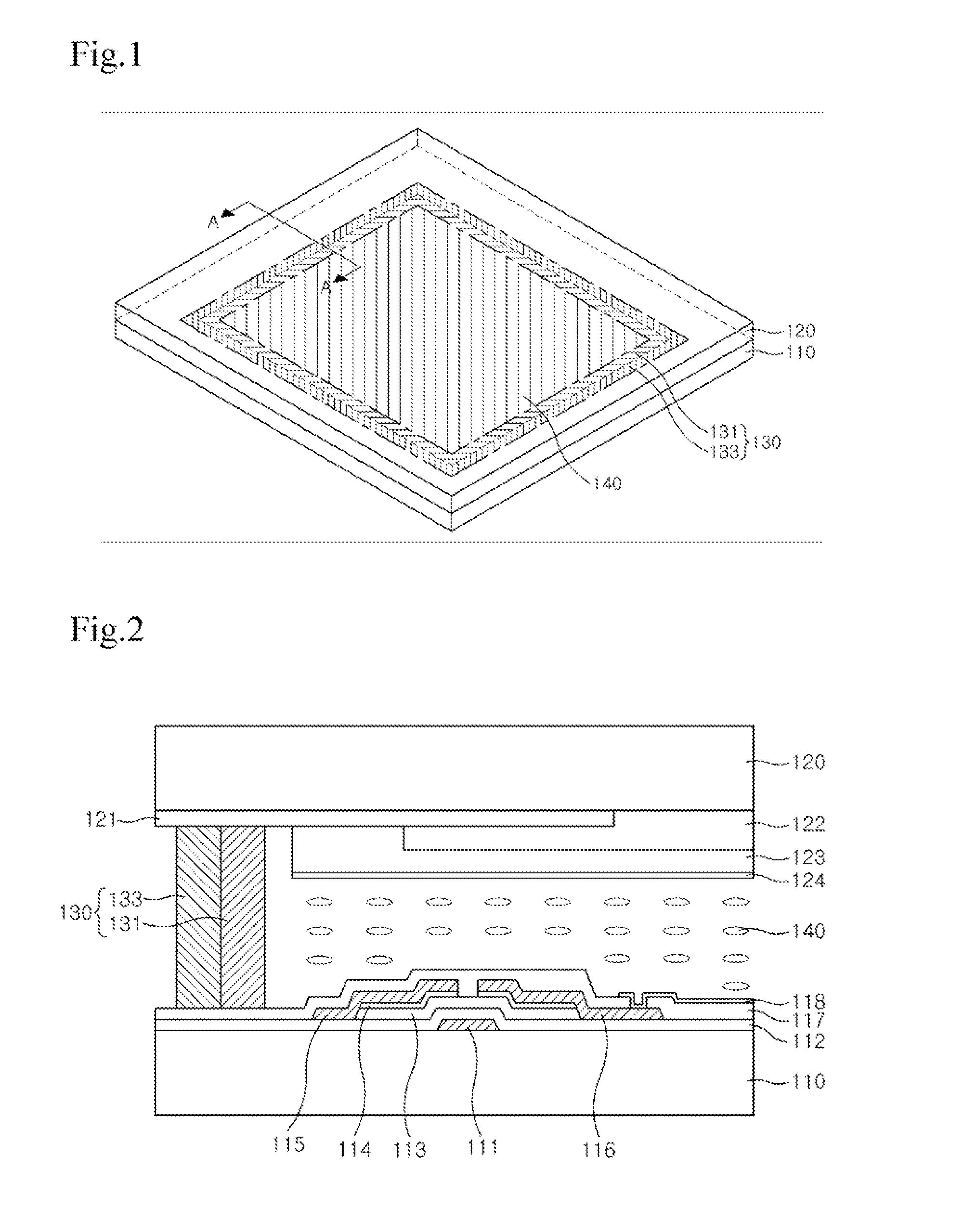

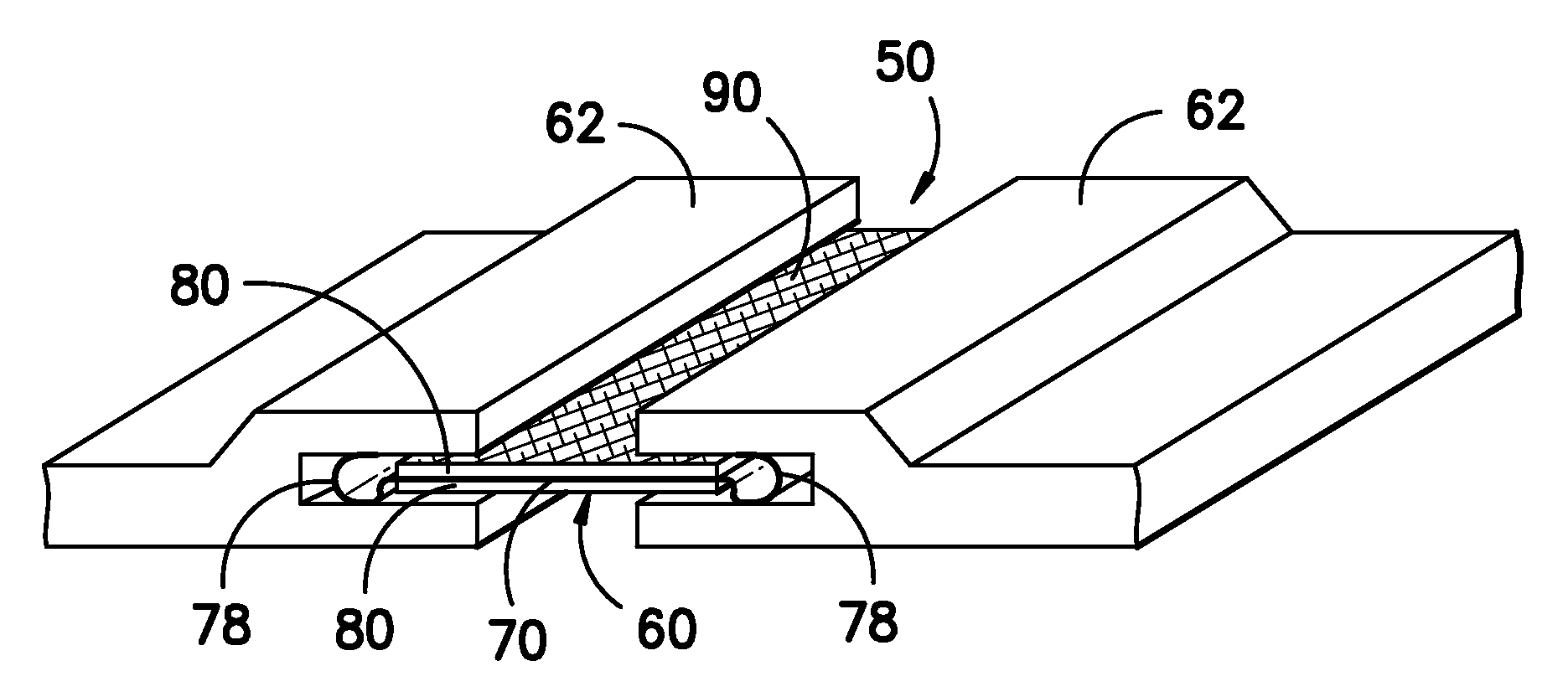

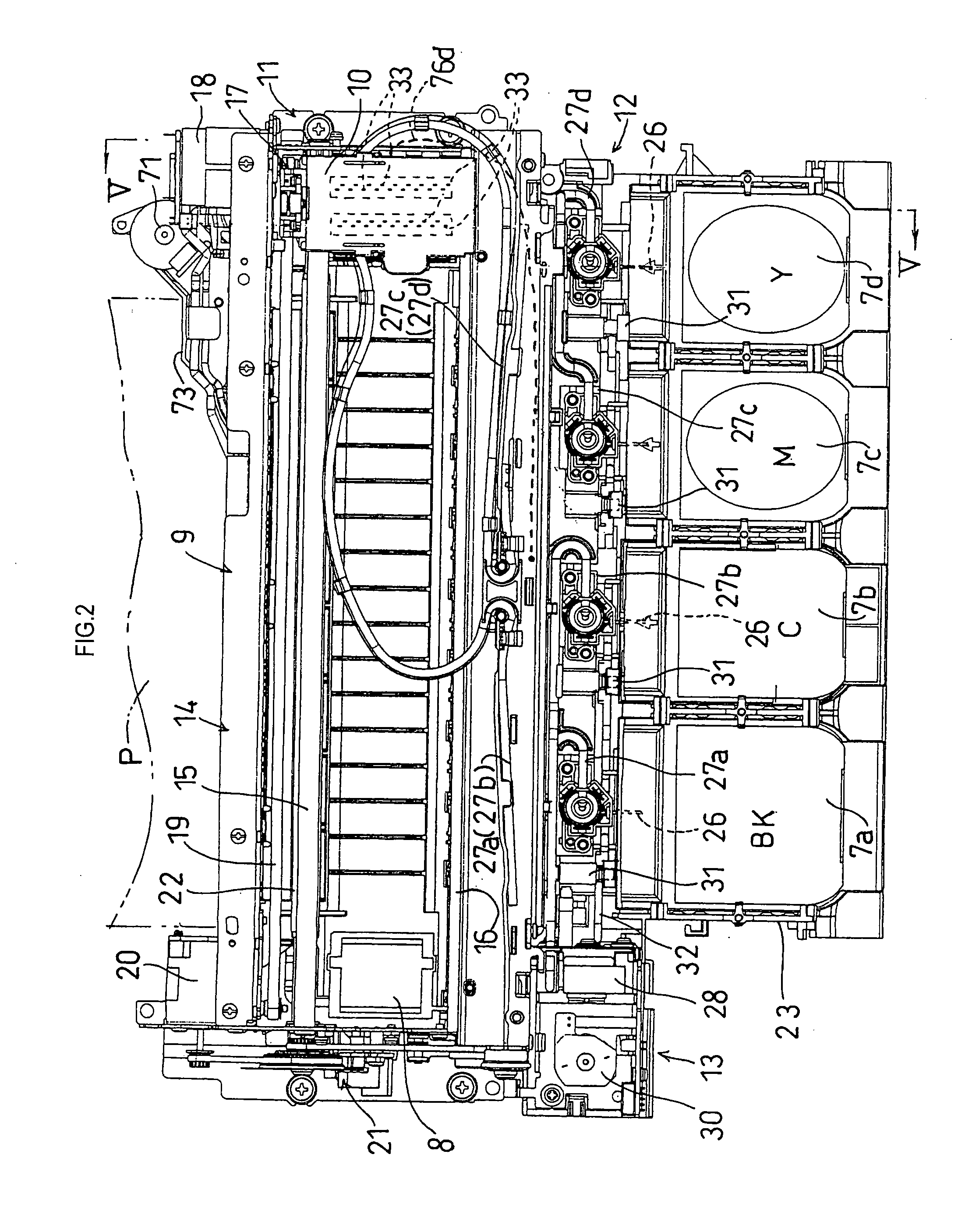

Sealant dispensing apparatus, liquid crystal display panel manufactured using the same and method of manufacturing liquid crystal display panel

InactiveUS20070095468A1Prevent bursting of liquid crystal dropping the liquid crystalAvoid it happening againLiquid crystal compositionsLiquid surface applicatorsInjection pressureLiquid-crystal display

The present invention relates to a sealant dispensing apparatus, a liquid crystal display panel manufactured using the sealant dispensing apparatus, and a method of fabricating the liquid display panel. The sealant dispensing apparatus. Comprises a body having an injection nozzle, a partition plate for dividing the interior of the body, into at least two spaces, and an injection pressure application section for applying an injection pressure to the spaces divided by the partition plate. A liquid crystal display panel manufactured using the sealant dispensing apparatus, comprises upper and lover substrates, a sealing pattern formed along edges of opposite upper and lower substrates, and liquid crystal interposed inward of the sealing pattern, wherein the sealing pattern comprises at least two kinds of sealants whose mixing ratio is changed along a widthwise direction of the sealing pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

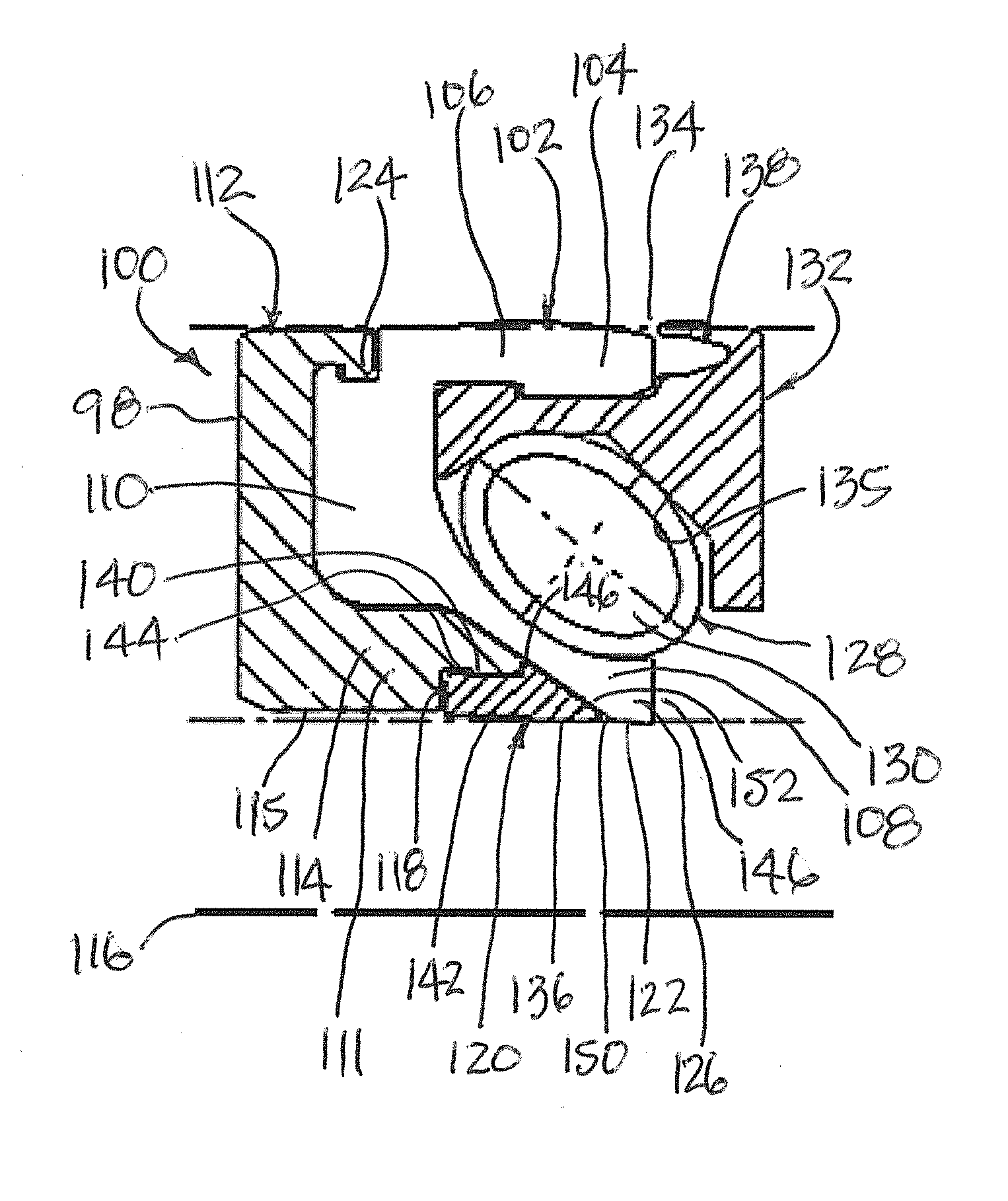

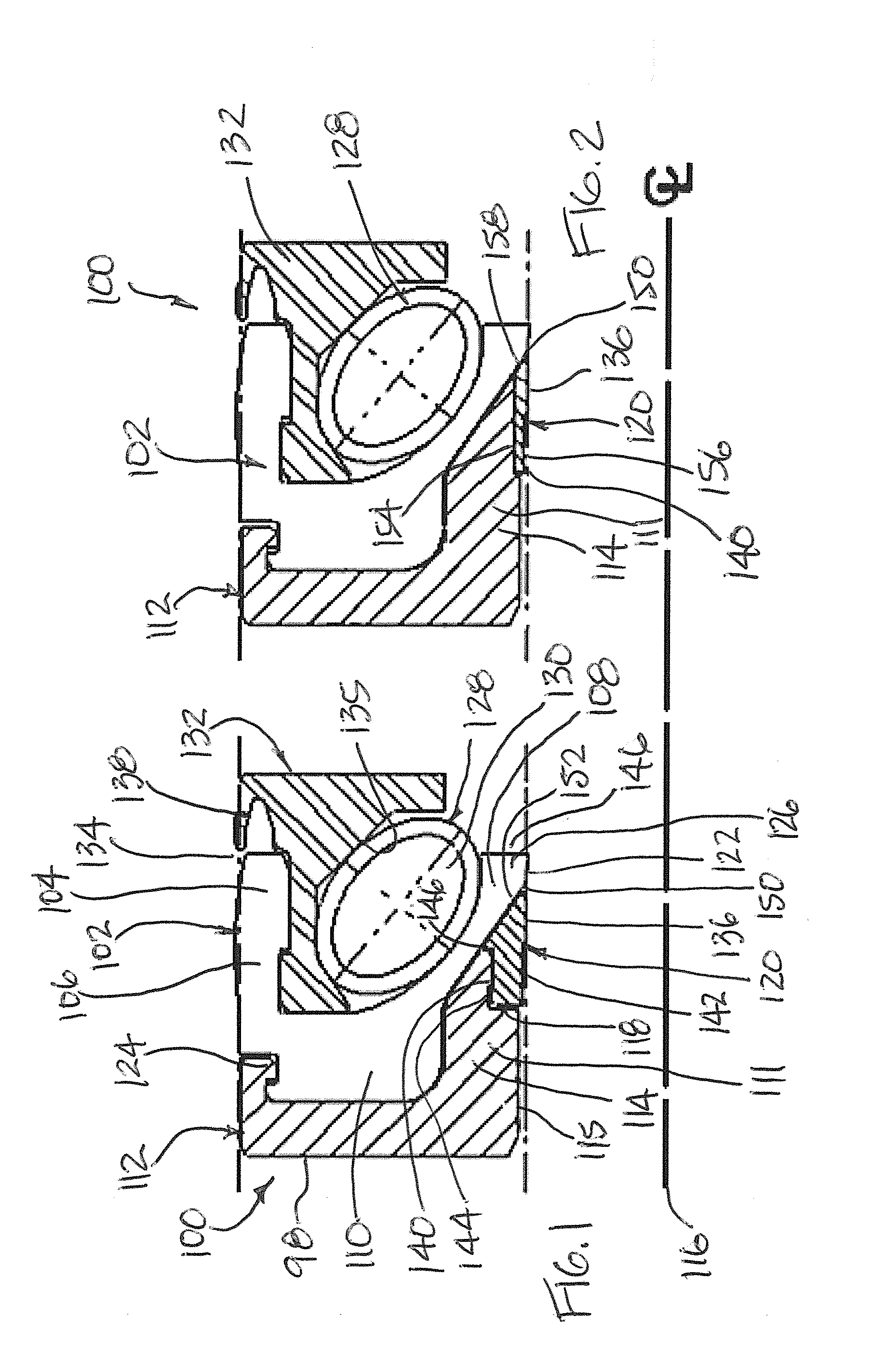

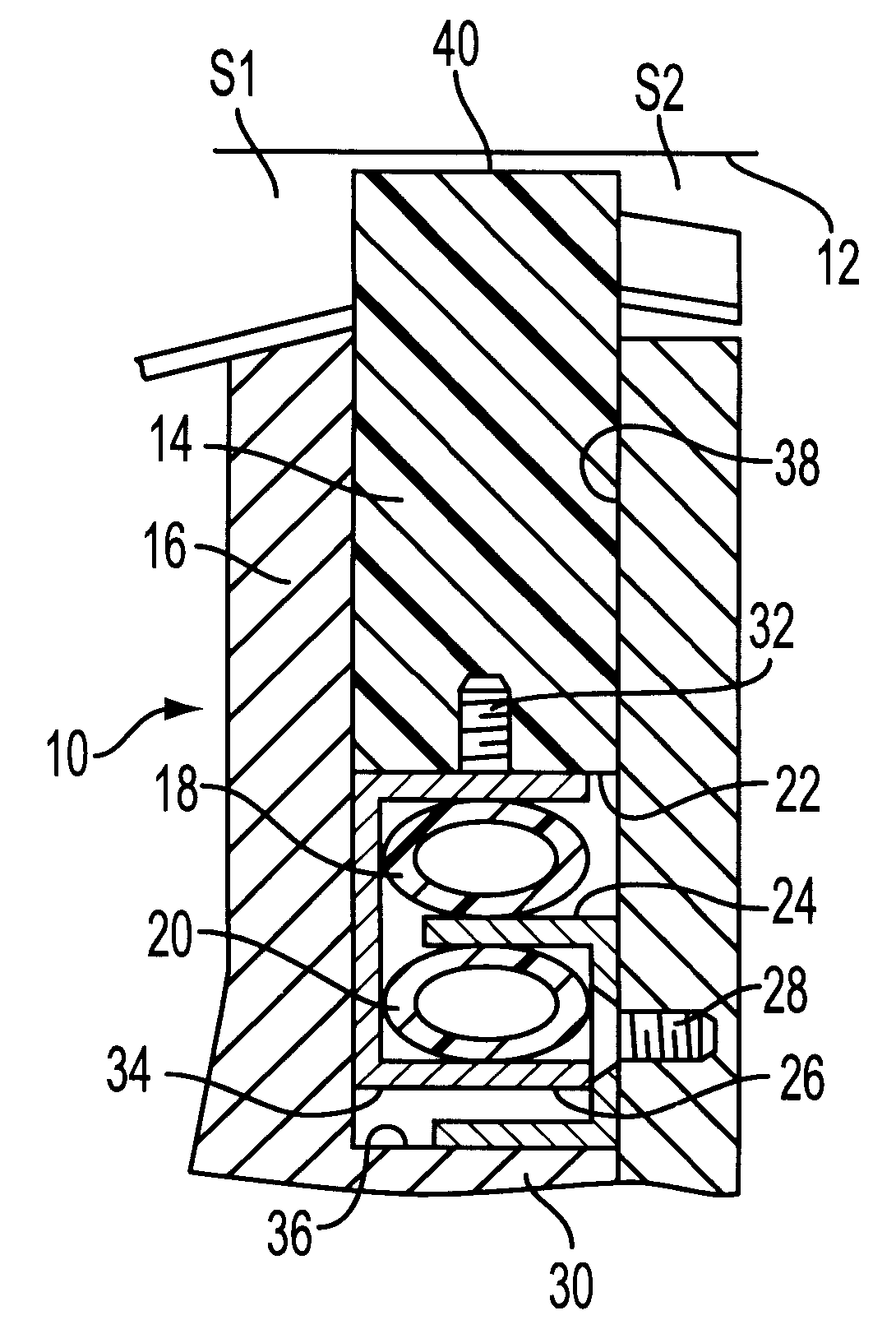

High pressure lip seals with Anti-extrusion and Anti-galling properties and related methods

ActiveUS20140265139A1High modulus materialReduce the possibilityEngine sealsEngineeringHigh pressure

Sealing assemblies to provide sealing between a shaft and a housing comprising a sealing component comprising a body section as well as an outer flange and an inner flange both extending from said body section; a supporting component receiving said sealing component and comprising a relatively thick inner arm projecting into said sealing component and providing a supporting area spanning an inner portion of said body section and a portion of said inner flange; an anti-extrusion component engaged with said relatively thick inner arm; the minimum clearance between said anti-extrusion component and said shaft being less than the minimum clearance between said relatively thick inner arm and said shaft; said inner flange comprising a sealing area; wherein said sealing assembly is to be received in a cavity in said housing or on said shaft.

Owner:BAL SEAL ENG LLC

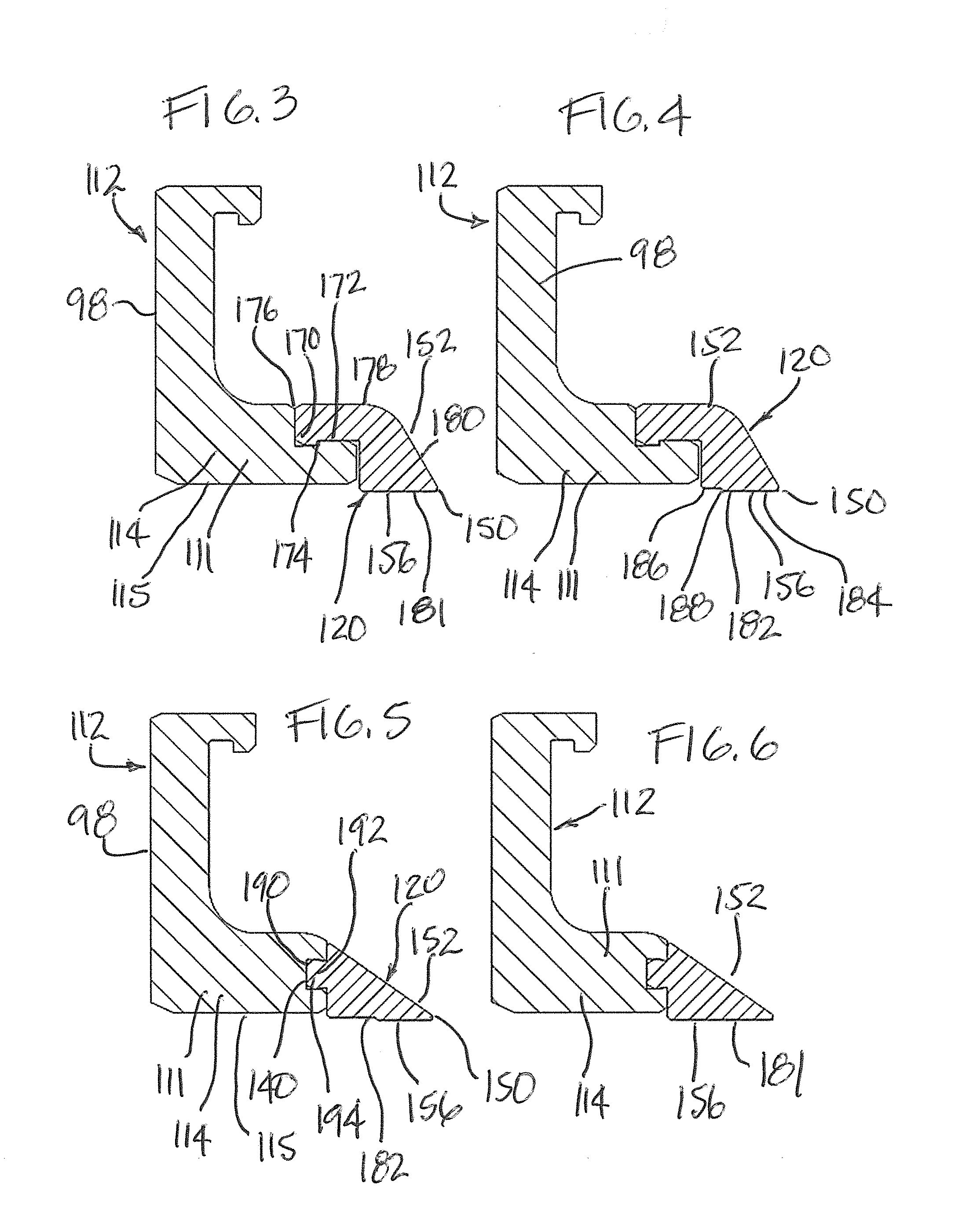

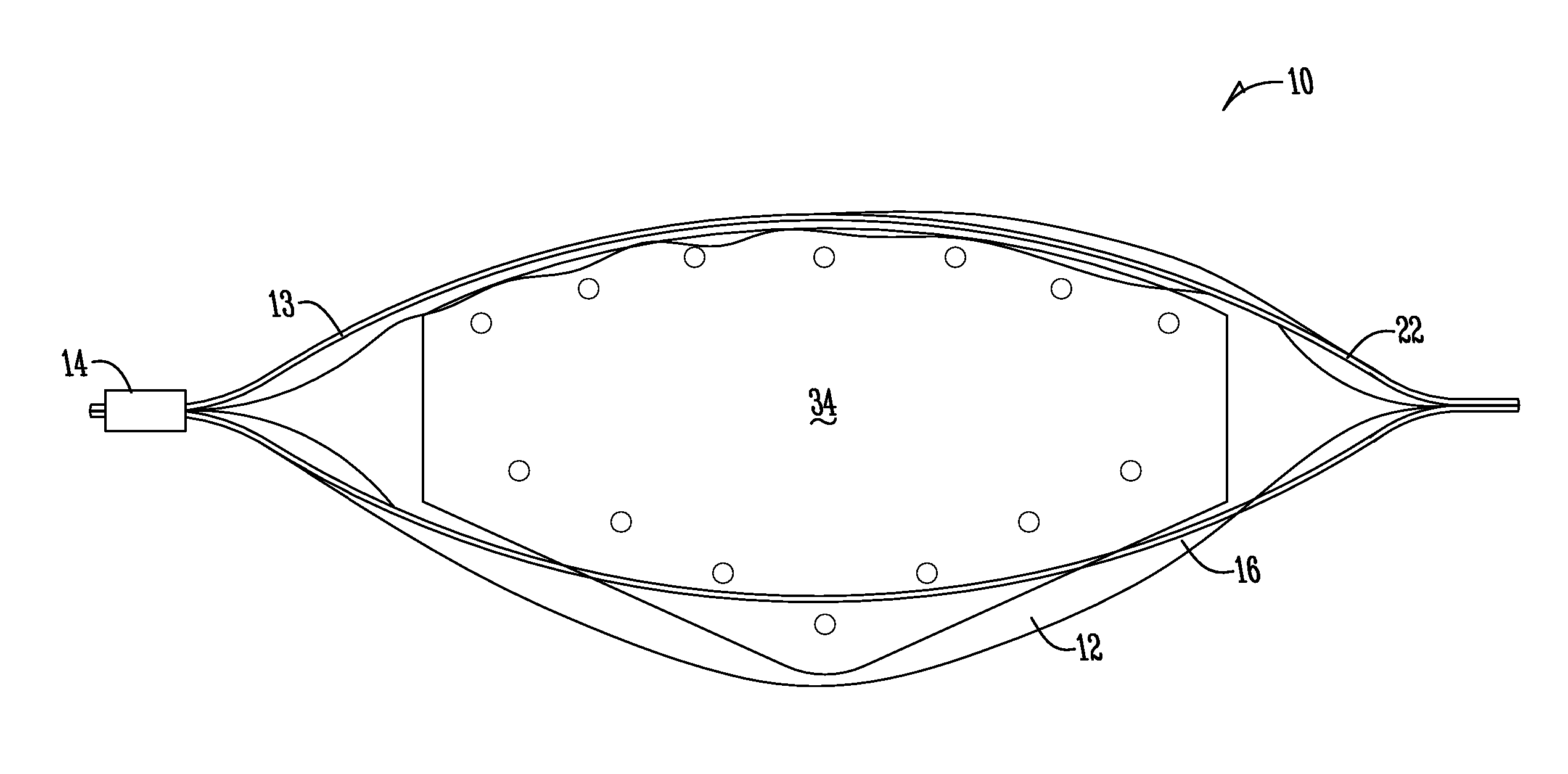

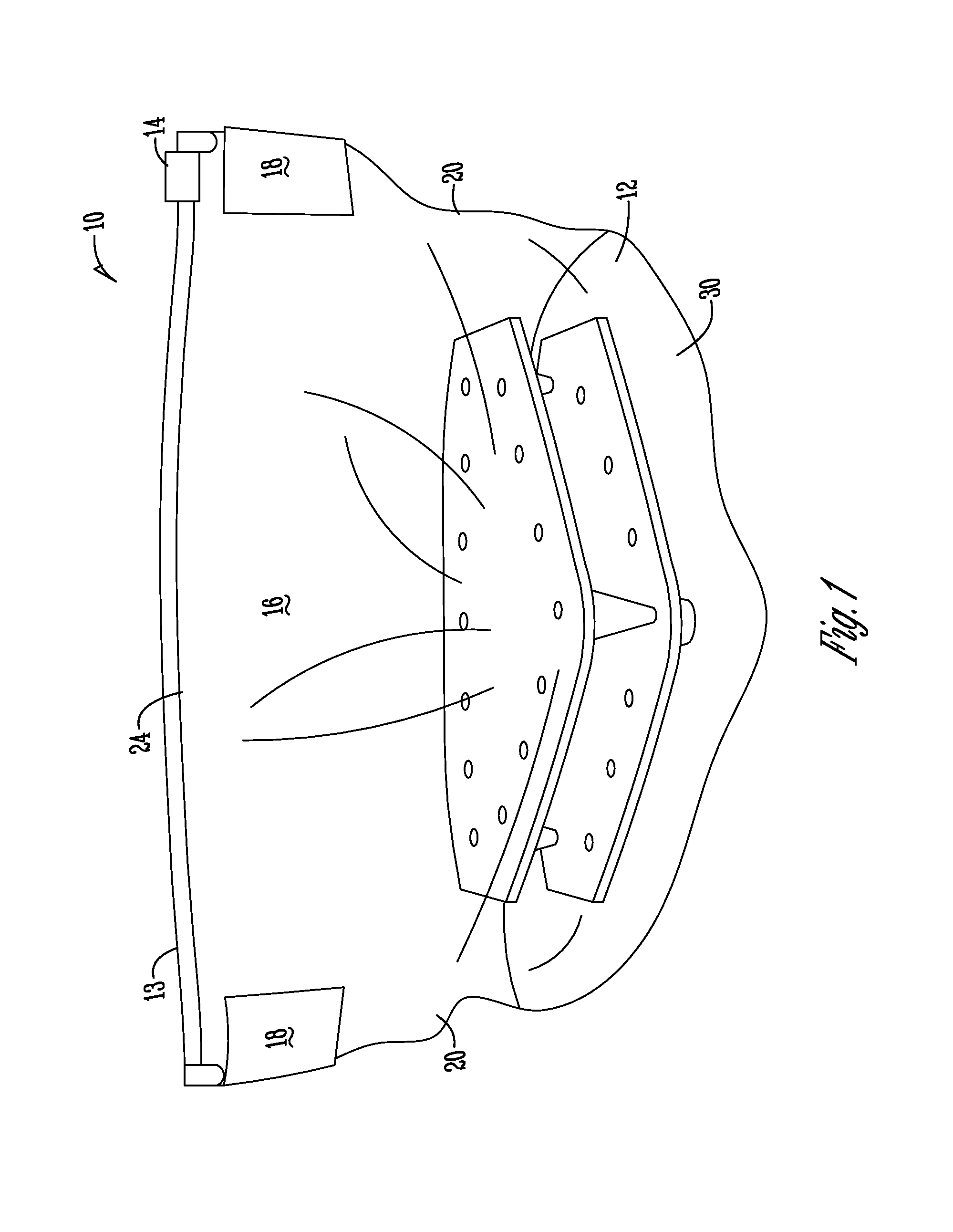

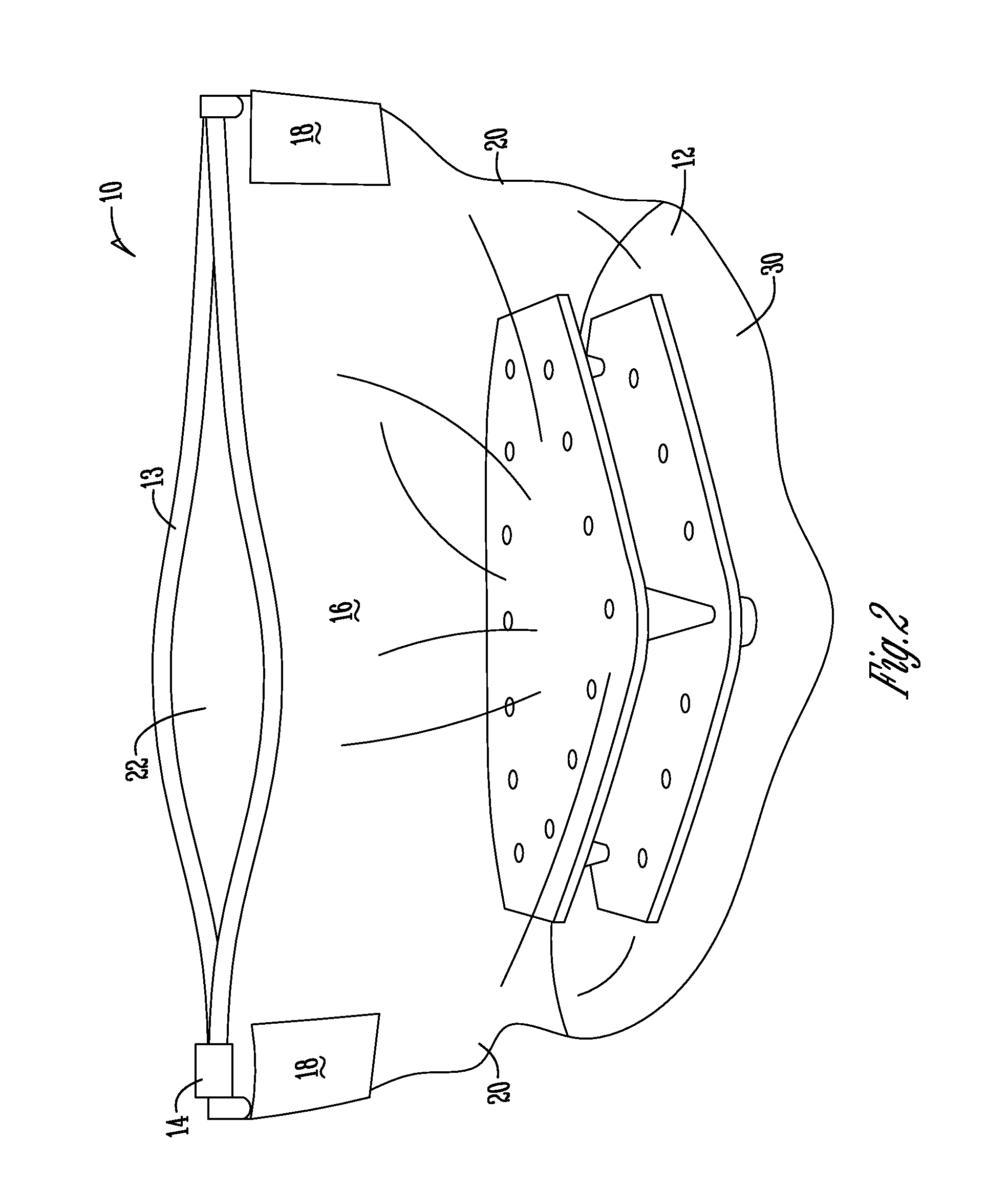

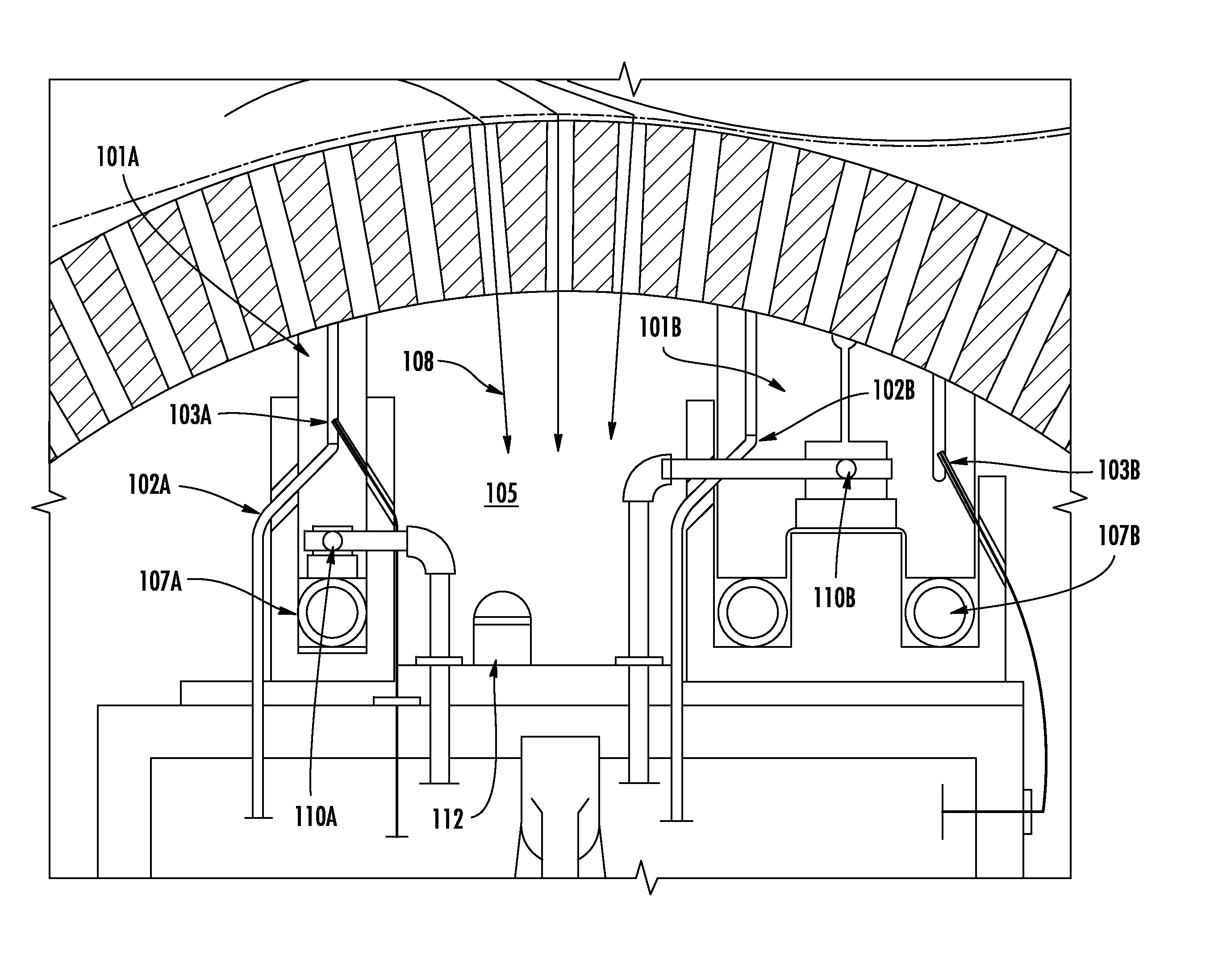

Sealing device and method for providing a seal in a turbine system

A sealing device and a method for providing a seal between adjacent components in a turbine system are disclosed. The sealing device includes a seal plate configured to provide a seal between adjacent components, a wire mesh mounted to the seal plate, the wire mesh defining a plurality of voids, and a sealant impregnating the wire mesh such that at least a portion of the plurality of voids include the sealant therein.

Owner:GENERAL ELECTRIC CO

Retrofittable severe duty seal for a shaft

The present invention discloses a seal and a method of sealing dynamic shaft applications. The seal comprises an inner portion, an outer portion, a faceplate, and at least one flexible member located between the inner and outer portions. The method comprises providing a dynamic shaft assembly containing a bore for receiving a seal, providing a unitized seal, and placing the unitized seal on the shaft, thus sealing the assembly so that lubricants may not escape, and foreign material may not enter. The unitized seal can provide permanently lubricated sealed bearings in severe service conditions such as rollers and idlers of track-driven vehicles and agricultural equipment.

Owner:DICHTOMATIK AMERICAS

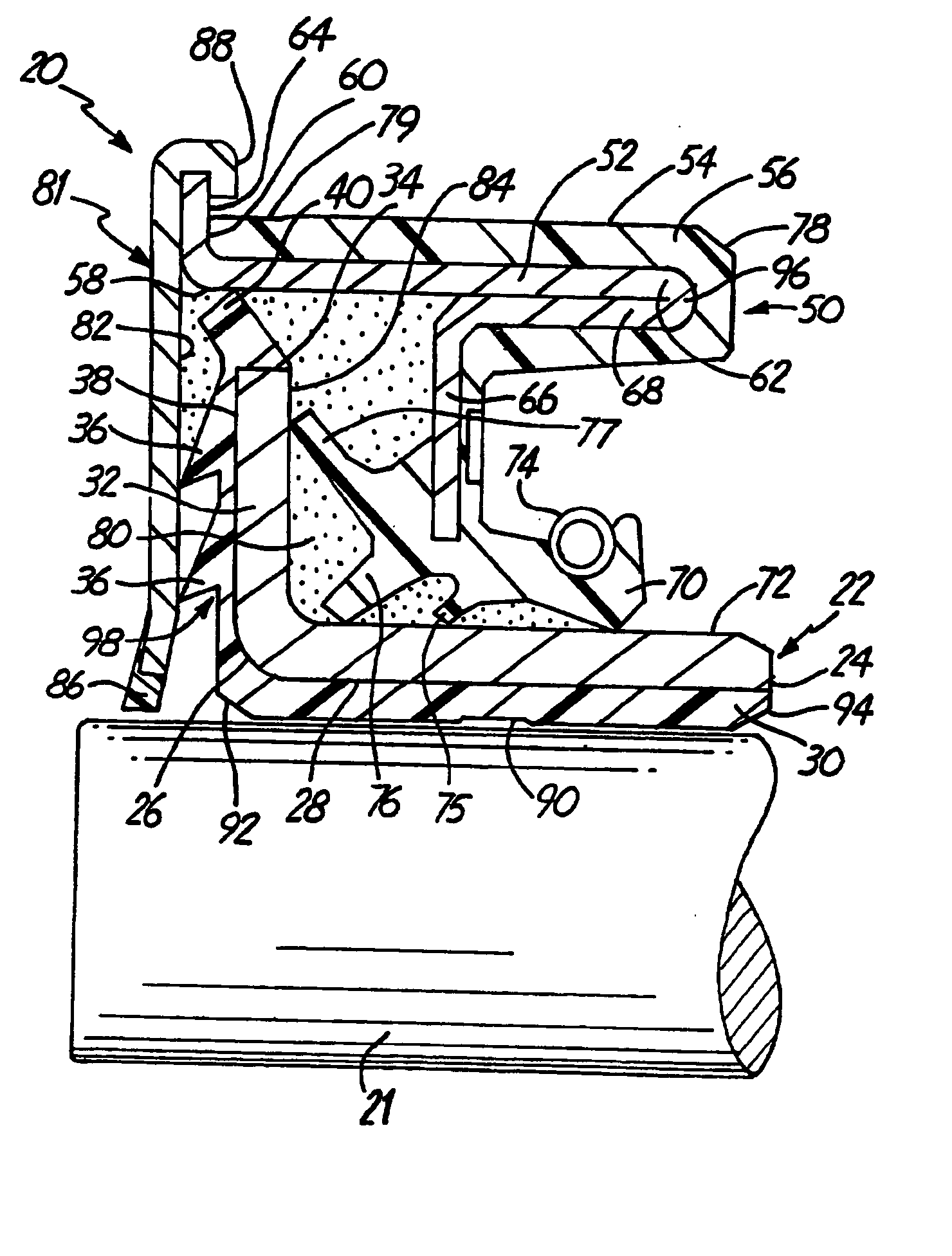

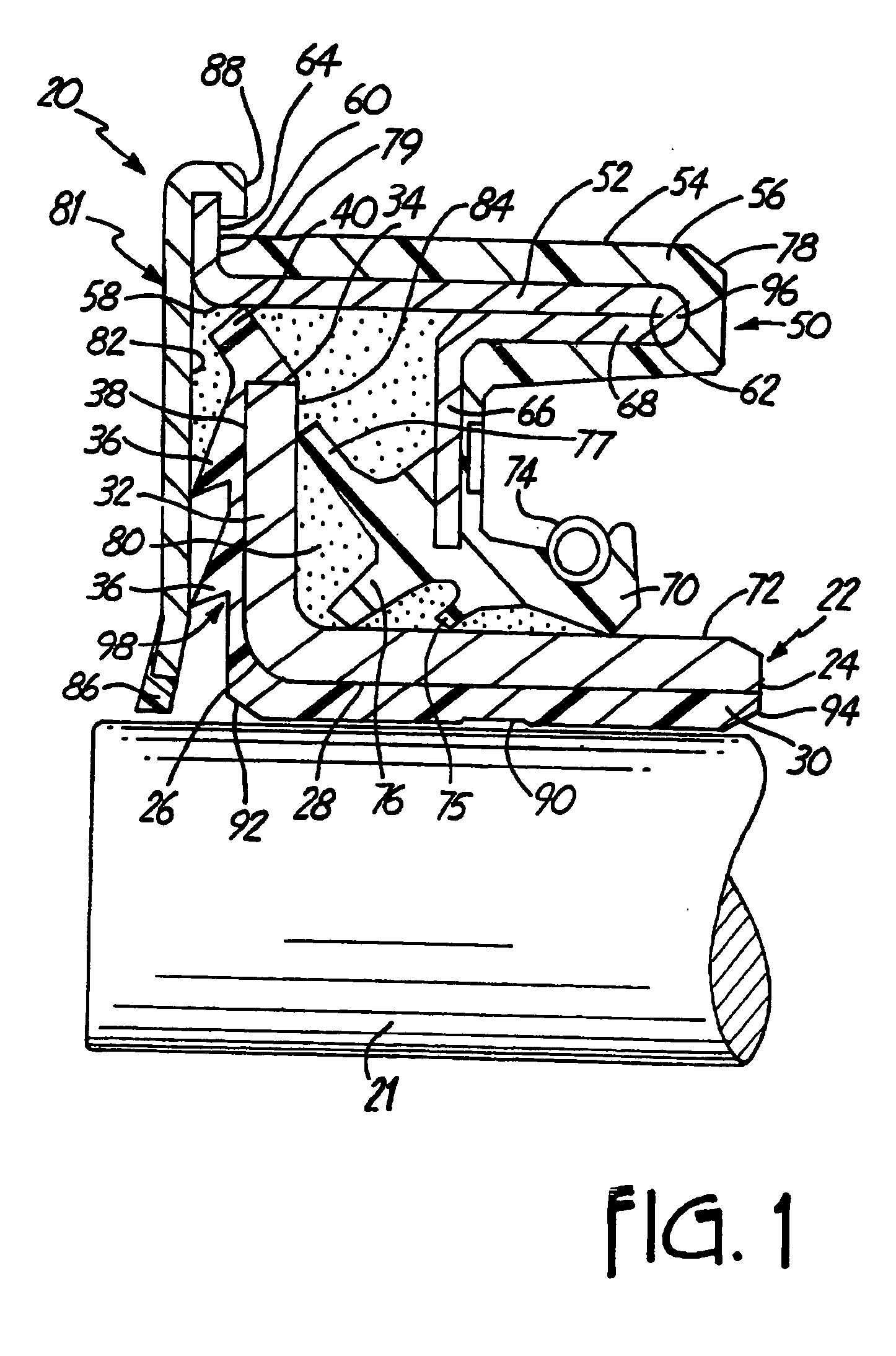

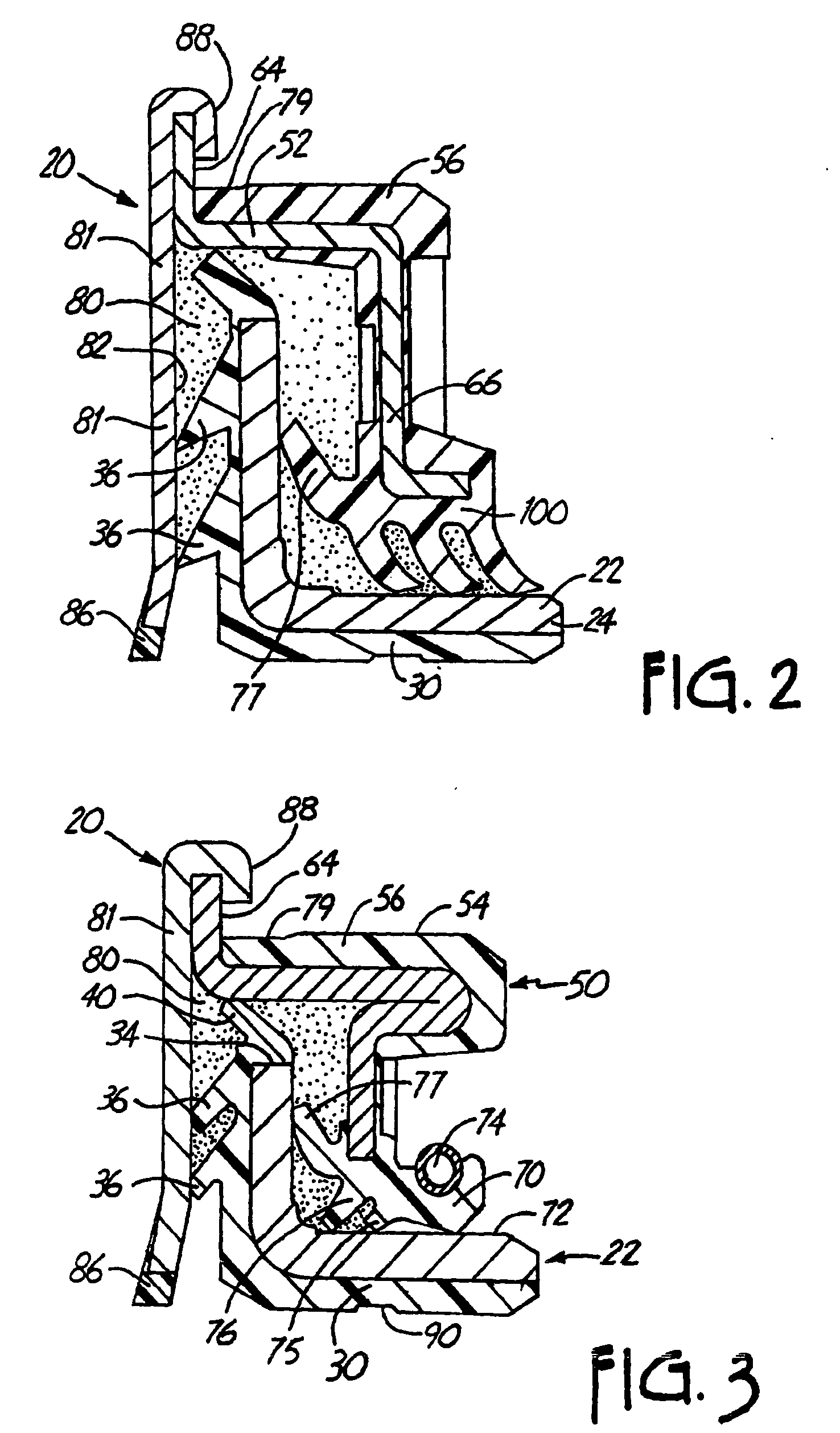

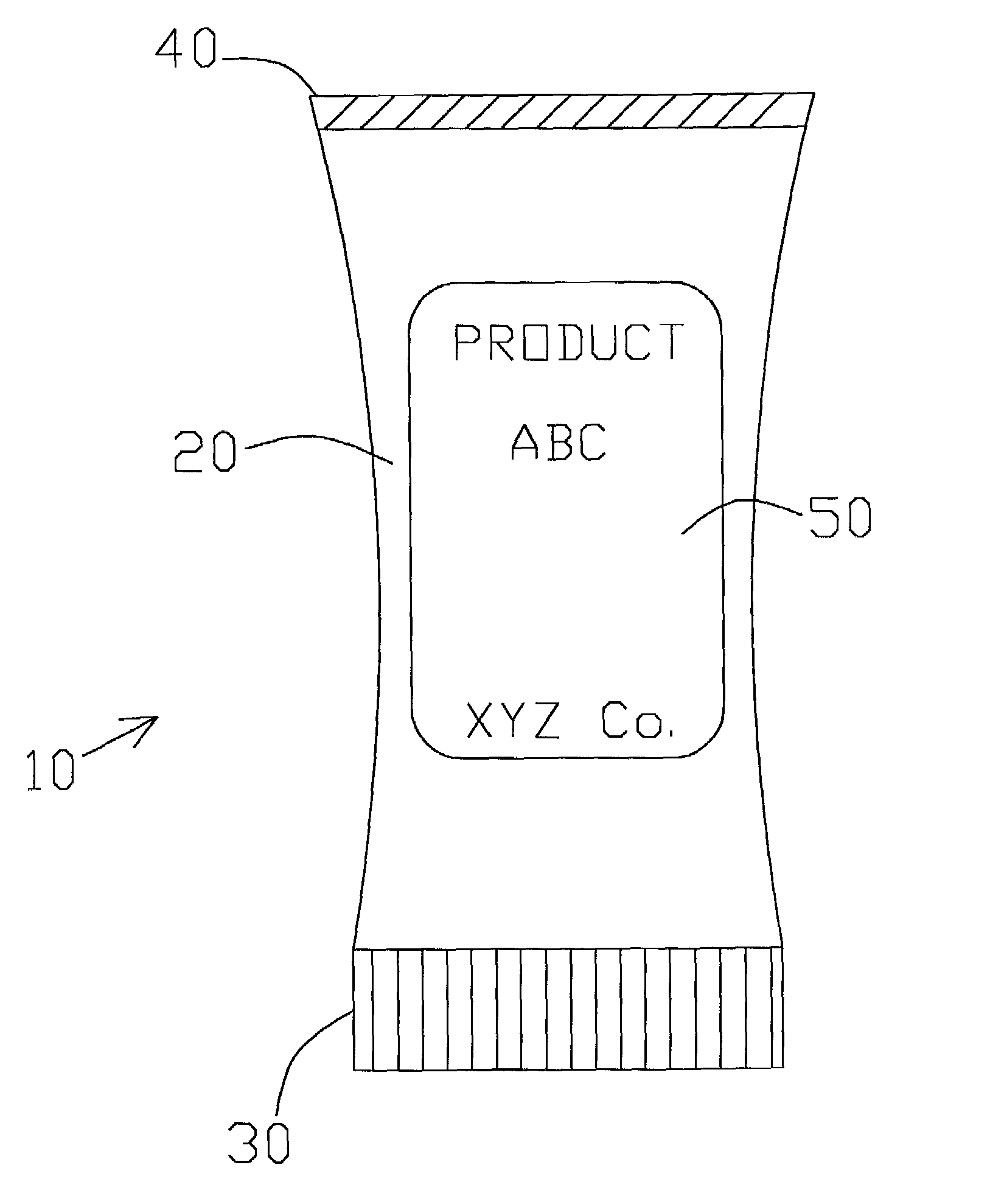

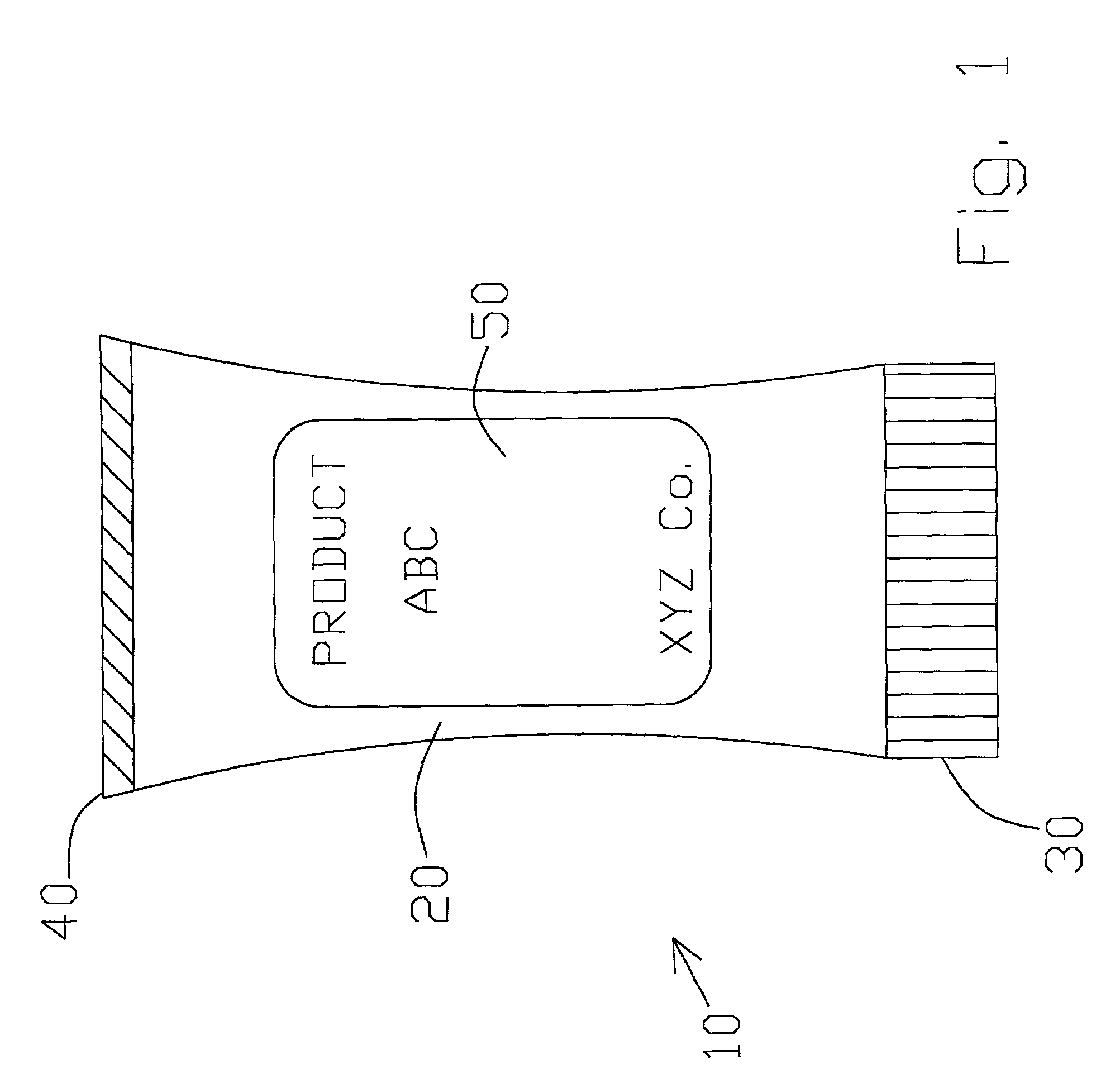

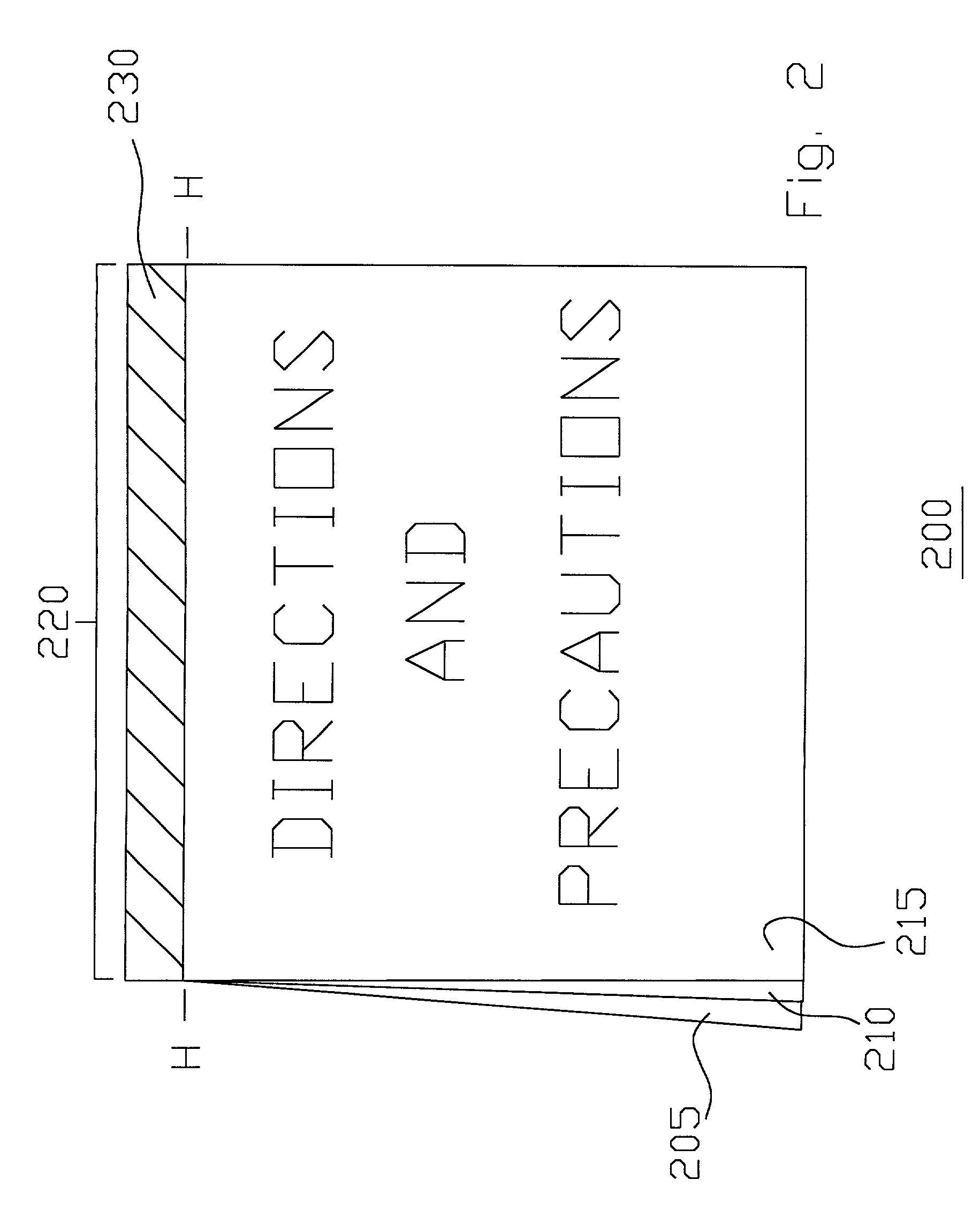

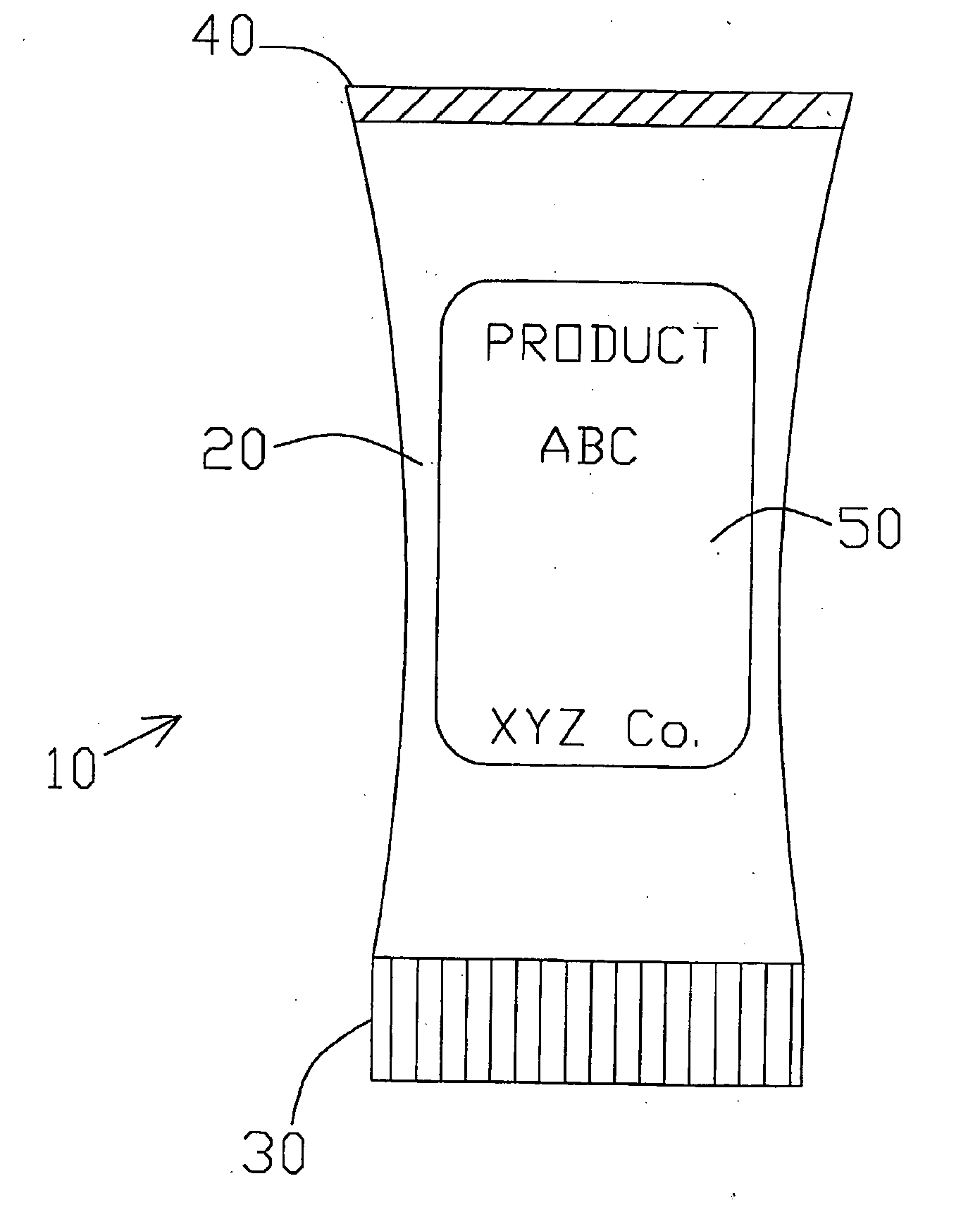

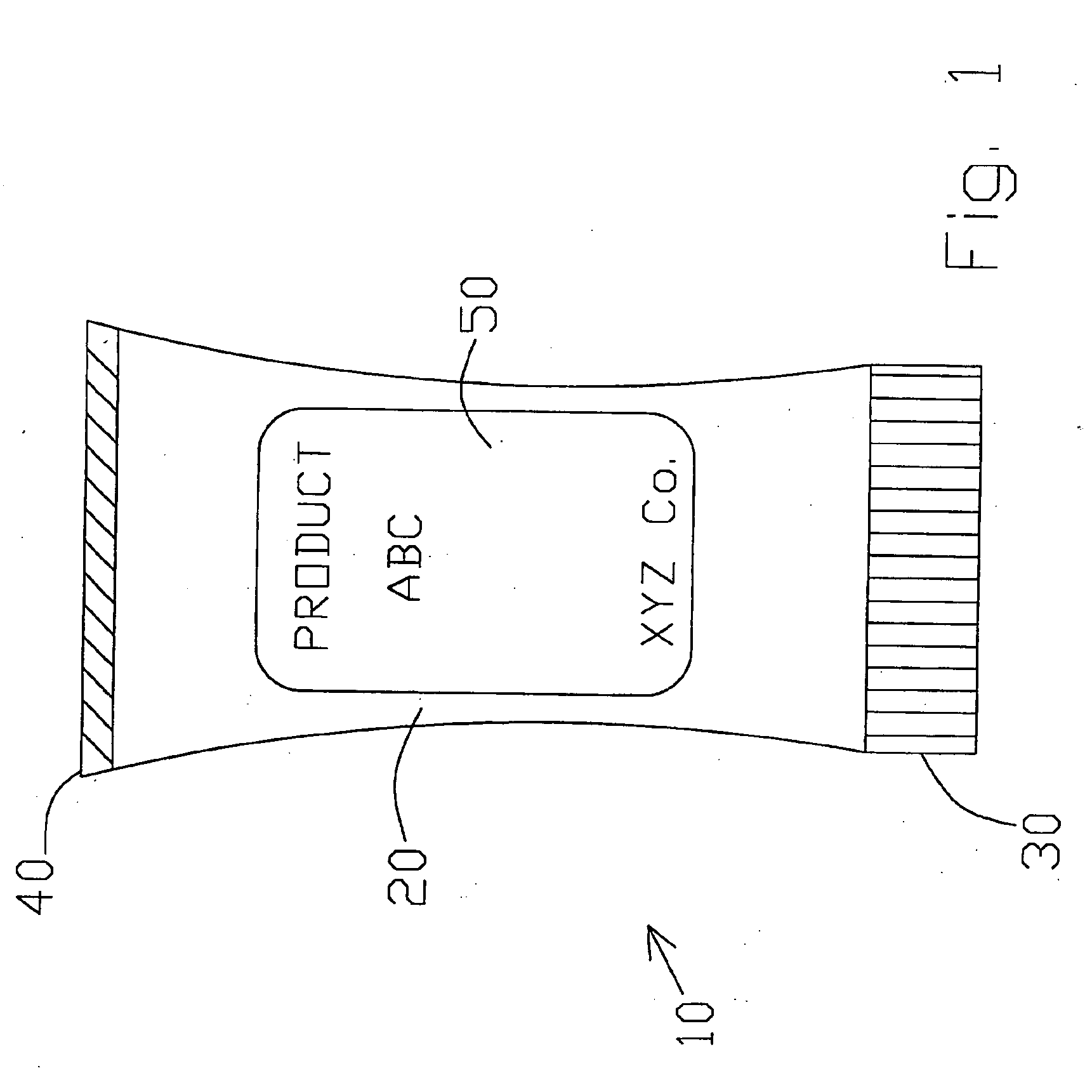

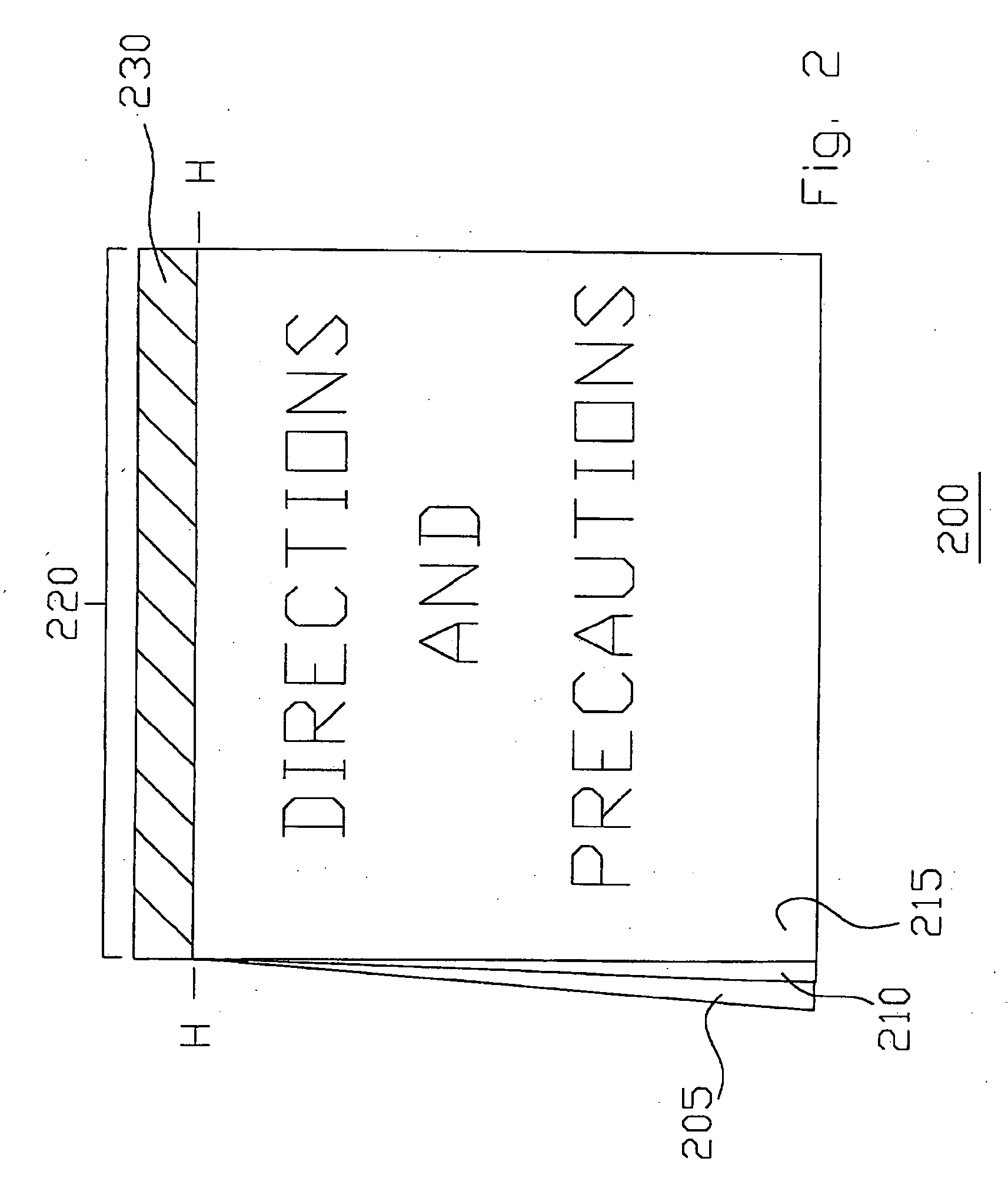

Extended text label for a tube container and method of manufacture thereof

InactiveUS7172220B2Simple and inexpensive to produceEasy to useStampsLayered productsEngineeringMethod seal

An extended text label is provided for a tube container, wherein the tube container includes a product dispensing end and a filling end opposite the dispensing end. The filling end is adapted to be sealed by a crimp method, subsequent to filling the tube container with a selected product. The extended text label includes a crimp edge. The crimp edge is capable of being securely joined to the filling end of the tube container by way of the crimp method.

Owner:QUALITY ASSURED ENTERPRISES

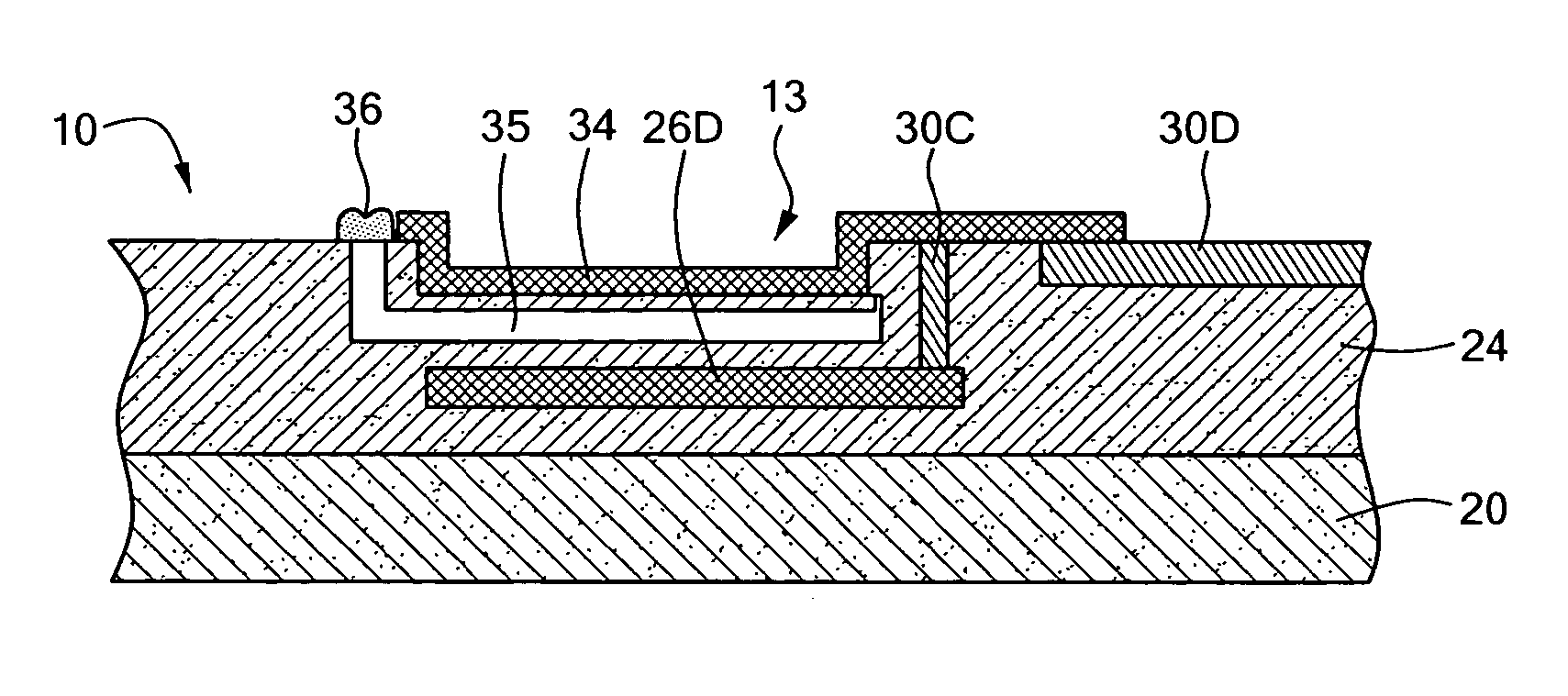

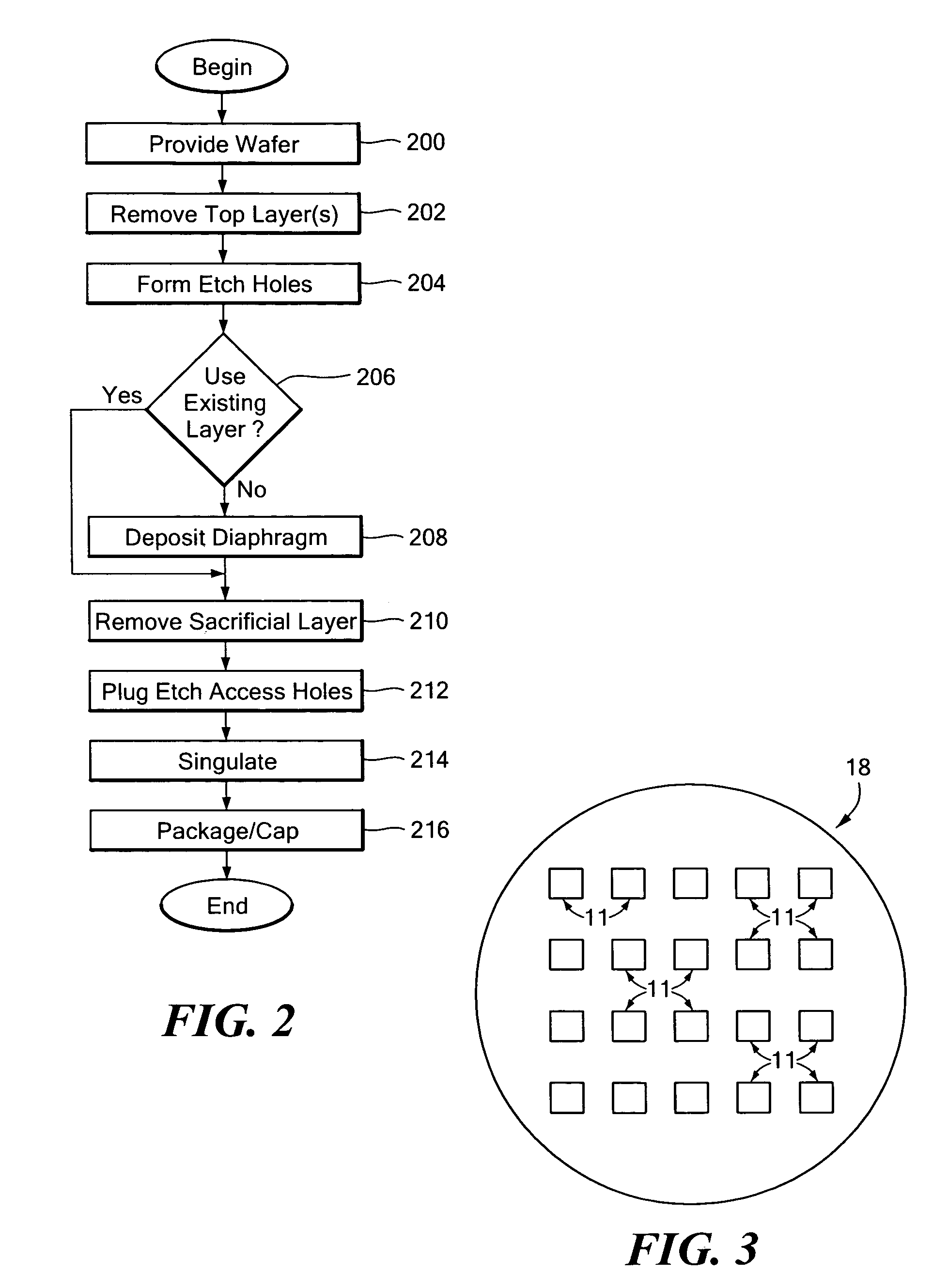

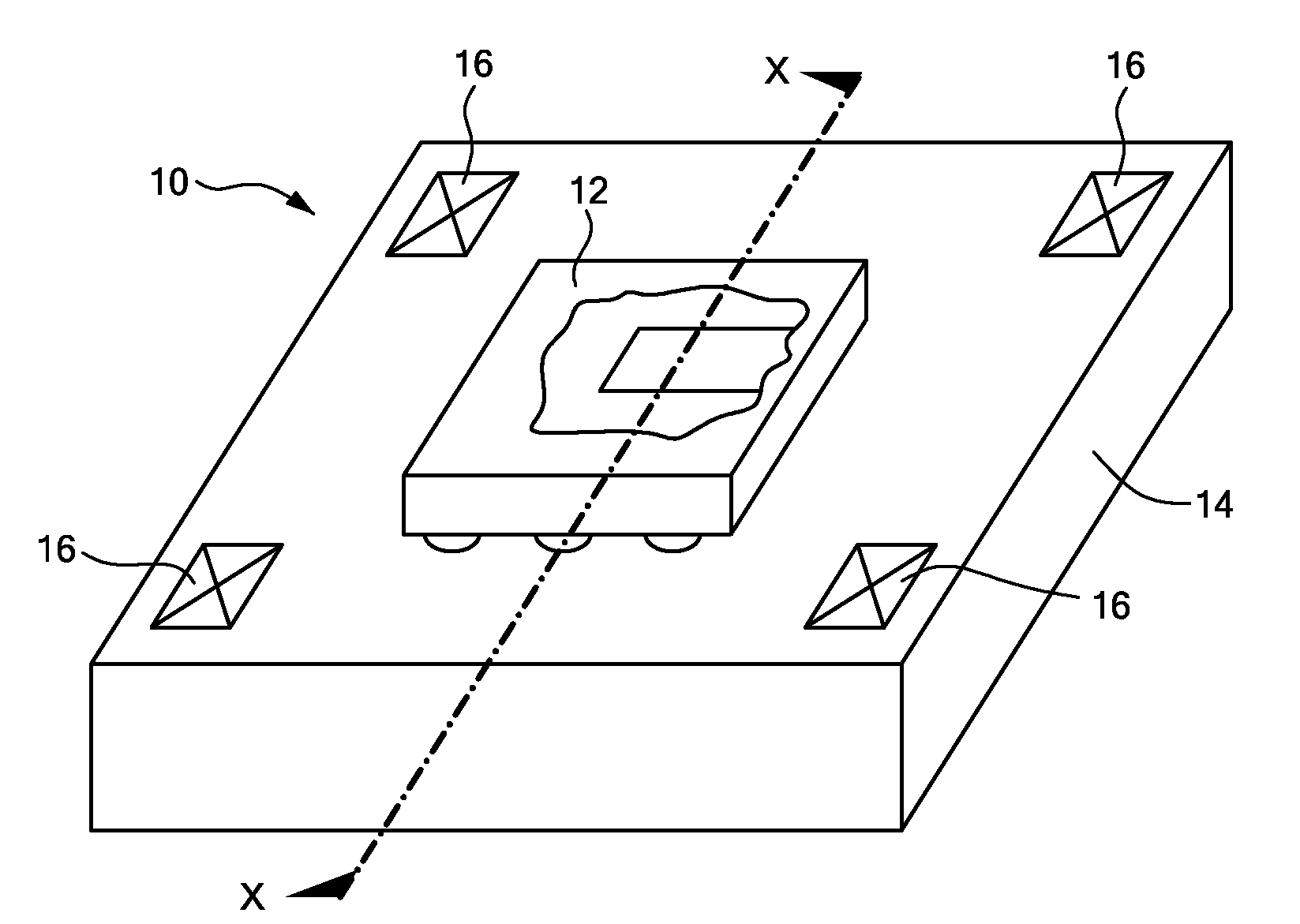

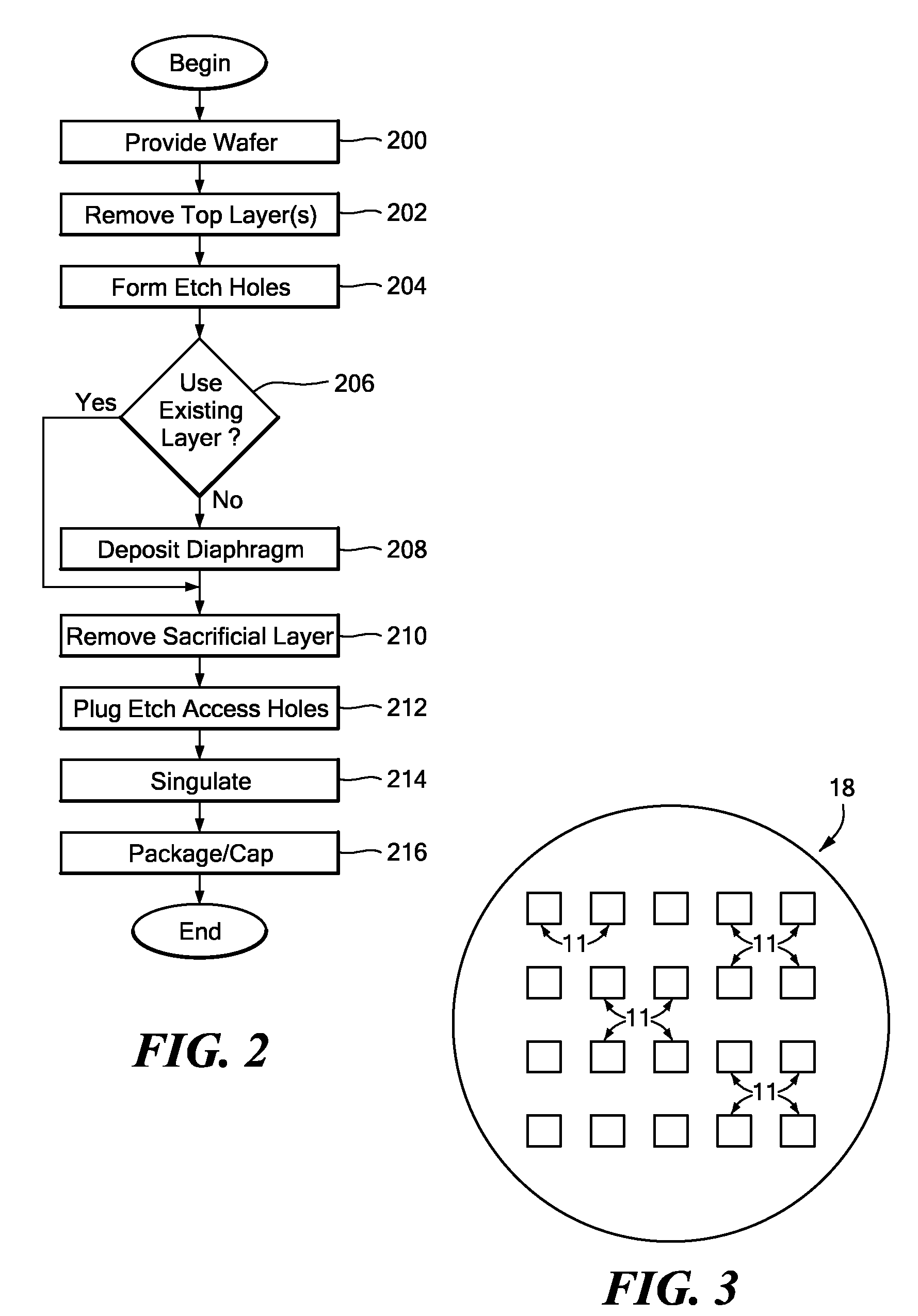

Method of forming a device by removing a conductive layer of a wafer

ActiveUS20050176163A1Easy to disassembleMovement can be detectedAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingEngineeringMethod seal

A method of forming a MEMS device provides a wafer having a base, a first conductive layer, a second conductive layer, and an intermediate conductive layer. After it provides the wafer, the method removes at least a portion of the intermediate conductive layer to form a cavity between the first and second conductive layers. At least a portion of the first conductive layer is movable relative to the base to form a diaphragm, while the second conductive layer is substantially immovable relative to the base. After it forms the cavity, the method seals the cavity.

Owner:ANALOG DEVICES INC

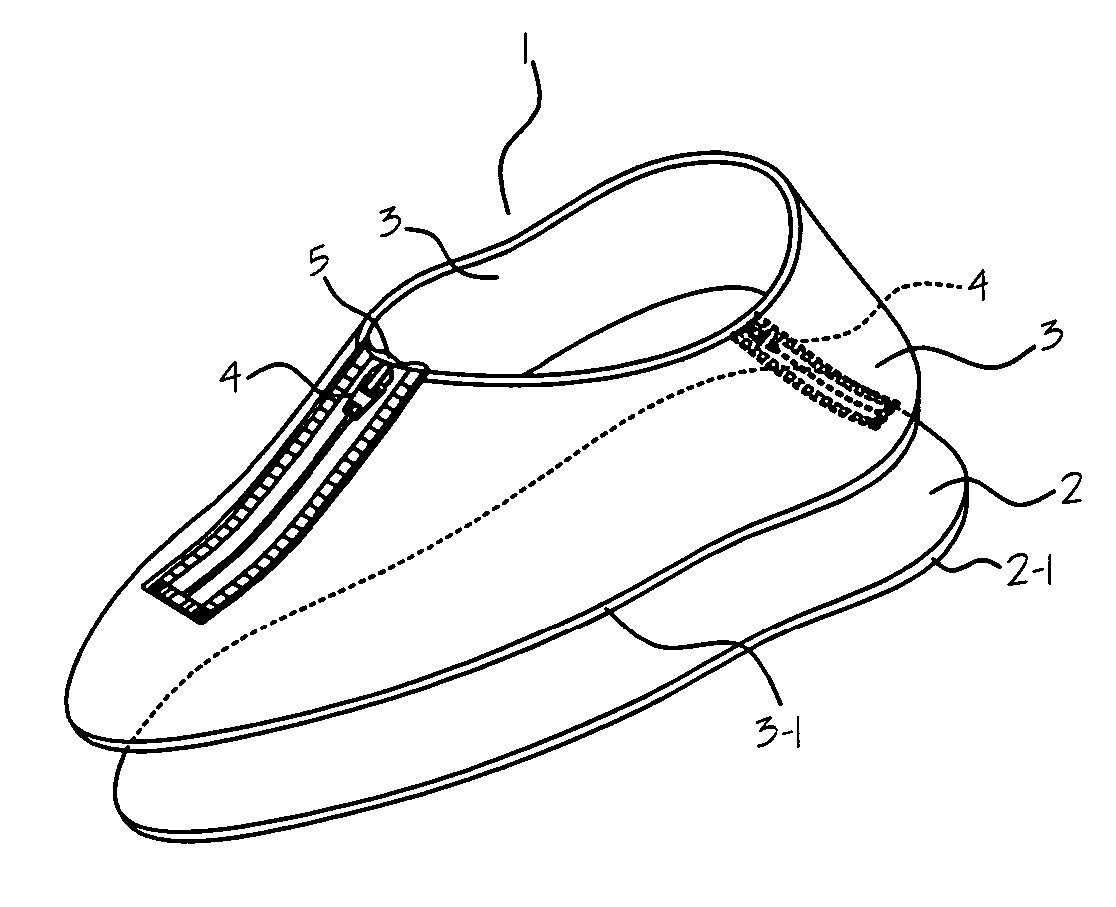

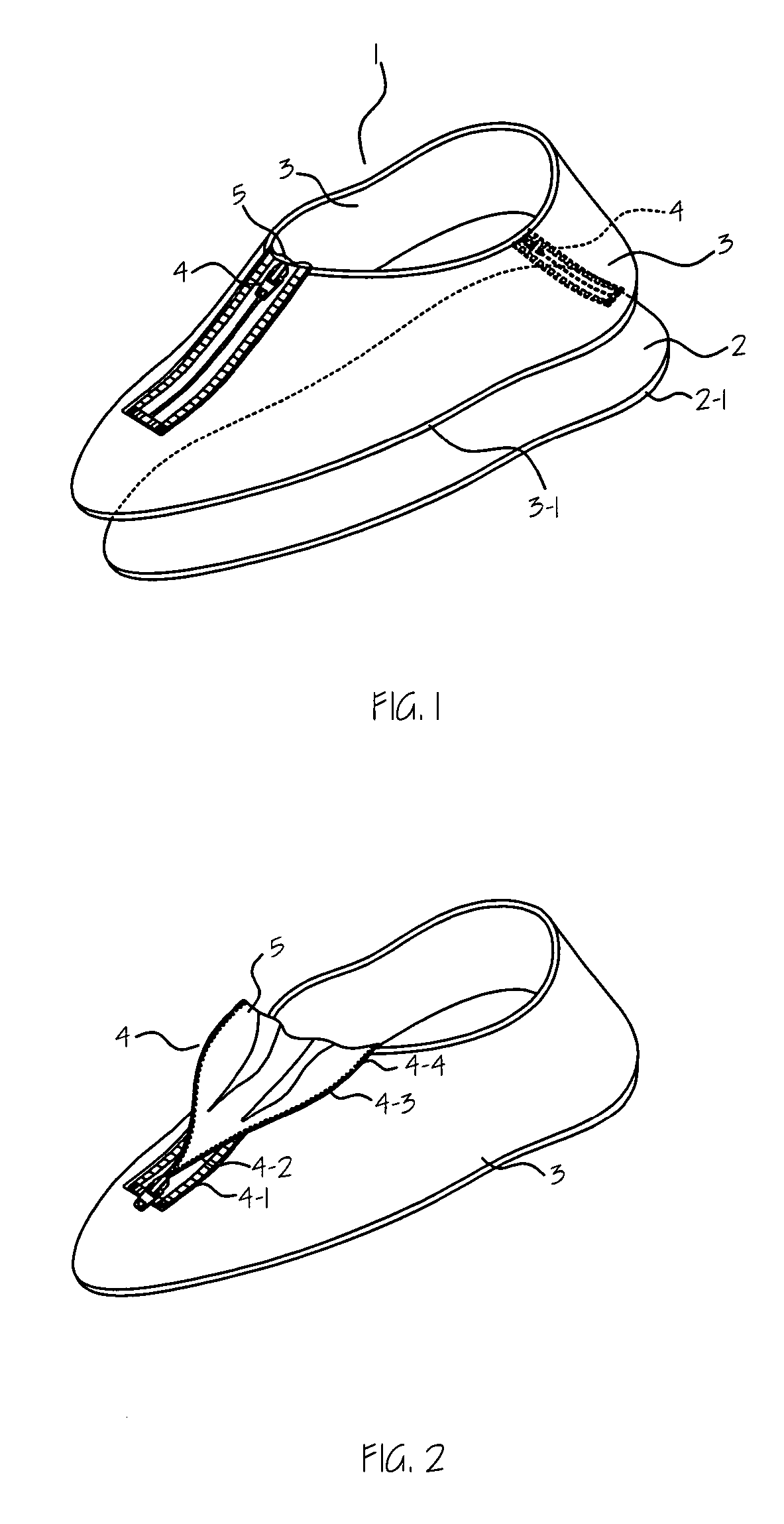

Reusable shoe shield equipped with a zipper with a back pocket and seasoned grooves

A reusable, elastic shoe shield for protecting formal shoes from being stained by contaminants such as dirt, grass and mud is provided. The shoe shield is made of flexible, resilient and elastic material. The shoe shield has an upper portion and a sole portion. A zipper with a back pocket is provided on the front portion of the upper portion. The upper portion and the sole portion are sealed by a heat sealing method. Pluralities of grooves seasoned on the sole portion vertically against the long axis of the shield enables the shoe shield to roll up, compacting into a pocket size.

Owner:BAEK FR B

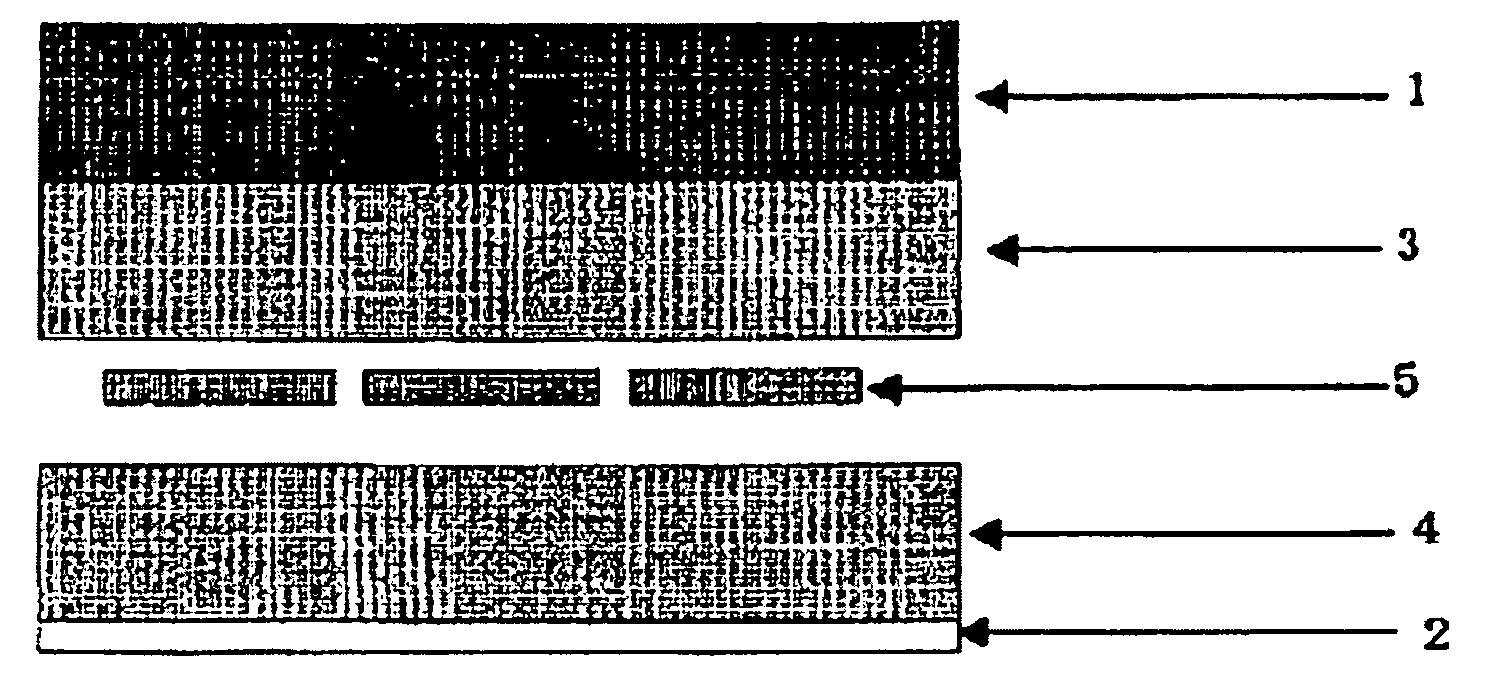

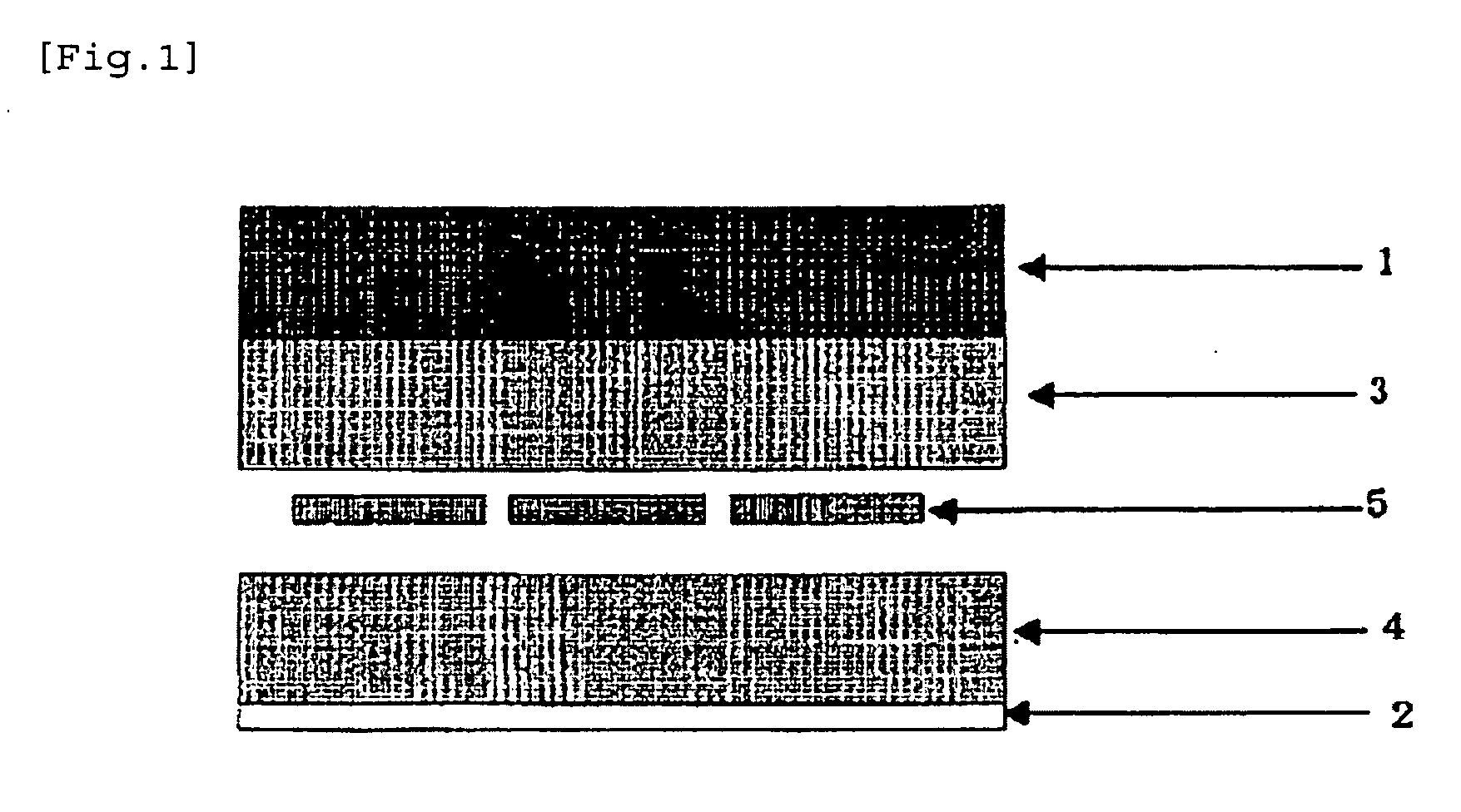

Composite Sheet and Use Thereof

InactiveUS20090044853A1Improve adhesionHighly valuable in practical usePV power plantsSemiconductor/solid-state device detailsHeat resistanceHardness

[Problems to be solved] The present invention provides a sealing sheet that can be used instead of the sealing sheet made from the conventionally widely used EVA, which has good transparency, heat resistance and adhesiveness with a polypropylene resin, and good productivity.[Means to solve the problems] The sealing sheet (I) is made from a thermoplastic resin composition comprising0 to 90 parts by weight of a propylene polymer (A) having a melting point, as measured by a differential scanning calorimeter, of 100° C. or higher, and10 to 100 parts by weight of a propylene copolymer (B), wherein the copolymer is formed from propylene, and at least one olefin selected from the group consisting of ethylene and α-olefins having 4 to 10 carbon atoms, and the copolymer has a shore A hardness of 30 to 80 and has a melting point, as measured by a differential scanning calorimeter, of 100° C. or lower or has no melting point to be observed (with the total of (A) and (B) being 100 parts by weight), wherein the thermoplastic resin composition has a permanent compression set, as measured at 23° C., of 5 to 35%, and a permanent compression set, as measured at 70° C., of 50 to 70%.

Owner:MITSUI CHEM INC

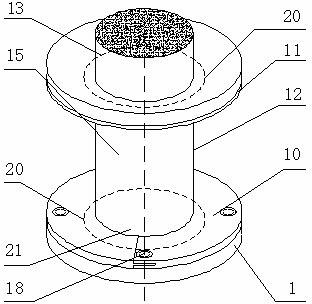

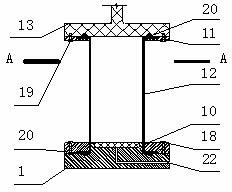

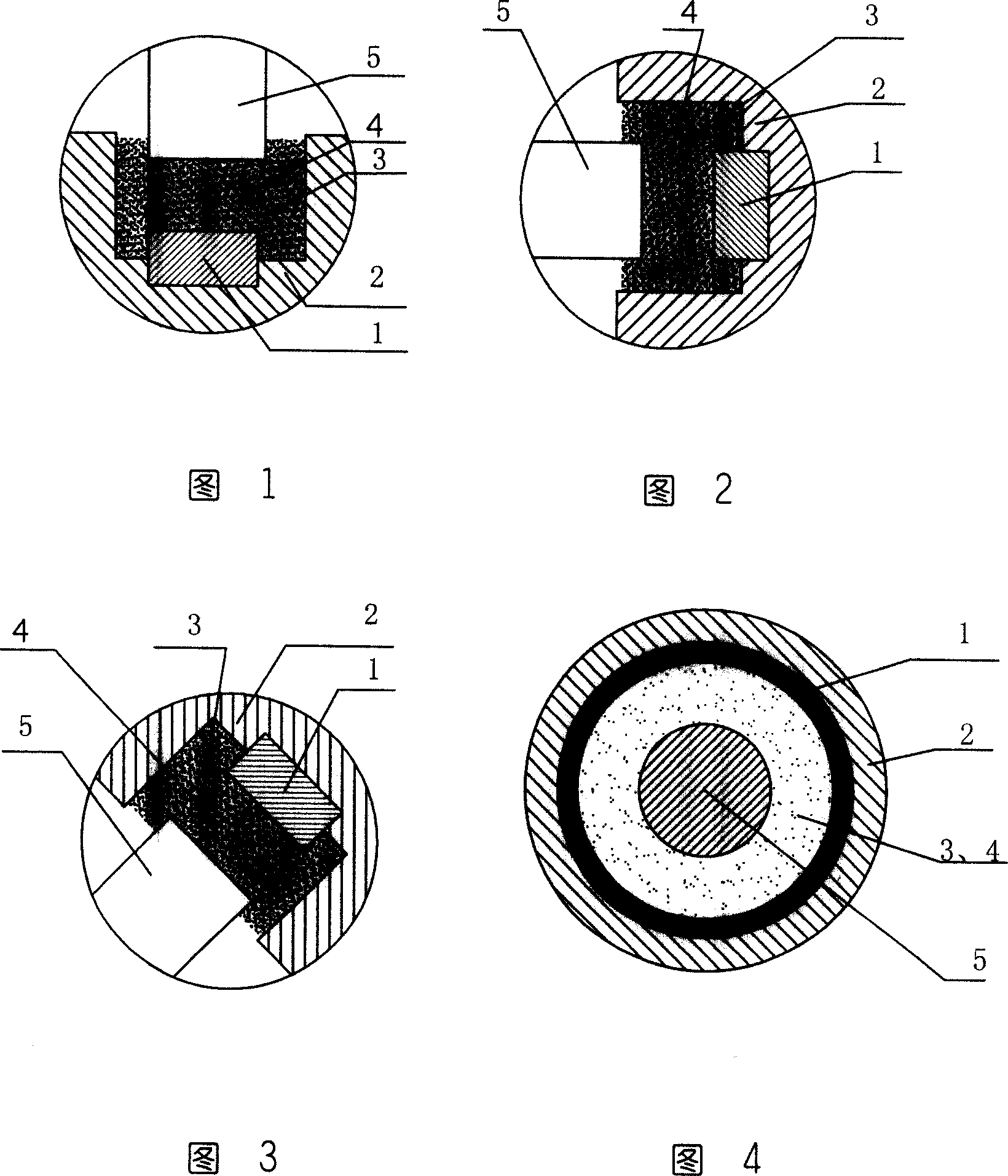

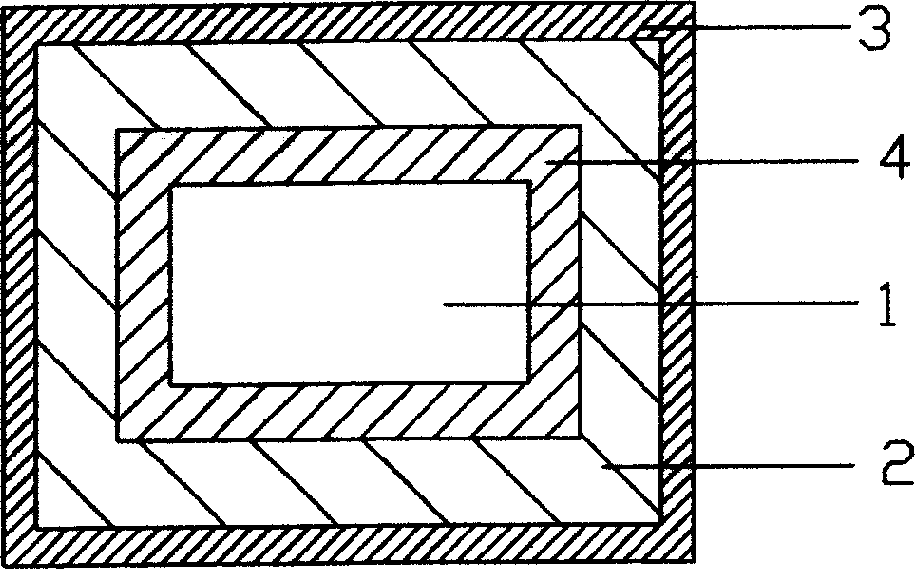

Device for sealing triaxial test sample of soil body and method for using device

ActiveCN102288480ASimple structureEasy to install and replaceStrength propertiesInternal pressureSoil science

Owner:HOHAI UNIV

Method and apparatus for cooking foods

The present invention is a microwavable pressure cooking container assembly and method using a flexible film vessel capable of holding a quantity of liquid and a food. A sealing device is at an upper portion of the vessel for sealing the vessel. An aperture is formed in an upper portion of the vessel which restricts release of steam from the vessel, so as to cause an increase in pressure and heat within the vessel to a level of pressure and heat which does not adversely affect the flexible film vessel, yet increases speed of cooking the food.

Owner:THE VIVIAN A SKAIFE TRUST

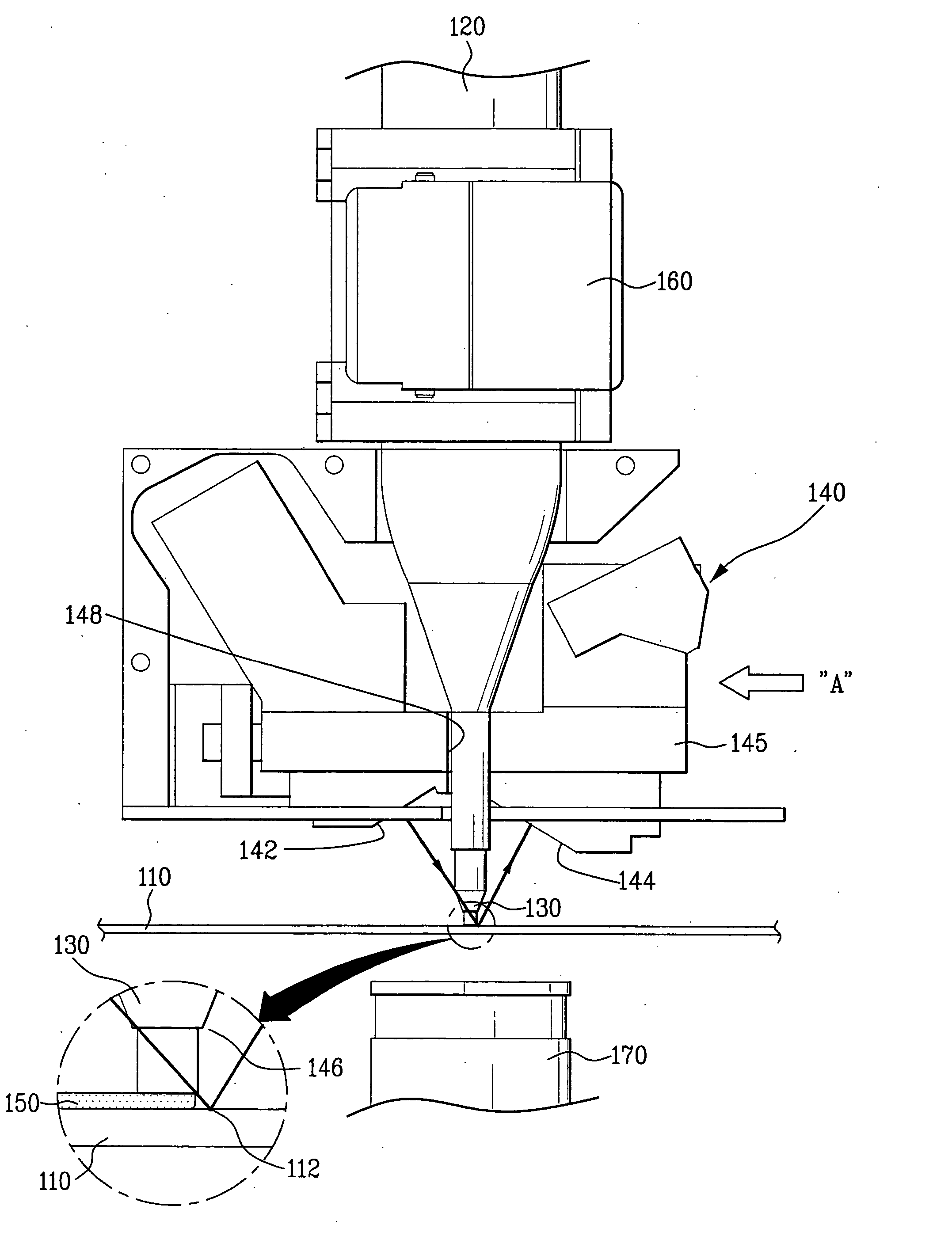

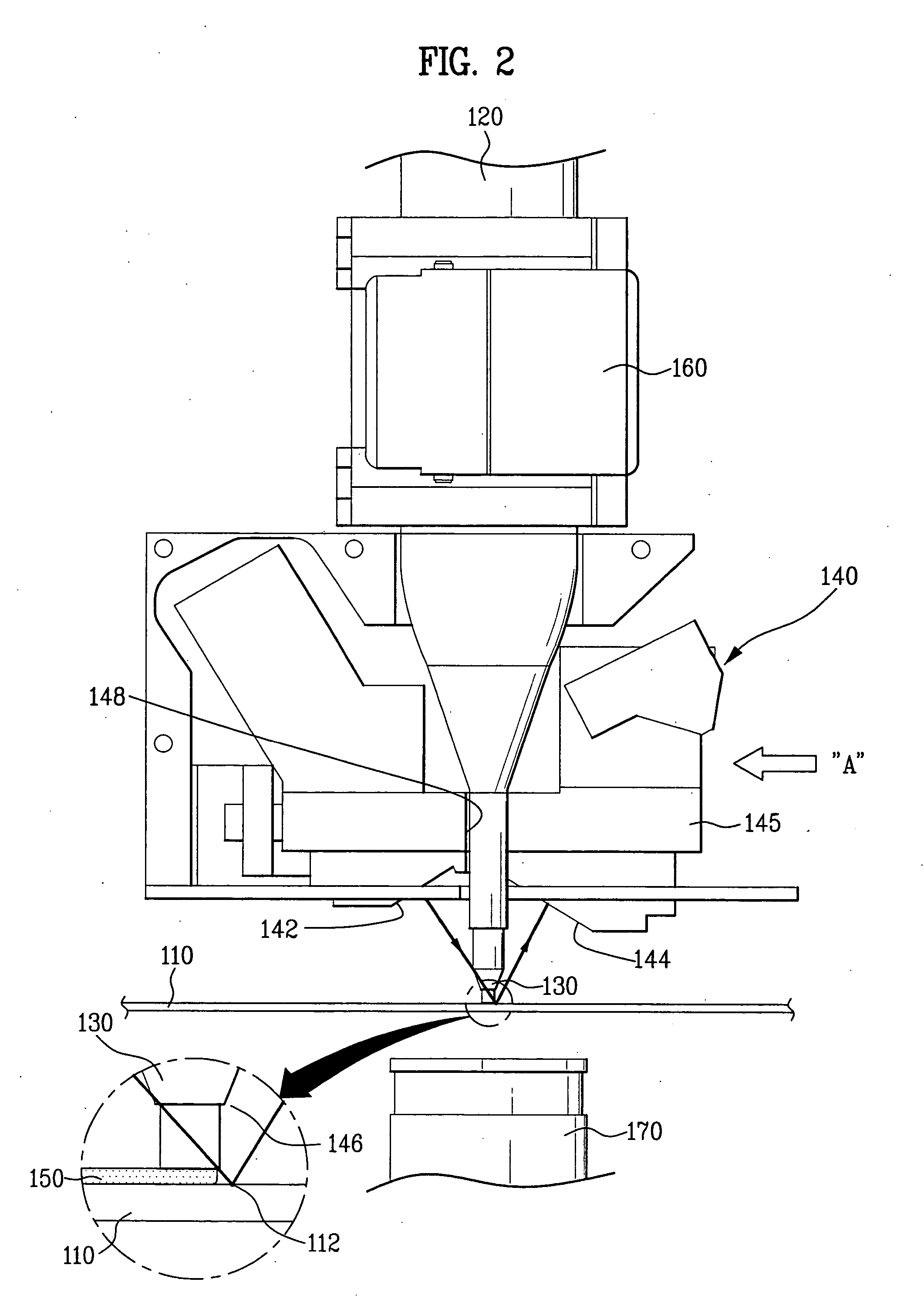

Sealant dispenser and control method thereof

ActiveUS20050269375A1Improve response speedControl amountLarge containersPretreated surfacesRelative motionSealant

Disclosed is a sealant dispenser for more precisely dispensing a sealant onto a substrate, and a control method thereof. The sealant dispenser includes a stage on which a substrate is mounted; a nozzle for dispensing a sealant while making a relative motion with the substrate; a syringe coupled to the nozzle, for storing the sealant; and a distance sensor installed on both sides of a lower portion of the syringe, for measuring a vertical distance between a principal plane of the substrate and an outlet of the nozzle. According to the principles of the present invention, because the nozzle and the syringe have substantially the same central axis, the response speed of the sealant to be dispensed is increased and the start point and the end point of paste pattern are more precisely dispensed. Also, by minimizing the distance between the nozzle and a measuring point provided by the distance sensor, it becomes possible to dispense the sealant at higher precision.

Owner:TOP ENG CO LTD

Sealing device and process for sealing a moving surface with the sealing device

Sealing device for laterally sealing of at least one overpressure zone and vacuum zone in a paper machine and process for sealing a moving surface with the sealing device. The sealing device includes a moving surface adjacent to the at least one overpressure zone and vacuum zone, at least one sealing element positioned opposite the moving surface, a holder in which the sealing element is mounted for movement relative to the moving surface, at least one loading element arranged to load the sealing element in a direction toward the moving surface, and at least one reset element arranged to act against the at least one loading element and to move the sealing element away from the moving surface. A sealing gap formed during operation between the sealing element and the moving surface is set by at least one of the reset element and the loading element. The process includes pressurizing the at least one loading element to press the sealing element against the moving surface, and pressurizing the at least one reset element to press the sealing element against the at least one loading element and in a direction away from the moving surface, whereby a gap is formed between the sealing element and the moving surface.

Owner:VOITH PATENT GMBH

Method for exploiting thick-layer heavy oil reservoir by in situ combustion assisted gravity drainage

InactiveCN102392626AIncrease productionBurial depth limit is smallInsulationFluid removalCombustionCement slurry

The invention relates to the technical field of heavy oil thermal recovery, especially a method for exploiting thick-layer heavy oil reservoir by in situ combustion assisted gravity drainage. The method comprises the following steps: firstly, under condition that the existing well network is not exchanged, sealing the penetrated perforation in the middle-upper part of the production well by cement slurry or packer; setting aside a 10-meter perforation segment for releasing oil in the lower part of the oil layer; keeping 10 meters of the upper parts of the air injecting well and the combustion perforation, sealing the lower ground layer by cement or packer, so as to form the in situ combustion assisted gravity drainage well network; heating the air in the air injecting well to higher than the threshold temperature of the high-temperature oxidation reaction of the crude oil by formation preheating or electric heater; according to the designing requirement, continuously injecting the air into the formation, so that the crude oil can flow outside from the lower perforation oil discharging channel of the production well; the crude oil is lifted to ground by using a lifting device. The invention realizes small limit on reservoir depth, the gas channeling is reduced and the crude oil output is increased.

Owner:联合石油天然气(盘锦)有限公司

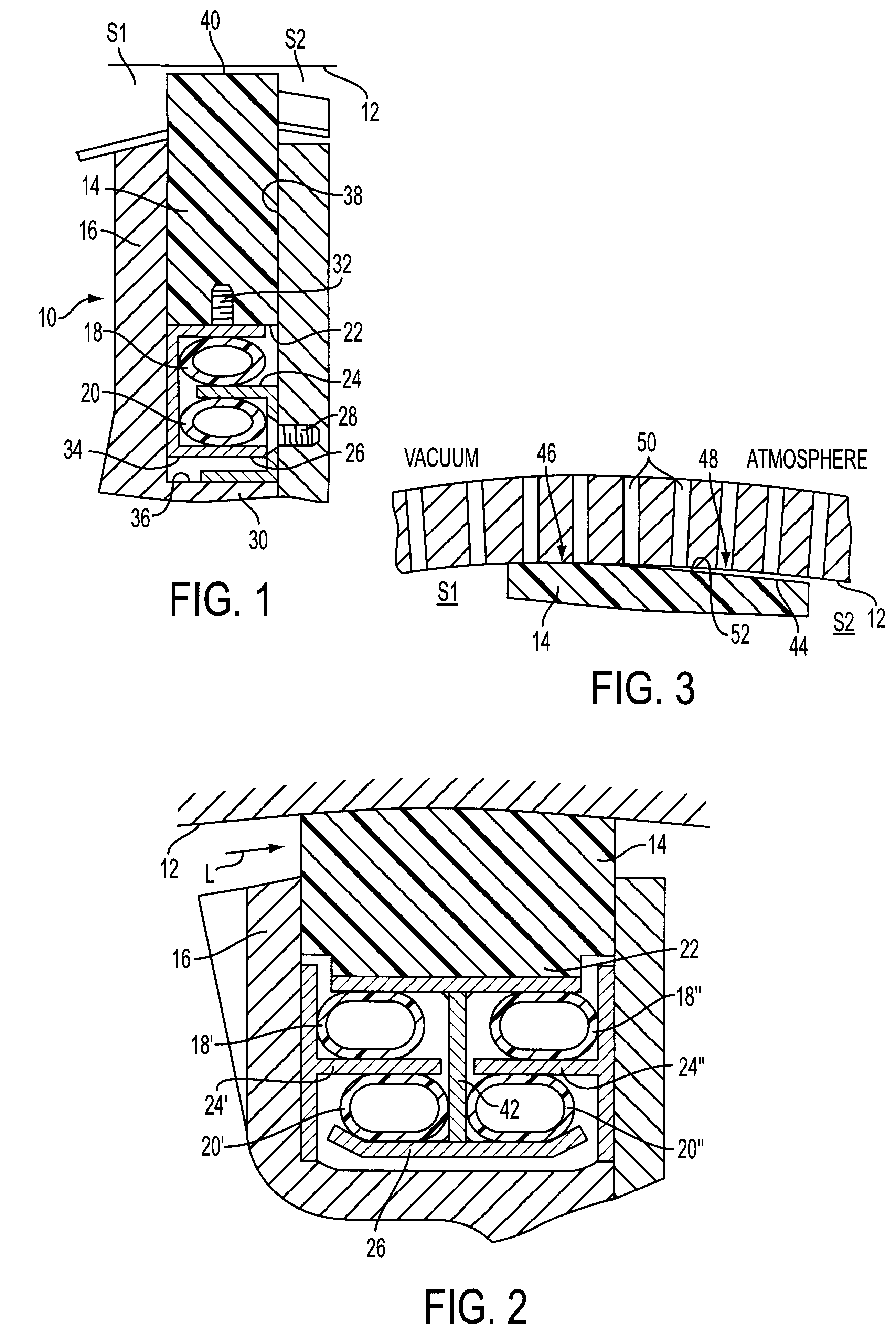

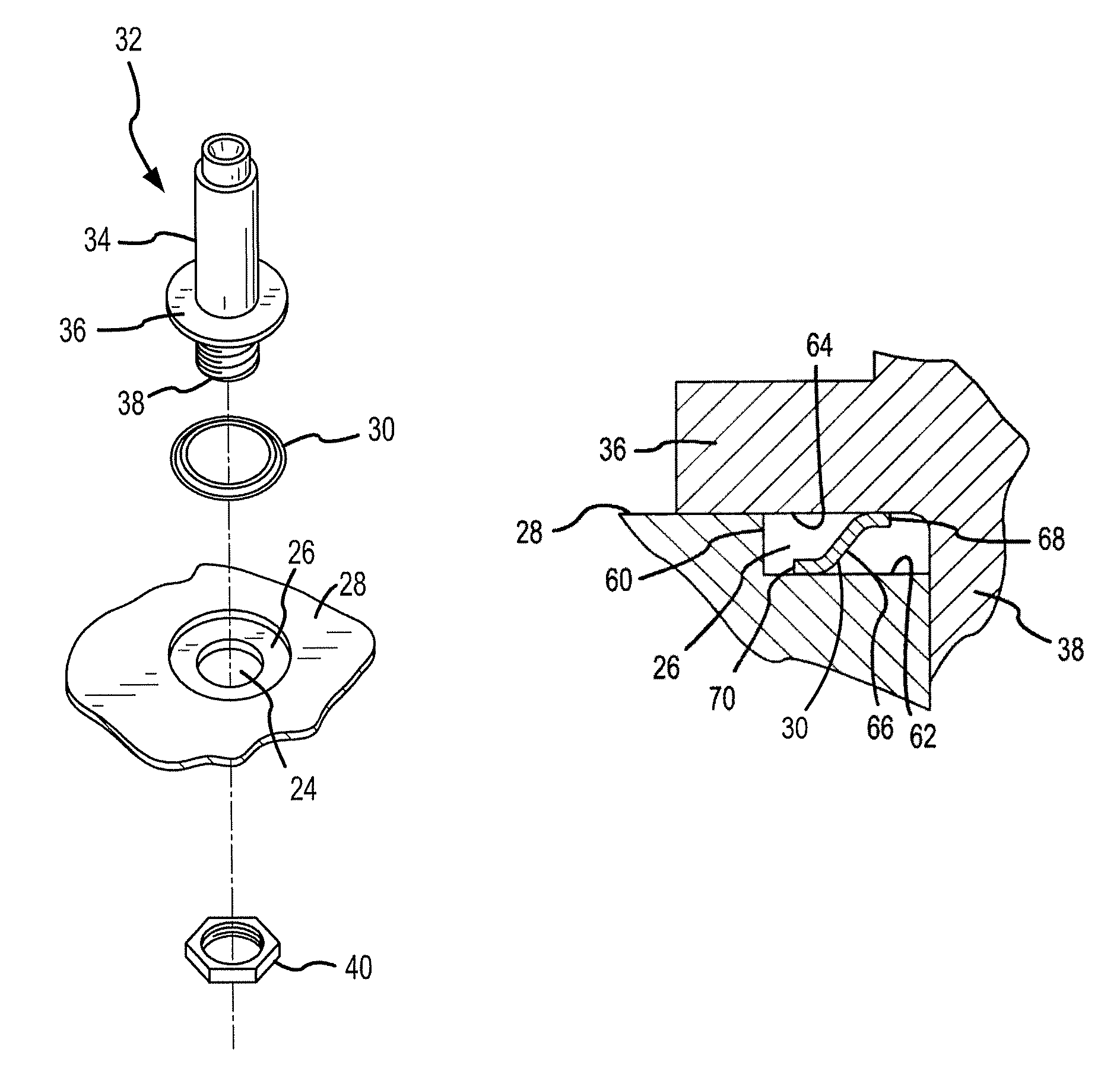

Hermetic seal for discrete opening in disk drive housing

ActiveUS8089721B1Apparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionHermetic sealEngineering

A hermetic seal is provided for sealing a discrete opening in a disk drive base plate. The hermetic seal comprises a sealing gasket that is disposed between planar facing surfaces of a component inserted through the opening and a recess formed on the interior of the base plate. As the gasket is compressed, a deformable plating applied to the gasket deforms and flows to fill microscopic voids that may be found in the abutting planar surfaces. Required access to the disk drive through the opening may be made in a rework process without destroying the seal. To seal the opening of the drive again, the sealing gasket is simply recompressed between the planar abutting surfaces. The invention also comprises a method by which to seal the castings of the disk drive housing, to include the base plate and top cover the disk drive. The method generally includes a two-time resin impregnation process to fill exposed pores on the surface of the castings.

Owner:SEAGATE TECH LLC

Extended text label for a tube container and method of manufacture thereof

InactiveUS20060145471A1Simple and inexpensive to produceEasy to useStampsOther printing matterEngineeringMethod seal

An extended text label is provided for a tube container, wherein the tube container includes a product dispensing end and a filling end opposite the product dispensing end. A crimp method seal is provided at the filling end that is crimped subsequent to filling the tube container with a selected product. An extended text label is then securely joined to the filling end of the tube container after the tube container is crimped shut, in a two-step operation.

Owner:FRO JOSEPH D SR

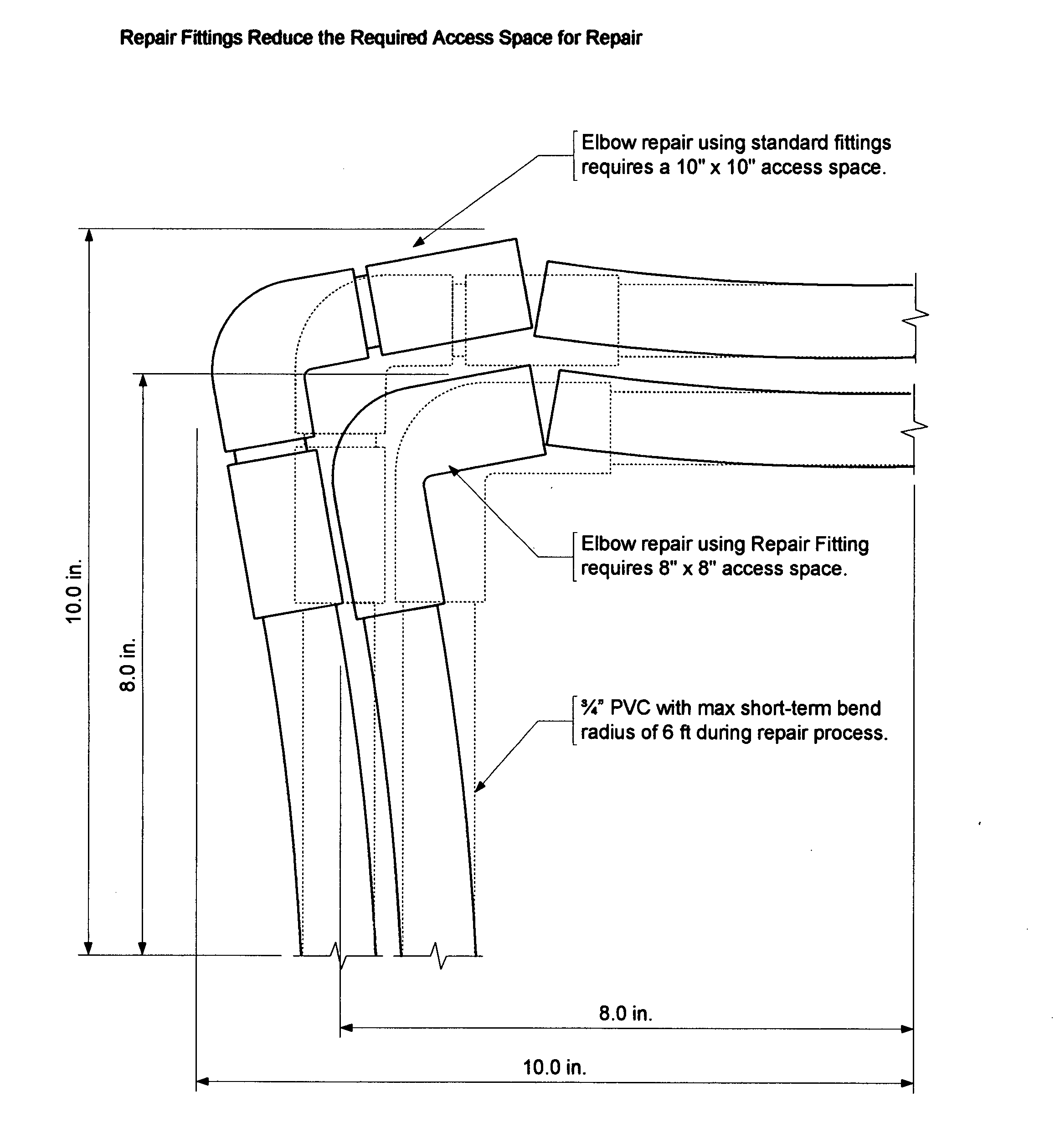

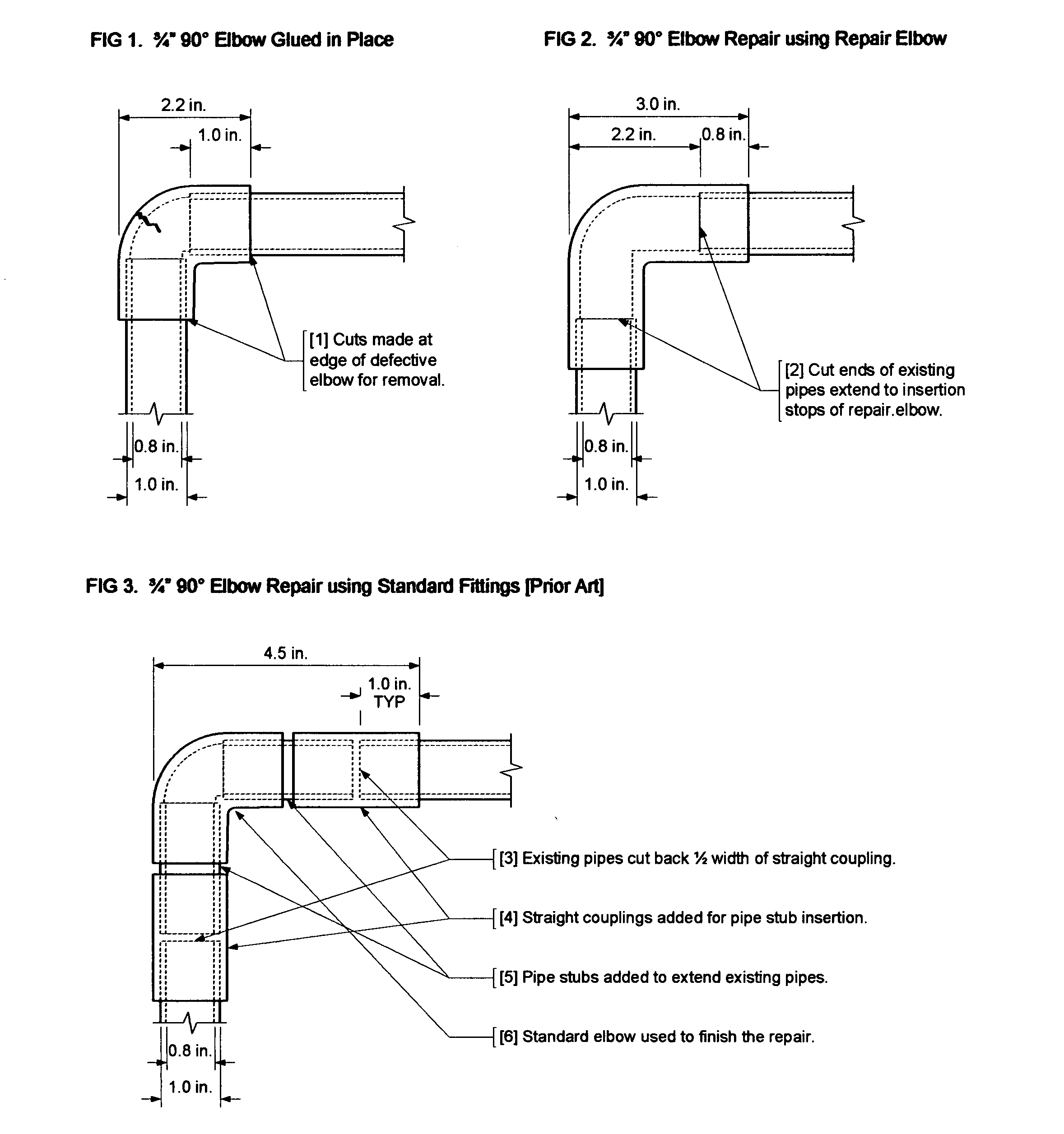

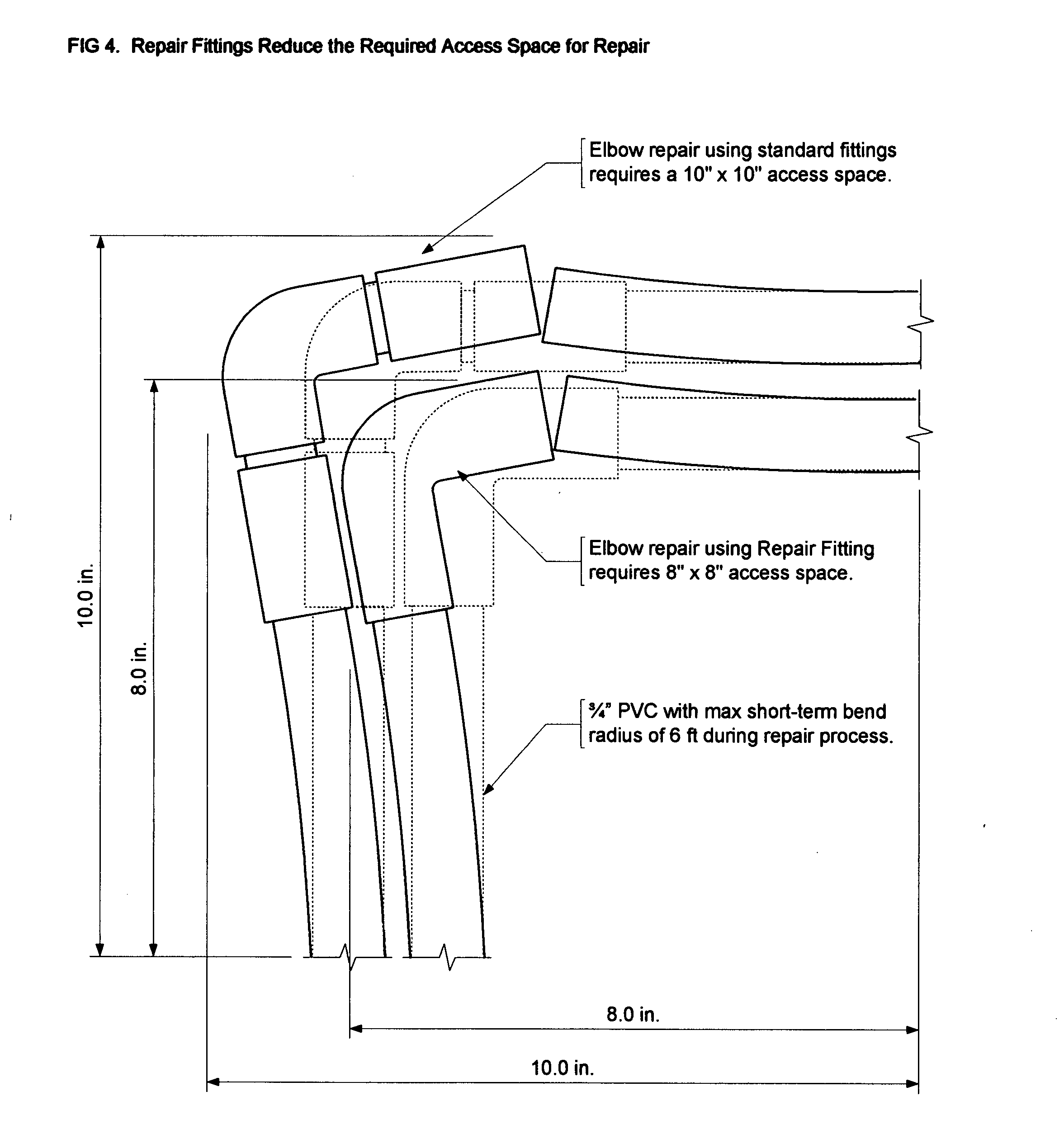

Repair pipe fittings

InactiveUS20080309067A1Reduce the amount requiredEasy to insertPipe elementsPipe fittingPlastic pipework

Disclosed is a pipe fitting specifically designed for repair applications called a Repair Pipe Fitting. One or more of the arms (inlets or outlets) of a Repair Pipe Fitting is longer than the corresponding arm on a standard pipe fitting, so that connecting pipes that have been cut to remove a standard pipe fitting do not have to be extended to install a Repair Pipe Fitting. Repair pipe fittings are best suited for use with plastic pipe, where joints are sealed with cement, although Repair Pipe Fittings may also be used with metal pipe, where joints are sealed with welds or threads. Repair pipe fittings may be sealed using the same sealing method as used by the original fittings, such as cement for plastic fittings and pipes. Repair pipe fittings may also be sealed using a non-permanent sealing method such as compression caps and gaskets.

Owner:FAZAKERLY WILLIAM B

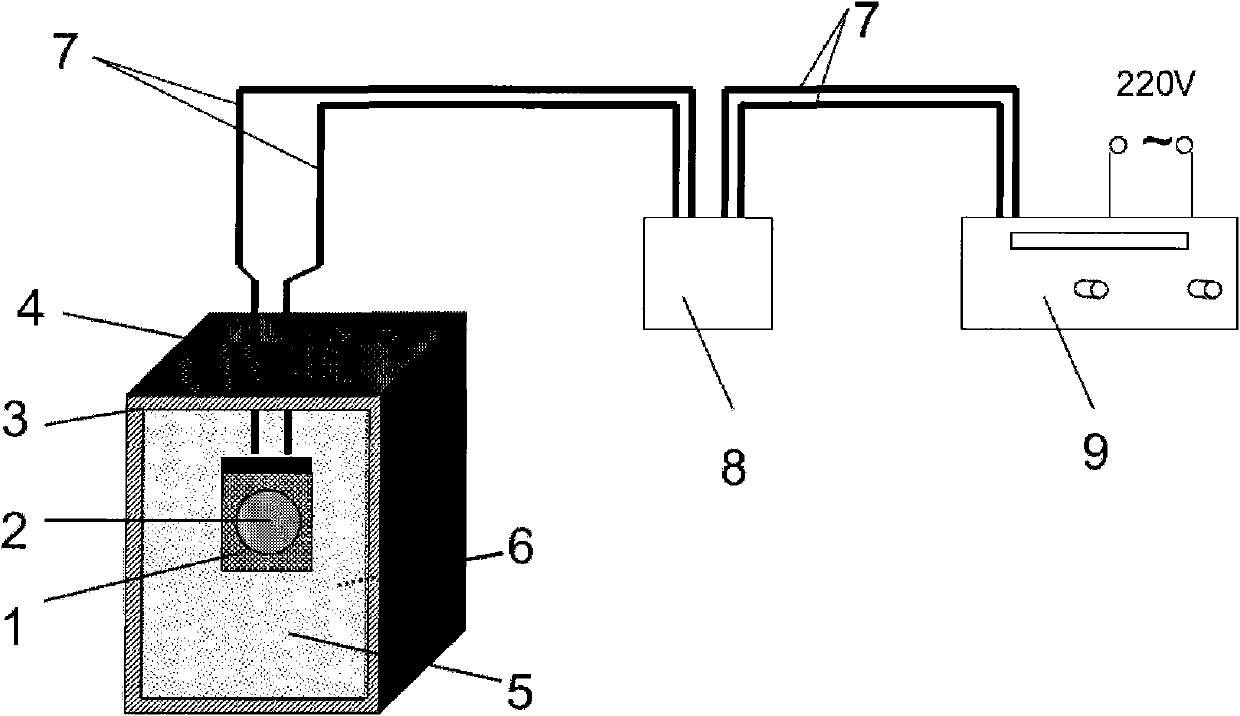

Method and device for detecting water oxygen infiltration index in device packaging

InactiveCN101949813AImprove detection accuracyShort detection cyclePermeability/surface area analysisMass loadingEngineering

The invention discloses a method and a device for detecting a water oxygen infiltration index in device packaging. The method comprises the following steps of: firstly, preparing a quartz crystal plated with an active metal layer; secondly, transferring the quartz crystal to a test box under the condition that air is isolated and sealing by using a packaging structure and a packaging method the same as the device packaging; and finally, connecting the test box with a crystal oscillator, a crystal controller and a power supply to form a quartz microbalance, switching on the power supply, sensing the piezoelectric effect and mass loading effect of the quartz crystal through the crystal controller, outputting the piezoelectric effect and mass loading effect to the microbalance in real time, calculating the increased mass of a metal film after infiltrated water is absorbed and then calculating the water oxygen infiltration rate and total infiltrated water oxygen content in unit time. The method and the device can be used for detecting the water oxygen infiltration rate in real time on line in the packaging of a water oxygen sensitive device, have the detection limit of lower than 5*10<-6>g.m<-2> / d, and can meet the limit detection requirement of packaging of organic photoelectric device products on water gas infiltration rate.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

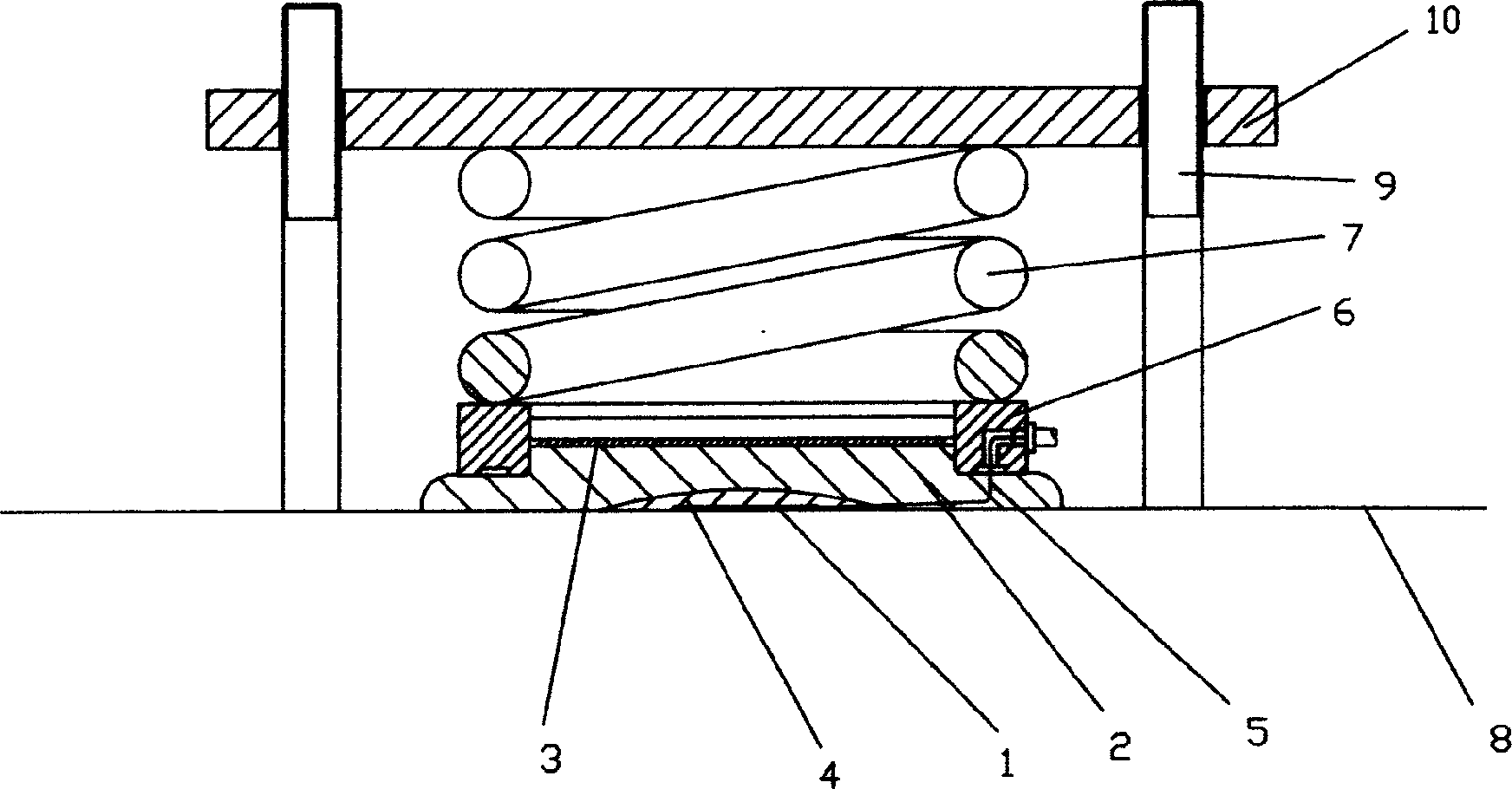

Magnetic field method for sealing air gap

InactiveCN101004220ASimple structureEasy maintenanceEngine sealsFurnace typesEngineeringElectrical and Electronics engineering

The present invention provides a magnetic field sealing method of air-gap. It is characterized by that on the air-gap of fixed body to be sealed a sealing groove correspondent to contact surface of mobile body is set, in the sealing groove bottom portion a magnetic field source is set, the groove interior is filled up with magnetic sealing medium to form magnetic field. The invented magnetic field flexible sealing theory is characterized by that in the air-gap to be sealed a magnetic field is created, the contact surface of said air-gap is filled up with magnetic sealing medium, under the action of magnetic field in the air-gap said magnetic sealing medium can be stably stored in the sealed air-gap, so that said sealed portion can obtain 'zero' leakage.

Owner:SHIJIAZHUANG RAILWAY INST

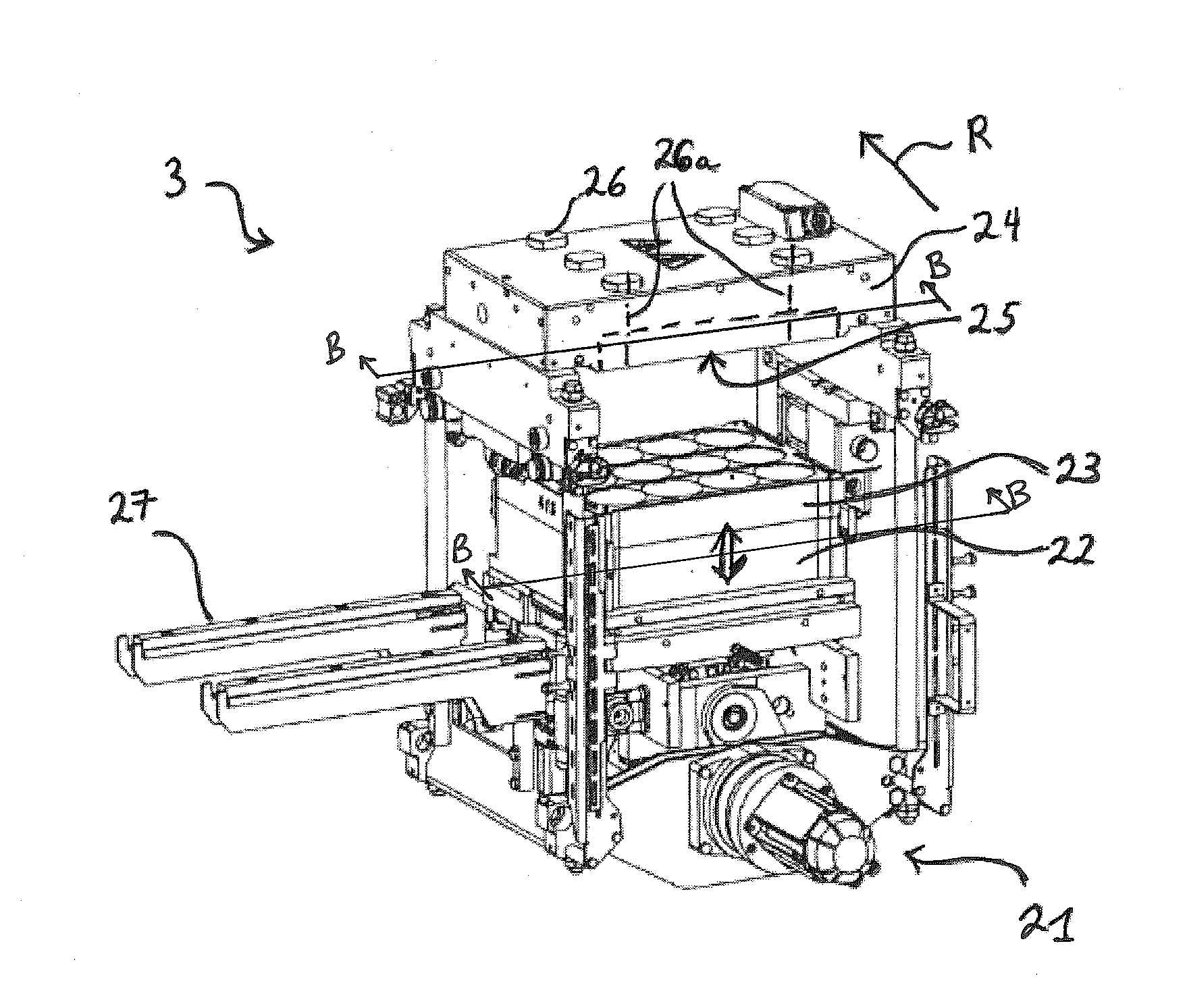

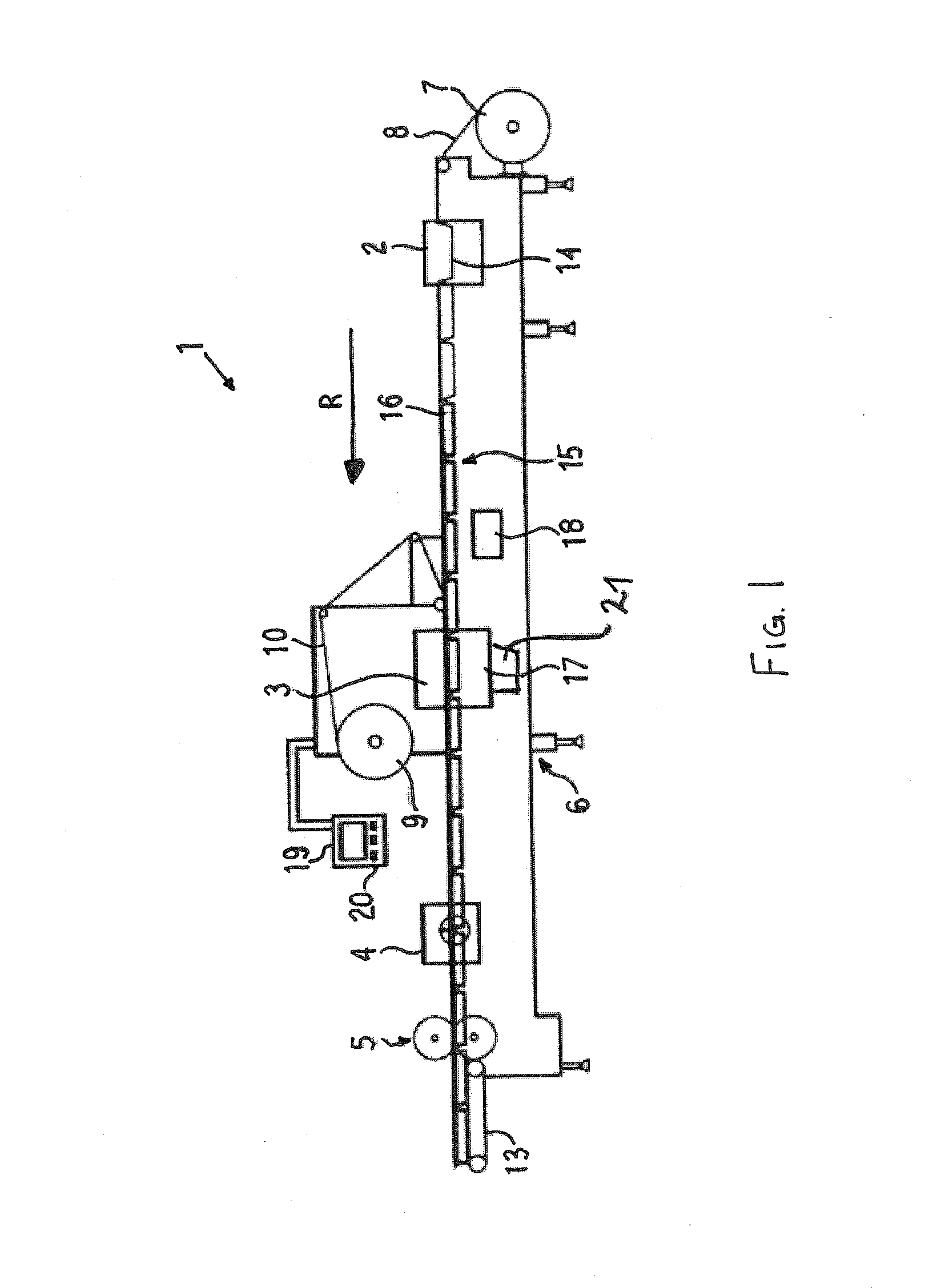

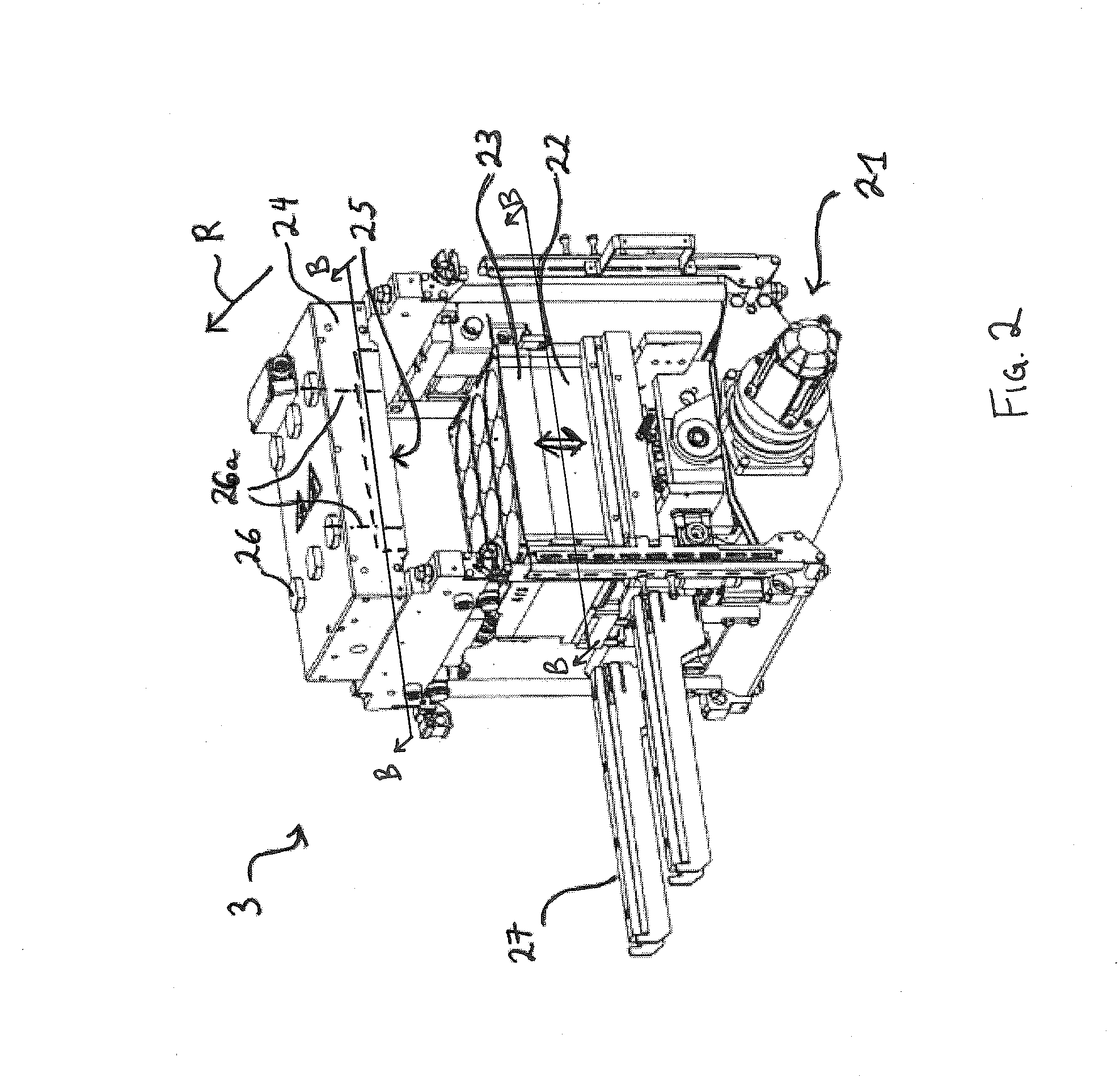

Deep-drawing packaging machine with sealing station and method

ActiveUS20140237942A1Easy to operateOperational securityPackaging by pressurising/gasifyingWrapper twisting/gatheringDeep drawingMethod seal

A deep-drawing packaging machine that includes a sealing station and a method for changing the sealing frame together with the sealing plate at the sealing station. The sealing station includes a sealing plate and a sealing frame. The sealing plate may be releasably coupled to an upper sealing tool part, and the sealing frame may be slidably removable at a lower sealing tool part. The sealing frame may be slidable on rails. The sealing frame may include one or more centering aids for aligning the sealing plate with respect to said sealing frame during removal thereof. The centering aids may be displaceable underneath a film web by the upper sealing tool part during the clamping of the film web between the sealing frame and the upper sealing tool part.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Pressure balance type seal method and its use

InactiveCN1749604ASimple structureGuaranteed internal pressureEngine sealsInternal pressureEngineering

The present invention discloses one kind of pressure balancing seal method. In measurement environment, the pressure difference between inside the measuring tool and outside the measuring tool is reduced to realize the seal of the measuring tool. The present invention discloses also one kind of sensor operating on the pressure balancing seal method, and the sensor includes sensor cavity and sensing element set on the inner wall of the cavity. On the outer surface of the sensing element, a sealing film of waterproof elastic polymer material and a metal net over the film are coated, and the sealing film has its edges fixed to the inner wall of the cavity by means of sealing unit. The present invention ensures the basically identical pressure between the inside of the measuring tool cavity and the outside to avoid leakage, and the measuring tool in the said sealing method has simple structure, long service life and high measurement precision.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

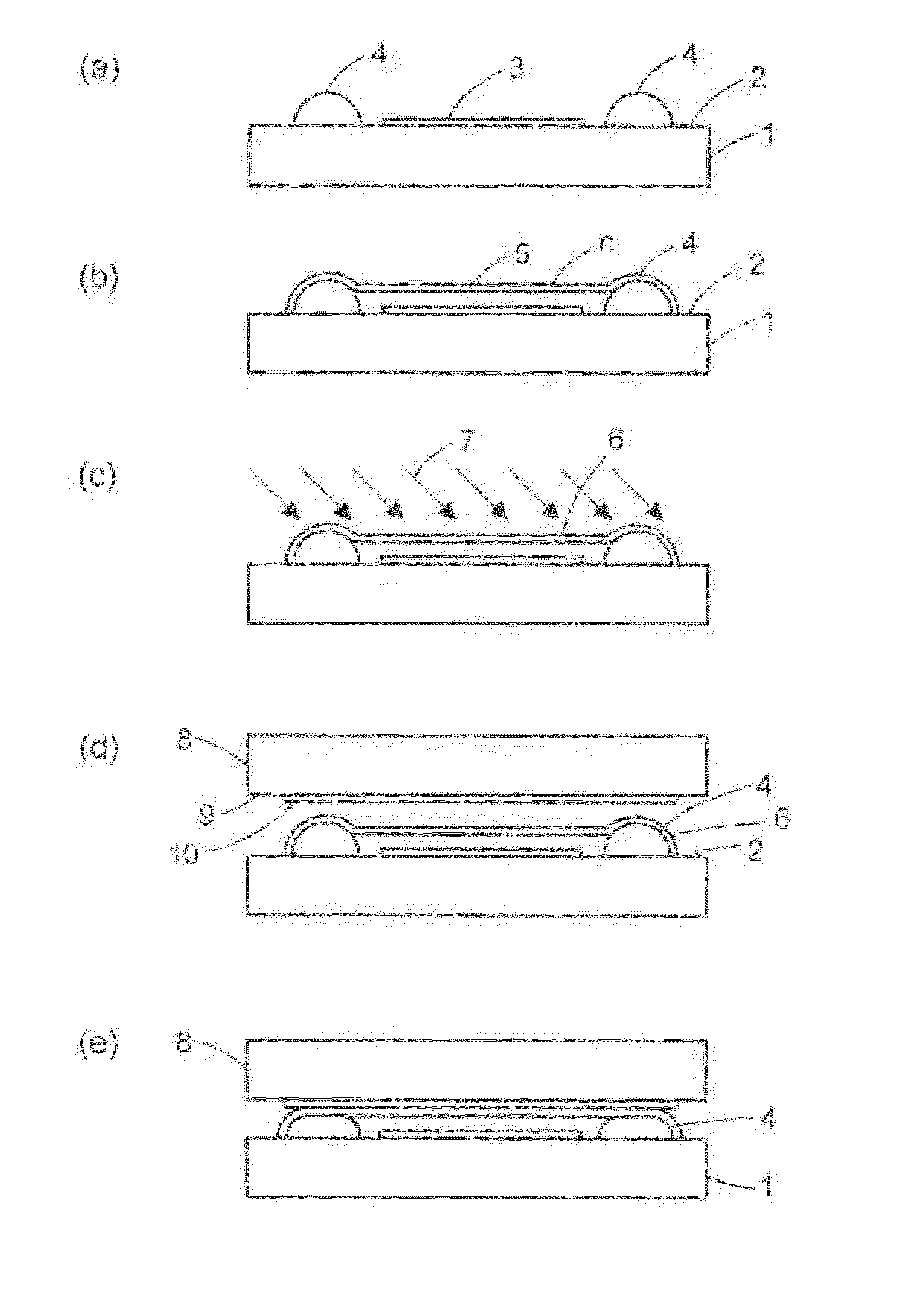

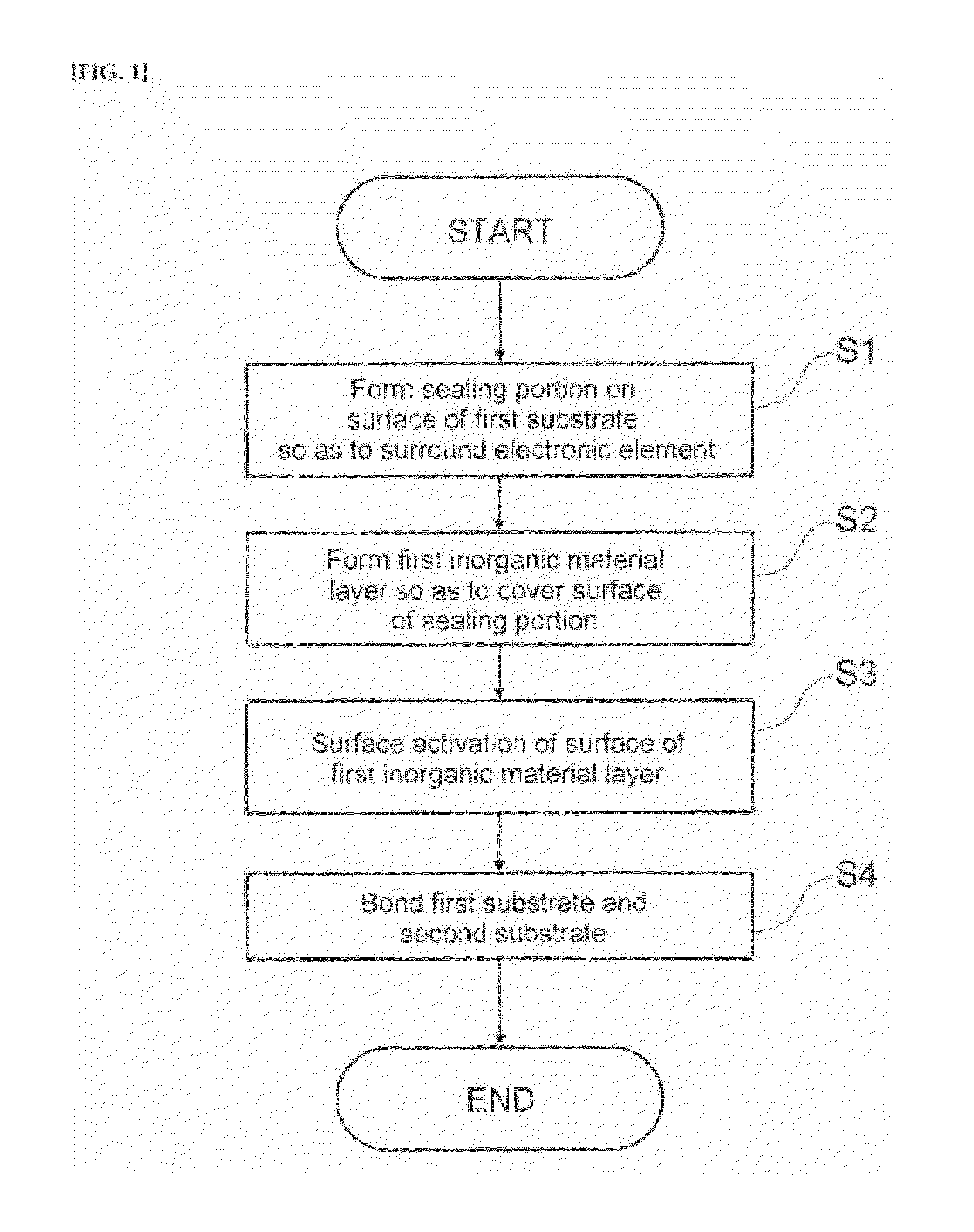

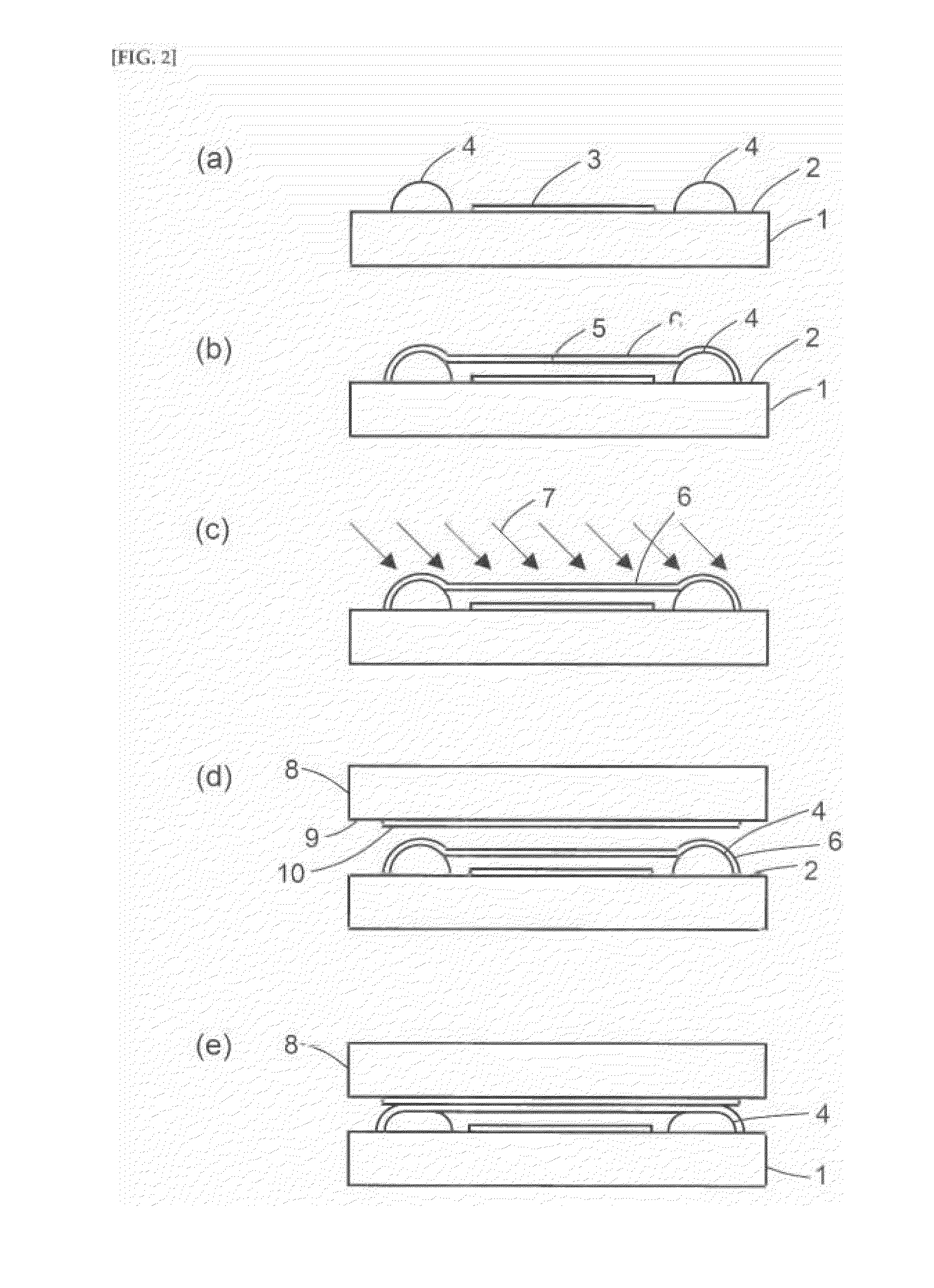

Electronic element sealing method and bonded substrate

ActiveUS20150171365A1Inhibit deteriorationPreventing deterioration of the electronic elementsSemiconductor/solid-state device detailsElectroluminescent light sourcesHydrogenOxygen

[Problem] The aim of the invention is to provide a method of sealing an electronic element such as an organic EL element using a normal temperature bonding method that enables bonding at low temperature and in which permeation of external gases such as hydrogen or oxygen through the sealed section (dam) formed by the organic material, or the junction interface of the sealed section and a cover substrate is suppressed. [Solution] A method of sealing an electronic element comprises a step of forming a sealing section by forming a sealing section including an organic material on the surface of a first substrate formed with the electronic element, surrounding this electronic element with a thickness that is larger than that of this electronic element; a step of forming a first inorganic material layer in which a first inorganic material layer is formed at least on the exposed surface of this sealing section; and a substrate bonding step of bonding the first substrate and the second substrate by pushing together the sealing section of the first substrate and the junction location of the second substrate.

Owner:LAN TECHN SERVICE

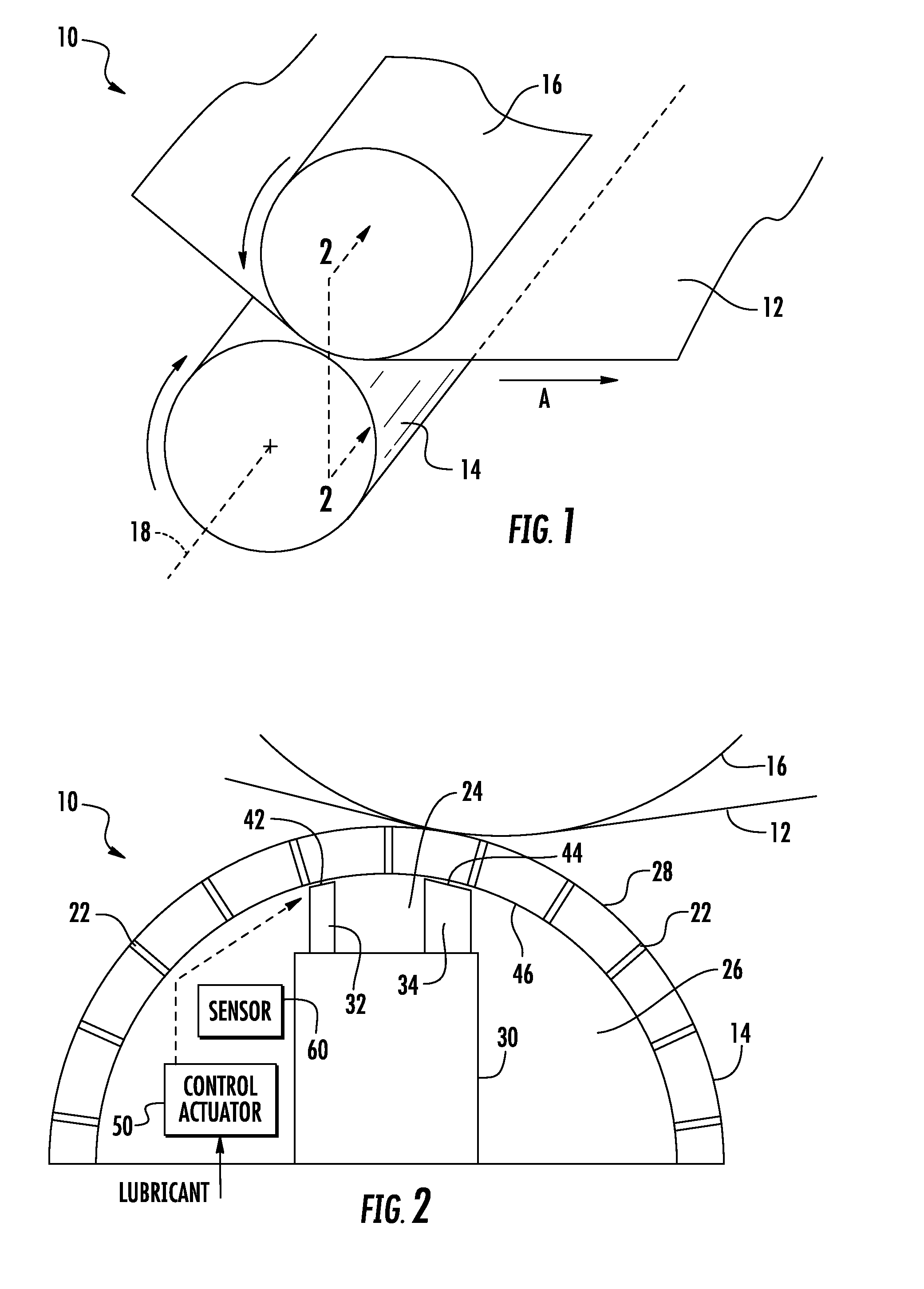

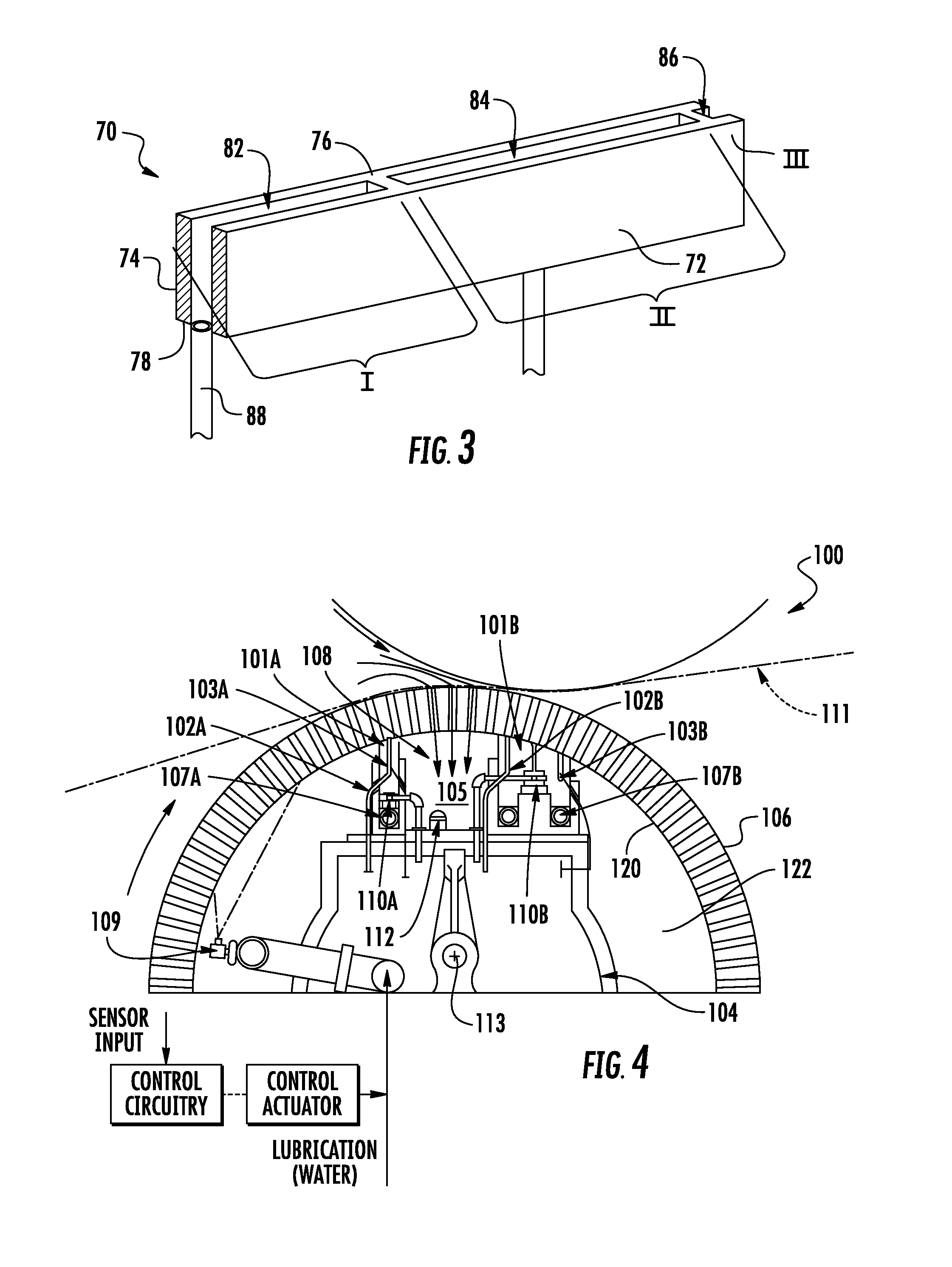

Sealing systems and related methods

Sealing systems and related methods are provided. In this regard, a representative sealing system includes: an elongated seal having a contact surface configured to form an airtight seal with an inner surface of the drum; contact sensor circuitry configured to provide an electrical signal containing information indicative of direct contact between the seal and the inner surface of the drum; and a control actuator configured to direct a flow of lubricant responsive to receiving the information from the contact sensor indicating direct contact such that the flow of lubricant forms a film of lubricant between the contact surface and the inner surface of the drum to prevent direct contact between the seal and the drum.

Owner:COLDWATER GRP

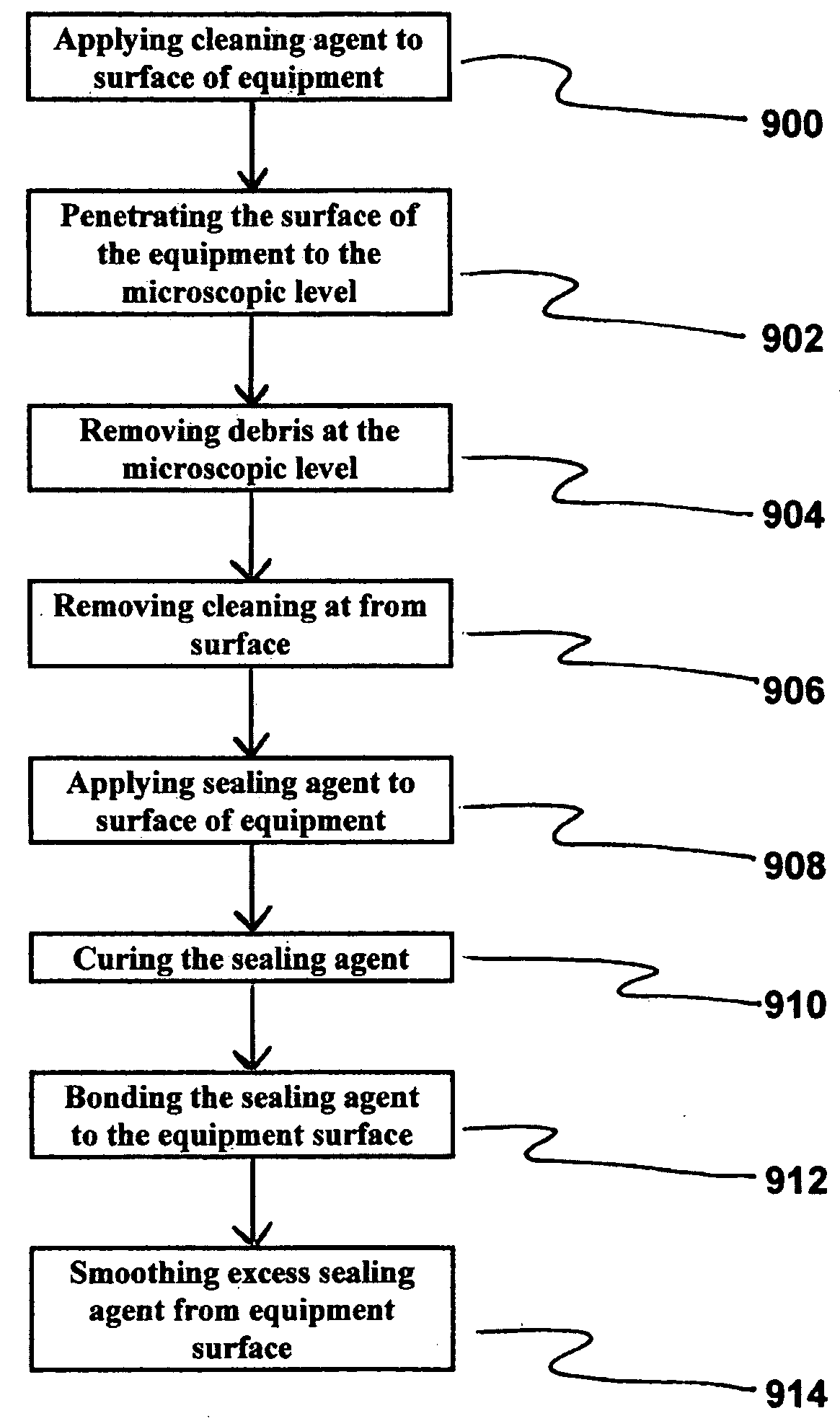

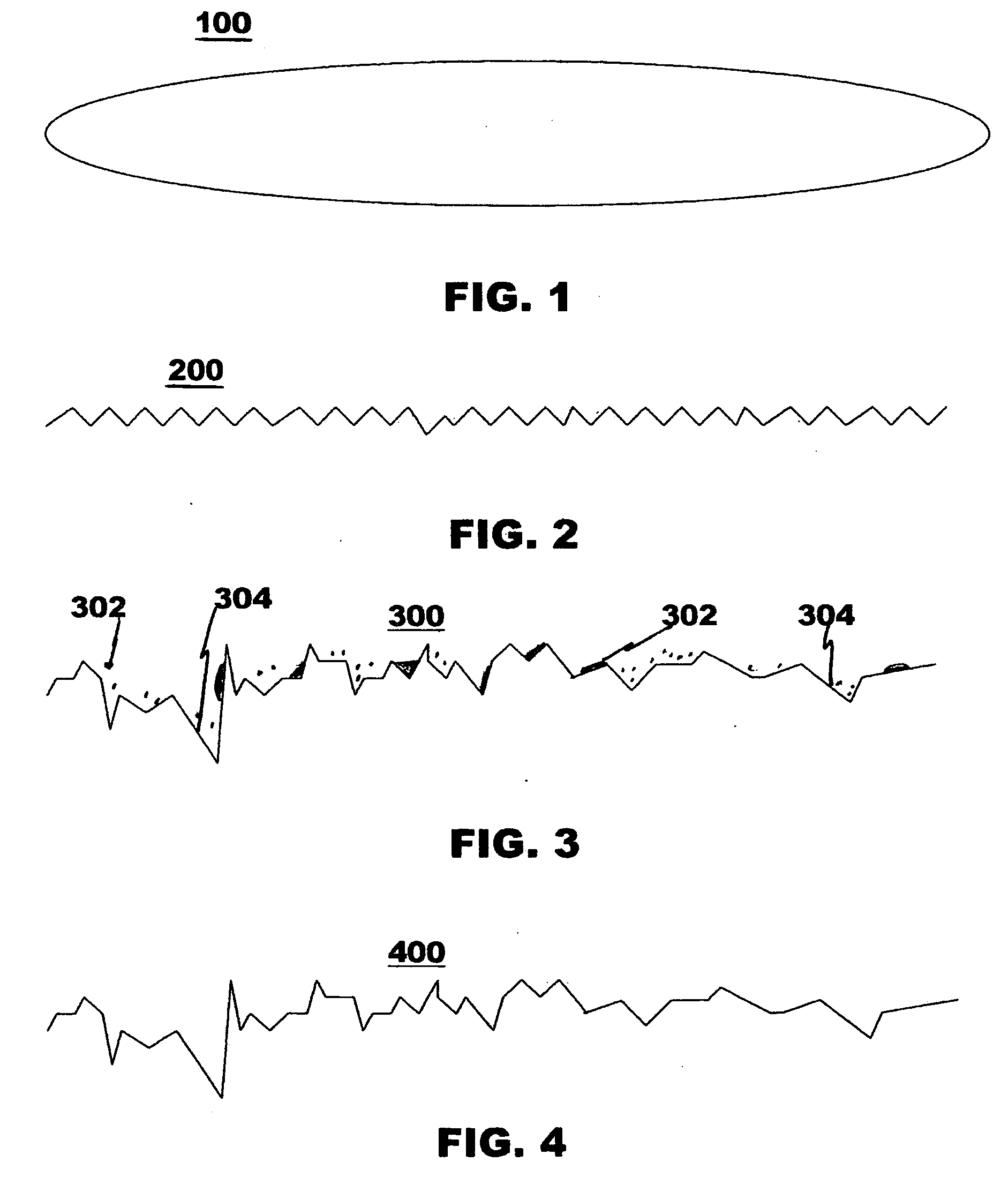

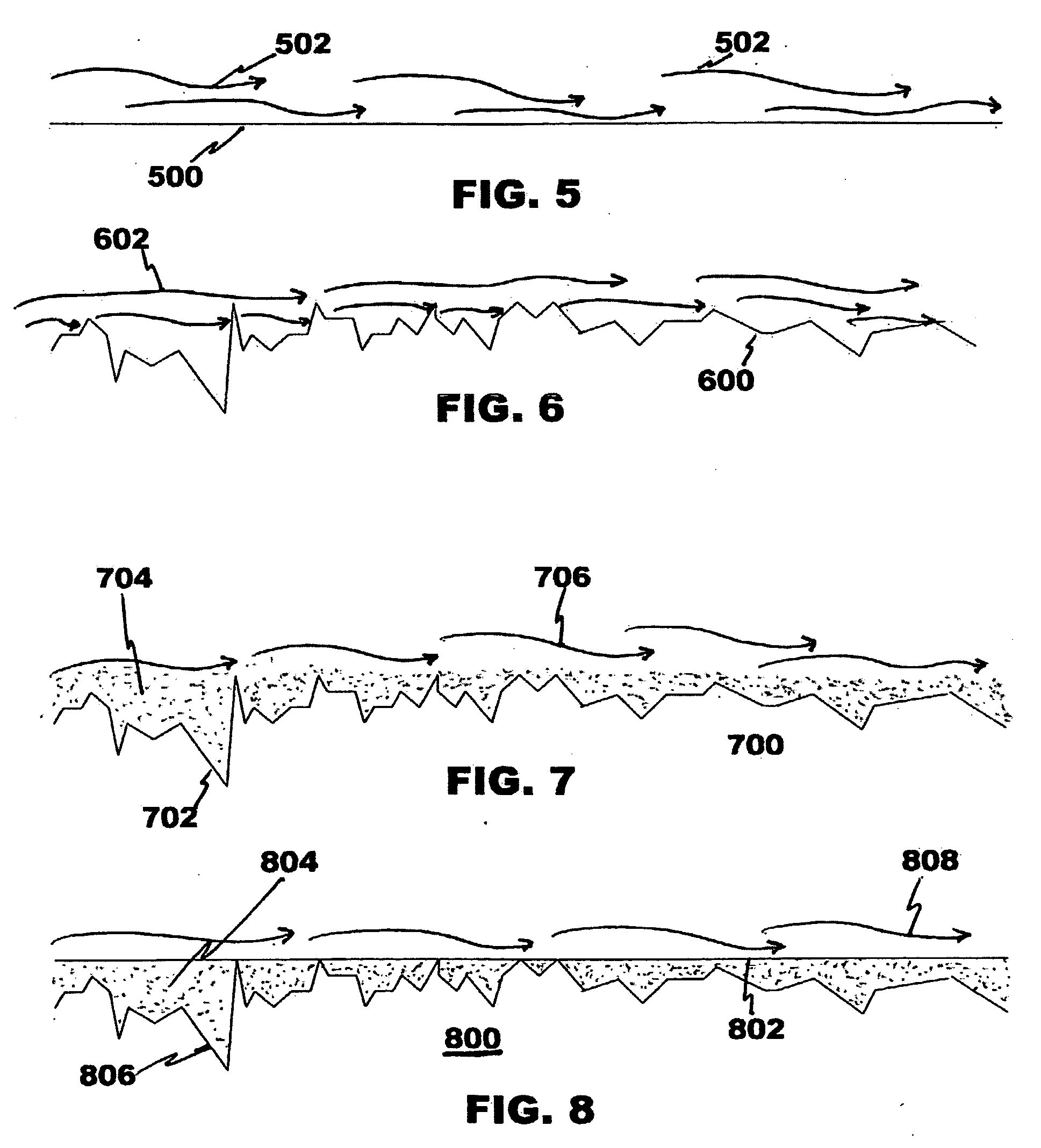

Method for Extending and Improving the Functionality of a Hard Surface

InactiveUS20090280252A1Improves aerodynamic flowAvoid accumulationInorganic/elemental detergent compounding agentsDetergent mixture composition preparationEngineeringMicroscopic level

A method for cleaning hard surfaces at the micro level incorporates a two-phase process that initially cleans a surface and then seals the surface. The cleaning phase implements a cleaning solution that penetrates the surface of equipment and removes dirt and debris at the micro or nana level of the equipment. The sealing phase of the method seals the surface of equipment such that gaps at the micro level are filled in to prevent debris from accumulating at the micro-level of the surface of the equipment. The sealed surface provides improved aerodynamic flow of air across the hard surface.

Owner:ARMSTRONG ANDREW +1

Cap and droplet discharge apparatus

A cap capable of sealing a nozzle by two methods and a droplet discharge apparatus using the cap. When the cap is pressed onto a nozzle surface with the nozzle aligned with a center of a covering portion, a lip continuously contacts the surrounding of an opening of the nozzle, thereby forming a sealed space on the surface formed with the opening of the nozzle. Although ink in the nozzle may dry when left for a long time, no influence on ink discharge operation immediately after the cap is detached is expected since the cap does not directly seal the opening. When the cap is pressed onto the nozzle surface with the nozzle aligned with a center of a sealing portion, the substantially flat sealing portion seals the opening, thereby effectively preventing drying of ink, although there may be an influence on discharge operation immediately after the cap is detached.

Owner:BROTHER KOGYO KK

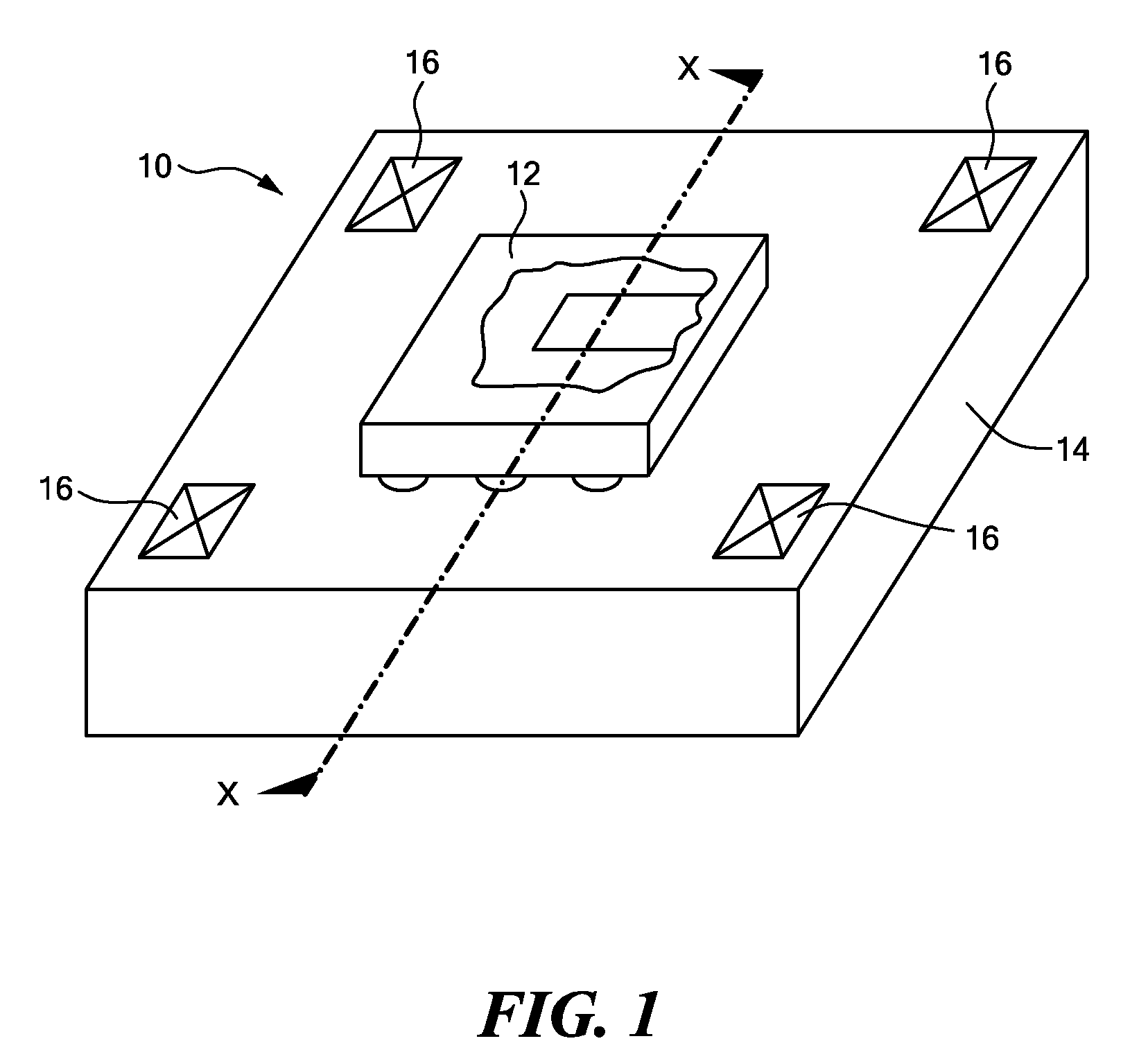

Method of Forming a Device by Removing a Conductive Layer of a Wafer

A method of forming a MEMS device provides a wafer having a base with a conductive portion. The wafer also has an intermediate conductive layer. After it provides the wafer, the method adds a diaphragm layer to the wafer. The method removes at least a portion of the intermediate conductive layer to form a cavity between the diaphragm layer and the base. At least a portion of the diaphragm layer is movable relative to the base. After it forms the cavity, the method seals the cavity.

Owner:ANALOG DEVICES INC

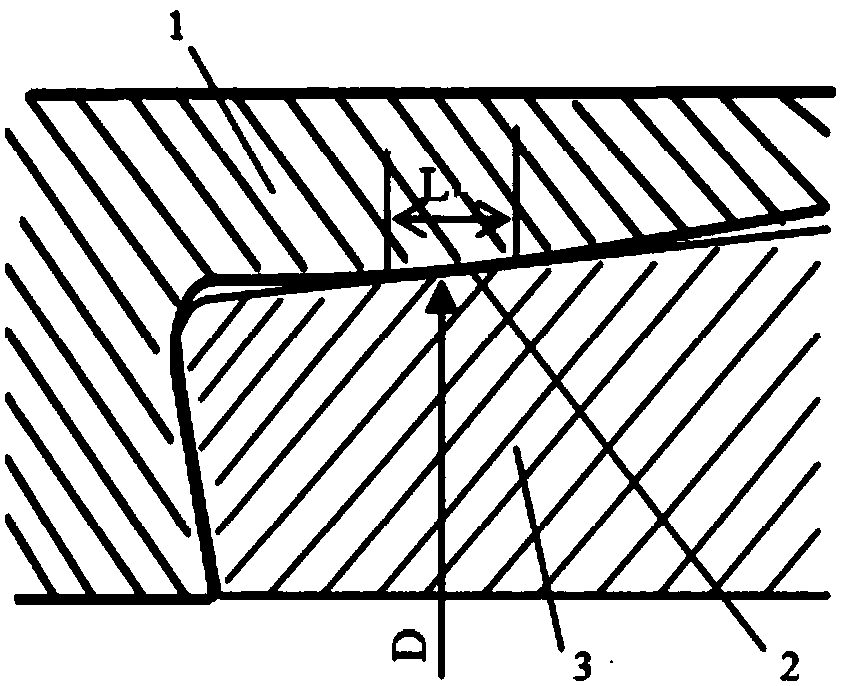

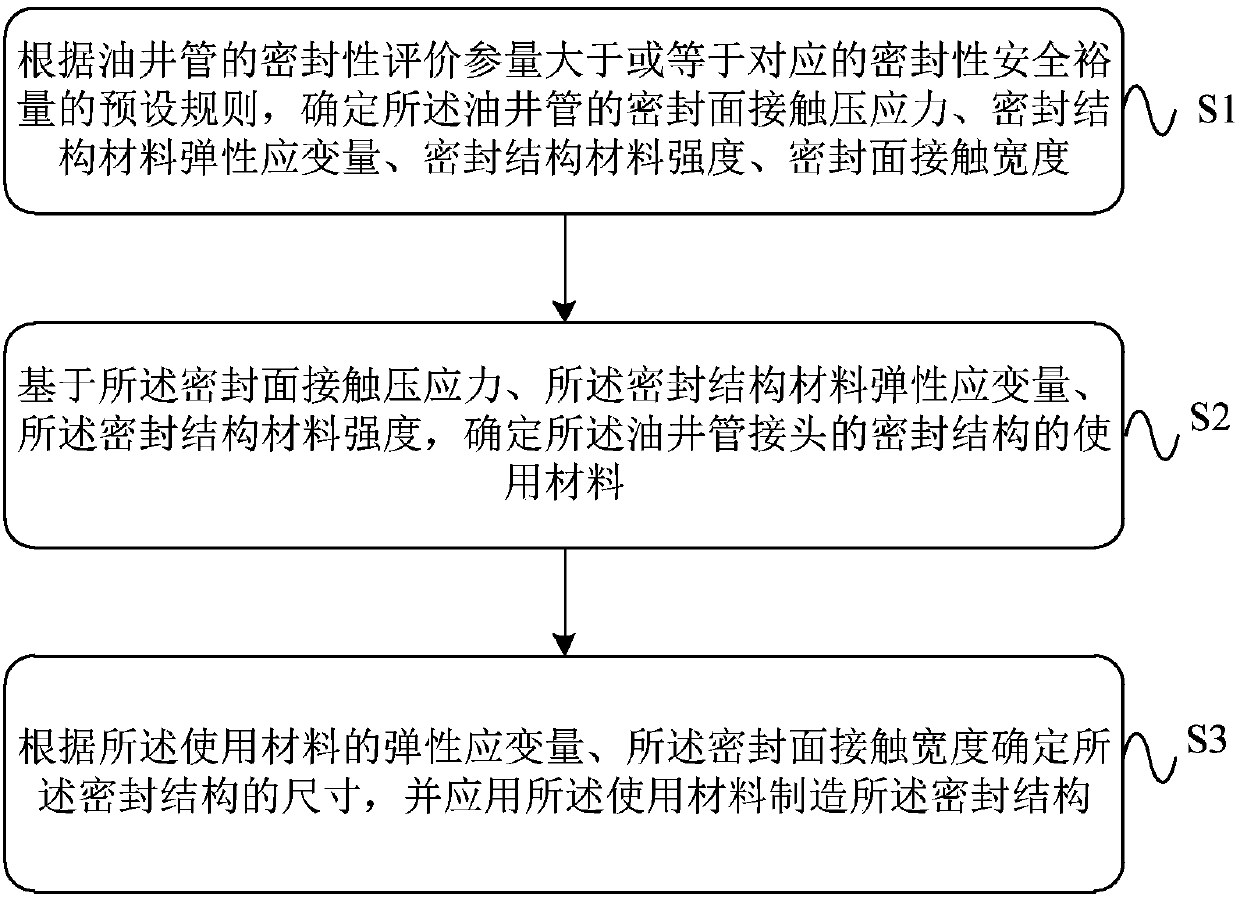

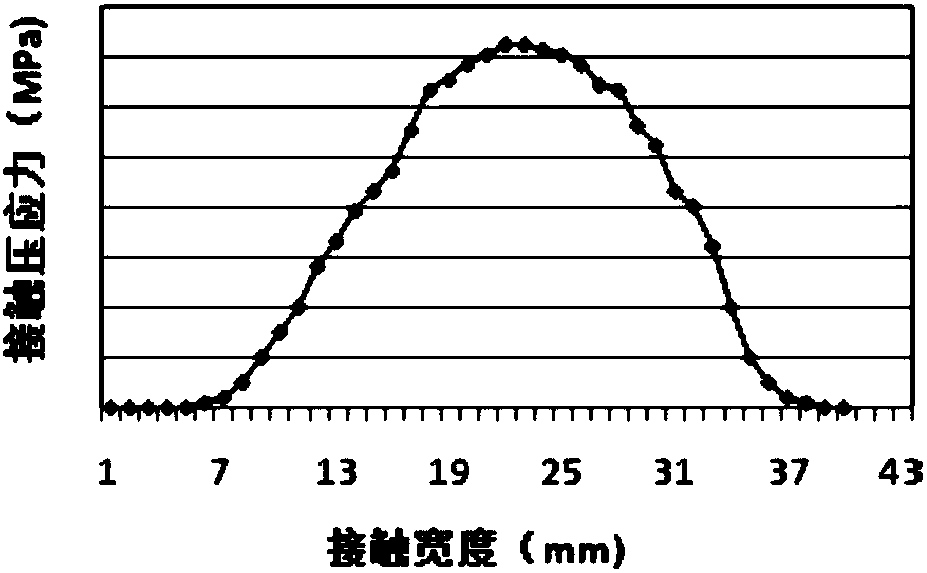

Designing and manufacturing method and sealing method of sealing structure of oil well pipe joint

ActiveCN110359858AImproves sealing reliabilityIncrease the amount of interferenceDrilling rodsDesign optimisation/simulationContact pressureAlloy

The invention provides a designing and manufacturing method and a sealing method of a sealing structure of an oil well pipe joint. The manufacturing method comprises the steps of according to a presetrule that a sealing performance evaluation parameter is larger than or equal to a corresponding sealing performance safety allowance of an oil well pipe, determining a sealing surface contact pressure stress, a sealing structure material elasticity strain capacity, sealing structure material strength and a sealing surface contact width of the oil well pipe; according to the sealing performance safety allowance of the oil well pipe, enabling the sealing structure material elasticity strain capacity to be larger than 0.5%; according to the sealing surface contact pressure stress, the sealing structure material elasticity strain capacity and the sealing structure material strength, determining a used material of the sealing structure; according to the determined sealing structure material elasticity strain capacity, determining the used material of the sealing structure as a hyperelastic alloy material with the elasticity strain capacity being larger than 0.5%; and manufacturing the sealing structure according to the used material and the elasticity strain capacity thereof. By utilizing the designing and manufacturing and the sealing method of the sealing structure of the oil well pipe joint provided by the embodiment of the invention, the reliability of a sealing performance of the oil well pipe joint is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Seal ring design without stop layer punch through during via etch

InactiveUS20050184388A1Avoid damageSemiconductor/solid-state device detailsSolid-state devicesCritical dimensionMethod seal

Owner:TAIWAN SEMICON MFG CO LTD

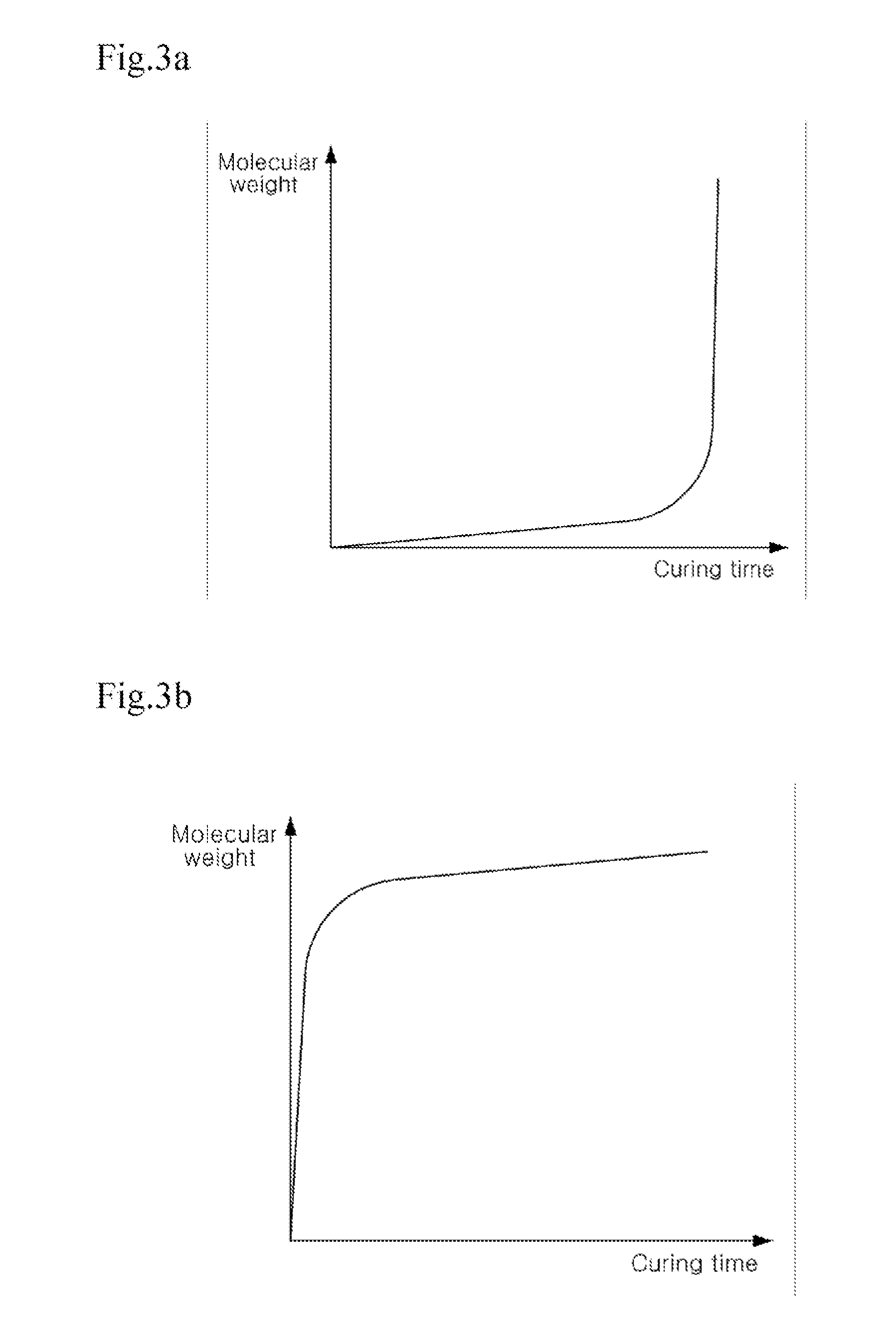

Non-reactive hot melt adhesive, its manufacture and its use in sealing packages

ActiveUS20170081572A1Stay cohesiveImprove adhesionAdhesive processesNon-macromolecular adhesive additivesPolymer scienceLactide

A non-reactive hot melt adhesive containing a copolymer being substantially composed of a reaction product of lactide (L) and caprolactone (C) in a molar ratio (L / C) of at least 1.5. The adhesive further includes a carbodiimide compound. The presence of a small but effective amount of carbodiimide causes a stabilizing effect on the sealing properties of the adhesive, especially if it is exposed to higher temperatures. A method manufactures the adhesive and a method seals a package with the adhesive.

Owner:PURAC BIOCHEM

Apparatus and method for providing a visual indication of seal integrity

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com