Pressure balance type seal method and its use

A balanced and pressure technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as failure of sealing device, large pressure difference of mechanical seal, hydraulic splitting of rubber seal interface, etc., to ensure consistency, guarantee Accuracy and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the measurement environment, the present invention transmits the pressure difference outside the measurement tool to the measurement tool by setting a film made of waterproof flexible material on the measurement tool, and reduces the pressure difference between the inside and outside of the measurement tool. Realize the sealing of the measuring tool.

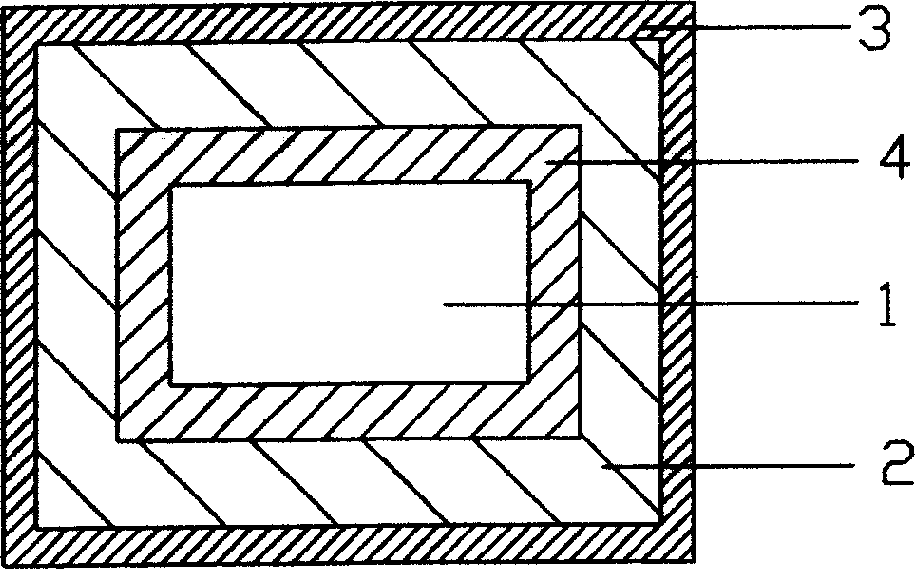

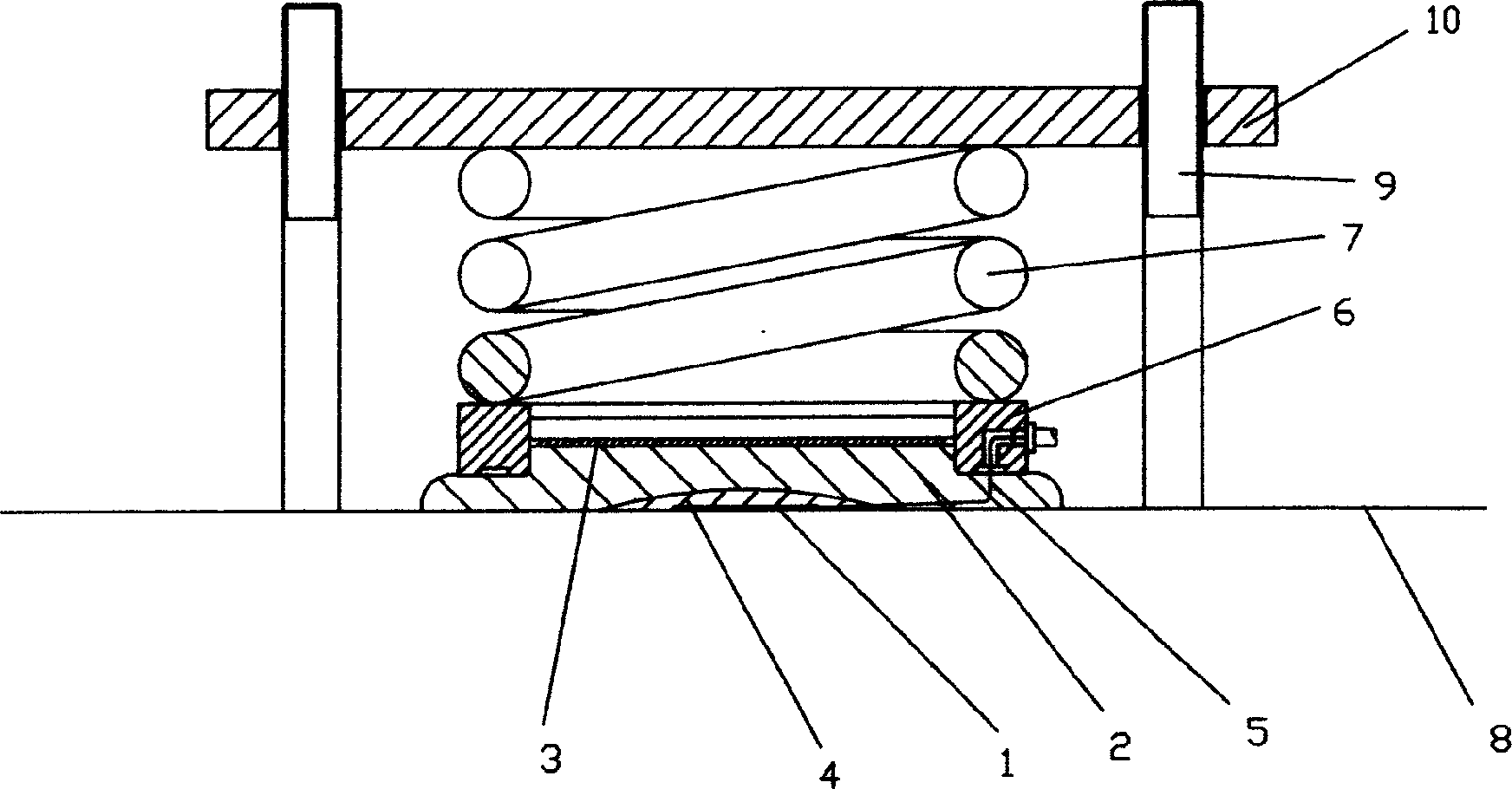

[0023] figure 1 and 2 Among them, one side of the sensitive element 1 is located on the inner wall 8 of the pressure balance sensor cavity, and the surface of the other side of the sensitive element 1 is coated with petroleum jelly 4, and the petroleum jelly 4 seals the sensitive element 1 with oil. On the outer surface of the vaseline 4, a layer of waterproof rubber 2 is covered. The waterproof rubber 2 has good elasticity, and a wire mesh 3 is also arranged on the surface of the waterproof rubber 2. A washer 6 is arranged on the edge of the waterproof rubber 2, and the edge of the waterproof rubber 2 is pressed aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com