Wet tissue and manufacture method thereof

A manufacturing method and technology of wet wipes, which are applied in paper, reinforcing agent addition, household appliances, etc., can solve the problems of insufficient wet strength of paper wet wipes, wet wipes are not easy to degrade, and inconvenient to use, so as to achieve good moist feeling and prevent Hydrogen bond breaking, production cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

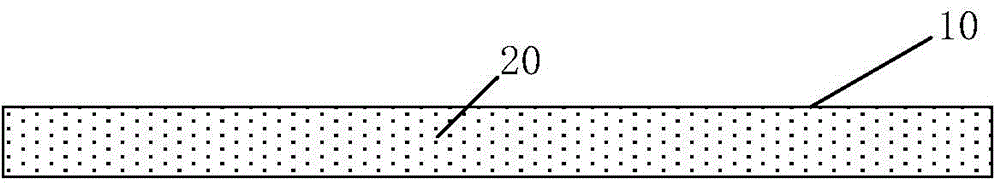

[0024] see figure 1 , figure 1 It is a structural schematic diagram of the wet tissue of the present invention. In this embodiment, the wet tissue includes a substrate 10 and a formula emulsion 20 . The substrate 10 is paper, and the formula emulsion 20 permeates into the substrate 10, and the weight of the formula emulsion 20 per gram of the substrate 10 is 1.0-1.8. For paper wet wipes with low liquid content, the substrate 10 itself has a certain wet strength, and its low liquid content of 1.0-1.8 can not only ensure that the substrate 10 of the wet wipes has a good moist feeling, but also ensure that the paper The substrate 10 of the quality wet tissue retains as many hydrogen bonds as possible to prevent the hydrogen bonds from breaking and the loss of wet strength after the substrate 10 is humidified.

[0025] Preferably, the substrate 10 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com