Self-suction negative pressure vibration sieve

A vibrating sieve and self-priming technology, which is applied in the direction of mobile filter element filter, filtration separation, separation device, etc., can solve the problems of small processing capacity and high liquid content of discharged cuttings, so as to reduce liquid content and increase treatment The effect of reducing the amount of processing work and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

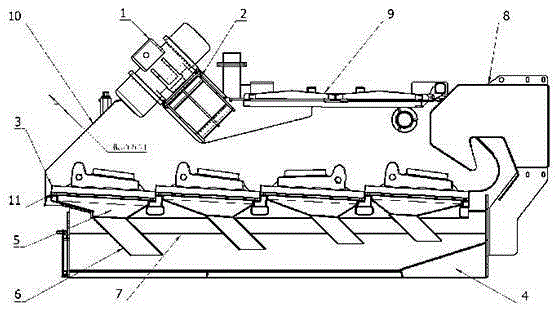

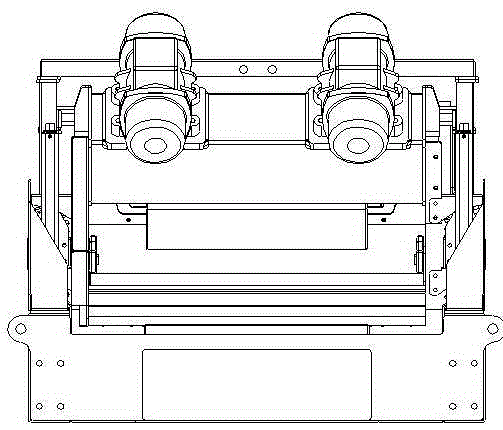

[0013] like figure 1 and figure 2 As shown, a self-priming negative pressure vibrating screen is mainly composed of a screen box 10, a vibrating motor 1, a screen 3, a liquid inlet funnel 8, a vibrating screen base 4, several negative pressure funnels 5 and a negative pressure tank 7. The net 3 is fixed on the screen base 11, the vibrating motor 1 is connected to the side plate of the screen box 10 through the motor base 2, the negative pressure funnel 5 is installed at the bottom of the screen support base 11 and connected to the vibrating screen base 4 through the liquid outlet 6 The negative pressure tank 7 forms a closed cavity through the drilling fluid. A liquid inlet funnel 8 is arranged on the side of the vibrating screen base 4. The outlet of the liquid inlet funnel 8 is located above the screen 3, and the drilling fluid baffle 9 is installed on the top of the screen 3 to prevent drilling. Liquid splash.

[0014] The working principle of the present invention is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com