Waste acid and sludge recycling cooperative treatment system

A sludge and resource technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as insufficient contact, high consumption of clogging, and impact, so as to reduce filler clogging, increase service life, and improve transmission efficiency. The effect of mass efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

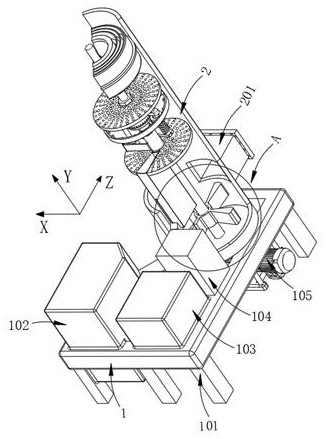

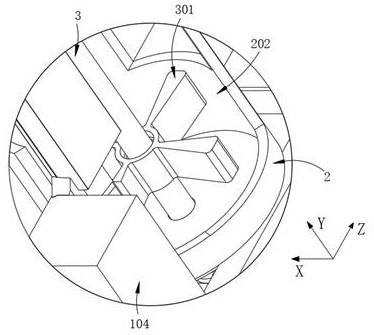

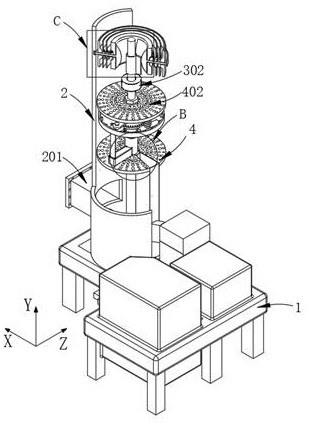

[0051] like Figure 1-3 As shown in the figure, a waste acid and sludge resource co-processing equipment includes a tower body 2 and a transmission unit 3 arranged in the tower body 2; it also includes: a mass transfer adjustment unit 4, and the mass transfer adjustment unit 4 is located in the The inside of the tower body 2 is drivingly connected with the transmission unit 3; the demisting unit 5, which is used for dynamically demisting the exhaust gas passing through the mass transfer adjustment unit 4, is arranged in the transmission unit. The top of the mass adjustment unit 4 is connected to the transmission unit 3 in a driving manner; the mass transfer adjustment unit 4 includes a scraping unit 407 and a mixing plate 409 for mixing and mass transfer adjustment of the filler and spray water; the transmission The packing at the top of the quality conditioning unit 4 mixes and transfers the gas phase of the exhaust gas and the liquid phase of the spray water under the rotati...

Embodiment 2

[0070] like Figure 11 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that the present invention also provides a waste acid and sludge resource co-processing system, which includes the following working steps:

[0071] Step 1. Preliminary mass transfer: through the rotary spray, the filler deposited on the surface of the mass transfer adjustment unit 4 is attached to the spray water, and the attached spray water exchanges gas-liquid impurities in the filler with the waste gas input from the waste gas inlet and outlet;

[0072] Step 2. Homogeneous mass transfer: The intermittently rotating mixing plate 409 periodically stirs the packing on the top of the mass transfer adjusting unit 4, so that the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com