Filter-aid feeder on horizontal screw discharge filter centrifuge

A horizontal screw and feeder technology, applied in centrifuges with rotating drums, centrifuges, etc., can solve the problems of inoperable centrifuges, high solid-phase moisture content, and failure to meet requirements, etc. Conducive to solid-liquid separation and the effect of reducing liquid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

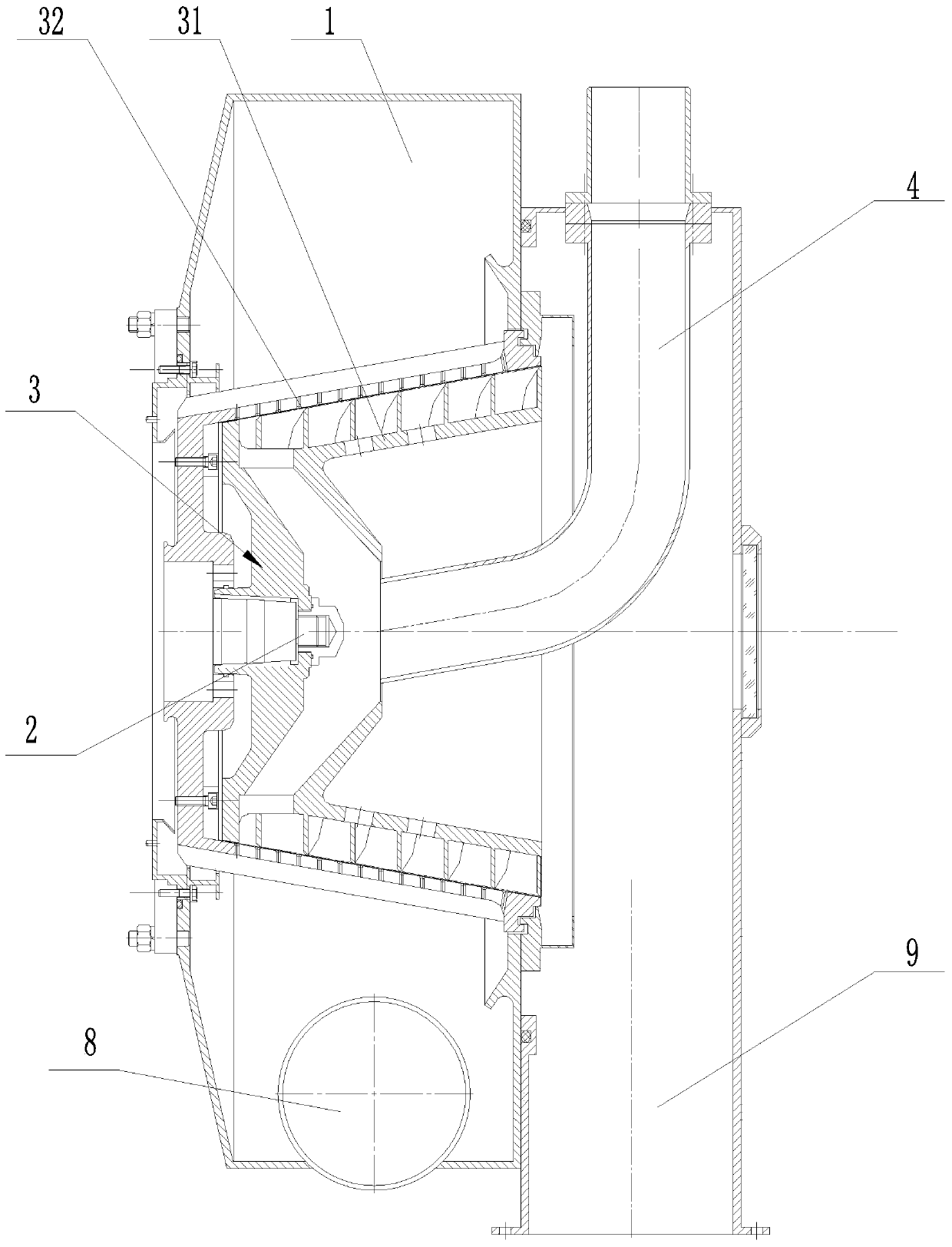

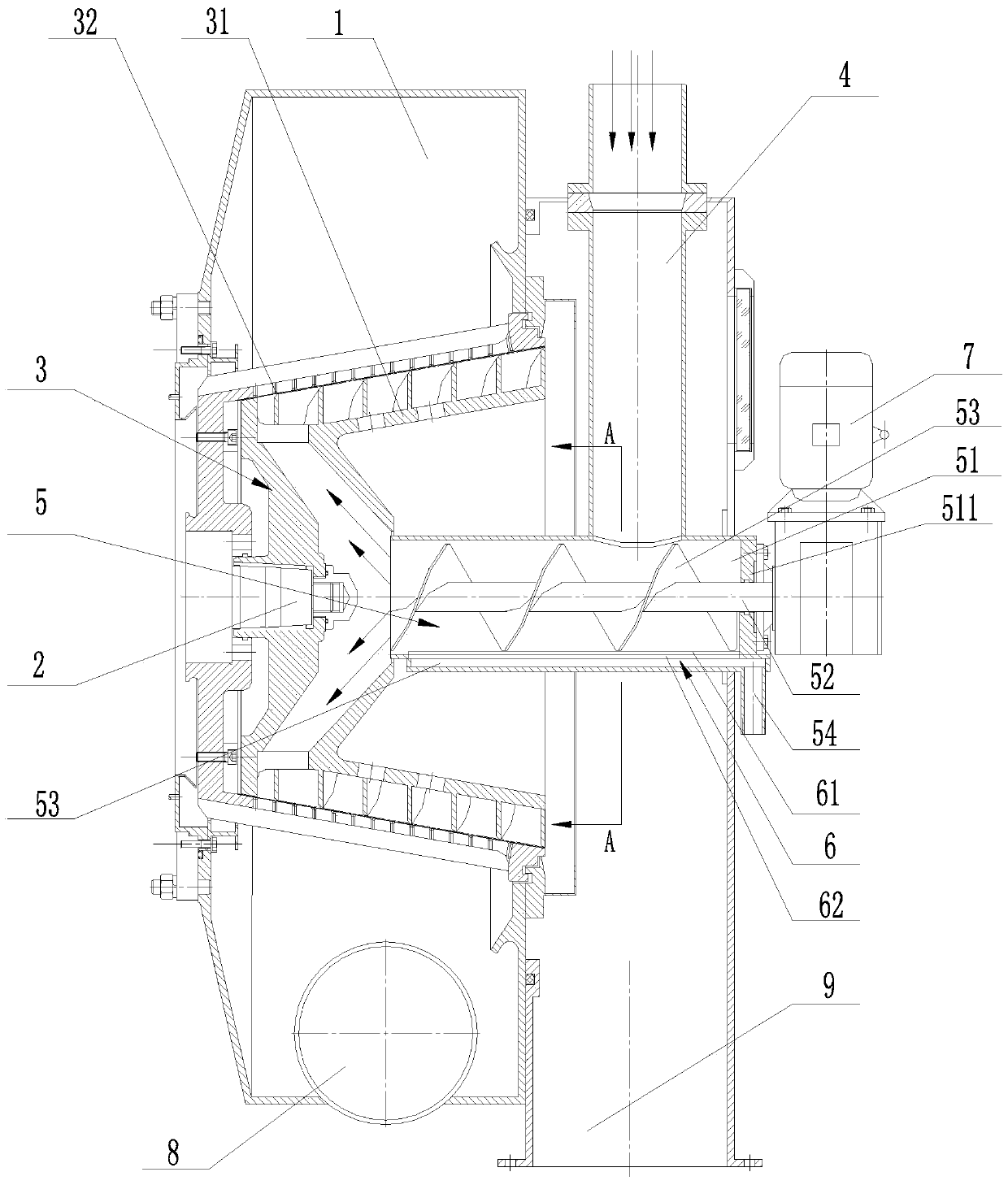

[0016] see figure 2 As shown, a filter aid feeder on a horizontal screw discharge filter centrifuge, the centrifuge includes a casing 1, a main shaft 2 arranged in the casing 1, and a drum 3 sleeved on the main shaft 2, the centrifuge The filter aid feeder is arranged on the feeding end of the drum 3, and is used to reduce the liquid content of the material entering the drum 3, thereby improving the solid-liquid separation capacity of the centrifuge.

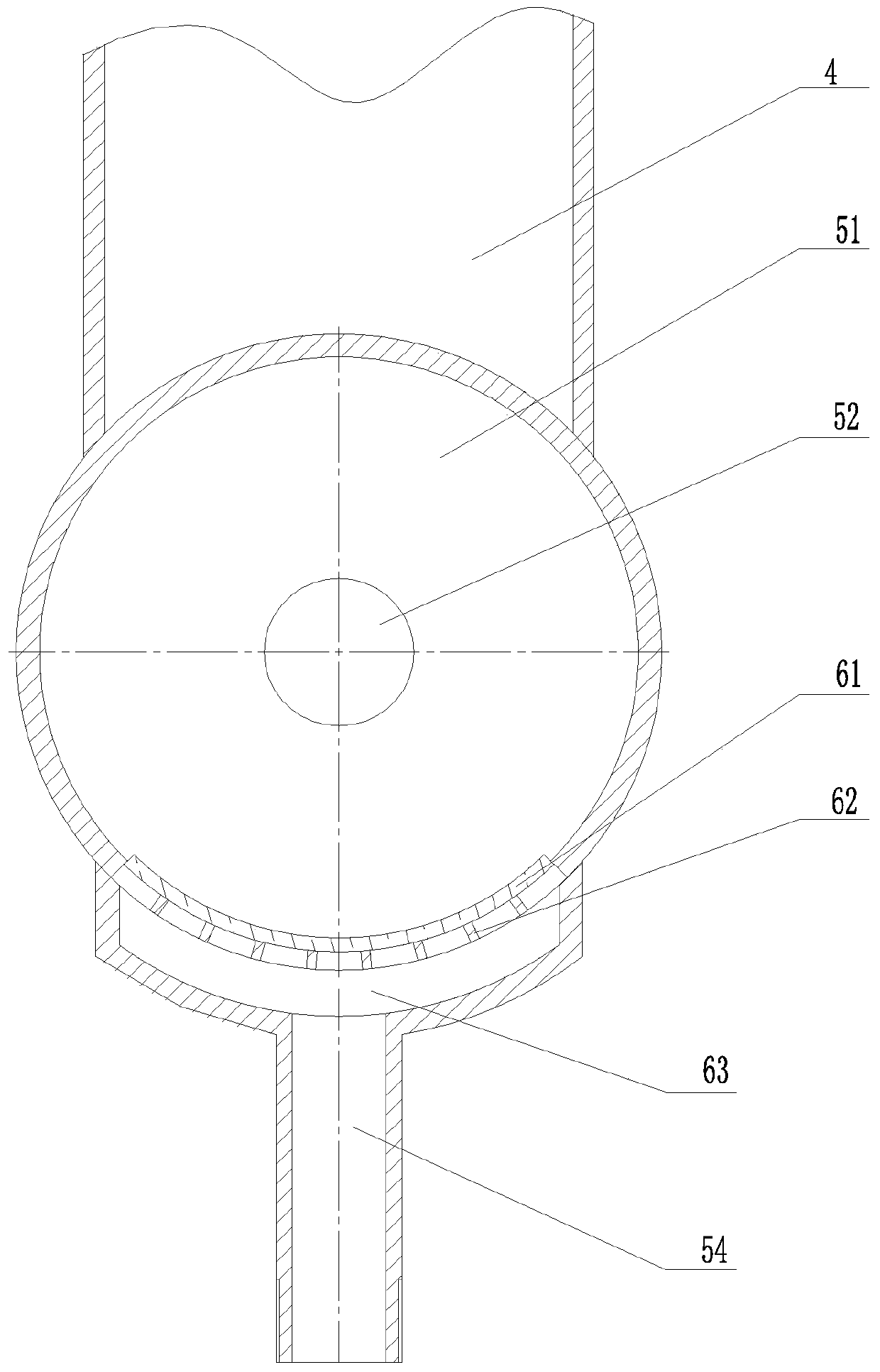

[0017] see figure 2 As shown, the filter aid feeder includes a feed pipe 4 inserted in the casing 1, a feed screw 5 arranged on the discharge end of the feed pipe 4, and the feed screw 5 includes a feed screw with an inner cavity. The material spiral tube 51, the rotating shaft 52 inserted in the feeding spiral tube 51, the spiral blades 53 fixed on the rotating shaft 52 and evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com