Method and apparatus for manufacturing, filling and packaging medical devices and medical containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

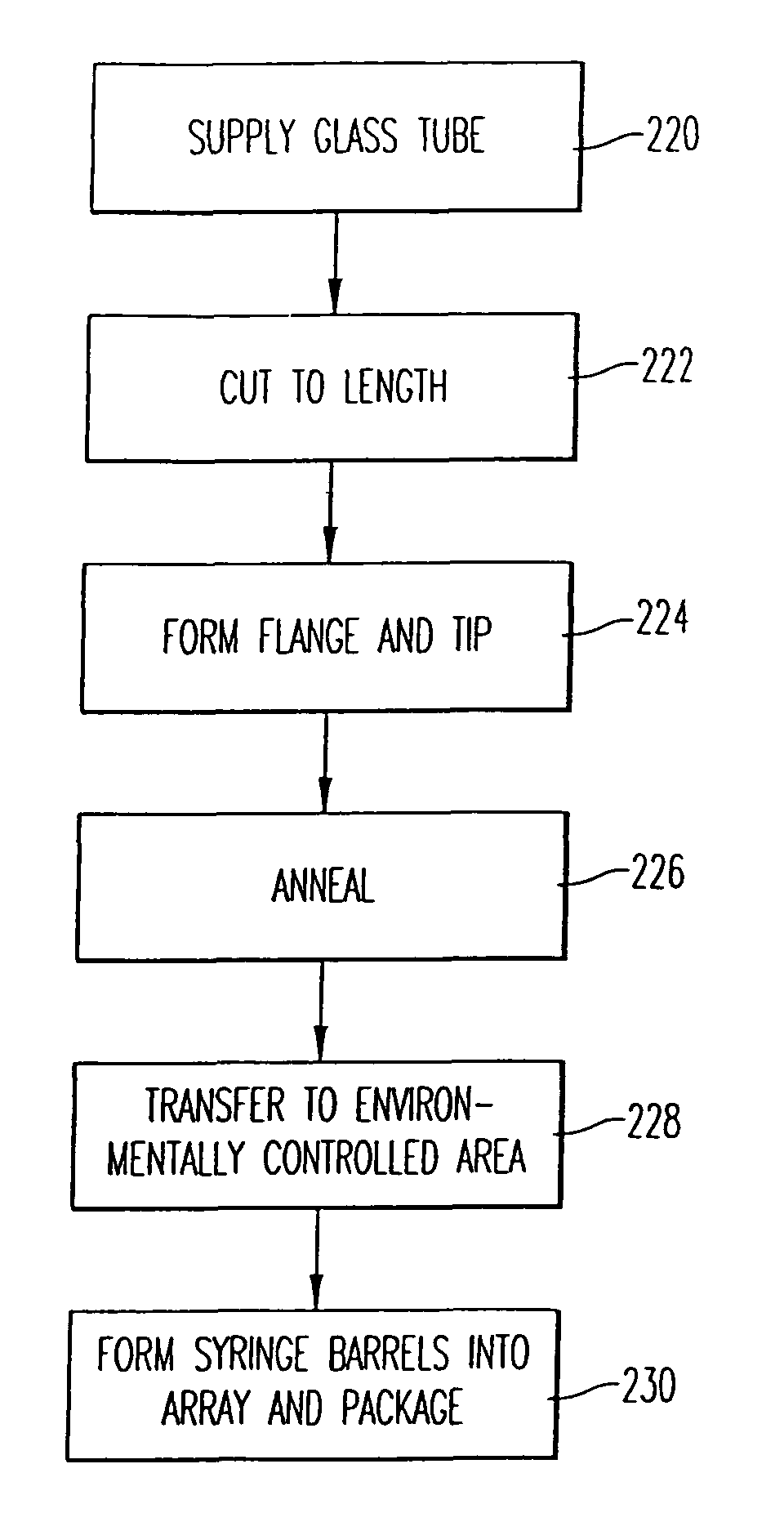

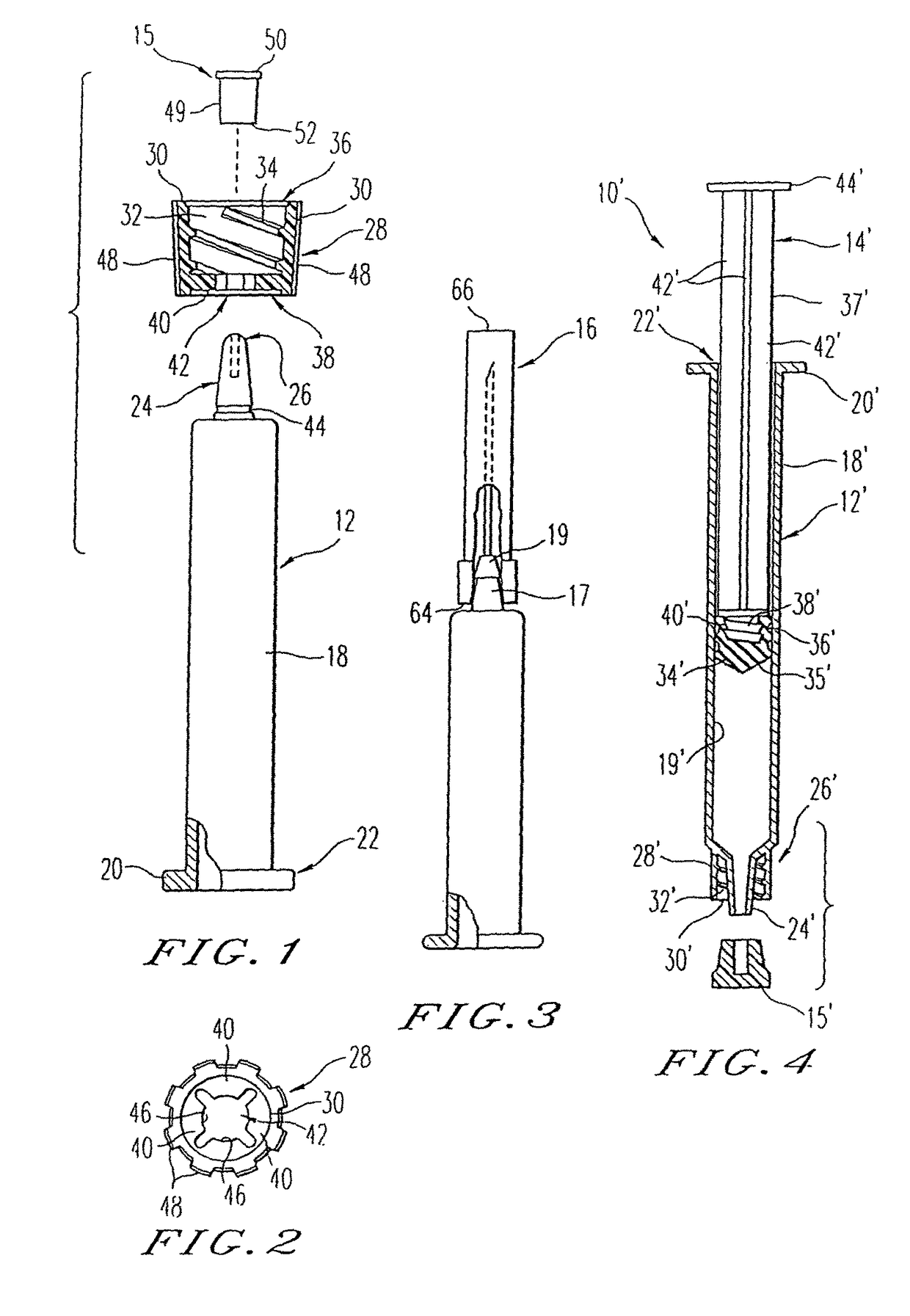

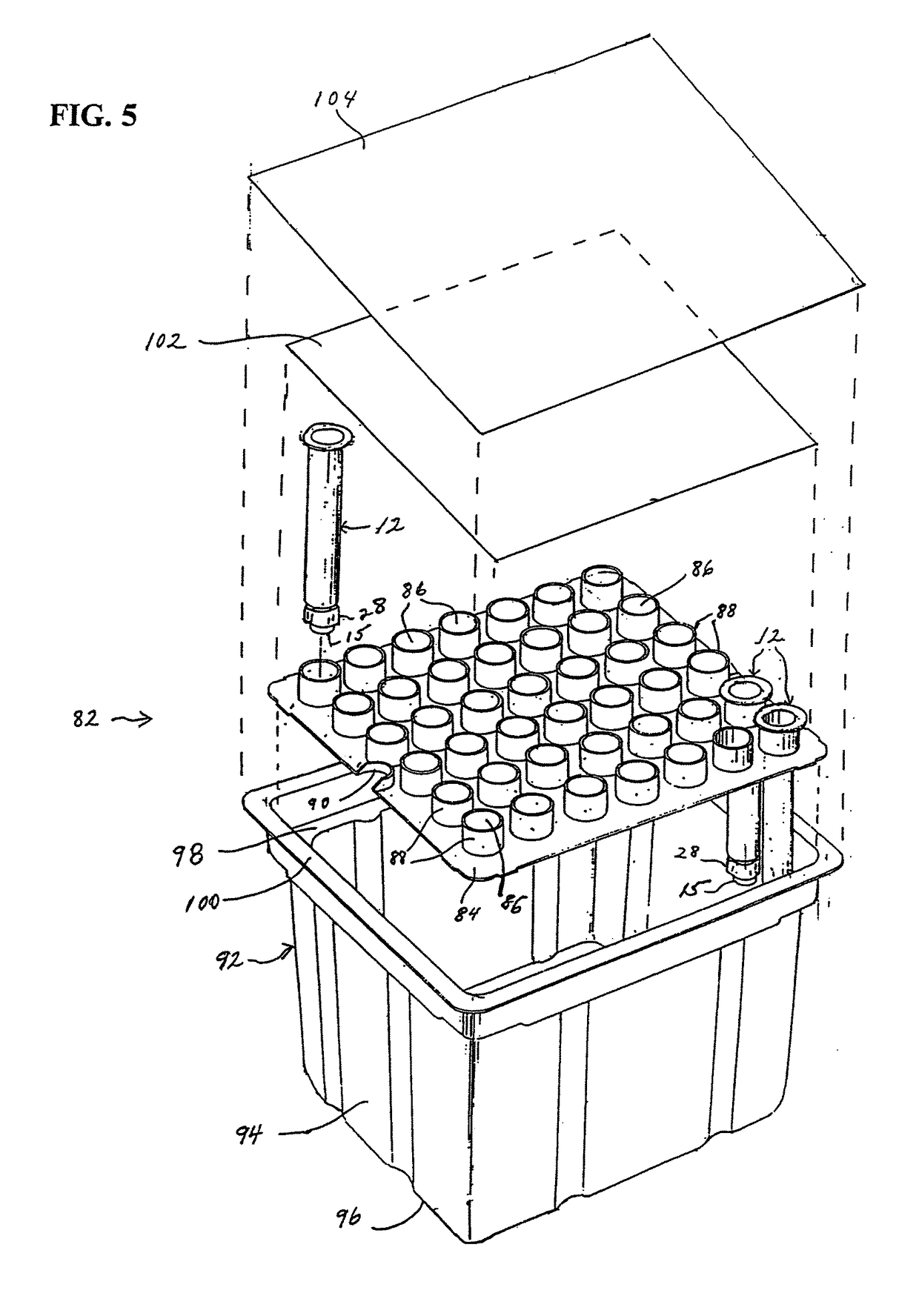

[0034]The present invention is directed to a method and apparatus for manufacturing and thereafter assembling and packaging medical containers, drug delivery devices and drug containers, such as vials, syringe barrels and prefilled syringes, in a clean, environmentally controlled area. As used herein, medical containers for containing and / or dispensing substances include vials and injection devices such as syringes. In addition, as used herein, a substance includes, for example, water, saline solutions, flush solutions and contrasting agents, pharmaceutical agents and vaccines in either a dry state or liquid state. The medical containers can be syringe barrels formed from a base material such as glass or plastic. The syringe barrels are used to assemble a syringe 10 as shown in FIG. 1. Although embodiments of the invention are disclosed as a hypodermic syringe assembly, it is within the purview of the present invention to include various other drug containers, such as plastic or gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com