White LED chip and manufacturing method thereof

A technology of LED chip and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of easy-to-contaminate LED chips, poor welding of white LED chips, and light leakage of LED chips, so as to improve luminous efficiency and avoid easy production and processing , The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

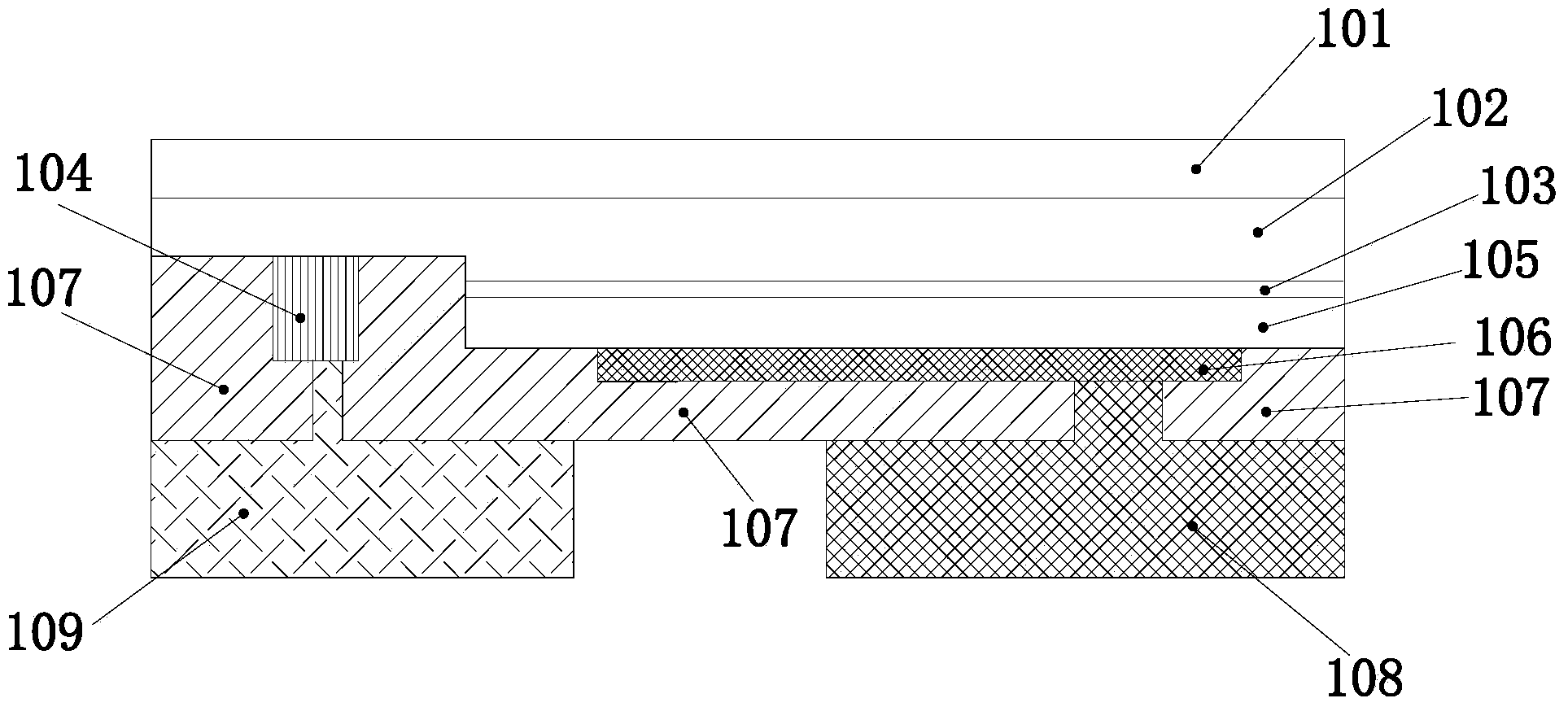

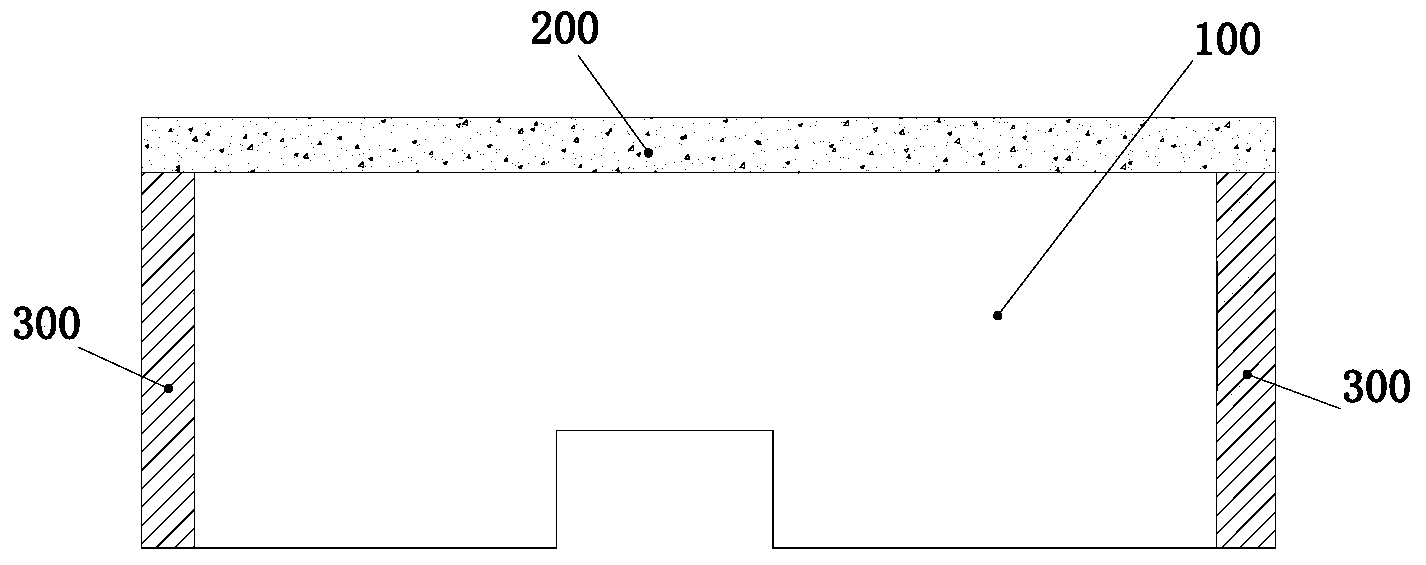

[0044] Such as figure 2 As shown, this embodiment discloses a white light LED chip, including a mounted LED chip 100, on the epitaxial substrate layer of the mounted LED chip 100, prefabricated light for light color conversion is mounted. The conversion layer sheet 200 is closely surrounded by a reflective wall 300 for preventing light leakage from the side of the LED chip around the mountable LED chip 100 , and the reflective wall 300 is connected to the light conversion layer sheet 100 .

[0045]Wherein, the light conversion layer sheet 200 is a prefabricated sheet-shaped material, and the light conversion layer sheet 200 is used to convert light color. For example, when the mounted LED chip 100 is a blue LED chip, the light conversion layer sheet 200 is selected. Yellow light conversion material, so as to convert blue light into white light. It should be noted that this patent is not limited to blue light LED chips and yellow light conversion materials. Other situations th...

Embodiment 2

[0058] Figure 4a- Figure 4c As shown, the difference between this embodiment and Embodiment 1 is that the (1) step of the manufacturing method of the white light LED chip of this embodiment is specifically as follows: the pre-prepared block-shaped reflective wall 300 is bonded to the light The surface of the conversion layer sheet 200 encloses a plurality of LED chip installation cavities.

[0059] In this embodiment, the process of making a white LED chip is specifically as follows:

[0060] 1. If Figure 4a1 As shown, now the pre-prepared block-shaped reflective wall 300 is bonded on the surface of the light conversion layer sheet 200, Figure 4a1 is a sectional view, Figure 4a2 It is a top view after bonding. It can be seen from the figure that the reflective wall 300 forms a plurality of LED installation cavities for installing LED chips on the surface of the light conversion layer sheet 200 .

[0061] 2. If Figure 4b As shown, then mount the mount-type LED chip 10...

Embodiment 3

[0063] This embodiment is also slightly different from Embodiment 1. This embodiment discloses a method for manufacturing a white light LED chip, which specifically includes the following steps:

[0064] (1), such as Figure 5a As shown, the LED chip 100 is first mounted on the surface of the prefabricated light conversion layer sheet 200;

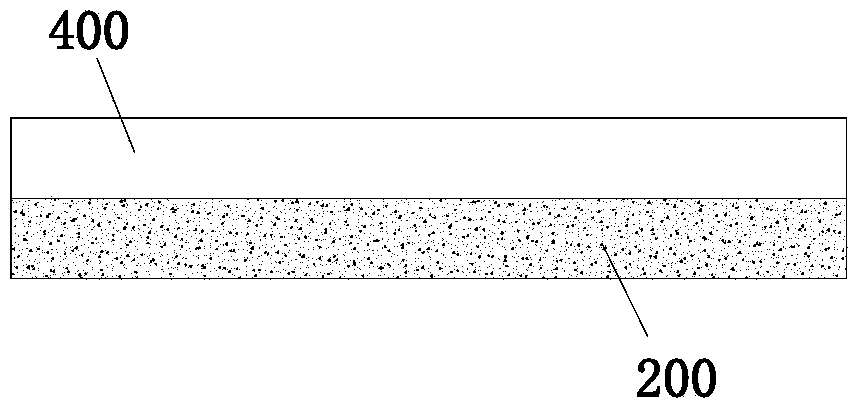

[0065] (2), such as Figure 5b As shown, a layer of polymer reflective material is coated on the light conversion layer sheet 200 pasted with the LED chip 100 and cured, and the polymer reflective material completely covers the LED chip;

[0066] (3), such as Figure 5c As shown, the polymer reflective material on the upper surface is ground to expose the electrodes of the LED chip, and it is cut into a single white LED chip with a light conversion layer on the top and a reflective wall around it, Figure 5d It is the final single white LED chip.

[0067] In this embodiment, the LED chip 100 is first mounted on the surface of the prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com