Self-restrained explosive welding device with high energy utilization rate

An explosive welding, high-energy technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low energy utilization rate of explosives, safety of composite board flying, hidden dangers, etc., to achieve reasonable energy utilization rate of explosives, improve Energy utilization, the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

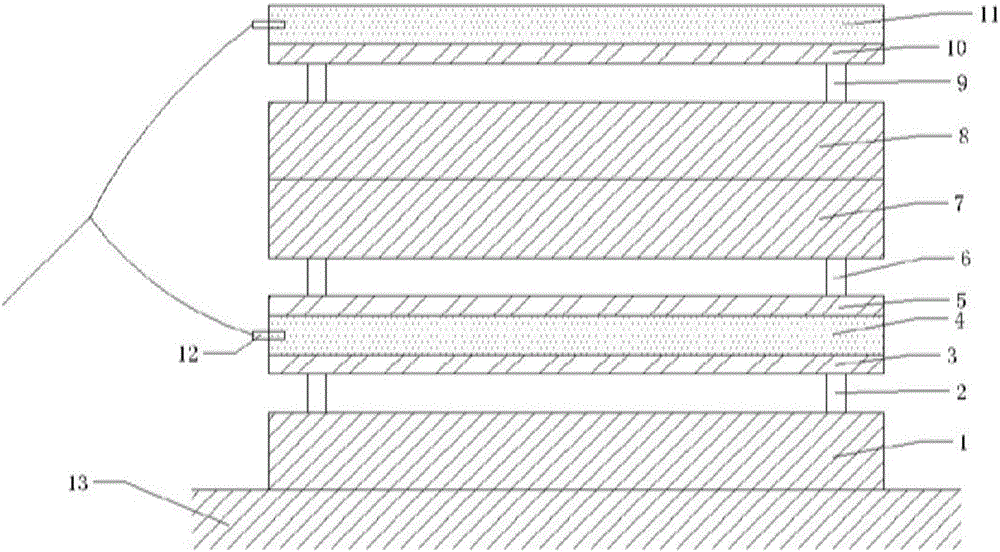

[0025] For stainless steel and steel and explosive composite, the substrate is steel, the size is: 4000mm×2000mm×20mm; the double plate is stainless steel, the size is 4000mm×2000mm×3mm.

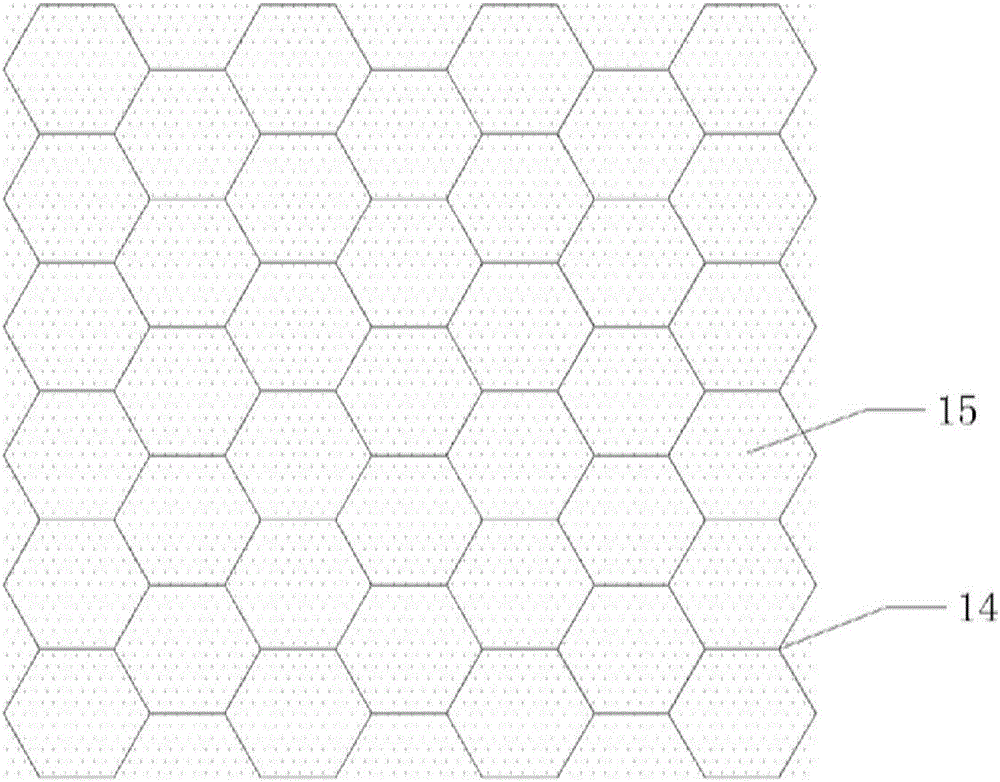

[0026] see figure 1 , this embodiment contains a group of double-sided welding combinations and a group of single-sided welding combinations. In the double-sided welding combination, the substrate A (1) is placed flat on the foundation (13) and the support column A (2) is evenly arranged on its upper surface, and the support column is rolled from a thin aluminum sheet. Wall thickness 0.5mm, height 8mm. According to the MTS test, a single support column can carry 1.2KN, and the estimated total load required is about 32KN, so 4 support columns are arranged per unit area, that is, 4×8×1.2=38.4KN>32KN; the first structural explosive ( 4) Its upper and lower surfaces are closely attached to doubler board A (3) and doubler board B (5), and the first structural explosive is composed of honeycomb ...

Embodiment 2

[0029] For the explosive cladding of stainless steel and aluminum, the base plate is stainless steel, the size is: 400mm×400mm×28mm; the double plate is aluminum, the size is 400mm×400mm×4mm.

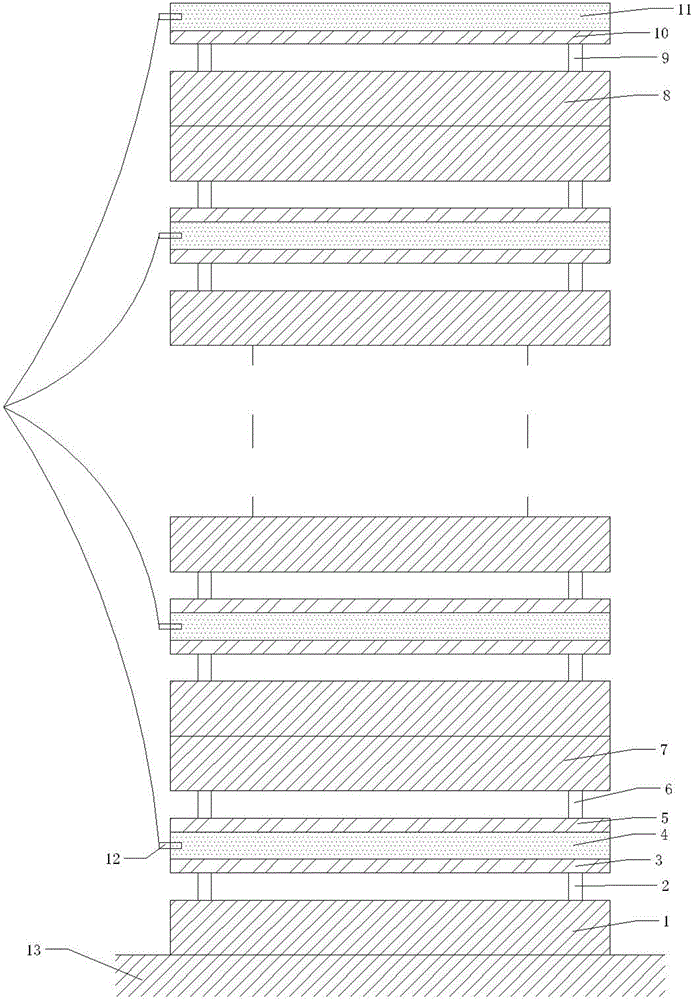

[0030] see image 3 , this embodiment contains n groups of double-sided welding combinations and a group of single-sided welding combinations. The double-sided welding combination is stacked sequentially from bottom to top, and the single-sided explosive welding combination is stacked on the uppermost substrate of the double-sided welding combination. The height of the supporting columns of each layer is 10mm high, and the number is determined by the bearing weight. The structural explosive is composed of honeycomb aluminum and powdered ammonium nitrate, and the height of the explosive is 22mm. The detonator is placed at the middle point of the left end of each layer of explosive and detonated simultaneously.

[0031] After the explosive is detonated, the composite plates on the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com