Silver copper diffusion welding method and device

A diffusion welding and welding device technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of easy introduction of pinholes or leakage welding, micro-channel blockage, micro-channel deformation, etc., to achieve good welding quality and reliability. , avoid oxidation, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

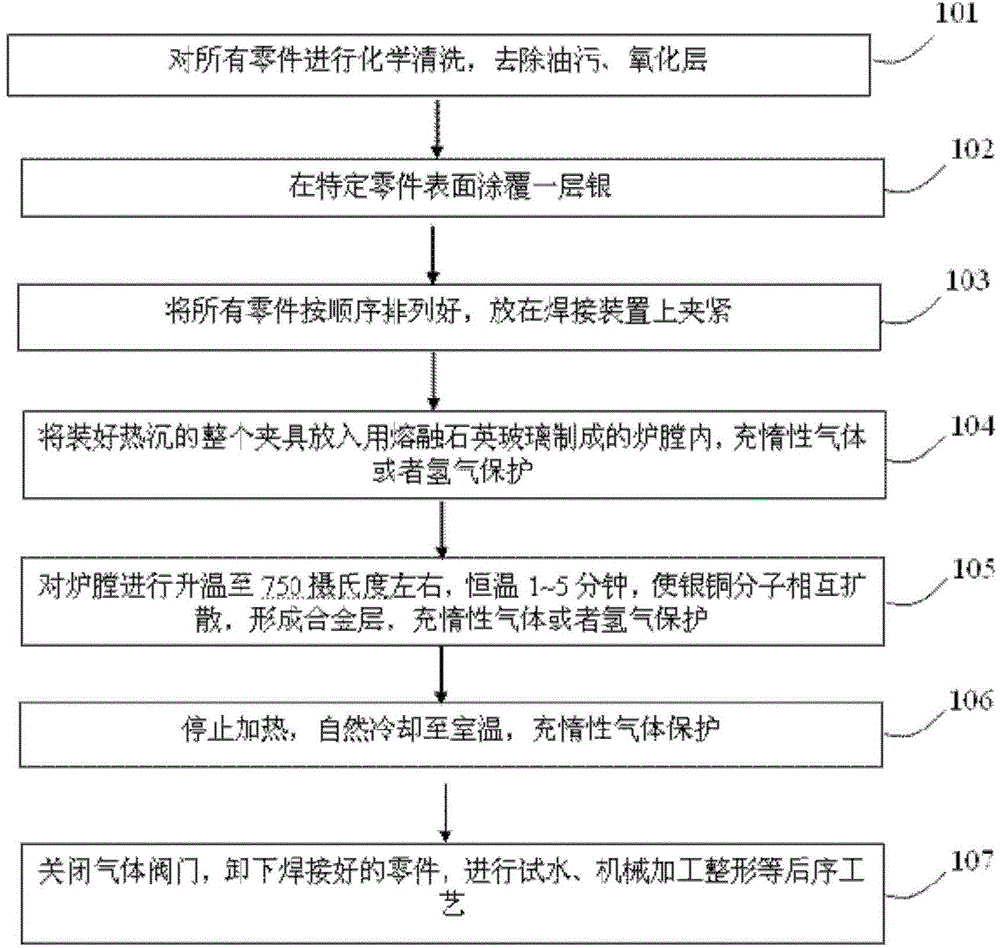

[0043] see figure 1 , figure 1 The flow chart of the novel silver-copper diffusion welding method provided by the invention, the method may further comprise the steps:

[0044] Step 101: Perform chemical cleaning on all parts to remove oil stains and oxide layers;

[0045] Step 102: coating a layer of silver on the surface of the specific part;

[0046] Step 103: Arranging all the parts in order, and clamping them on the welding device;

[0047] Step 104: Put the entire jig with the heat sink installed into a furnace made of fused silica glass, and fill it with inert gas or hydrogen for protection;

[0048] Step 105: Heating the furnace to about 800 degrees Celsius and keeping the temperature constant for 15 minutes, so that the silver and copper molecules diffuse each other to form an alloy layer, and fill it with inert gas or hydrogen for protection;

[0049] Step 106: Stop heating, naturally cool to room temperature, and fill with inert gas for protection;

[0050] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com