Car lock lug welding fixture

A welding jig, car lock technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of insufficient space for the welding jig for locking and paying ears, achieve good welding consistency and improve welding. Yield, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

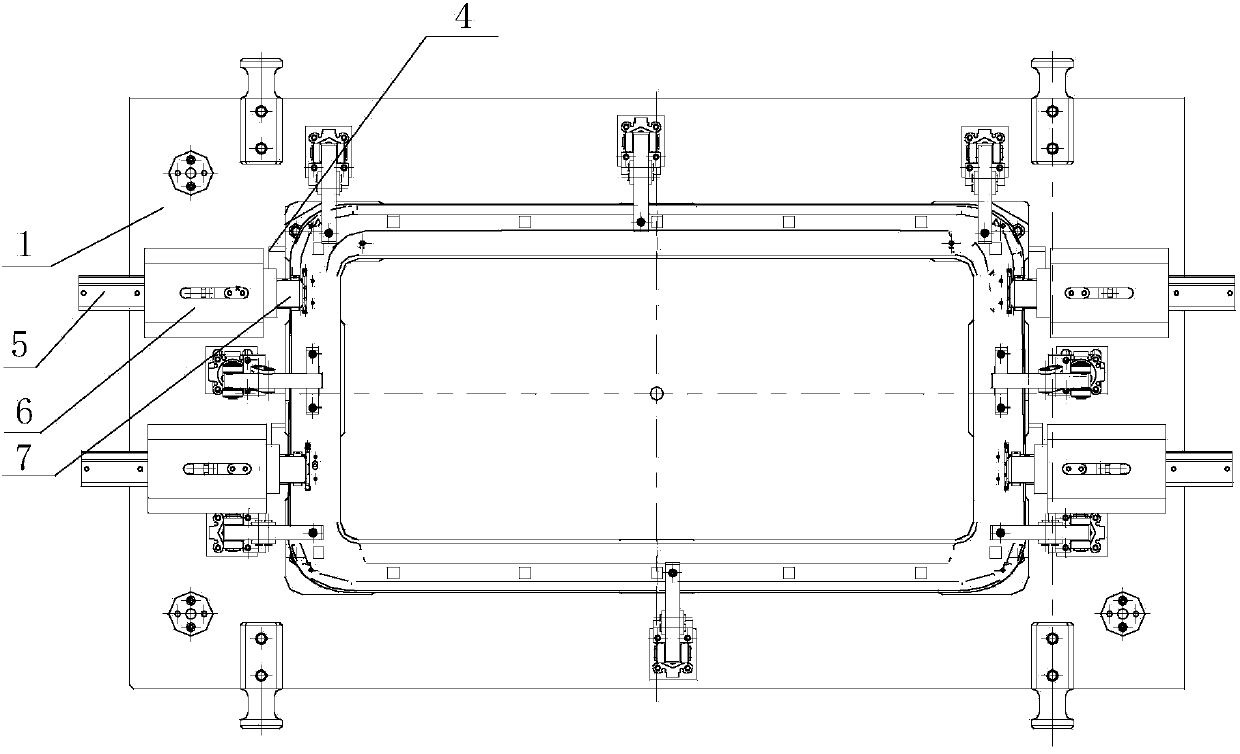

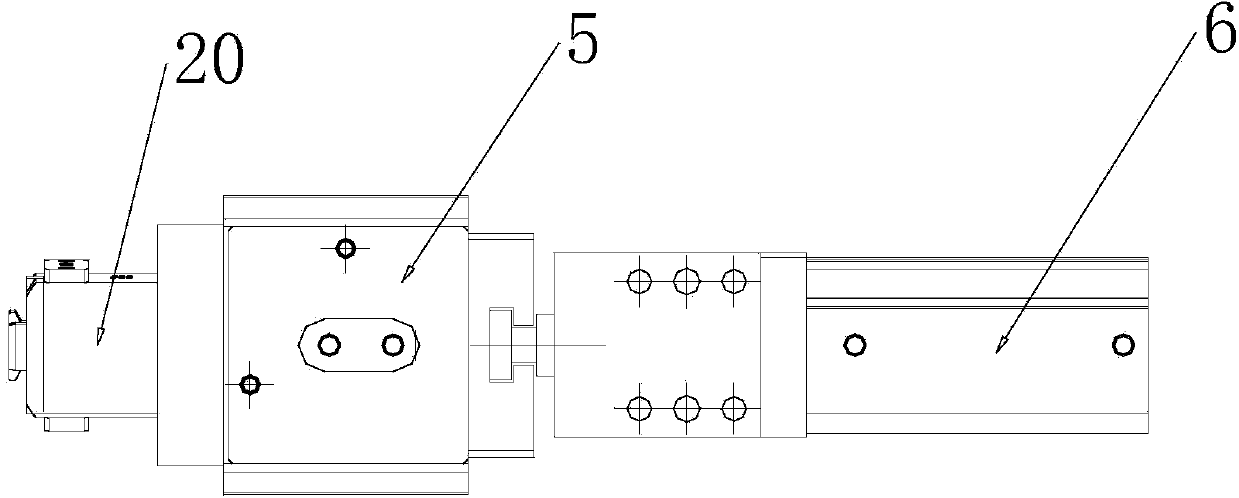

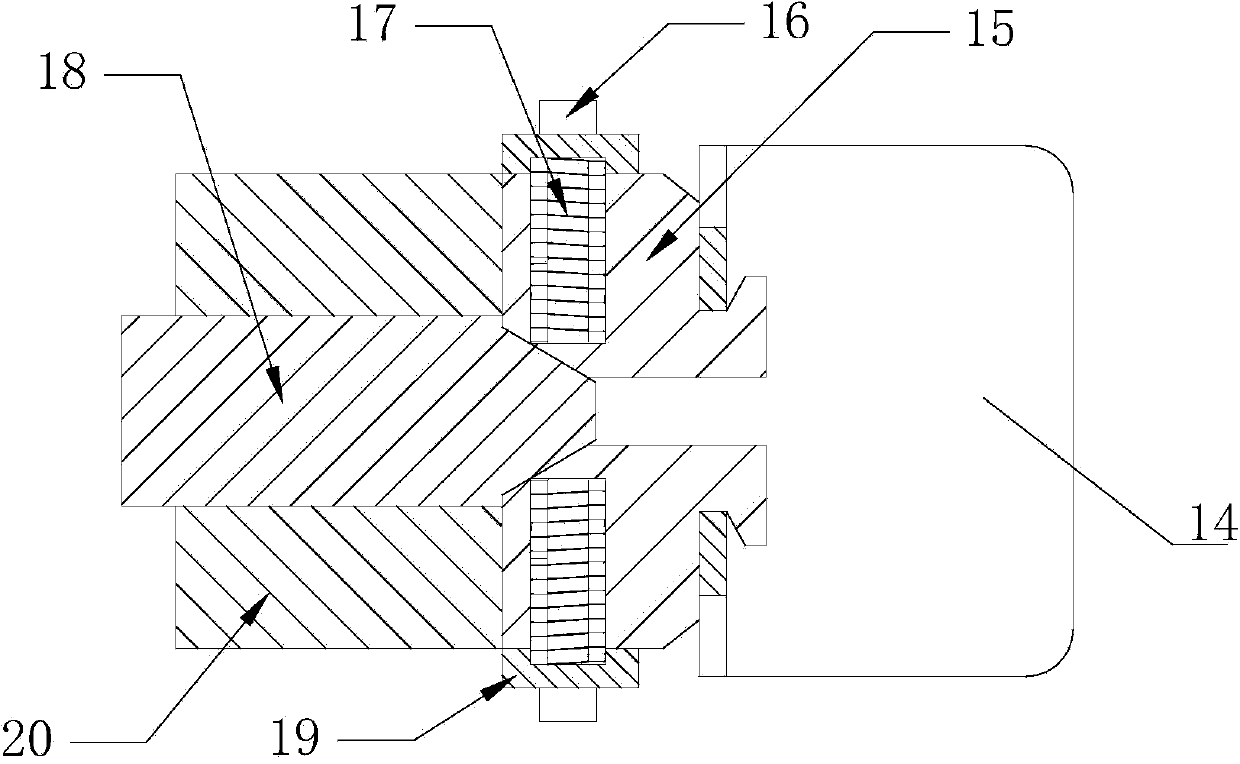

[0008] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, the fixture of this embodiment includes a rectangular welding fixture platform 1, a plurality of positioning seats 4 and an ear piece clamping unit, the rectangular welding fixture platform 1 is provided with a plurality of positioning seats 4, and each positioning seat 4 is provided with Ear clamping unit, each ear clamping unit includes ear clamping cylinder 5, ear positioning cylinder 6 and wedge mechanism 7, each wedge mechanism 7 includes wedge 18, housing 20, two slides Block 15, two springs 17 and two limit plates 19, the lug positioning cylinder 6 is connected with the wedge mechanism 7 and drives the wedge mechanism 7 to do horizontal movement, the connection of the lug clamping cylinder 5 and the wedge 18 can drive The oblique chisel 18 moves, and the oblique chisel 18 is made by connecting the bottom surface of the cuboid and the prism into one body. The oblique chisel 1...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Image 6 Describe this embodiment, the end of the bevel 18 of this embodiment has a groove, and the oil outlet rod of the lug clamping cylinder 5 is arranged in the groove, this structure is stable in movement and accurate in positioning. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Image 6 To illustrate this embodiment, guide rails 18-2 are provided on both sides of the wedge 18 in this embodiment, and the wedge 18 slides in the housing 20 through the guide rails 18-2. This structure has the advantages of stable movement and accurate positioning. Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com