Automatic cell welding machine for small solar component

A technology for solar battery packs and solar cells, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve the problems of high labor intensity, high defect rate, low welding efficiency, etc., so as to reduce labor intensity and improve production efficiency. and welding yield, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

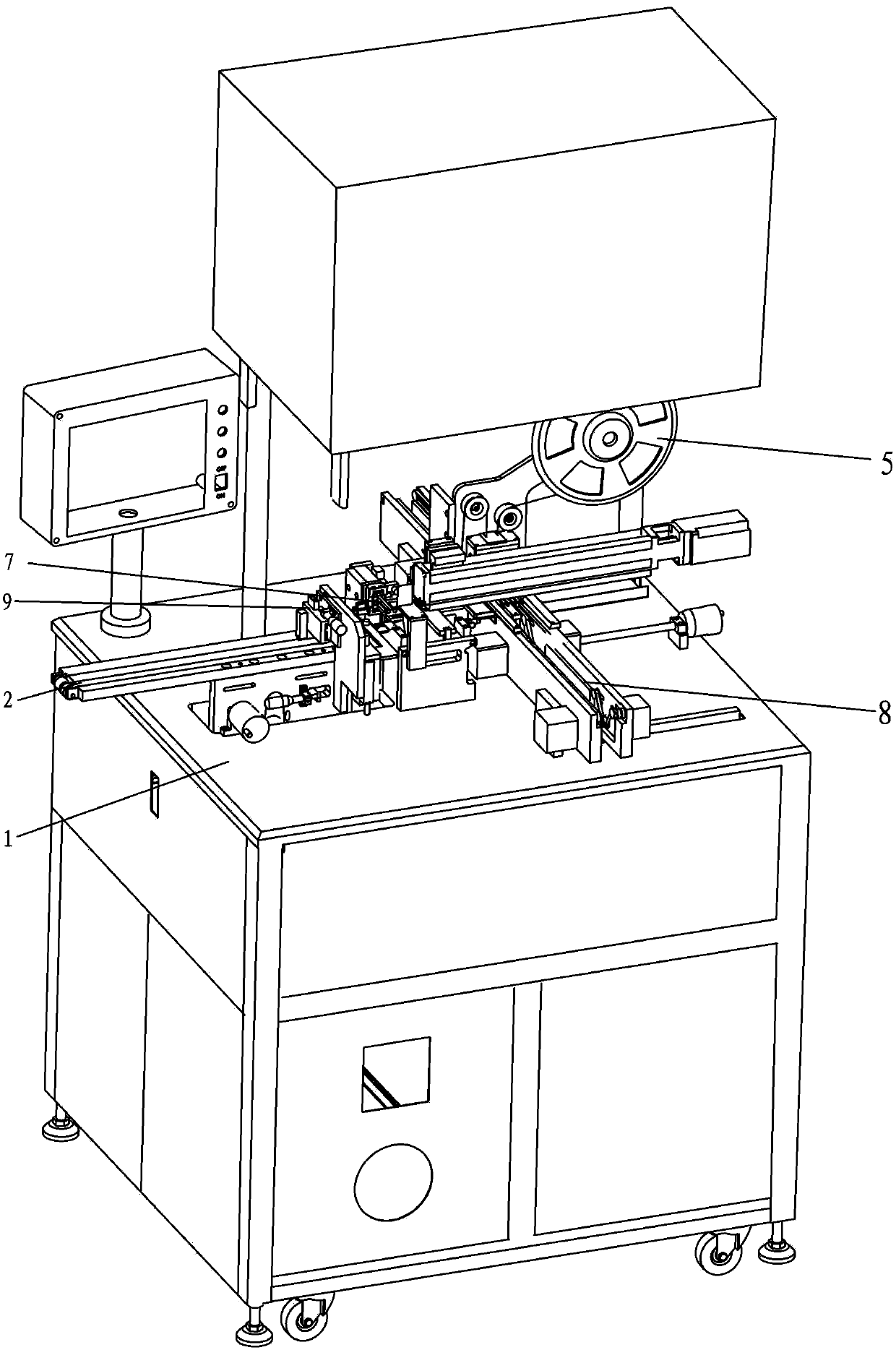

Embodiment 1

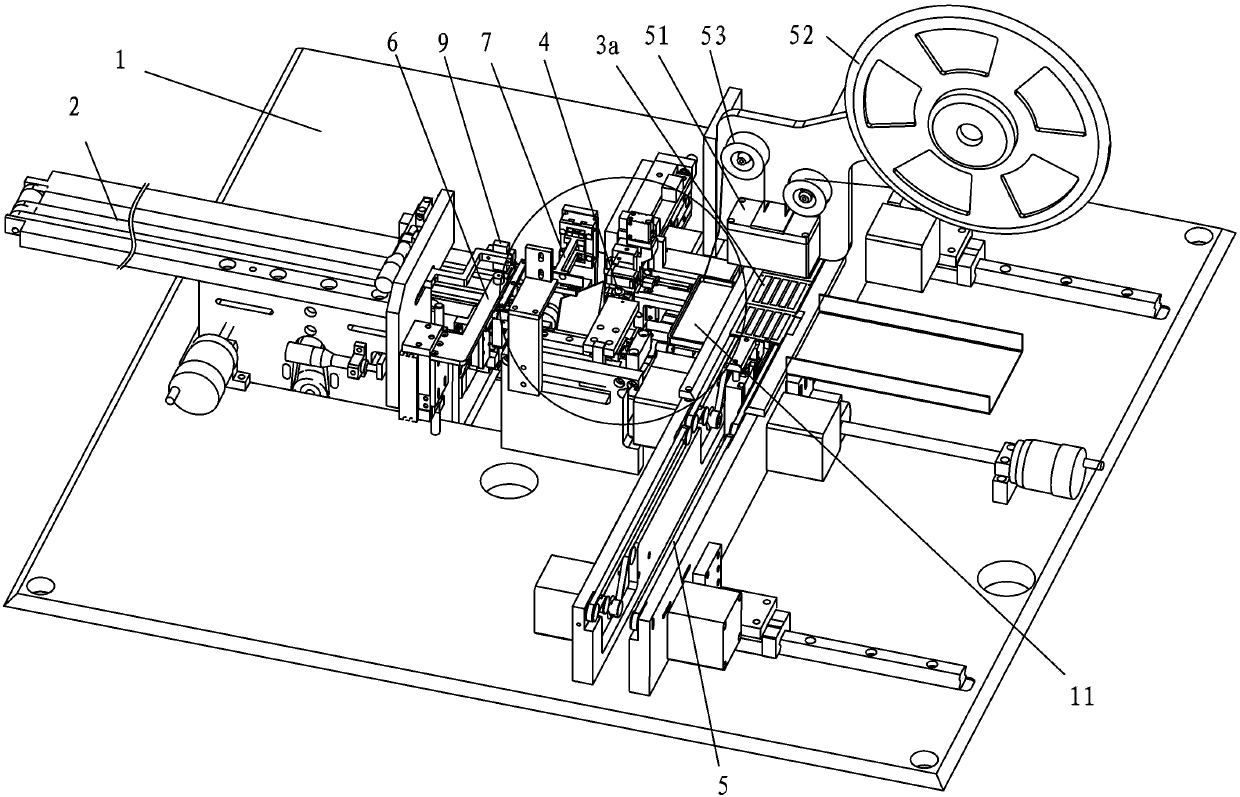

[0049] In this embodiment, the slicing mechanism 3 includes a pair of first presser feet 31, a top plate 32, a presser foot cylinder and a top plate cylinder. A pair of first pressing feet 31 are arranged opposite to each other up and down, and a pair of first pressing feet 31 and a top plate 32 are sequentially arranged at the discharge end of the conveyor belt 2 along the feeding direction. The upper first presser foot 31 is connected to the piston rod of the presser foot cylinder, and the action of clamping and unclamping the solar cell stack sheet 1a is realized through the telescopic action of the piston rod of the presser foot cylinder. The top plate 32 is connected to the piston rod of the top plate cylinder. When the piston rod of the top plate cylinder is extended, the top plate 32 is driven to move upward, and the top plate 32 is pressed against the exposed part of the solar cell panel 1a sandwiched between the pair of first pressers 31 And separate one solar cell she...

Embodiment 2

[0052] In this embodiment, the splitting mechanism 3 includes two pairs of first presser feet and two presser foot cylinders. Each pair of first presser feet is set up and down correspondingly, two pairs of first presser feet are arranged side by side on the discharge end of the conveyor belt 2, two pairs of first presser feet are respectively connected to the piston rod of a presser foot cylinder, two pairs of first presser feet respectively The staggered lifting is realized by the respective presser foot cylinders, as described below.

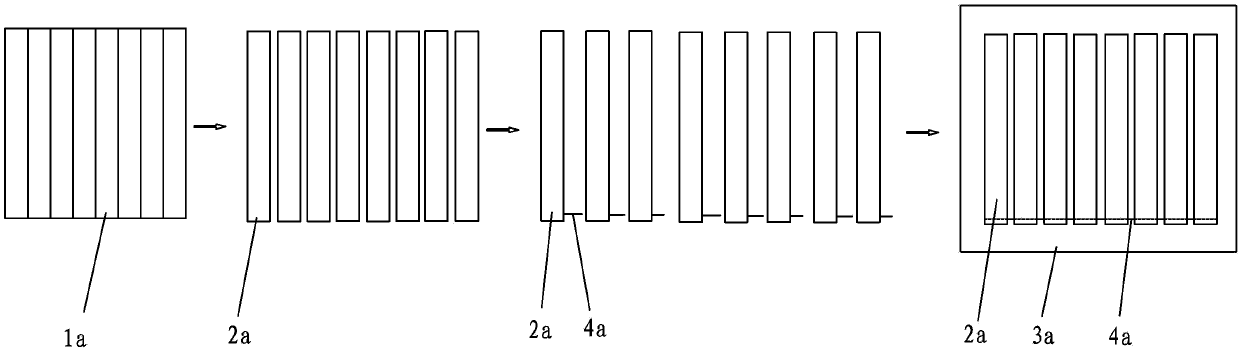

[0053] Firstly, a cut is cut on the front or back of the solar cell assembly sheet 1a, and the solar cell assembly sheet 1a is divided into a plurality of solar cell sheets 2a with a predetermined width. When the solar cell stack sheet 1a enters the two pairs of first presser feet, the two pairs of first presser feet clamp the solar cell sheet 2a by their respective cylinders. One pair of the first presser foot is slightly shifted relative to t...

Embodiment 3

[0055] Compared with the first embodiment, this embodiment also includes an infrared cutting mechanism, which can generate a laser beam. The laser beam emitting end of the infrared cutting mechanism corresponds to the feeding end of a pair of first presser feet 31. The front or back of the battery sheet 1a is cut with a number of cut marks, thereby dividing the solar battery sheet 1a into a plurality of solar battery sheets 2a with a predetermined width. Then, the solar cell assembly sheet 1a is divided into the solar cell sheets 2a along the cut by the dislocation and slicing method in the foregoing embodiments.

[0056] The welding mechanism 4 includes a soldering station 41, a soldering iron 42, a second presser foot, a soldering iron cylinder, and a second presser foot cylinder. The soldering station 41 is fixed on the worktable 1 and is arranged between the output end of the slicing mechanism 3 and the placement output mechanism 8. The second presser foot and the soldering i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com