White-light LED chip and manufacturing method for white-light LED chip

An LED chip and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of easily polluted LED chip electrodes, poor welding of white LED chips, etc., so as to improve luminous efficiency, avoid easy production and processing, and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

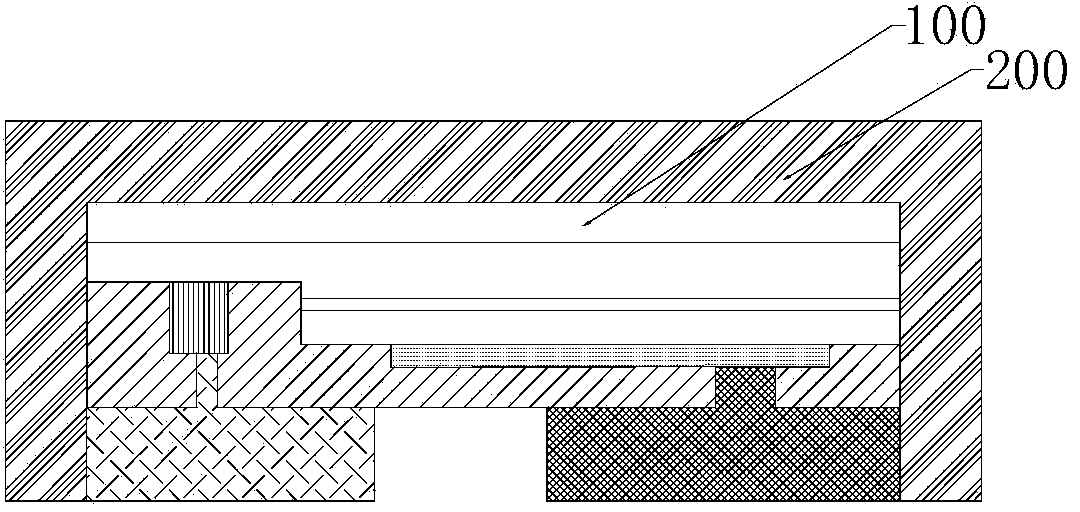

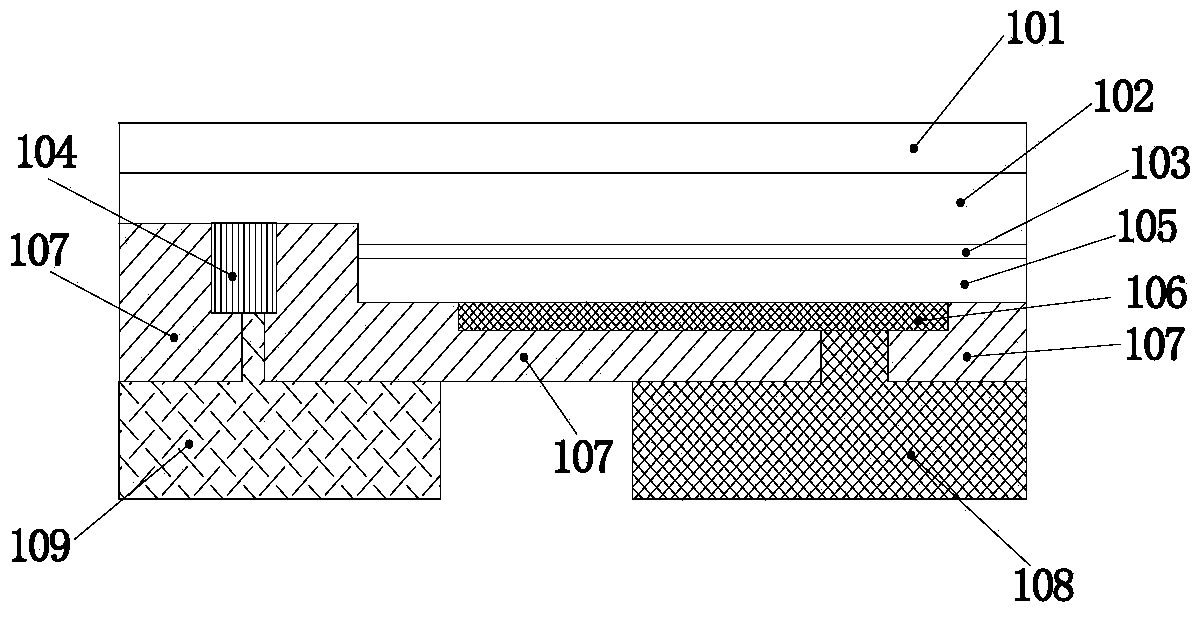

[0058] Such as Figure 1b As shown, the mounted LED chip 100 selected in this embodiment is a flip-chip LED chip, which includes an epitaxial substrate layer 101, an N-type gallium nitride layer 102 grown on the upper surface of the epitaxial substrate layer 101, and an N-type gallium nitride layer 102 grown on the epitaxial substrate layer 101. The light-emitting layer 103 on the upper surface of the N-type gallium nitride layer 102, the N-type ohmic contact layer 104 grown on the upper surface of the N-type gallium nitride layer 102, and the P-type nitrogen grown on the upper surface of the light-emitting layer 103 The gallium nitride layer 105 and the P-type ohmic contact layer 106 grown on the upper surface of the P-type gallium nitride layer 105, the P-type gallium nitride layer 105, the P-type ohmic contact layer 106, and the N-type gallium nitride layer Layer 102 and N-type ohmic contact layer 104 are also provided with an insulating layer 107 on the upper surface of th...

Embodiment 2

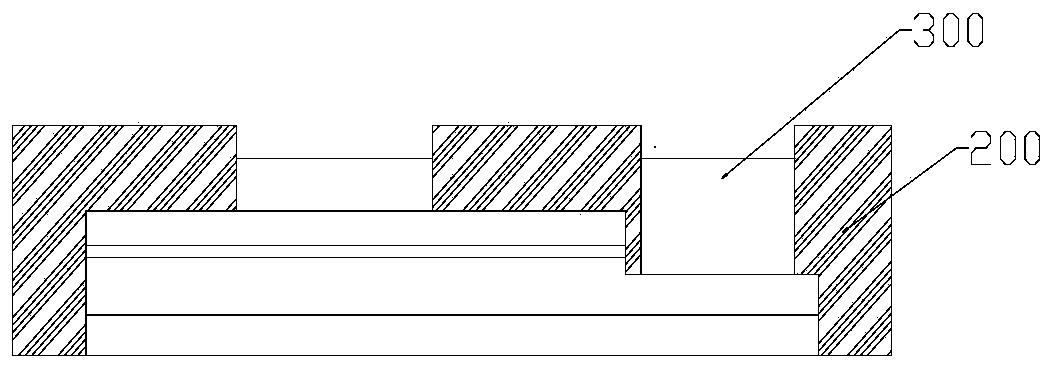

[0070] Such as figure 2 , as shown in Fig. 9, Fig. 10 and Fig. 11, the difference between this embodiment and Embodiment 1 is that the white light LED chip described in this embodiment is a front-mounted LED chip, which includes an epitaxial substrate layer, grown on the epitaxial substrate layer The N-type gallium nitride layer on the upper surface of the bottom layer, the light-emitting layer grown on the upper surface of the N-type gallium nitride layer part, the N-type ohmic contact layer on the upper surface of the N-type gallium nitride layer part, the The P-type gallium nitride layer on the upper surface of the light-emitting layer and the P-type ohmic contact layer on the upper surface of the P-type gallium nitride layer, a transparent conductive layer covering the P-type ohmic contact layer of the first LED chip, and a The insulating layer covers part of the surface of the first transparent conductive layer, and the first and second metal pads are respectively arrang...

Embodiment 3

[0074] Such as image 3 , as shown in Figure 12, Figure 13 and Figure 14, the difference between this embodiment and Embodiment 1 is that the white LED chip is a vertical LED chip, which includes a metal substrate layer, bonded on the metal substrate layer The P-type gallium nitride layer on the upper surface, the light-emitting layer grown on the upper surface of the P-type gallium nitride layer, the N-type gallium nitride layer grown on the upper surface of the light-emitting layer, and the N-type gallium nitride layer grown on the N-type nitrogen An N-type ohmic contact layer on the upper surface of the gallium chloride layer. The N-type ohmic contact layer is provided with a metal pad.

[0075] The difference between the manufacturing method of the white light LED chip of this embodiment and the first embodiment is as follows: a plurality of LED chip mounting cavities with openings are formed by stamping the vertical type LED chips. The opening pattern is used for electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com