Shock absorbing tube and manufacturing method thereof

A manufacturing method and technology for shock absorbers, which are applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of difficult connection of pipe fittings and unsatisfactory welding consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

[0029] For the sake of convenience, the present invention defines the numerical range involved in the description process of the specification: on the one hand, the threshold includes the original number, such as greater than or equal to 2.5 if it is above 2.5, equal to or less than 10 if it is less than 10, and greater than or equal to -8, etc.; on the other hand, the approximate number or approximate number is calculated according to ±10% of the central value, such as about 15 means 15±10%, roughly 3 means 3±10%, equivalent to 6 means 6±10% 10%, roughly 120 means 120±10%, close to 6.2 is 6.2±10%, ..., etc.; and so on, and so on.

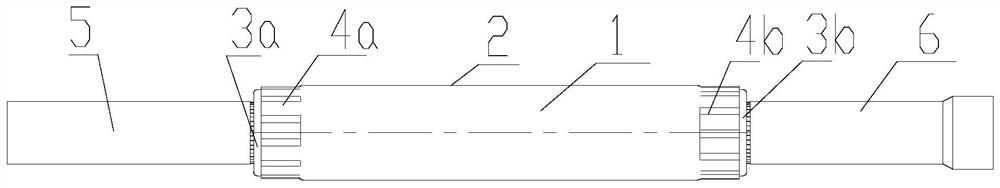

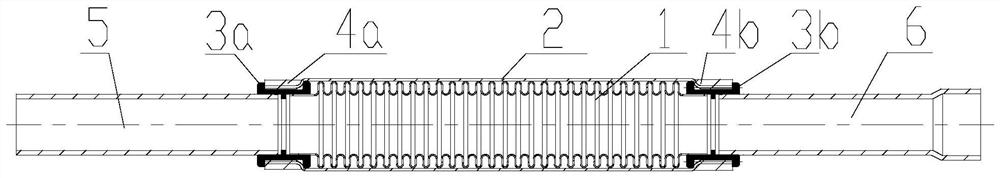

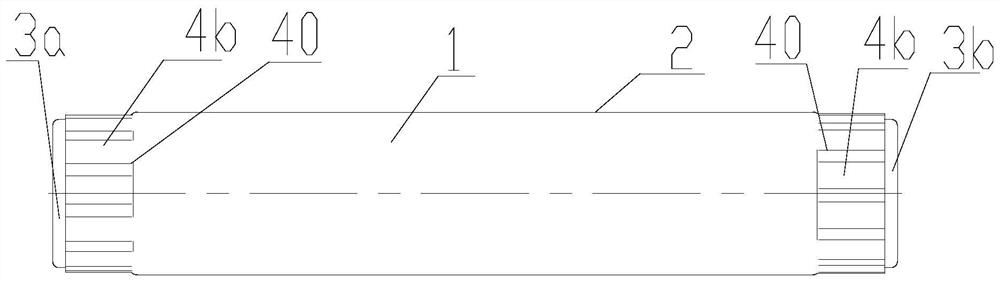

[0030] See also Figure 1 to Figure 16 , which respectively show the structure of the shock absorbing tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com