A manufacturing process of gold-plastic welded steel wire reinforced endotracheal intubation tube

A technology for tracheal intubation and manufacturing process, applied in the field of medical devices, can solve the problems of cumbersome process operation, long processing time period, poor product consistency, etc., and achieve the effects of avoiding peculiar smell and toxicity, fast welding speed and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

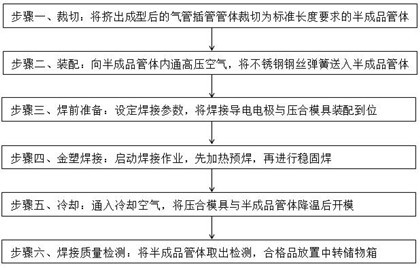

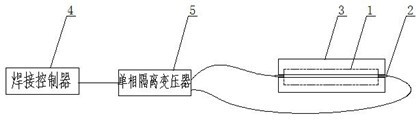

[0029] like figure 1 As shown, a kind of gold-plastic welded steel wire-reinforced tracheal intubation manufacturing process of the present invention, the manufacturing process is as follows:

[0030] Step 1, cutting: cutting the extruded tracheal intubation tube body to a semi-finished tube body of the length required by the standard specification.

[0031] Step 2, assemble the stainless steel wire spring: connect the two ends of the semi-finished pipe body to the inflatable joint, fill the semi-finished pipe body with high-pressure air through the inflatable joint, so that the inner diameter of the semi-finished pipe body expands and increases, and the inflatable joint is removed from the semi-finished pipe body. After the two ends are removed, the stainless steel wire spring is threaded into the inside of the semi-finished pipe body, so that the stainless steel wire spring is in a smooth and natural bounce state, and the stainless steel wire spring is located in the middle ...

Embodiment 2

[0043] like figure 1 and figure 2 As shown, a kind of gold-plastic welded steel wire-reinforced tracheal intubation manufacturing process of the present invention, the manufacturing process is as follows:

[0044] Step 1, cutting: assemble the extruded endotracheal tube body to the automatic feeding mechanism of the automatic cutting machine, set the cutting parameters and start the cutting machine, and cut the tube body to the length required by the standard specification For the semi-finished pipe body, the cutting parameters are set as follows: the cutting length is 36CM, and the cutting speed is 1m / s.

[0045] Step 2: Assemble the stainless steel wire spring: Connect the two ends of the semi-finished pipe body to the inflatable joint, fill the semi-finished pipe body with high-pressure air with a pressure of 0.4-0.6 MPa through the inflatable joint, and keep the pressure for 1 second, so that the semi-finished pipe body The inner diameter of the semi-finished pipe expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com