Elastic press-holding mechanism

A pressing mechanism and elastic technology, applied in the field of solar cell module production equipment, can solve the problems affecting the consistency of the battery string production process, changes in the force of the cells, hidden cracks or slivers, etc., to achieve simple structure and high working stability , good welding consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

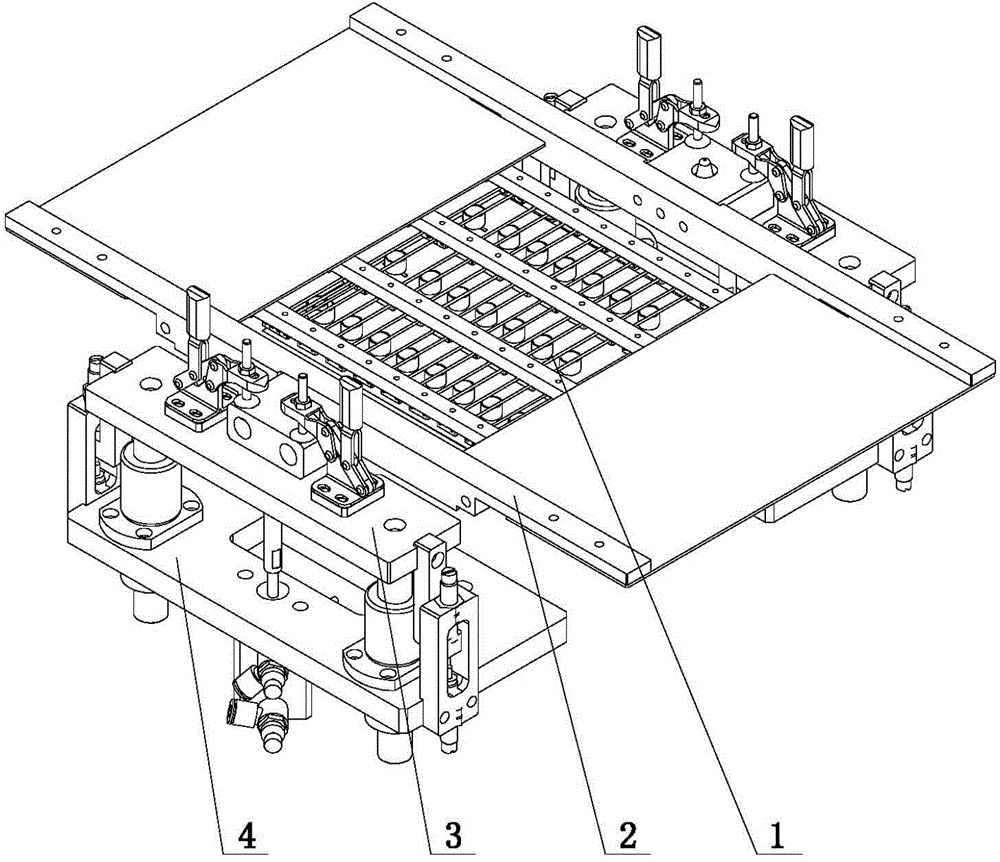

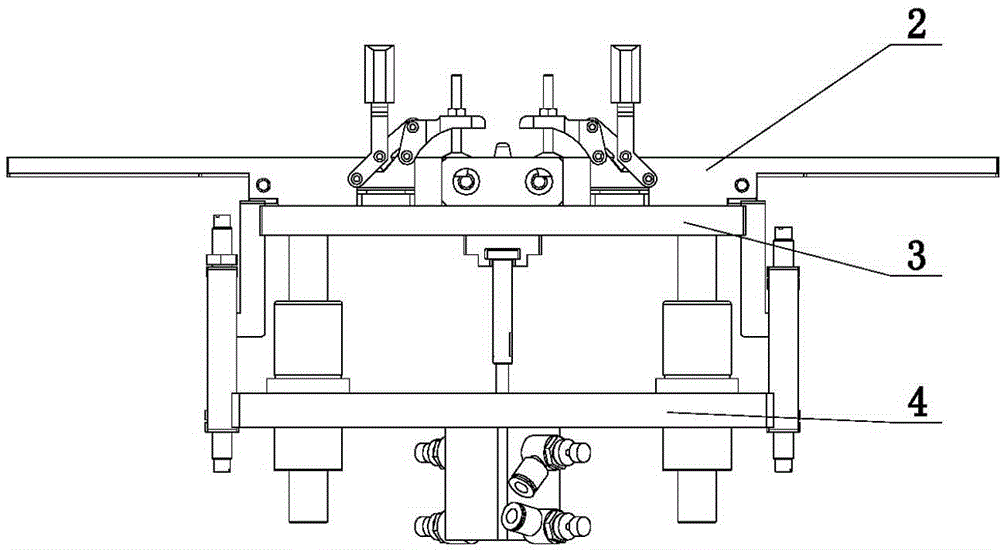

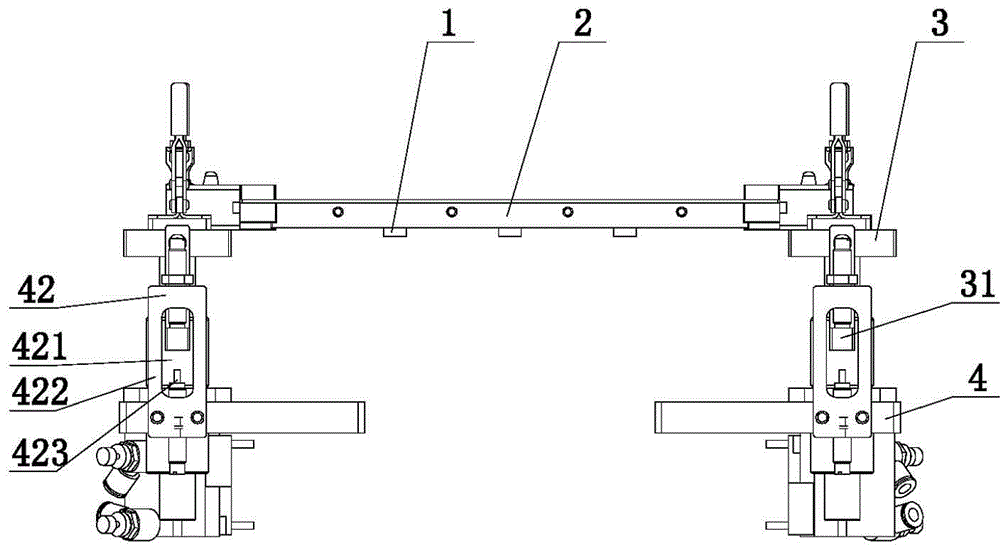

[0022] The present invention includes a mounting bracket 2 with an elastic pressing needle 1, and is characterized in that: both ends of the mounting bracket 2 are provided with lifting seats 3;

[0023] The elastic indenter 1 includes two parallel rod-shaped indenter frames 11 , and a cylindrical compression spring 12 is arranged under the rod-shaped indenter frames 11 ; both ends of the indenter frames 11 are connected with the mounting bracket 2 .

[0024] Described mounting bracket 2 comprises two parallel transverse connection plates 21, and transverse connection plate 21 links to each other with described elevating base 3; Two parallel longitudinal installation plates 22 are arranged between two transverse connection plates 21; Two longitudinal installation plates 22 and two A plurality of transverse installation plates 23 parallel to each other are arranged in the area enclosed by the transverse connection plates 21 ; a plurality of elastic pressing pins 1 are arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com