Ultrasonic rolling welding device based on full-wave welding head

A welding device and ultrasonic technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult control of the end of the welding head, poor welding, poor welding stability, etc., and achieve easy control of coaxiality and Circular beating, good welding consistency, and good rigidity of the welding head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

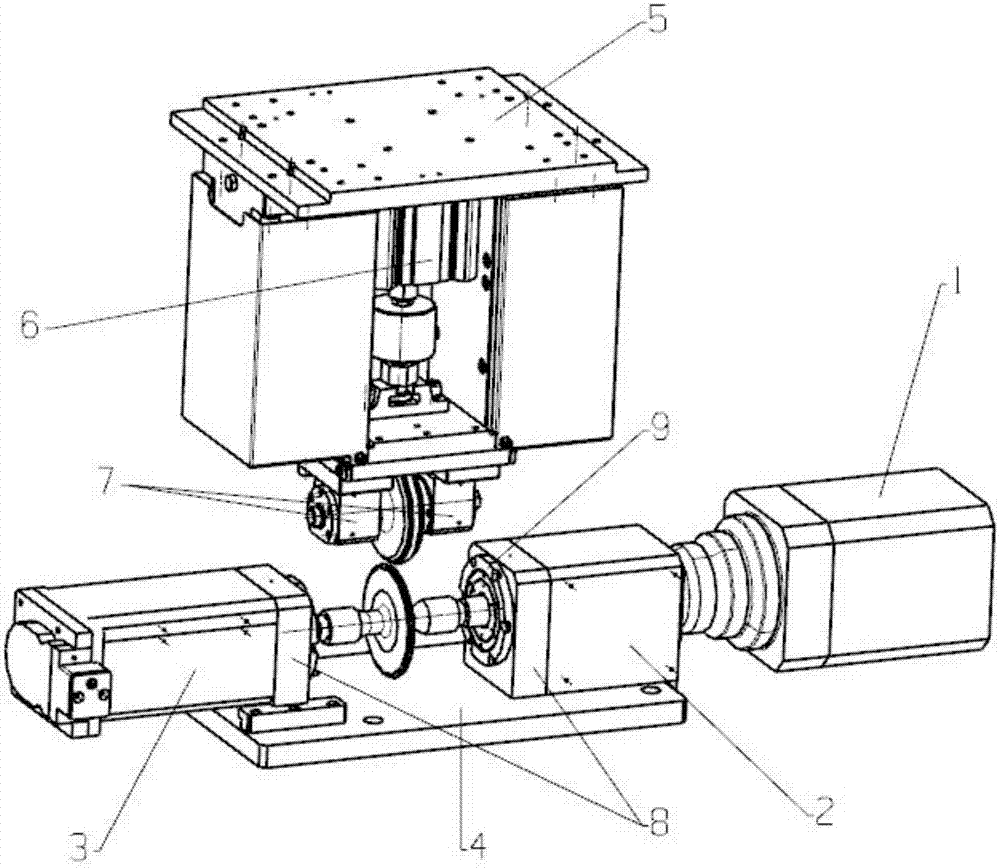

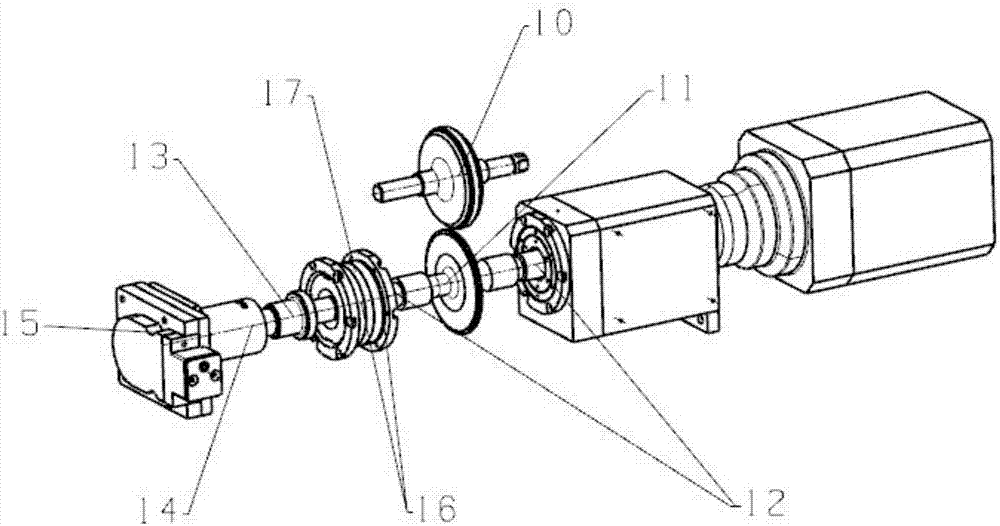

[0015] Such as figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: an ultrasonic rolling welding device based on a full-wave welding head, including a motor 1, a motor side cover 2, a transducer side cover 3, a mounting base plate 4, and a cylinder mounting base plate 5. Cylinder 6, welding seat support seat 7, bearing seat 8, flange 9, welding seat 10, welding head 11, support modulator 12, coefficient amplification modulator 13, transducer 14, conductive brush device 15, rolling bearing 16 and a fixed ring 17; there are two bearing seats 8, and the bearing seats 8 are respectively fixedly connected to the left and right sides of the upper surface of the installation base plate 4; there are two supporting amplitude modulators 12, and the supporting amplitude modulating The device 12 is locked in the installation shaft and the rolling bearing 16 on the bearing seat 8 through the flange 9; the flange 9 is used to lock the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com