Non-standard bent pipe and flange welding positioning tool

A flange welding and positioning tooling technology, applied in the field of tooling fixtures, can solve the problems of low precision, poor consistency between flanges and elbows, and affect quality, and achieve the effects of high welding quality, good welding consistency, and high-precision positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

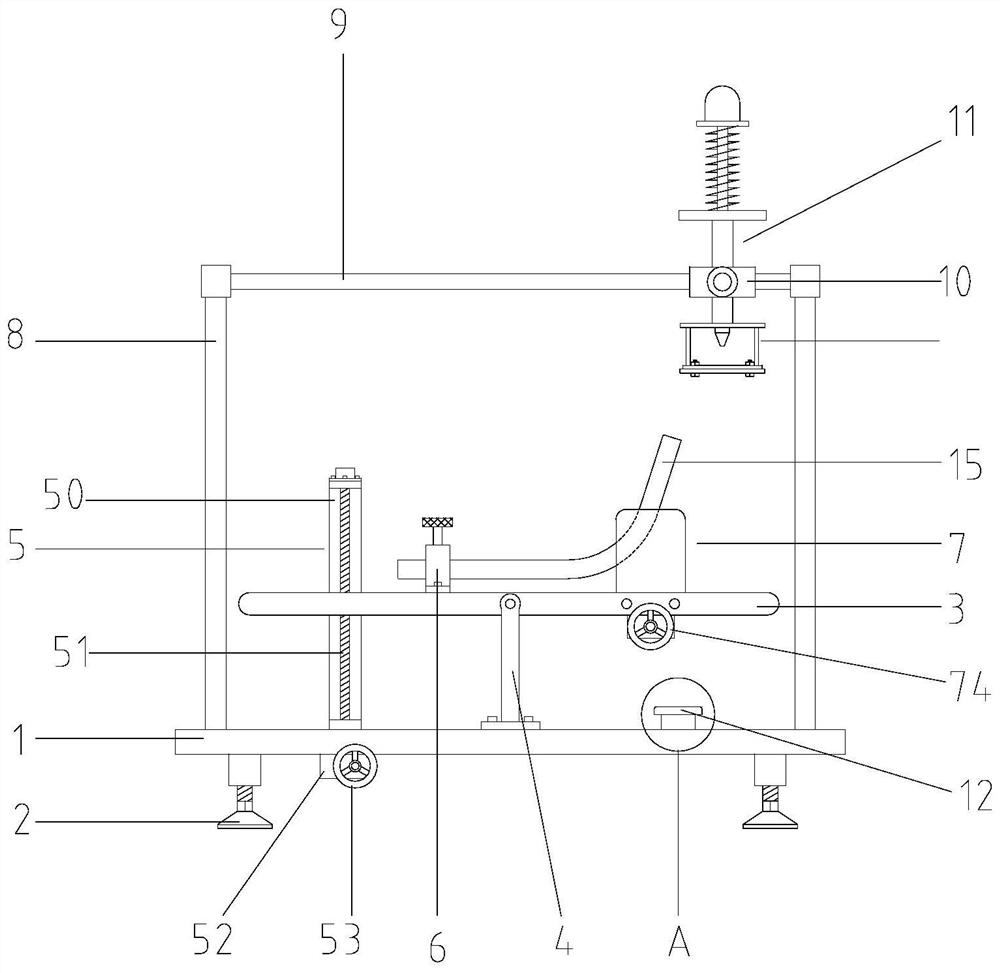

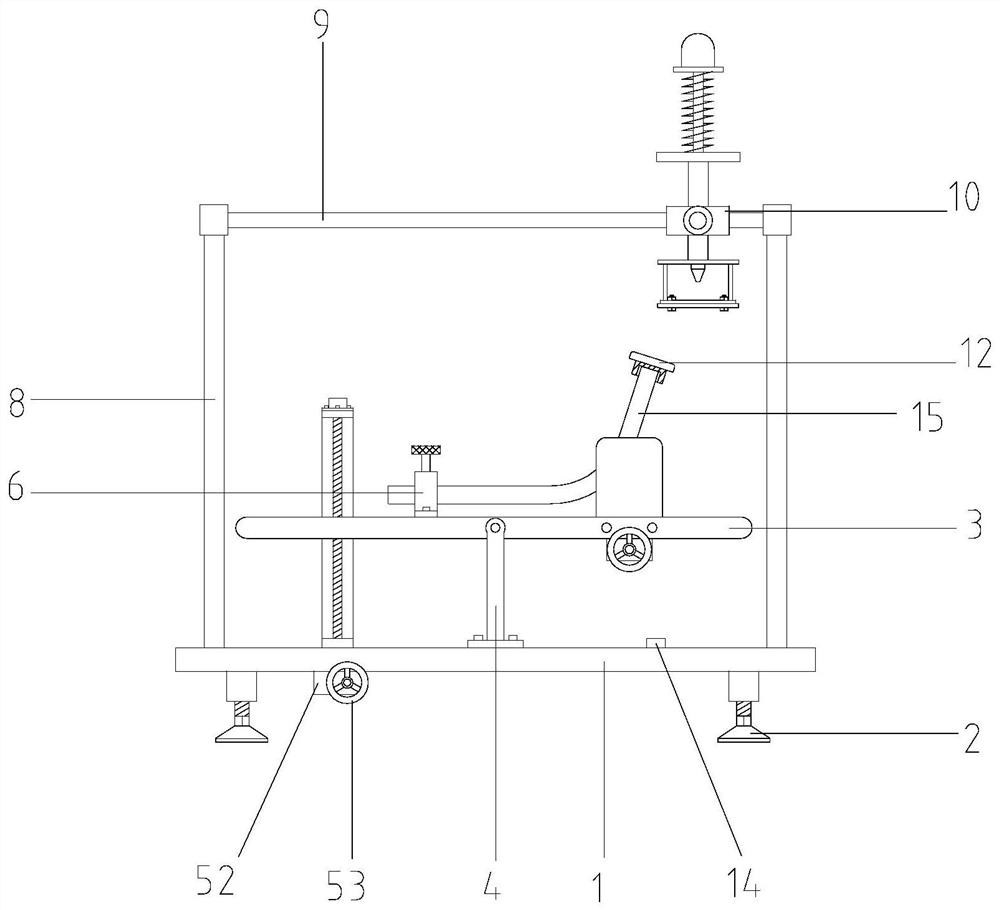

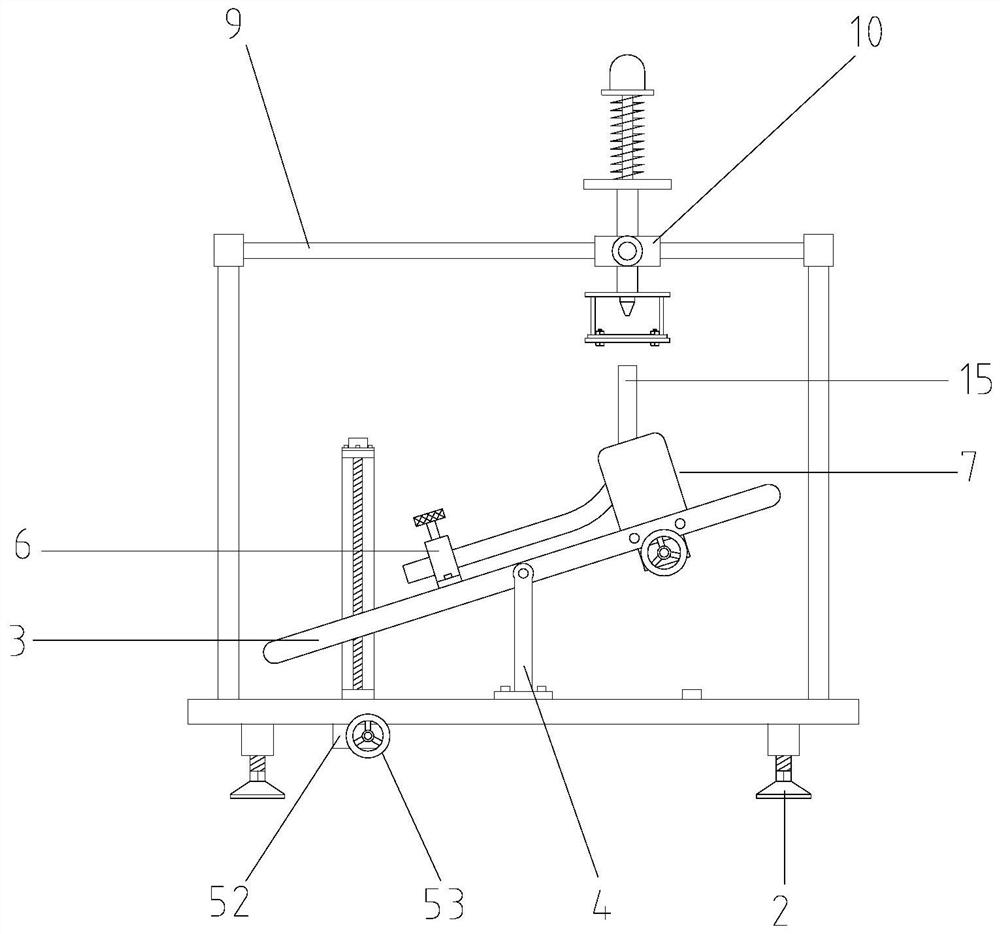

[0028] Such as figure 1 , figure 2 , image 3 , Figure 5 with Image 6The shown non-standard elbow flange welding positioning tool includes a bottom plate 1, three height-adjustable support feet 2 are provided at the bottom of the bottom plate 1, and elbow positioning plates 3 distributed in parallel are arranged above the top surface of the bottom plate 1 The two sides in the middle of the elbow positioning plate 3 are provided with support columns 4, the lower end of the support column 4 is fixedly connected with the base plate, the upper end of the support column 4 is rotationally connected with the elbow positioning plate 3, and the left end of the elbow positioning plate 3 is connected with the base plate. There is an angle adjustment mechanism 5 for adjusting the angle of the elbow positioning plate, and the elbow positioning plate 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com