NTC temperature sensor insert production device and method

A temperature sensor and production device technology, applied in thermometers, measuring devices, electrical devices, etc., can solve the problems of unguaranteed welding quality, low product qualification rate, slow manual welding speed, etc., and achieve tight and controllable welding process. , The welding speed is fast, and the effect of reducing labor occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

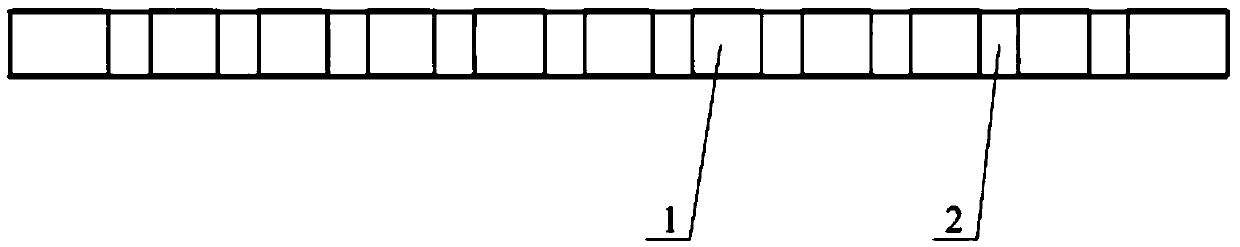

[0019] The NTC temperature sensor insert production device of the present invention includes a fixing plate 1 , a wire core positioning jig 3 and a wire core shaping jig 5 . Such as figure 1 As shown, the fixed plate 1 has a rectangular parallelepiped structure. The fixed plate 1 is provided with a plurality of vertical wire slots 2 at intervals along its length direction, and the wire slots 2 are used to place the wires 7 of the temperature sensor.

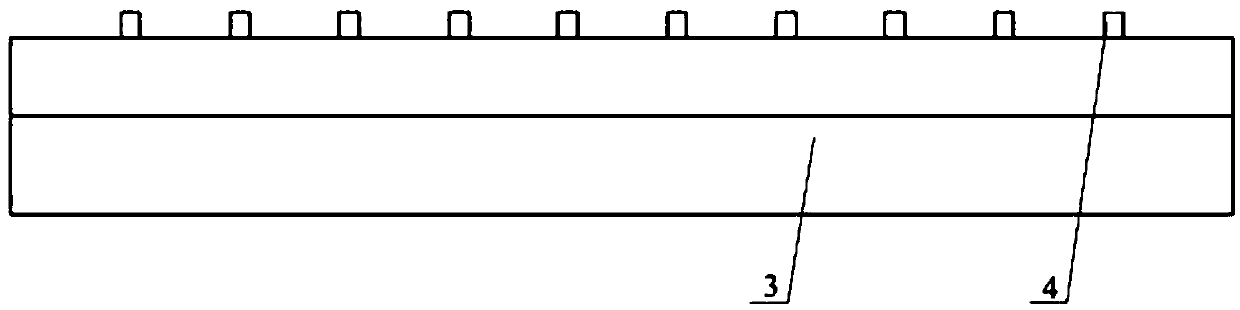

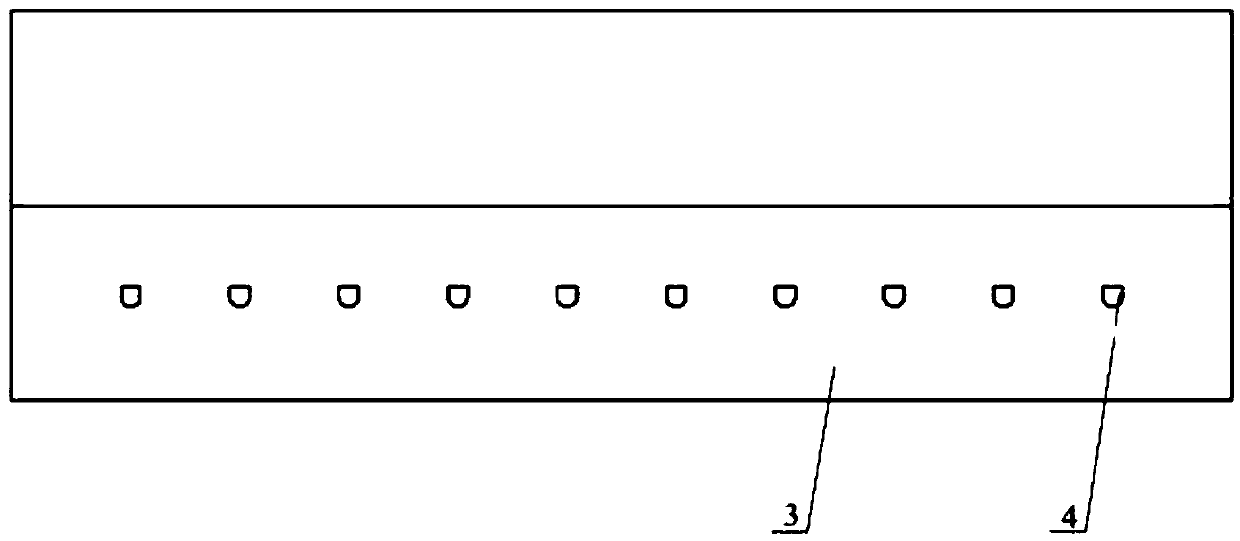

[0020] Such as figure 2 and 3 As shown, the wire core positioning jig 3 is mainly used in conjunction with the fixing plate 1 . The wire rod and core positioning jig 3 has a rectangular parallelepiped or cube structure, and the top surface of the wire rod and core positioning jig 3 is provided with bosses 4 that are consistent with the number of slots 6 on the fixing plate 1, and the distance between adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com