Welding method

A welding method and welding gun technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the efficiency of work, such as excellent products, unstable materials in the fixture, and affecting the welding effect, so as to achieve low production cost , Improve the pressing effect and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

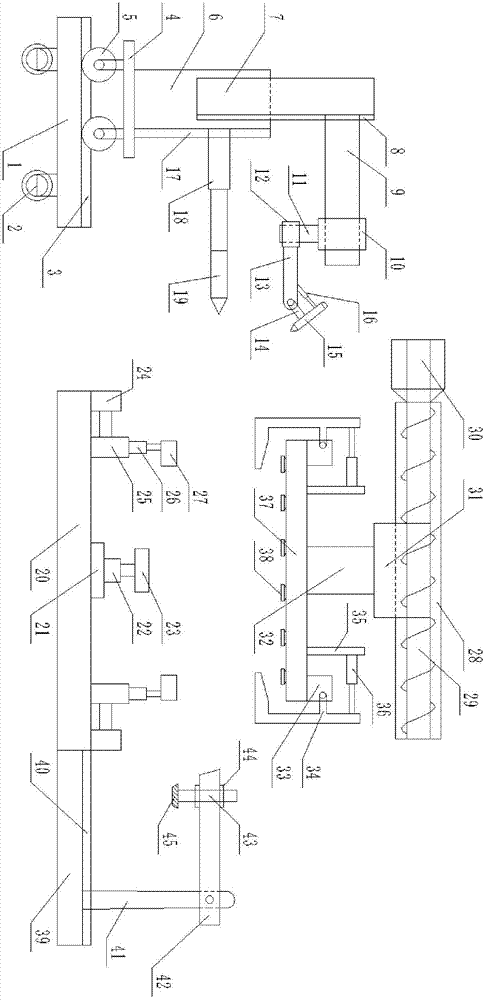

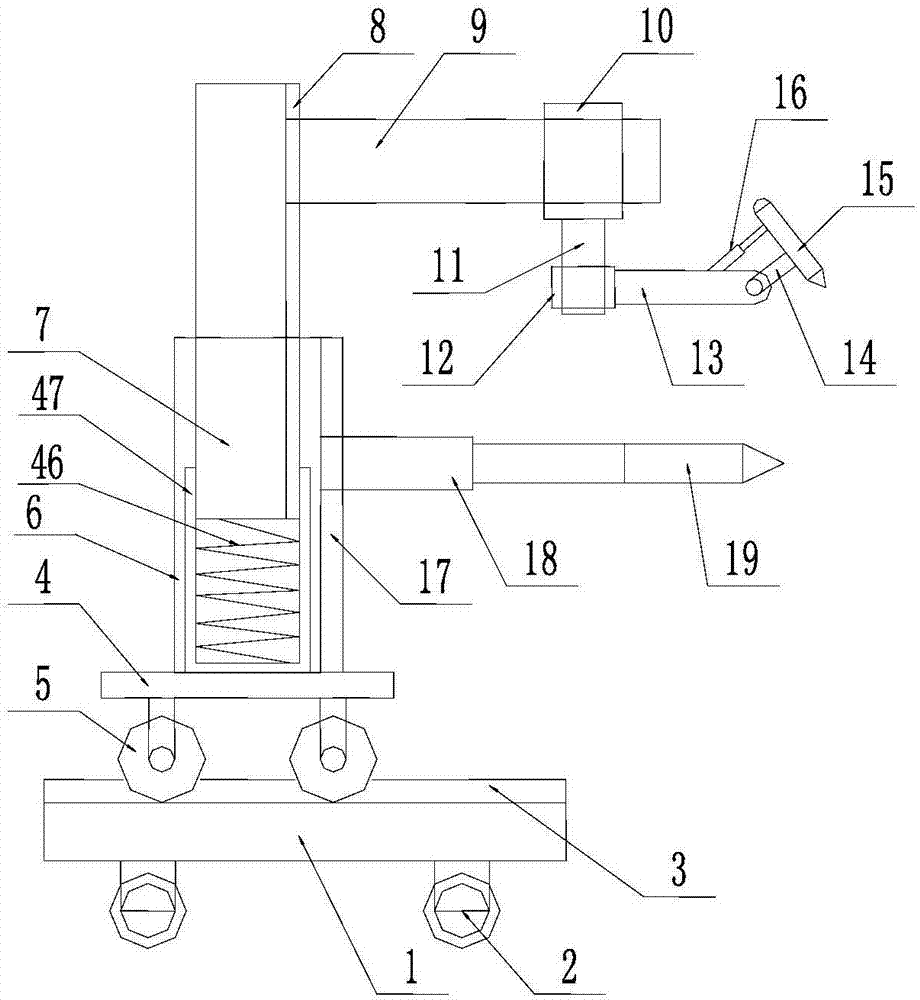

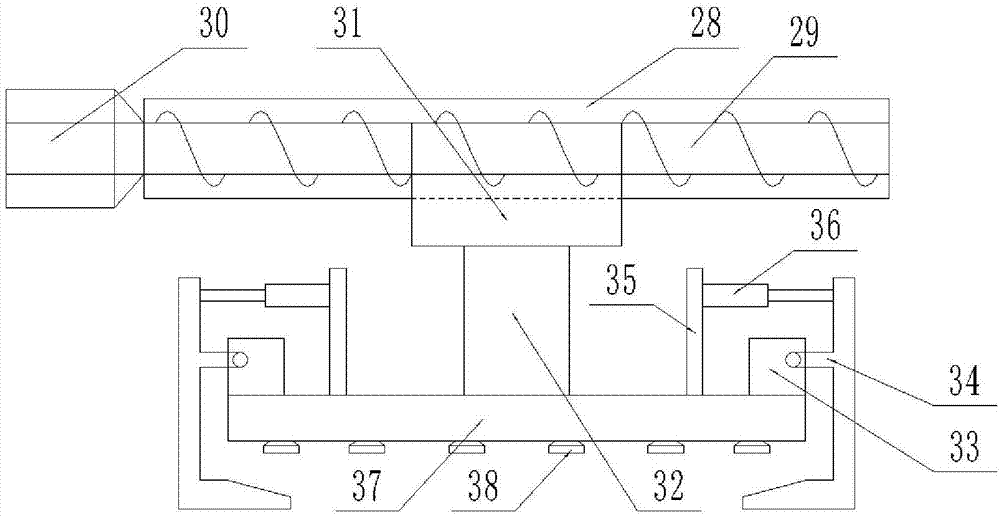

[0018] Such as figure 1 with figure 2 As shown, this specific embodiment adopts the following technical solutions: a welding device for automobile processing and manufacturing, including a base 1, a universal wheel 2, a chute 3, a fixed seat 4, a pulley 5, an outer tube 6, an inner tube 7, a second A slide rail 8, a first crossbeam 9, a first jacket 10, a connecting rod 11, a second outer tube 12, a second crossbeam 13, a rotating shaft 14, a main welding gun 15, an air pressure rod 16, a second slide rail 17, a third Beam 18 and auxiliary welding torch 19; The lower surface of described base 1 is provided with several universal wheels 2, and universal wheel 2 has locking structure, and this locking structure is used for locking the position of universal wheel 2; The surface is fixedly connected with a chute 3; the lower surface of the fixed seat 4 is provided with several pulleys 5, and the pulley 5 is in clearance fit with the chute 3; the pulley 5 is arranged on the chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com