Automobile clamp stable in material clamping

一种稳定、汽车的技术,应用在制造工具、辅助装置、辅助焊接设备等方向,能够解决影响工作的效率产品优良、夹具夹不稳材料、影响焊接的效果等问题,达到生产成本低、提高压紧效果、安装方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

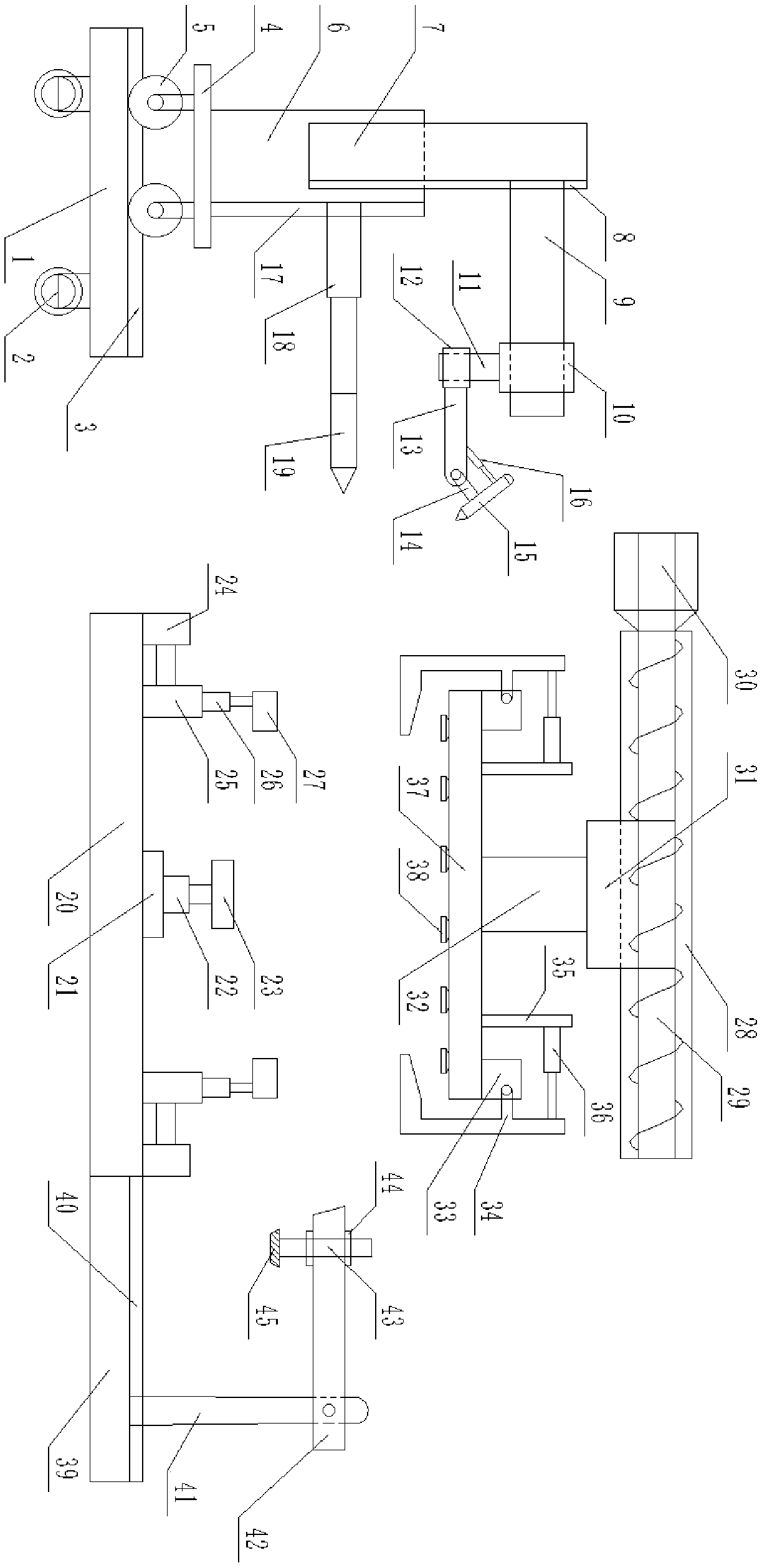

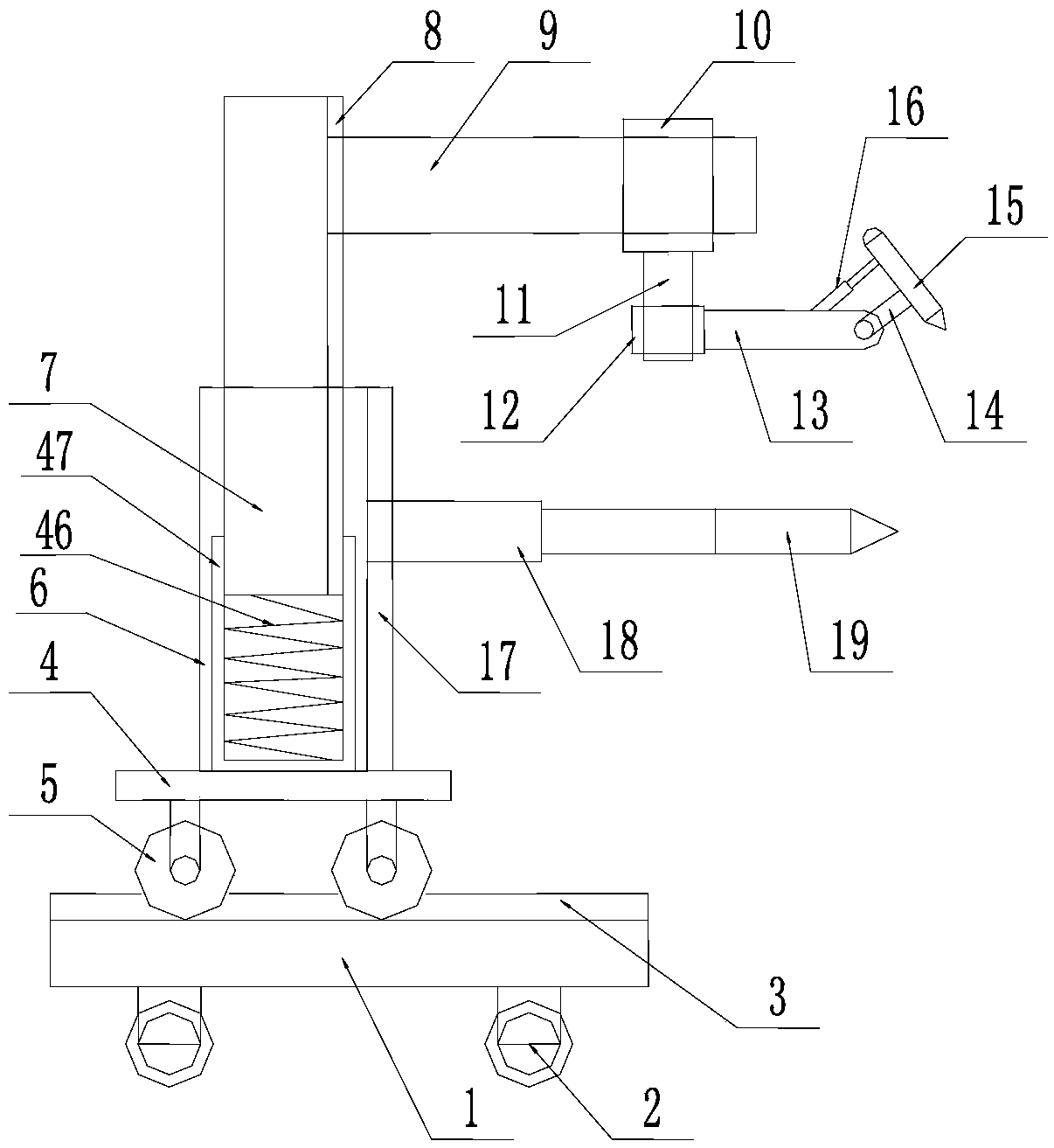

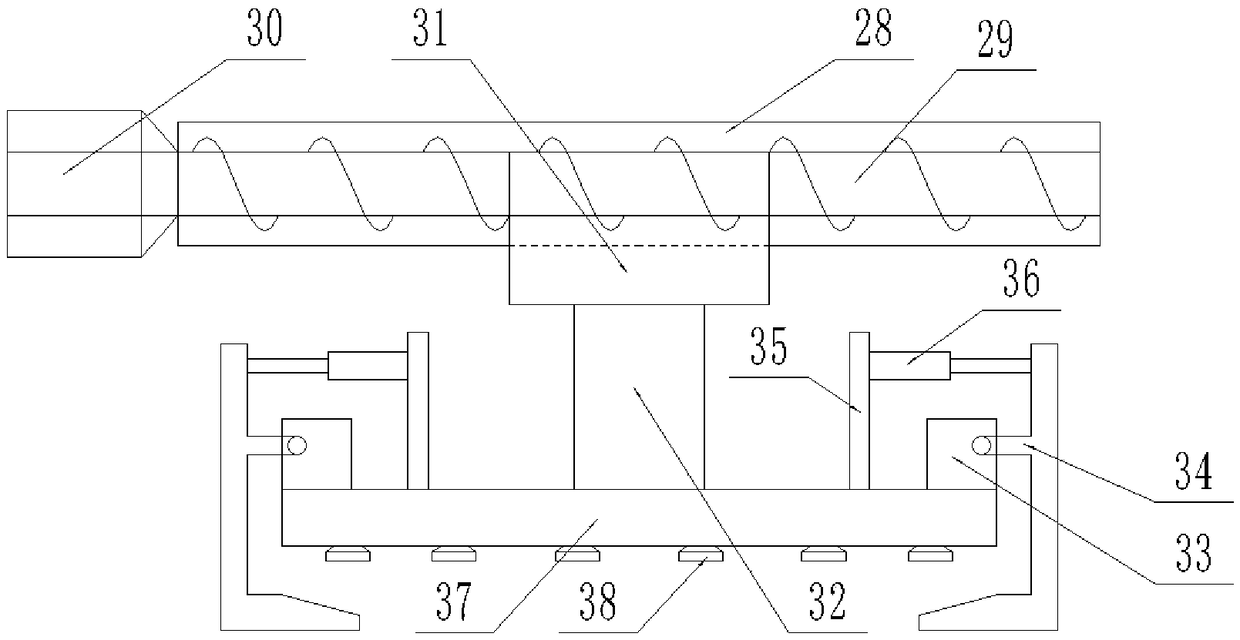

[0017] Such as figure 1 and figure 2 As shown, this specific embodiment adopts the following technical scheme: a kind of automobile clamp with stable material clamping, including base 1, universal wheel 2, chute 3, fixed seat 4, pulley 5, outer tube 6, inner tube 7, the first A slide rail 8, a first crossbeam 9, a first jacket 10, a connecting rod 11, a second outer tube 12, a second crossbeam 13, a rotating shaft 14, a main welding gun 15, an air pressure rod 16, a second slide rail 17, a third Beam 18 and auxiliary welding torch 19; The lower surface of described base 1 is provided with several universal wheels 2, and universal wheel 2 has locking structure, and this locking structure is used for locking the position of universal wheel 2; The surface is fixedly connected with a chute 3; the lower surface of the fixed seat 4 is provided with several pulleys 5, and the pulley 5 is in clearance fit with the chute 3; the pulley 5 is arranged on the chute 3; the upper surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com