Vibration tool cutting mechanism and cutting machine

A technology of cutting mechanism and vibrating knife, which is applied in textiles and papermaking, metal processing, and cutting of textile materials, etc. It can solve the problems of cutting accuracy and quality not meeting the requirements, clothing fabric wrinkles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

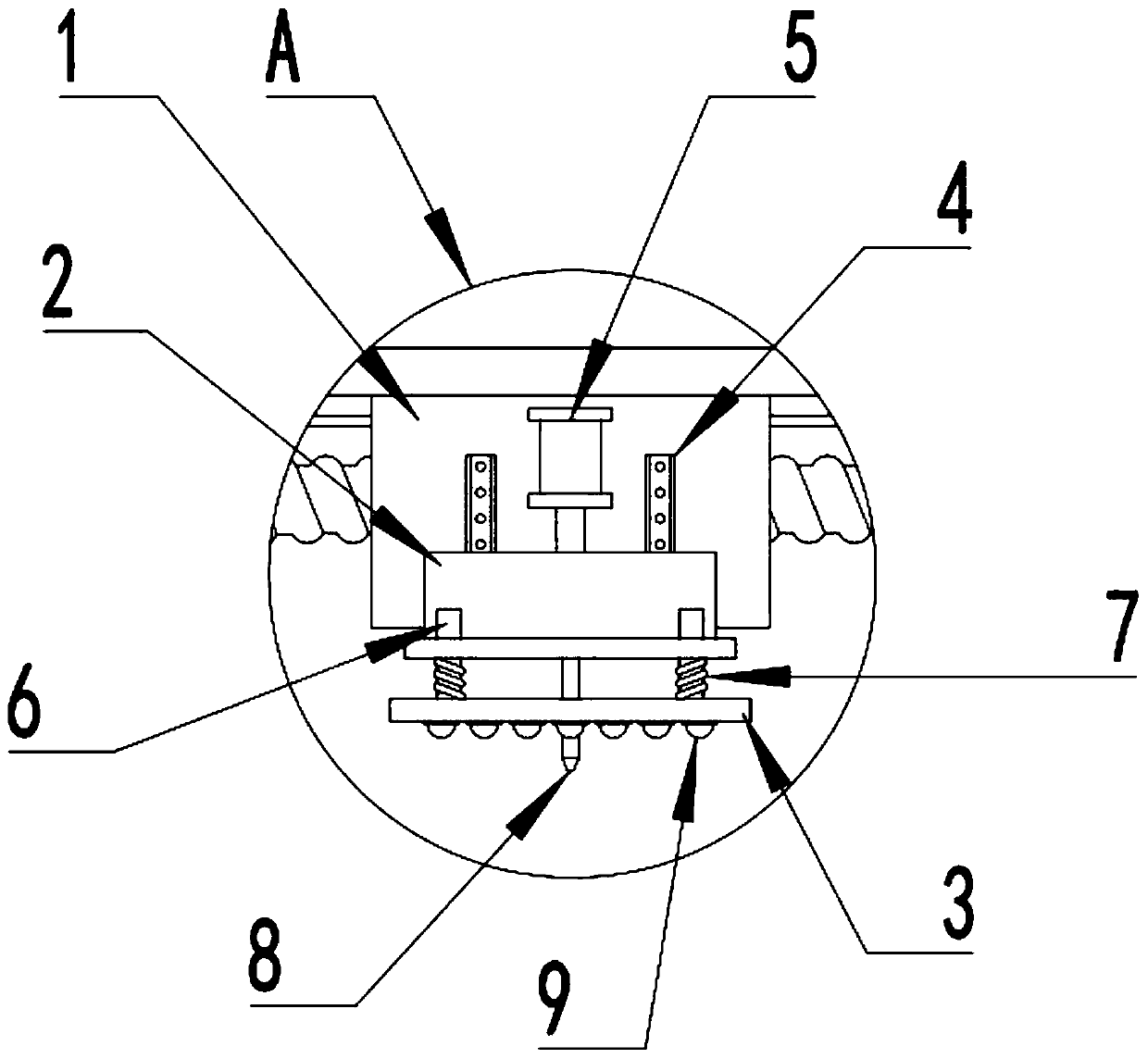

[0022] see figure 1 , in an embodiment of the present invention, a vibrating knife cutting mechanism includes a moving seat 1, a vibrating knife seat 2, an electric push rod 5 and a vibrating knife head 8, and the vibrating knife seat 2 slidingly matched with it is installed on the moving seat 1 A vibrating knife head 8 is installed on the vibrating knife seat 2, and an electric push rod 5 for driving the vibrating knife seat 2 to move is also installed on the moving seat 1. The bottom of the vibrating knife seat 2 is elastically connected with a pressure plate 3. Specifically, The pressing plate 3 is directly below the vibrating knife seat 2, and several connecting shafts 6 are fixed on the pressing plate 3, each of the connecting shafts 6 passes through the steps on the outside of the vibrating knife seat 2 and is slidably matched with the vibrating knife seat 2 , the outer sleeve of the connecting shaft 6 is provided with a spring 7, and the two ends of the spring 7 are res...

Embodiment 2

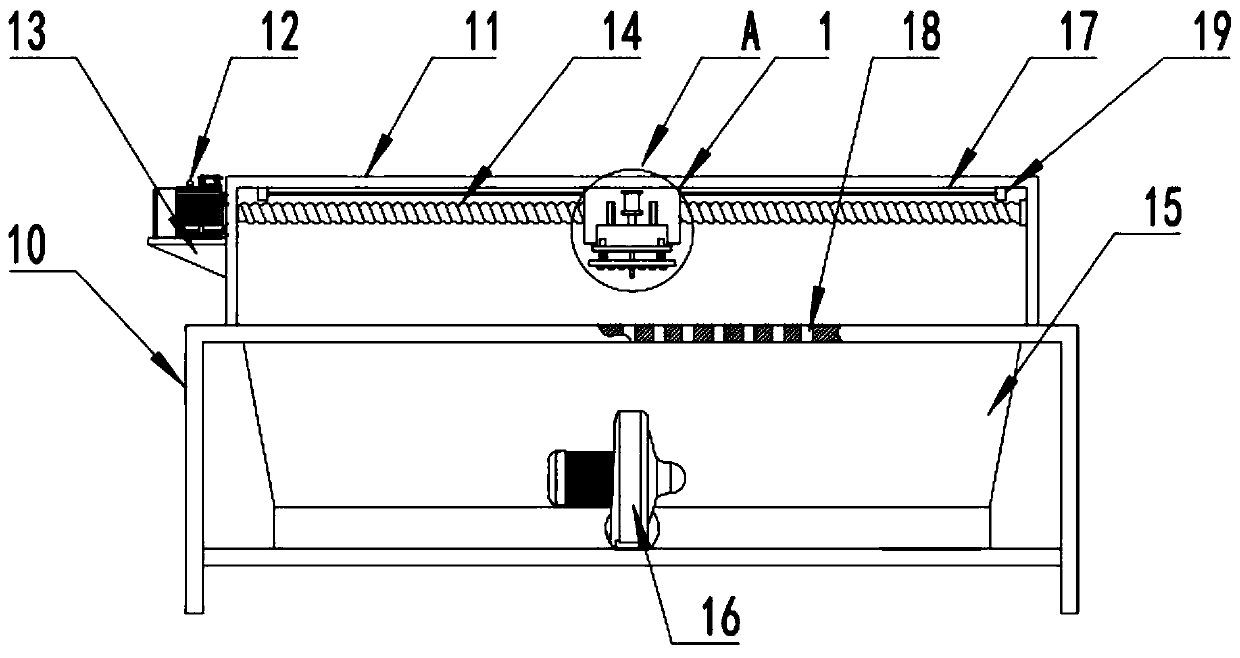

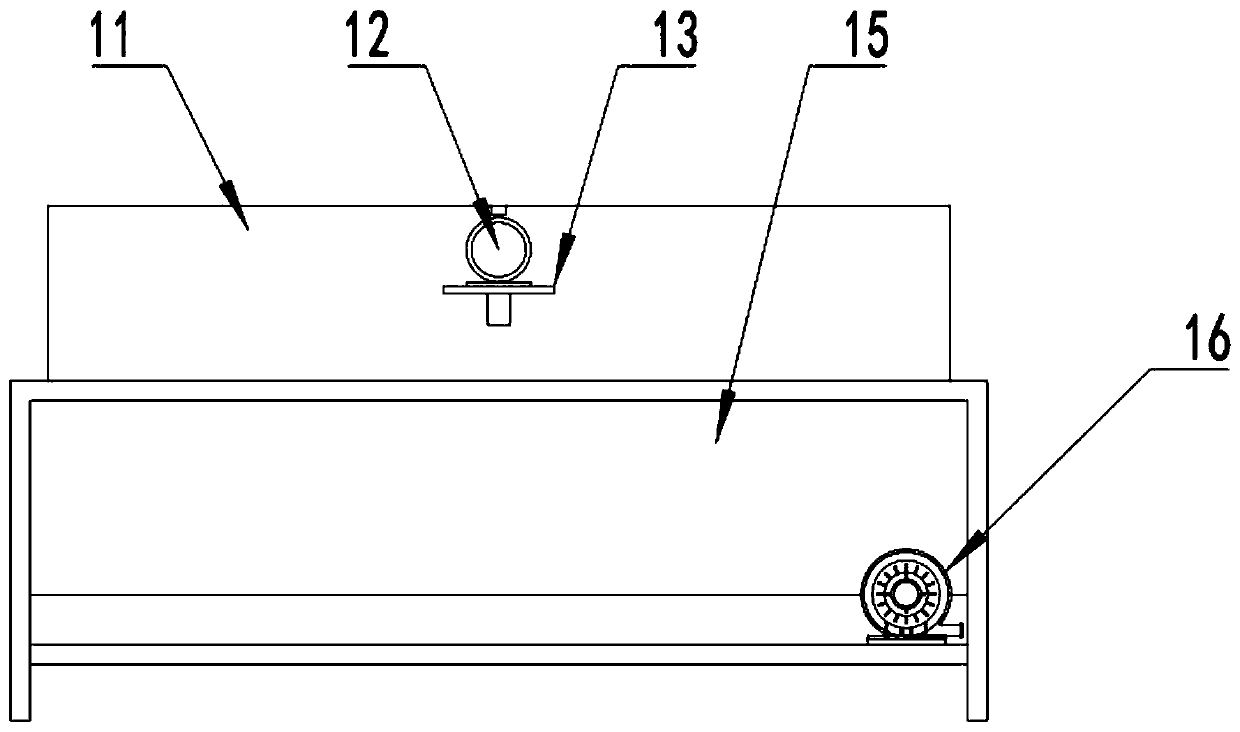

[0026] see Figure 2~3 , In the embodiment of the present invention, a cutting machine is also proposed, including the bottom bracket 10, and also includes the vibrating knife cutting mechanism as described in the above embodiment.

[0027] A mounting bracket 11 is fixed on the bottom bracket 10, a servo motor 12 is installed on the mounting bracket 11 through a motor mounting seat 13, a ball screw 14 is installed on the output end of the servo motor 12, and the moving seat 1 and the ball screw 14 form a spiral Auxiliary transmission, the moving base 1 is also slidingly matched with the slide rail 17 arranged on the mounting bracket 11; of course, in order to limit the stroke of the moving base 1, travel switches 19 are installed at both ends of the sliding base 17. In practical application, the moving base 1 can be subjected to the action of the servo mechanism formed by the servo motor 12 and the ball screw 14 to perform reciprocating motion to realize the adjustment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com