Waterproof and seepage-proofing coiled material paving equipment

A technology for waterproofing membranes and membranes, which is applied in the directions of roofs, roads, buildings, etc., can solve the problems of threatening the operation safety of construction workers, low efficiency of manual laying, and unsatisfactory waterproofing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

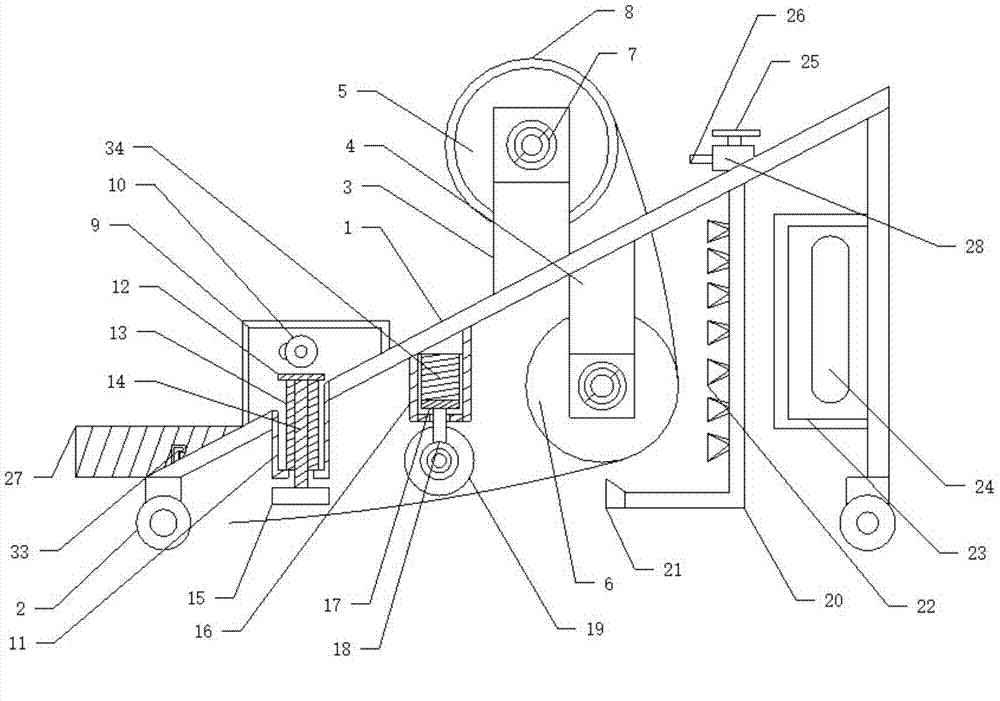

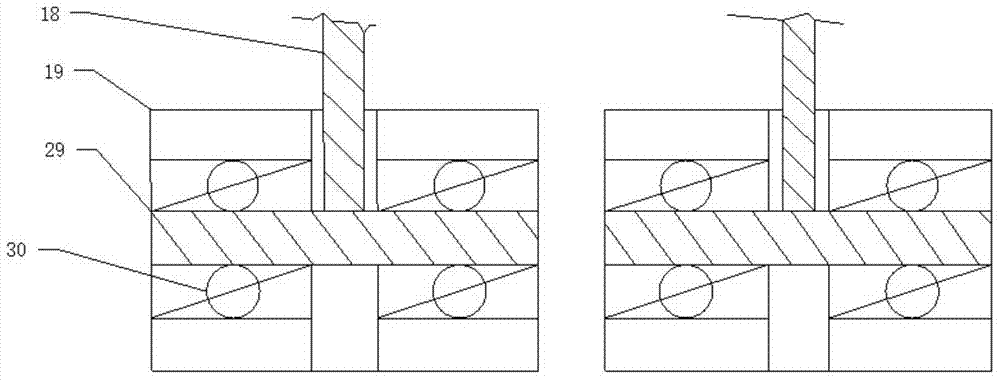

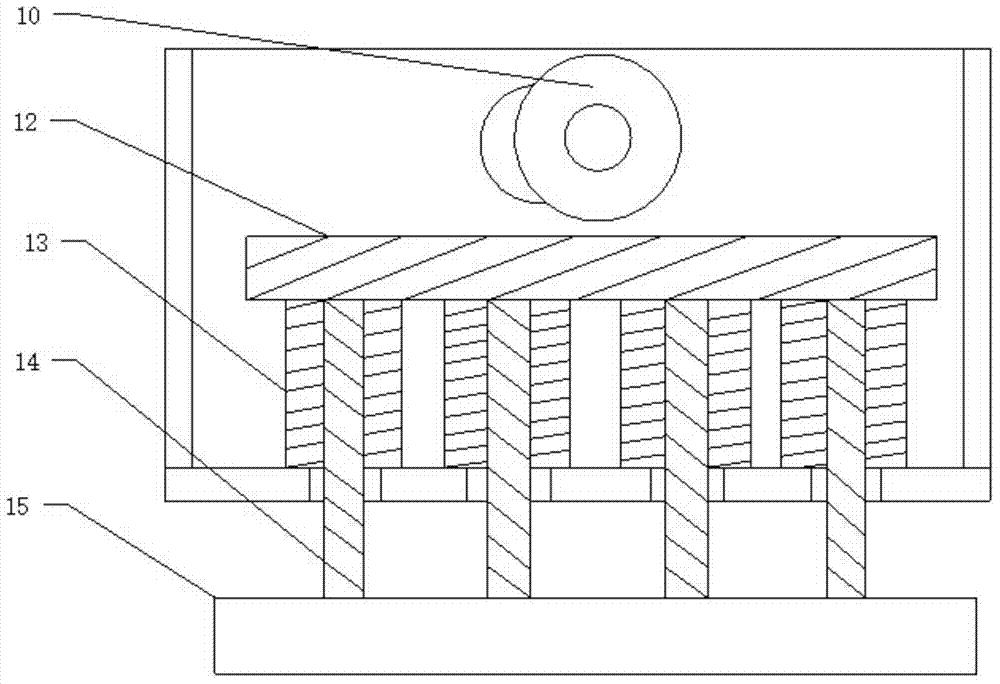

[0030] Such as Figure 1 to Figure 4As shown, a waterproof and anti-seepage coiled material laying equipment includes an organic body 1 and rollers 2 arranged at the four corners of the body 1, and also includes upper brackets 3 arranged on both sides of the body 1 and arranged on both sides of the body 1 and The lower bracket 4 corresponding to the upper bracket 3 is provided with a coil roller 5 on the upper bracket 3 on the two sides, and the coil roller 5 can rotate around the first bearing 7, and the lower bracket 4 on both sides A guide wheel 6 is provided, and the body 1 also includes two pressure wheel grooves 16, the second spring 34 and the pressure wheel pressure plate 17 elastically pressed by the second spring 34 are respectively arranged in the pressure wheel groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com