A prepreg tape automatic laying device

A prepreg tape, laying technology, applied in the direction of final product manufacturing, manufacturing tools, laser welding equipment, etc., can solve the problems of low laying efficiency, adhesion and pulling on the surface of the anvil knife and the tape, and can only be layered layer by layer. , to achieve the effect of ensuring the laying effect, saving laying time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

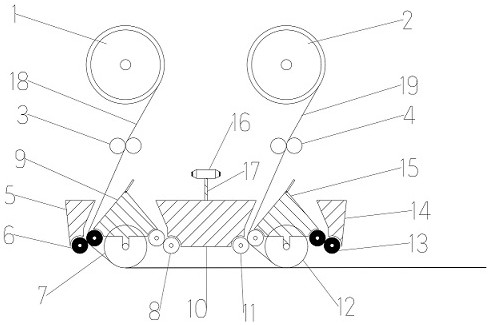

[0031] As shown in the figure: an automatic prepreg tape laying device, including a feeding mechanism, a laying mechanism, a cutting mechanism, a guiding mechanism and a reversing mechanism, and the cutting mechanism is arranged in the horizontal direction. Between the reversing mechanisms, the reversing mechanism is located directly below the feeding mechanism, wherein:

[0032] The feeding mechanism includes a left tape roll 1, a right tape roll 2, a first pair of nip rolls 3, a second pair of nip rolls 4, a first prepreg tape 18 and a second prepreg tape 19. The first The prepreg tape 18 is sleeved on the left tape roll 1 , the first pair of clamping rollers 3 are two clamping rollers arranged symmetrically on the left and right, and the first pair of clamping rollers 3 are located on the left tape roll 1 . Below, the second prepreg tape 19 is sleeved on the right tape roll 2, the second pair of clamping rollers 4 are two clamping rollers arranged symmetrically on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com