An automatic laying method

An automatic and laying technology, applied in the direction of climate sustainability, final product manufacturing, weight reduction, etc., can solve the problems of layer-by-layer stacking, low laying efficiency, adhesion and pulling of the anvil knife and the surface of the tape, etc. Achieve the effects of improving production efficiency, ensuring laying effect, and saving laying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

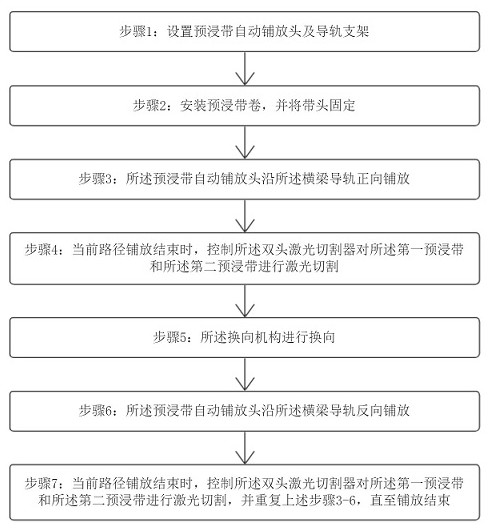

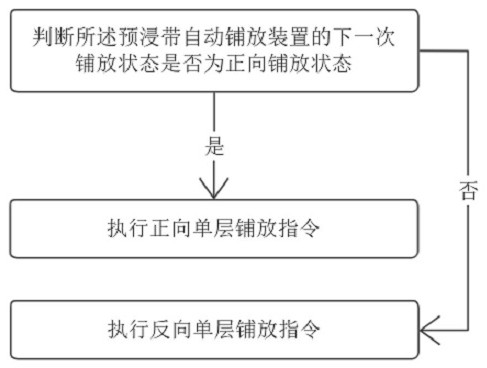

[0046] As shown in the figure: an automatic laying method, characterized in that: comprising the following steps:

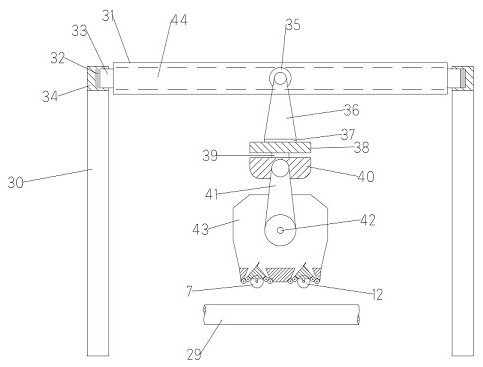

[0047] Step 1: Set up the automatic prepreg tape placement head and the guide rail bracket: the guide rail bracket includes two U-shaped support columns 30, rolling beams 31 and a placement head fixing device, and the two U-shaped support columns 30 are symmetrically arranged on the On both sides of the automatic prepreg tape laying head, the two ends of the rolling beam 31 are respectively connected with the tops of the two U-shaped support columns 30, and the rolling beam 31 is provided with a beam guide 44 inside. The outer side of the automatic prepreg tape laying head is provided with a cover 43, the cover 43 is connected with the rolling beam 31 through the laying head fixing device, and the second rolling wheel 35 of the laying head fixing device can be in the beam guide 44. Rolling, the automatic prepreg tape laying head includes a feeding mechanism, a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com